Bridgeport Boss5 stepper to servo

01 Jan 2016 05:17 #67637

by Duc

Replied by Duc on topic Bridgeport Boss5 stepper to servo

Had to finish up the pulleys for the Y-axis and Z-axis but really needed a break from tuning.

X-axis

Reason why I cant change the pulley ratio on the X-axis. No dam room but I can buy a servo gearbox later on.

Finished very similar to the Y-axis for the tig welding on the pulley adapter.

Z-axis.

Turned the boss off the Z-axis pulley.

Fit like a champ

X-axis

Reason why I cant change the pulley ratio on the X-axis. No dam room but I can buy a servo gearbox later on.

Finished very similar to the Y-axis for the tig welding on the pulley adapter.

Z-axis.

Turned the boss off the Z-axis pulley.

Fit like a champ

Please Log in or Create an account to join the conversation.

12 Apr 2016 02:37 - 12 Apr 2016 02:48 #73139

by Duc

Replied by Duc on topic Bridgeport Boss5 stepper to servo

Forgot to finish the thread but the Yaskawa AC servos are working out excellent on the mill.

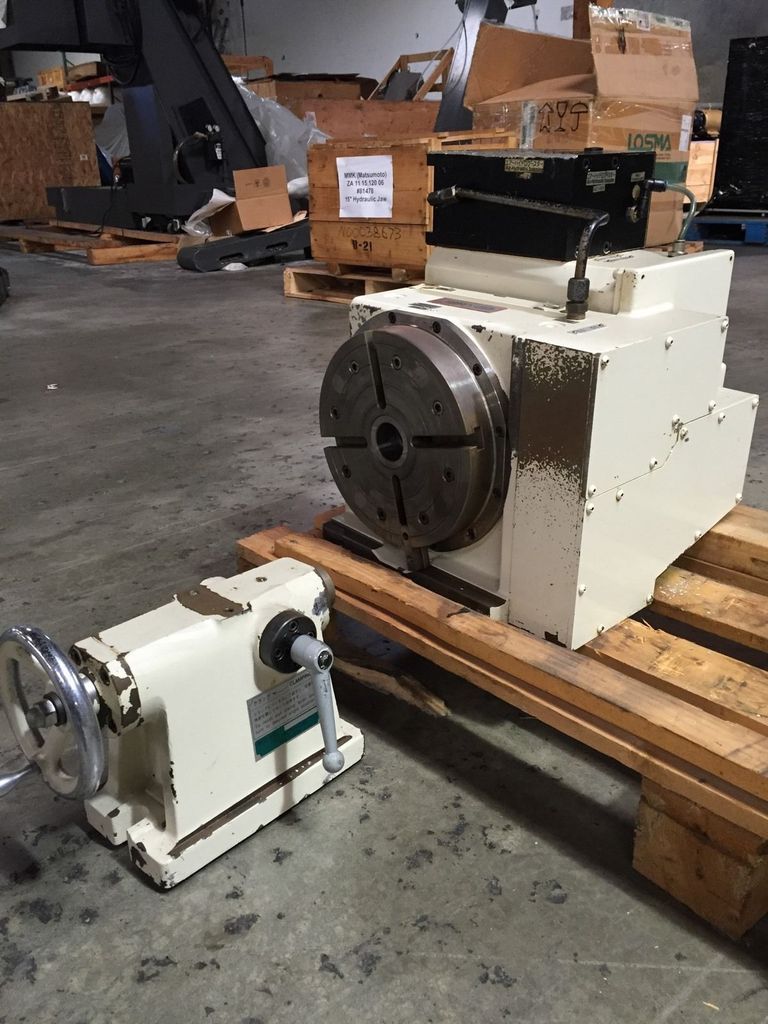

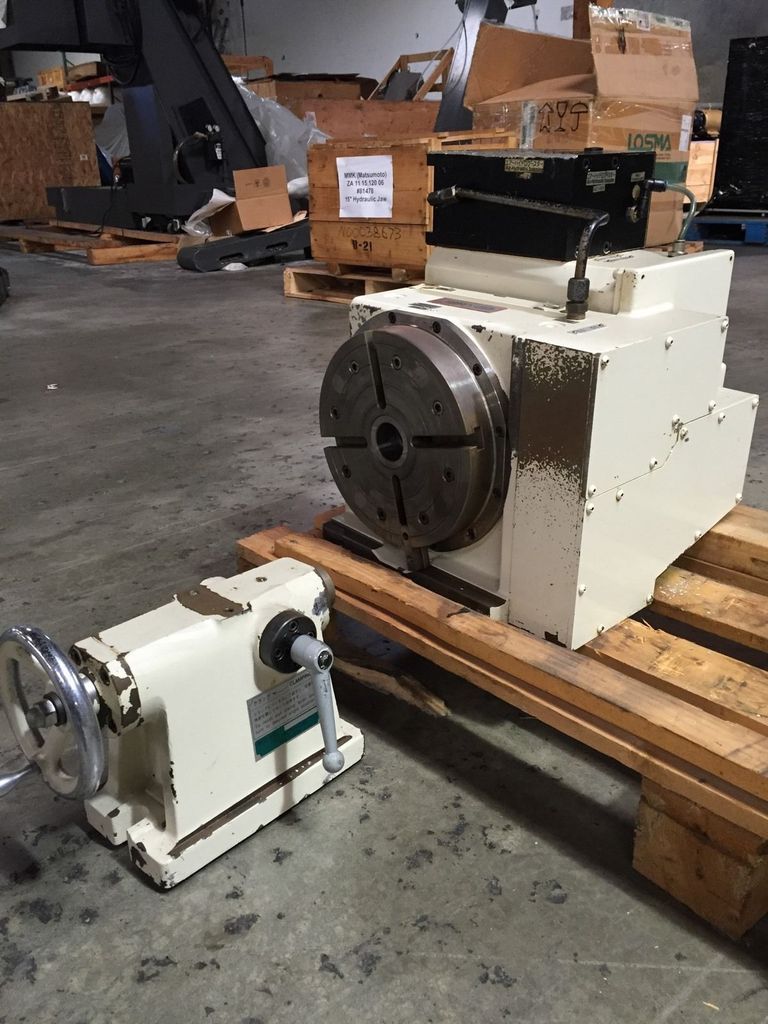

Got a urge to start setting up a 4th axis before I have a project need. No desire for a cheap unit that would only frustrate me or crap out later on. All Chinese and converted super spacers were off the table. I wanted at minimum a HAAS rotary but really wanted to justify a rotary in the Nikken, Tsudakoma, etc class of tables. We have a ton of Tsudakoma tables at work so I could use that as a way into tech support if needed. Ebay has alot of used rotary tables but difficult to weed thru the units unless you have a idea of what you want. Next was selecting a size that would fit on my bridgeport mill and not take up all the knee travel and weight limit. I was looking for a 160mm table but in the end I settled with a 200mm table.

Turns out a lot of people will take about 1/5 ebay price when you actually offer them money. Got this table for $1200 delivered to work with the tail support and hydraulic booster for the unit.

Once I got the unit home I was like a child at Christmas, Must open unit to see what I bought!!!!

Surprise surprise, the rotary had a Yaskawa SGMG-09A2ADS AC servo motor and not a DC servo motor like I was expecting.

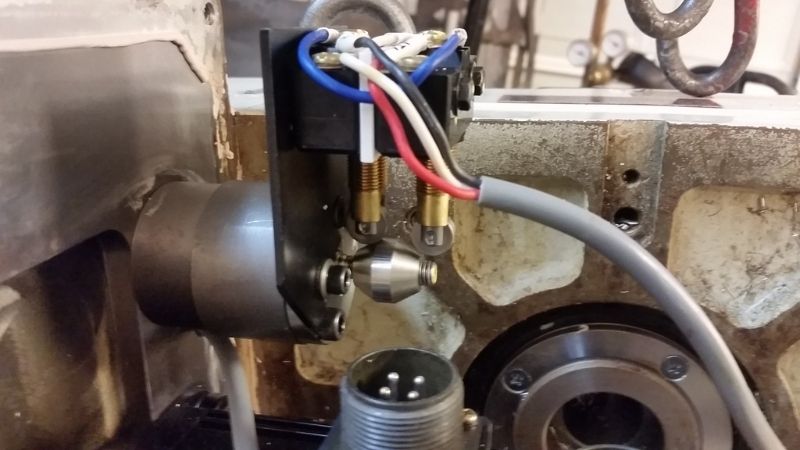

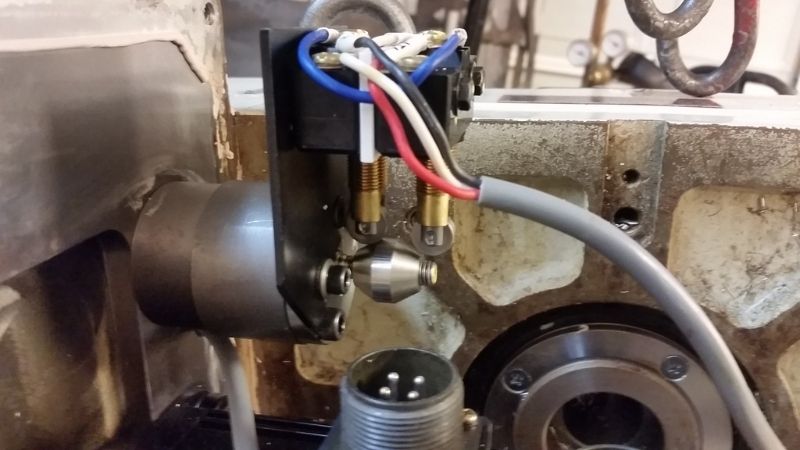

Switches for the hydraulic brake indicator. Dual switch setup.

Got a urge to start setting up a 4th axis before I have a project need. No desire for a cheap unit that would only frustrate me or crap out later on. All Chinese and converted super spacers were off the table. I wanted at minimum a HAAS rotary but really wanted to justify a rotary in the Nikken, Tsudakoma, etc class of tables. We have a ton of Tsudakoma tables at work so I could use that as a way into tech support if needed. Ebay has alot of used rotary tables but difficult to weed thru the units unless you have a idea of what you want. Next was selecting a size that would fit on my bridgeport mill and not take up all the knee travel and weight limit. I was looking for a 160mm table but in the end I settled with a 200mm table.

Turns out a lot of people will take about 1/5 ebay price when you actually offer them money. Got this table for $1200 delivered to work with the tail support and hydraulic booster for the unit.

Once I got the unit home I was like a child at Christmas, Must open unit to see what I bought!!!!

Surprise surprise, the rotary had a Yaskawa SGMG-09A2ADS AC servo motor and not a DC servo motor like I was expecting.

Switches for the hydraulic brake indicator. Dual switch setup.

Last edit: 12 Apr 2016 02:48 by Duc.

Please Log in or Create an account to join the conversation.

12 Apr 2016 03:17 #73141

by Duc

Replied by Duc on topic Bridgeport Boss5 stepper to servo

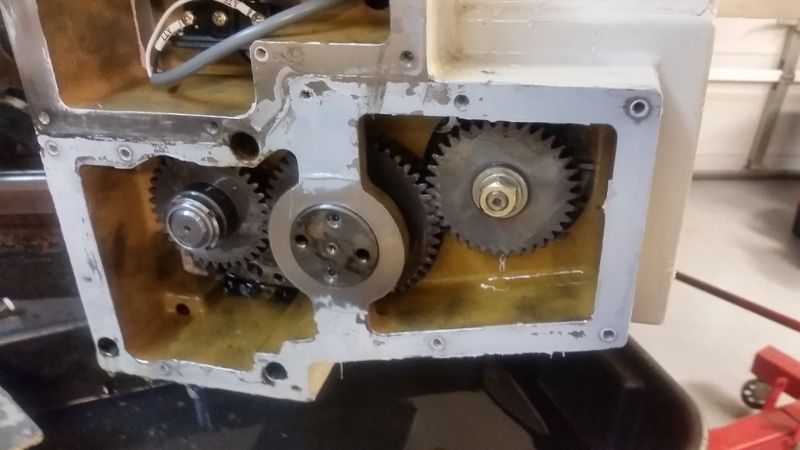

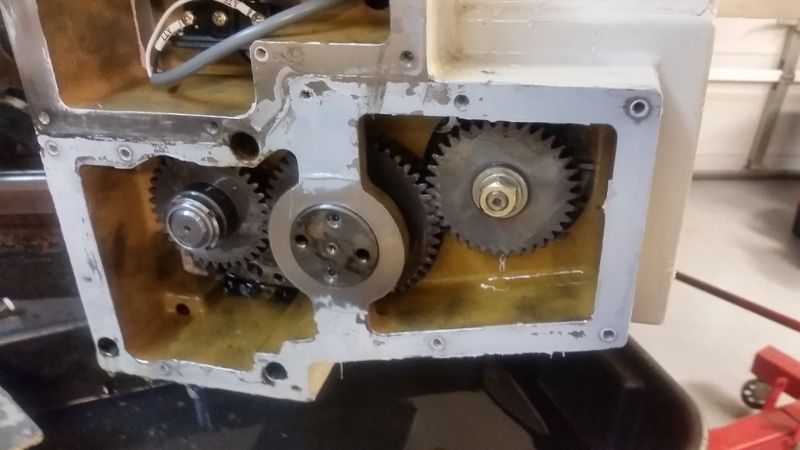

Also opened up the covers to inspect the worm gear a bit and the motor gears. Dam near looked new. Beginning to think this had low hours and the job went under or the business did.

Now that I had a idea of what was in the rotary table, I could start researching interfacing the motor to my system.

Motor spec

Yaskawa SGMG-09A2ADS

850 Watt AC servo motor

8192 P/R incremental encoder

Sigma class of motors

At this point I would have loved to use a Sigma5 drive but all data points to that being a losing battle. According to Yaskawa website I need a SGDB-10ADG servo drive for this motor. I found a few on ebay but nobody was taking the low ball offers but manage to find a bid auction for 3 of them. I won one of them at $216 but others went for less than $200. One company was bidding against me for the units. Still cheap compared to normal prices.

Cables

I couldn't find shit for Tsudakoma cables on ebay and I didn't dare call the company for some. End connectors alone retail for $200 each. I did find the end connectors for $20 each on ebay and a 4 pack of 12ft supertrex cables (10 wire -16Ga) for $35.

MS3106F20-29S (encoder plug)

and

MS3102R28-11S, MR06-28-11P-A66-A106 (Motor power and I/O)

Had to switch the rotary power plug to a female to match what I could find on ebay.

Original plug

Now that I had a idea of what was in the rotary table, I could start researching interfacing the motor to my system.

Motor spec

Yaskawa SGMG-09A2ADS

850 Watt AC servo motor

8192 P/R incremental encoder

Sigma class of motors

At this point I would have loved to use a Sigma5 drive but all data points to that being a losing battle. According to Yaskawa website I need a SGDB-10ADG servo drive for this motor. I found a few on ebay but nobody was taking the low ball offers but manage to find a bid auction for 3 of them. I won one of them at $216 but others went for less than $200. One company was bidding against me for the units. Still cheap compared to normal prices.

Cables

I couldn't find shit for Tsudakoma cables on ebay and I didn't dare call the company for some. End connectors alone retail for $200 each. I did find the end connectors for $20 each on ebay and a 4 pack of 12ft supertrex cables (10 wire -16Ga) for $35.

MS3106F20-29S (encoder plug)

and

MS3102R28-11S, MR06-28-11P-A66-A106 (Motor power and I/O)

Had to switch the rotary power plug to a female to match what I could find on ebay.

Original plug

Please Log in or Create an account to join the conversation.

04 Jun 2016 23:05 #75511

by Duc

Replied by Duc on topic Bridgeport Boss5 stepper to servo

OK I will have to get back to the rotary updates later but here is the INI and Hal files that are giving me trouble for adding a linear encoder to the knee.

encoder 00 is for knee

Knee is W axis

encoder 00 is for knee

Knee is W axis

Please Log in or Create an account to join the conversation.

06 Sep 2017 13:51 #98581

by vista_joe

Replied by vista_joe on topic Bridgeport Boss5 stepper to servo

I would really enjoy reading your entries - however due to photobucket I cannot see any of your photos.

Thanks,

Joe

Thanks,

Joe

Please Log in or Create an account to join the conversation.

26 Feb 2018 18:59 #106546

by Duc

Replied by Duc on topic Bridgeport Boss5 stepper to servo

Might have sometime to fix that this week.

Also the machine will be for sell sometime this week. Decided to step up to a bigger VMC and no extra room in garage to keep the unit.

Also the machine will be for sell sometime this week. Decided to step up to a bigger VMC and no extra room in garage to keep the unit.

The following user(s) said Thank You: vista_joe

Please Log in or Create an account to join the conversation.

26 Feb 2018 20:42 - 26 Feb 2018 20:48 #106562

by vista_joe

Replied by vista_joe on topic Bridgeport Boss5 stepper to servo

I would really appreciate that. I have been looking at the text but pictures are worth.... I also found your thread on the control panel interesting - hopefully you can fix that at the same time. Photobucket's changes really messed up many people...

I have a Boss5 that was converted to run mach3 by a previous owner. It uses the original steppers with gecko drives.

It also has a servo 4th axis and a VFD for the spindle. I plan to add many things that were not included in the original conversion (spindle control from mach3, stepper or servo for the knee to accommodate tool length changes - too little z axis now, encoder on the spindle for rigid tapping etc...)

I have a Boss5 that was converted to run mach3 by a previous owner. It uses the original steppers with gecko drives.

It also has a servo 4th axis and a VFD for the spindle. I plan to add many things that were not included in the original conversion (spindle control from mach3, stepper or servo for the knee to accommodate tool length changes - too little z axis now, encoder on the spindle for rigid tapping etc...)

Last edit: 26 Feb 2018 20:48 by vista_joe. Reason: clarification

Please Log in or Create an account to join the conversation.

27 Feb 2018 02:56 #106598

by Duc

Replied by Duc on topic Bridgeport Boss5 stepper to servo

So I cant edit the links in the thread anymore but Chrome with the Photobucket Hotlink fix addon will allow the pics to show.

Please Log in or Create an account to join the conversation.

27 Feb 2018 05:25 #106601

by vista_joe

Replied by vista_joe on topic Bridgeport Boss5 stepper to servo

Great! I searched for the hotlink fix addon and found a firefox version as well.

It now shows the images -

I'm sorry to hear that you are moving away from the Boss5 but you do what you have to do.

Thanks,

Joe

It now shows the images -

I'm sorry to hear that you are moving away from the Boss5 but you do what you have to do.

Thanks,

Joe

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.089 seconds