Need some brain storming or what would you do

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 17781

- Thank you received: 5909

28 Aug 2016 21:34 #79618

by tommylight

Need some brain storming or what would you do was created by tommylight

I have plenty of hardware gathering dust in my shop, so i would like your opinion on what would you do with the parts listed below, as the need has arisen for an aluminium milling cnc, a better one as i already have one i built in march that works ok but to damn slow (0.3mm pass @ 0.2mm depth). Moving on, parts:

THK SNS 35

1x 1080mm rail +1x780mm +1x300mm, 4x wide carriages +2 narrow

THK SNS 30

2x 360mm rail, 2x narrow carriages

HiWin HGR25

1x2500mm +1x2000mm+2x1180mm+1x320mm, 5xHGH25 carriages

NOOK 16x5mm ball screws 6 pieces form 240mm to 460mm travel

NSK 25x5mm ball screw 1 piece 380mm travel

NSK 40x10mm ball screw 1 piece 1500mm travel

??? Chinese ball screws 2 pieces 2400mm +1 piece 600mm

A 1KW servo motor with reduction 17:1 with 4 jaw head stock already mounted to it, with a 500 cpr encoder, no drive, info below

2 Big INDRAMAT motors, one with reduction unknown, no drives, so i'll skip them for now.

plenty of servo motors ranging from 50 to 200w, already built drives for them

plenty of stepper motors and drives from nema 17 to nema 34, some very strong nema 24 (7 of them), drives from GECKO, LAM Technologies etc

way to much of other stuff, like 4 plasma cutters, 2 welders around 50 other BOSH power tools........never mind.

I need an idea for a mill that can rip ALU, preferably with 4th axis, and if it is viable to use that 1KW servo for lathe work and 4th axis.

Eagerly awaiting responses ( even bad ones )

All this is to be done with the metal parts i have in the pictures attached below, as i can not find full metal bars over 40x40mm here. I do have more of them.

Thanks in advance,

Tom

THK SNS 35

1x 1080mm rail +1x780mm +1x300mm, 4x wide carriages +2 narrow

THK SNS 30

2x 360mm rail, 2x narrow carriages

HiWin HGR25

1x2500mm +1x2000mm+2x1180mm+1x320mm, 5xHGH25 carriages

NOOK 16x5mm ball screws 6 pieces form 240mm to 460mm travel

NSK 25x5mm ball screw 1 piece 380mm travel

NSK 40x10mm ball screw 1 piece 1500mm travel

??? Chinese ball screws 2 pieces 2400mm +1 piece 600mm

A 1KW servo motor with reduction 17:1 with 4 jaw head stock already mounted to it, with a 500 cpr encoder, no drive, info below

2 Big INDRAMAT motors, one with reduction unknown, no drives, so i'll skip them for now.

plenty of servo motors ranging from 50 to 200w, already built drives for them

plenty of stepper motors and drives from nema 17 to nema 34, some very strong nema 24 (7 of them), drives from GECKO, LAM Technologies etc

way to much of other stuff, like 4 plasma cutters, 2 welders around 50 other BOSH power tools........never mind.

I need an idea for a mill that can rip ALU, preferably with 4th axis, and if it is viable to use that 1KW servo for lathe work and 4th axis.

Eagerly awaiting responses ( even bad ones )

All this is to be done with the metal parts i have in the pictures attached below, as i can not find full metal bars over 40x40mm here. I do have more of them.

Thanks in advance,

Tom

Please Log in or Create an account to join the conversation.

28 Aug 2016 22:08 #79621

by emcPT

Replied by emcPT on topic Need some brain storming or what would you do

I would try to sell most of the parts (or all in ebay) and buy a used old milling machine. If you are lucky you could buy one with good servos drives and motors, that you could use "directly" with linuxcnc.

Building one from scratch cannot match the rigidity of a 2000-5000 dollars used machine.

This is the opinion of someone that already try to build one and bought one .

.

Building one from scratch cannot match the rigidity of a 2000-5000 dollars used machine.

This is the opinion of someone that already try to build one and bought one

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 17781

- Thank you received: 5909

28 Aug 2016 22:14 #79622

by tommylight

Last week i had to stop that, as i did find a nice 2600KG mill in Germany, but transport and tax and customs came out to over 4000 Euros plus the price of the mill..........to much. And to big, i have an 80 sq. meter workshop so that is to big and way to big for what i need it to do.

So back to the idea, about 500X250mm on XY and 100-200 on Z axis is all i need.

Replied by tommylight on topic Need some brain storming or what would you do

Last week i had to stop that, as i did find a nice 2600KG mill in Germany, but transport and tax and customs came out to over 4000 Euros plus the price of the mill..........to much. And to big, i have an 80 sq. meter workshop so that is to big and way to big for what i need it to do.

So back to the idea, about 500X250mm on XY and 100-200 on Z axis is all i need.

Please Log in or Create an account to join the conversation.

29 Aug 2016 12:18 - 29 Aug 2016 12:19 #79646

by rodw

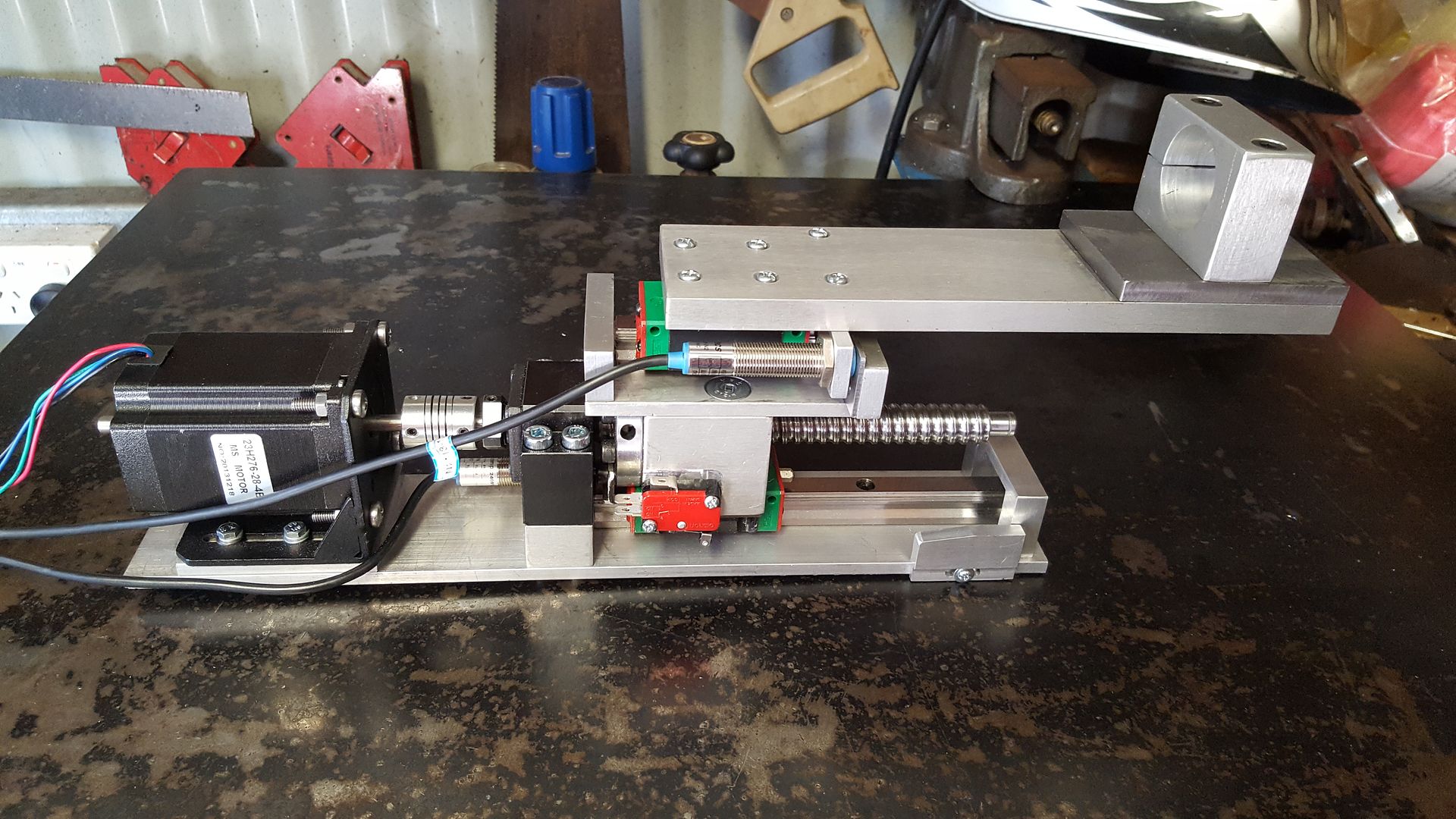

It seems like you have a solid frame to work with. Probably not quite strong enough for a router but here is the Plasma Z axis I have recently made with a 150mm ball screw. Complete with floating head and magnetic breakaway. Might give you some ideas for the Z.

I left the floating bearing off the end of the ballscrew as it ate into available travel. I had a few pieces of guiderail which I cut up with an angle grinder. It wouldn't be hard to mount the stepper on the reverse side pointing the other way so you could add a reduction belt drive.

Replied by rodw on topic Need some brain storming or what would you do

Last week i had to stop that, as i did find a nice 2600KG mill in Germany, but transport and tax and customs came out to over 4000 Euros plus the price of the mill..........to much. And to big, i have an 80 sq. meter workshop so that is to big and way to big for what i need it to do.

So back to the idea, about 500X250mm on XY and 100-200 on Z axis is all i need.

It seems like you have a solid frame to work with. Probably not quite strong enough for a router but here is the Plasma Z axis I have recently made with a 150mm ball screw. Complete with floating head and magnetic breakaway. Might give you some ideas for the Z.

I left the floating bearing off the end of the ballscrew as it ate into available travel. I had a few pieces of guiderail which I cut up with an angle grinder. It wouldn't be hard to mount the stepper on the reverse side pointing the other way so you could add a reduction belt drive.

Last edit: 29 Aug 2016 12:19 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 17781

- Thank you received: 5909

29 Aug 2016 12:23 #79647

by tommylight

Replied by tommylight on topic Need some brain storming or what would you do

That is nice !

I have done plenty of those but not at that level, i just use double drawer slides for it! Have a look near the bottom is a video of one of mine, still in use and still functioning without issues.

www.youtube.com/channel/UCS0X88R7n7P2jIF...0&shelf_id=0&sort=dd

Thanks for the input.

I have done plenty of those but not at that level, i just use double drawer slides for it! Have a look near the bottom is a video of one of mine, still in use and still functioning without issues.

www.youtube.com/channel/UCS0X88R7n7P2jIF...0&shelf_id=0&sort=dd

Thanks for the input.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 17781

- Thank you received: 5909

29 Aug 2016 12:33 #79649

by tommylight

Replied by tommylight on topic Need some brain storming or what would you do

The problem is.........choice !! As Morpheus would put it, i have plenty of parts and plenty of ways to do it, i am just interested in getting some opinions, i need something small and functional that i can add 4th axis and use that as a lathe for small spindles i make for the engravers. I already have a micro mill i made ( there is a video of it in that link ), but it is way to slow and the head stock is to weak, hence yesterdays inspiration to do something a bit beefier. I also have 2 XY slides for an old mill and the drill, both heavy and all but slides i don't like much.

Sourcing a smaller mill here is near impossible, and i don't have the space for big ones. I would love to get a HURCO BMC xx and run it with Linuxcnc, but that is not an option for now.

Sourcing a smaller mill here is near impossible, and i don't have the space for big ones. I would love to get a HURCO BMC xx and run it with Linuxcnc, but that is not an option for now.

Please Log in or Create an account to join the conversation.

29 Aug 2016 13:07 - 29 Aug 2016 13:07 #79651

by rodw

Replied by rodw on topic Need some brain storming or what would you do

Maybe look at a small mill like the Seig SX3 which is what I have made my Z axis on. I really like it! A friend in my street has a CNC version of the same mill. It uses NEMA 23 for X and Y and a NEMA 34 on the Z. There is a cheaper X3 Version without the electronics which is a better CNC candidate.

I liked your videos. We have a similar plasma (60,90,120 amps) to the big one you have at my work. Was given to us and was not working. We found someone who rewound a burnt out torroid for $100 and it like new again.

Wrong side of the world for you but I had considered this might be a good base for a small mill project.

www.machineryhouse.com.au/M198

I liked your videos. We have a similar plasma (60,90,120 amps) to the big one you have at my work. Was given to us and was not working. We found someone who rewound a burnt out torroid for $100 and it like new again.

Wrong side of the world for you but I had considered this might be a good base for a small mill project.

www.machineryhouse.com.au/M198

Last edit: 29 Aug 2016 13:07 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 17781

- Thank you received: 5909

29 Aug 2016 13:27 #79652

by tommylight

Replied by tommylight on topic Need some brain storming or what would you do

I have 2 better and bigger ones, and i had one of them set with cnc, but to much backlash. I do not have the time to make the mods for balls crews.

Thank you for the input.

Thank you for the input.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.535 seconds