2.7.8 Trajectory Planner settings for 3d work

- beltramidave

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 4

01 May 2017 12:00 #92433

by beltramidave

2.7.8 Trajectory Planner settings for 3d work was created by beltramidave

Still dialing in new cnc and upgrade to 2.7.8 running 10.04. Had much better speed running 3d work than with 2.5, but I am looking for suggestions for the new trajectory planner settings.

I seem to have by best luck with G64 set to P.001. If I go to P.01, things runs faster, but quality and precision is not there. Can someone give me a good starting point for arc_blend settings based on wanting to run quality 3d work. Not sure if I should also look at changing accel settings, I think I have them set pretty good now.

I have also noticed when I tried to run a 15mb file that keyboard commands slowed greatly and jog commands did not respond correctly (long movements from short key presses). I did find that turning off program preview seems to have fixed this, but the program file takes forever to load. Is this a RAM issue? I have on 2Gb of RAM.

Thanks for the help, this forum is Great!

Dave

I seem to have by best luck with G64 set to P.001. If I go to P.01, things runs faster, but quality and precision is not there. Can someone give me a good starting point for arc_blend settings based on wanting to run quality 3d work. Not sure if I should also look at changing accel settings, I think I have them set pretty good now.

I have also noticed when I tried to run a 15mb file that keyboard commands slowed greatly and jog commands did not respond correctly (long movements from short key presses). I did find that turning off program preview seems to have fixed this, but the program file takes forever to load. Is this a RAM issue? I have on 2Gb of RAM.

Thanks for the help, this forum is Great!

Dave

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4963

- Thank you received: 1369

01 May 2017 14:45 #92447

by Todd Zuercher

Replied by Todd Zuercher on topic 2.7.8 Trajectory Planner settings for 3d work

There is a point where the acceleration of your machine is the limiting factor, and no amount of tweaking of the trajectory planner will make any difference. Your machine's accelerations limits is the max rate at which your machine can change directions, and the only way for it to go faster is to make the commanded path of the machine not change directions as fast (rounding the corners more).

It sounds as if you might be at that limit. So the only way to to increase the feed is to smooth out the path (decrease precision) or increase your acceleration. (larger G64 tolerances smooth the path)

What are your accelerations currently set at? What are the mechanics and structure of your machine? (including motor type and size)

It sounds as if you might be at that limit. So the only way to to increase the feed is to smooth out the path (decrease precision) or increase your acceleration. (larger G64 tolerances smooth the path)

What are your accelerations currently set at? What are the mechanics and structure of your machine? (including motor type and size)

Please Log in or Create an account to join the conversation.

- beltramidave

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 4

01 May 2017 16:00 #92454

by beltramidave

Replied by beltramidave on topic 2.7.8 Trajectory Planner settings for 3d work

Hey Todd, it's me again...

Ran a few test files over the weekend. Just trying to get the most out of my machine in regards to running 3d files without a lot of slow downs. Seems to be better than with 2.5, but just don't understand all the Traj settings yet.

I am attaching my .ini file and motor stepper info so you can see where I am at. I think that I am about maxed out on Z speeds, but pretty sure I can get more out of X&Y, if needed. Just tried to find a spot where I wasn't getting to much shake from rapid changes in direction (I still have my machine on a heavy roller stand).

I have one of the new Fine Line Automation Saturn 4x4 machines. It's quite heavy 6-700lbs of steel. It has rack and pinion drives on X&Y and ballscrew on Z. Let me know if there is something more you need. Thanks!

Ran a few test files over the weekend. Just trying to get the most out of my machine in regards to running 3d files without a lot of slow downs. Seems to be better than with 2.5, but just don't understand all the Traj settings yet.

I am attaching my .ini file and motor stepper info so you can see where I am at. I think that I am about maxed out on Z speeds, but pretty sure I can get more out of X&Y, if needed. Just tried to find a spot where I wasn't getting to much shake from rapid changes in direction (I still have my machine on a heavy roller stand).

I have one of the new Fine Line Automation Saturn 4x4 machines. It's quite heavy 6-700lbs of steel. It has rack and pinion drives on X&Y and ballscrew on Z. Let me know if there is something more you need. Thanks!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4963

- Thank you received: 1369

01 May 2017 18:11 #92471

by Todd Zuercher

Replied by Todd Zuercher on topic 2.7.8 Trajectory Planner settings for 3d work

One thing that might make a difference, is using different G64 P and Q settings. By default Q when not specified is set equal to P. So instead of just G64 P0.01, try G64 P0.01 Q0.001 and see if the precision is any better. It might not make much if any difference, then again, never know till you try.

Please Log in or Create an account to join the conversation.

- beltramidave

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 4

02 May 2017 02:43 #92489

by beltramidave

Replied by beltramidave on topic 2.7.8 Trajectory Planner settings for 3d work

I can try the Q setting when I run my next file. I have never used it before. What I was wondering to start off was, are my Traj settings in the ini file respectable for good look ahead. I think I just used what was in the documentation.

Also, any thought on the sluggish response to jogging and long program loading times?

Dave

Also, any thought on the sluggish response to jogging and long program loading times?

Dave

Please Log in or Create an account to join the conversation.

02 May 2017 03:14 #92490

by cmorley

Replied by cmorley on topic 2.7.8 Trajectory Planner settings for 3d work

When loading program the preview actually runs it internally to draw it -large files take a long time.

You can control the AXIS preview with 'MAGIC" comments:

linuxcnc.org/docs/devel/html/gui/axis.html#axis:preview-control

Keyboard and screen response is a non-realtime event - so can get laggy if the realtime side is using up lots of cycles.

As you noted tabbing off the preview helps with GUI response.

setting your base period larger can help with lag but of course hurts stepper max speed performance.

A more powerful CPU could help too. What are you using now?

Chris M

You can control the AXIS preview with 'MAGIC" comments:

linuxcnc.org/docs/devel/html/gui/axis.html#axis:preview-control

Keyboard and screen response is a non-realtime event - so can get laggy if the realtime side is using up lots of cycles.

As you noted tabbing off the preview helps with GUI response.

setting your base period larger can help with lag but of course hurts stepper max speed performance.

A more powerful CPU could help too. What are you using now?

Chris M

Please Log in or Create an account to join the conversation.

- beltramidave

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 4

02 May 2017 11:23 #92510

by beltramidave

Replied by beltramidave on topic 2.7.8 Trajectory Planner settings for 3d work

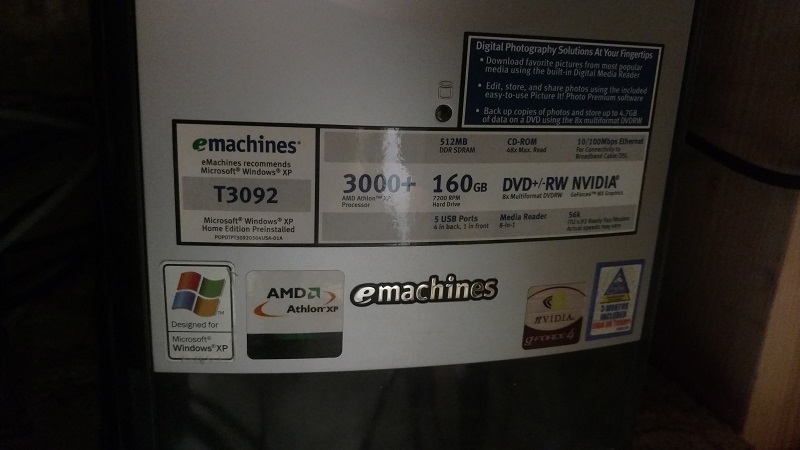

Hi Chris,

Thanks for the heads up on the Preview control. I had seen that in the past, but never thought about using it.

My PC specs are attached. They are correct other than I have 2gb RAM. I have a lower base period (40000) with this machine than my last one (100000), so I am sure that is why I am noticing the difference in loading speed.

Thanks for the heads up on the Preview control. I had seen that in the past, but never thought about using it.

My PC specs are attached. They are correct other than I have 2gb RAM. I have a lower base period (40000) with this machine than my last one (100000), so I am sure that is why I am noticing the difference in loading speed.

Please Log in or Create an account to join the conversation.

- beltramidave

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 4

02 May 2017 19:30 #92538

by beltramidave

Ok, so I tried this and it made absolutely no difference in time or as far as I can tell quality in the carvings.

Dave

Replied by beltramidave on topic 2.7.8 Trajectory Planner settings for 3d work

One thing that might make a difference, is using different G64 P and Q settings. By default Q when not specified is set equal to P. So instead of just G64 P0.01, try G64 P0.01 Q0.001 and see if the precision is any better. It might not make much if any difference, then again, never know till you try.

Ok, so I tried this and it made absolutely no difference in time or as far as I can tell quality in the carvings.

Dave

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4963

- Thank you received: 1369

02 May 2017 19:50 - 02 May 2017 19:51 #92540

by Todd Zuercher

Replied by Todd Zuercher on topic 2.7.8 Trajectory Planner settings for 3d work

It was a long shot to see if the naive cam detection was screwing with your quality. And the answer apparently is no. You are probably just up against the physical limits of your configuration, and the only way to go faster would be to increase your accelerations. Assuming the mechanics of the machine can handle it, if not, you're done.

Last edit: 02 May 2017 19:51 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

Time to create page: 0.133 seconds