Mesa 5i25 & 7i76 to GE Af-300 VFD?

22 Feb 2017 04:08 #88480

by panchula

Replied by panchula on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

I snuck in some time on the CNC this evening. Here's a head scratcher: Using the manual control screen in Axis, I can turn on the spindle CCW (F10), but not CW (F9). The CW On the MDI screen, I can issue an M3 or M4 and the spindle works fine. Any ideas?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17810

- Thank you received: 5924

22 Feb 2017 12:13 #88491

by tommylight

Replied by tommylight on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

Try m3 sxxxx where xxxx is desired rpm

Please Log in or Create an account to join the conversation.

22 Feb 2017 18:22 #88505

by panchula

Replied by panchula on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

I did use the Sxxxx along with M3 and M4. No trouble at all using the MDI panel commands, and the spindle is happy to run in either direction I choose. Switching over to the Manual Control panel is another story. Pressing F10, the spindle runs CCW at maximum RPM. Press F9 and it sits there motionless. In both cases before starting the spindle, the spindle brake has a check in it's box and the stop is depressed in the Manual Control panel. When either F9 or F10 is pressed the spindle brake box becomes unchecked, the stop button is no longer depressed, and the appropriate CW or CCW icon changes to depressed. This is as expected. I do not yet have the physical components of the spindle brake connected yet (relay & air supply). Anyone else encounter this?

-Mike

-Mike

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17810

- Thank you received: 5924

23 Feb 2017 00:45 #88526

by tommylight

Replied by tommylight on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

What happens when you press F9 and then F12 several times ?

The following user(s) said Thank You: panchula

Please Log in or Create an account to join the conversation.

23 Feb 2017 03:16 #88529

by Benb

Replied by Benb on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

According to this Wiki

wiki.linuxcnc.org/cgi-bin/wiki.pl?Keyboard_Shortcuts

F9 and F10 are toggle soft switches. Have you tried F9 ON F9 OFF followed by F10?

Please Log in or Create an account to join the conversation.

23 Feb 2017 03:55 #88532

by panchula

Replied by panchula on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

I know how the F9 and F10 are supposed to work. This machine ran on earlier versions of linuxcnc and used to be controlled with a CNC4PC C11-G parallel port breakout card. I'm loving the Mesa cards so far, but have encountered weird problems -- which seems to be my norm. I'm at the point in the wiring and configuration where I'd be comfortable to back up the configs and do a wipe and reload. I do appreciate the help and suggestions --you guys are great!

-Mike

-Mike

Please Log in or Create an account to join the conversation.

16 Mar 2017 16:46 #89753

by Lcvette

Replied by Lcvette on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

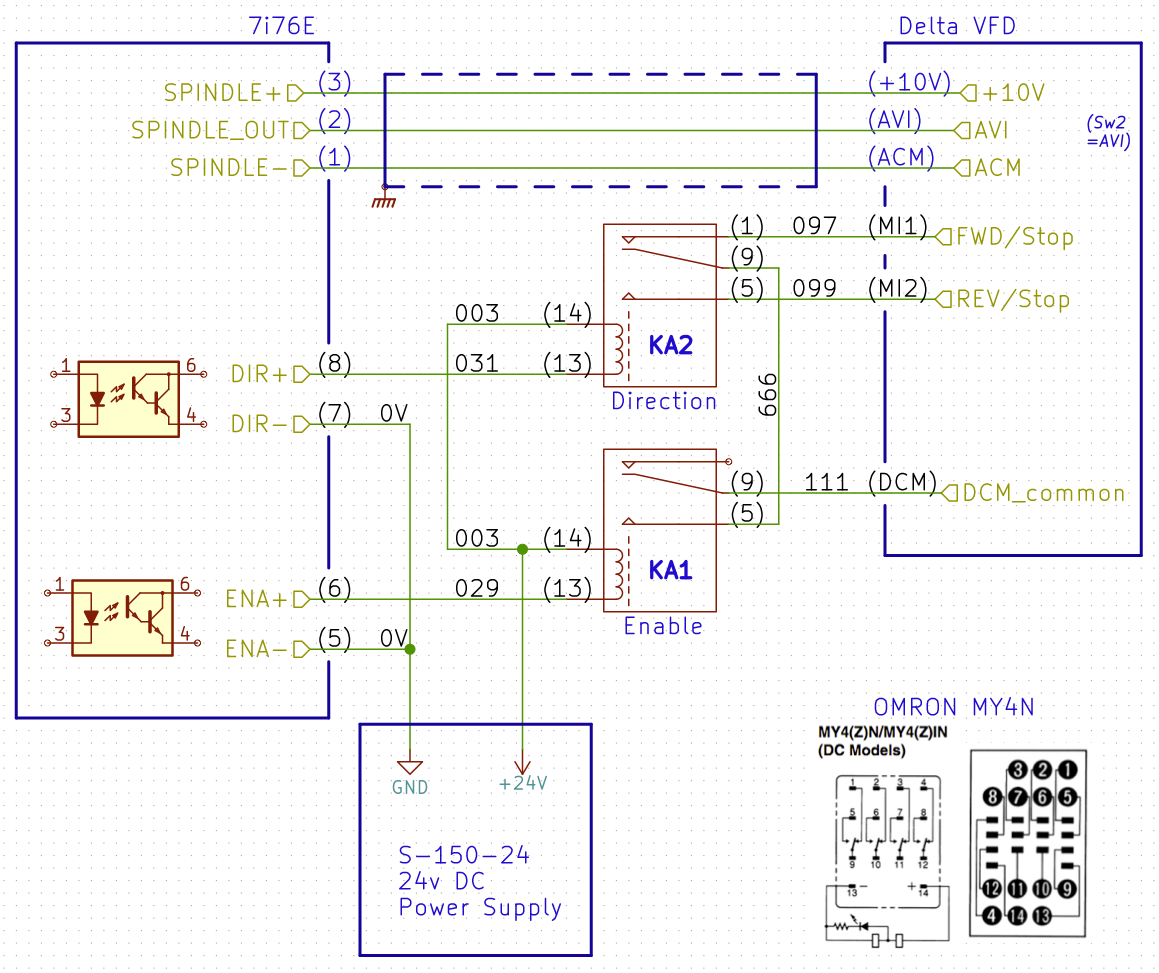

Did you ever get this figured out? I'm getting ready to write mine up and have been researching for a solution, think I found a good reference from a fellow boarder, below is the explanation in a wiring diagram. Looks as if it's creating a safety circuit using the enable and direction outputs and two relays.

Please Log in or Create an account to join the conversation.

16 Mar 2017 19:32 #89776

by andypugh

Replied by andypugh on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

It's not a safety circuit as such, that is how to control a VFD with separate FWD and REV inputs with the 7i776 (Which has ON and DIR) outputs.

The following user(s) said Thank You: Lcvette

Please Log in or Create an account to join the conversation.

16 Mar 2017 19:50 #89778

by PCW

Replied by PCW on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

A couple things:

Flyback diodes are required across the relay coils (diode cathode to +24V side of coil)

Also you really don't need 2 relays since the ENA OPTO can function as KA1s contacts

Flyback diodes are required across the relay coils (diode cathode to +24V side of coil)

Also you really don't need 2 relays since the ENA OPTO can function as KA1s contacts

Please Log in or Create an account to join the conversation.

16 Mar 2017 22:01 #89783

by Lcvette

Replied by Lcvette on topic Mesa 5i25 & 7i76 to GE Af-300 VFD?

A couple things:

Flyback diodes are required across the relay coils (diode cathode to +24V side of coil)

Also you really don't need 2 relays since the ENA OPTO can function as KA1s contacts[/quot

I'm not an EE, and would have never known that, could you possibly elaborate maybe sketch on the picture to better illustrate what your stating. Curious about a single Relay as well instead of using two. Would be greatly appreciated!

And is there a matter schematic somewhere that has all of these tidbits of information so it isn't over looked? And now I'm nervous I'm missing other stuff that may b cause issues... Crums!

Thanks,

Chris

Please Log in or Create an account to join the conversation.

Time to create page: 0.357 seconds