how can i use my linuxcnc router manually?

21 Sep 2017 18:34 - 21 Sep 2017 18:36 #99217

by jlroch

how can i use my linuxcnc router manually? was created by jlroch

i want to be able to use my cnc (sometimes) in a manual mode(without writing code or creating a design). for instance, if i have a surface that i want to make a "quick and dirty" mortise for a tenon, or yet again drill a pattern of holes already marked off on a wood surface.

how can i do this?

in other words, i want to jog manually to a given point, jog the z to a given depth, pull the z back out and go on to the next point, etc.

jacques

how can i do this?

in other words, i want to jog manually to a given point, jog the z to a given depth, pull the z back out and go on to the next point, etc.

jacques

Last edit: 21 Sep 2017 18:36 by jlroch. Reason: adding info.

Please Log in or Create an account to join the conversation.

21 Sep 2017 19:01 #99219

by grump

Replied by grump on topic how can i use my linuxcnc router manually?

Use the arrow / pgup and down keys + shift to go full speed and jog away.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4962

- Thank you received: 1369

21 Sep 2017 19:11 #99220

by Todd Zuercher

Replied by Todd Zuercher on topic how can i use my linuxcnc router manually?

On way is to just issue MDI commands manually.

Another way to do this is with a Jog Wheel pendent.

Something like this one:

www.ebay.com/itm/Universal-CNC-6-Axis-MP...c:g:CUQAAOSwEWJZv2t1

or this

www.ebay.com/itm/WHB04L-Mach3-USB-Wirele...d:g:-poAAOSwx2dYHUif

Another useful tool is to use a macro tool like NGCGUI or NativeCAM, to do simple milling routines.

Another way to do this is with a Jog Wheel pendent.

Something like this one:

www.ebay.com/itm/Universal-CNC-6-Axis-MP...c:g:CUQAAOSwEWJZv2t1

or this

www.ebay.com/itm/WHB04L-Mach3-USB-Wirele...d:g:-poAAOSwx2dYHUif

Another useful tool is to use a macro tool like NGCGUI or NativeCAM, to do simple milling routines.

Please Log in or Create an account to join the conversation.

21 Sep 2017 19:51 #99222

by jlroch

Replied by jlroch on topic how can i use my linuxcnc router manually?

that is to jog, which i am aware of. what i need to know specifically is how to over ride the need to open any file, and :

a: start the the spindle, set the speed i want

b: jog the xy axis (which can be done with the keys, but not while the spindle is turning)

c: jog the z position to the depth i need

d: etc

i know how to "fast jog" with the keys, but not how to jog AND have the spindle working

jacques

a: start the the spindle, set the speed i want

b: jog the xy axis (which can be done with the keys, but not while the spindle is turning)

c: jog the z position to the depth i need

d: etc

i know how to "fast jog" with the keys, but not how to jog AND have the spindle working

jacques

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4962

- Thank you received: 1369

21 Sep 2017 20:15 #99223

by Todd Zuercher

Replied by Todd Zuercher on topic how can i use my linuxcnc router manually?

You can jog perfectly fine with the keyboard while the spindle is on. (Just walked over to a machine and did it to make sure.)

But it is often easier to make a precise move at a specific feed rate with an MDI command, especially if the move isn't co-linear with one axis, or heaven forbid needs to be a curve.

But it is often easier to make a precise move at a specific feed rate with an MDI command, especially if the move isn't co-linear with one axis, or heaven forbid needs to be a curve.

Please Log in or Create an account to join the conversation.

21 Sep 2017 20:19 #99224

by jlroch

Replied by jlroch on topic how can i use my linuxcnc router manually?

if i were to enter mdi, ( i know where in the software, but not certain as to how to correctly enter and execute the gcode manually) how would i do this for the following example:

a: with my end mill set to home, and wanting a series of 6 holes set apart at 6" in a straight line?

b: with my end mill set to home, i want to make 6 holes is random (already marked spots on the wood surface) places?

jacques

a: with my end mill set to home, and wanting a series of 6 holes set apart at 6" in a straight line?

b: with my end mill set to home, i want to make 6 holes is random (already marked spots on the wood surface) places?

jacques

Please Log in or Create an account to join the conversation.

21 Sep 2017 20:26 #99225

by jlroch

Replied by jlroch on topic how can i use my linuxcnc router manually?

in my line of work (i repair/restore antique furniture--www.atelierdebois.com--) it sometimes is more of a pain to make a design etc, just to accomplish a few holes or mortises. i have a mortising machine and a few plunge routers that i used to do this in the past, but the setup time for jigs etc is a pain.

so i want to put the cnc sitting next to me idly to good use.

i just want to be able to manually turn on the spindle, move it to a wanted area, plunge cut, move on to the next area, etc.

i am already using the cnc for it's designated purpose, and quite happy with the results.

jacques

so i want to put the cnc sitting next to me idly to good use.

i just want to be able to manually turn on the spindle, move it to a wanted area, plunge cut, move on to the next area, etc.

i am already using the cnc for it's designated purpose, and quite happy with the results.

jacques

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4962

- Thank you received: 1369

21 Sep 2017 20:58 - 21 Sep 2017 21:07 #99226

by Todd Zuercher

Replied by Todd Zuercher on topic how can i use my linuxcnc router manually?

Lets say you want to mill in a straight line 4 inches over in the X direction and 1 back in the Y direction. Doing that with just manual jogging is a real trick, (but there are ways to do it.)

But it is very simple with an MDI command. Jog the machine to where you want the cut to start, turn on the spindle, then on the MDI screen just type G91 G1 X4 Y1 F50, pres Enter and wait for it to finish.

Drilling is an even better example where MDI commands can be really useful if you add canned cycles like G81 or G82 or G83.

Say you wanted to drill 6 holes in a row. Move to where you want your 1st hole, If you wanted to drill down 1inch from that point at F50 then do the same a 6 inches over in the X direction.

In MDI type G91G81G98Z-1R0F50, press enter, wait for the drill cycle to finish, type X6, Enter wait for the drill cycle to finish... once you've drilled all your holes type G80 to cancel the drill cycle.

But it is very simple with an MDI command. Jog the machine to where you want the cut to start, turn on the spindle, then on the MDI screen just type G91 G1 X4 Y1 F50, pres Enter and wait for it to finish.

Drilling is an even better example where MDI commands can be really useful if you add canned cycles like G81 or G82 or G83.

Say you wanted to drill 6 holes in a row. Move to where you want your 1st hole, If you wanted to drill down 1inch from that point at F50 then do the same a 6 inches over in the X direction.

In MDI type G91G81G98Z-1R0F50, press enter, wait for the drill cycle to finish, type X6, Enter wait for the drill cycle to finish... once you've drilled all your holes type G80 to cancel the drill cycle.

Last edit: 21 Sep 2017 21:07 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

21 Sep 2017 21:40 - 21 Sep 2017 21:41 #99227

by jlroch

Replied by jlroch on topic how can i use my linuxcnc router manually?

so you are telling me that there is no way of turning on the spindle, jogging to point x via the keyboard, jogging down the z via keyboard, pulling back out via keyboard and jogging to the next point?

jacques

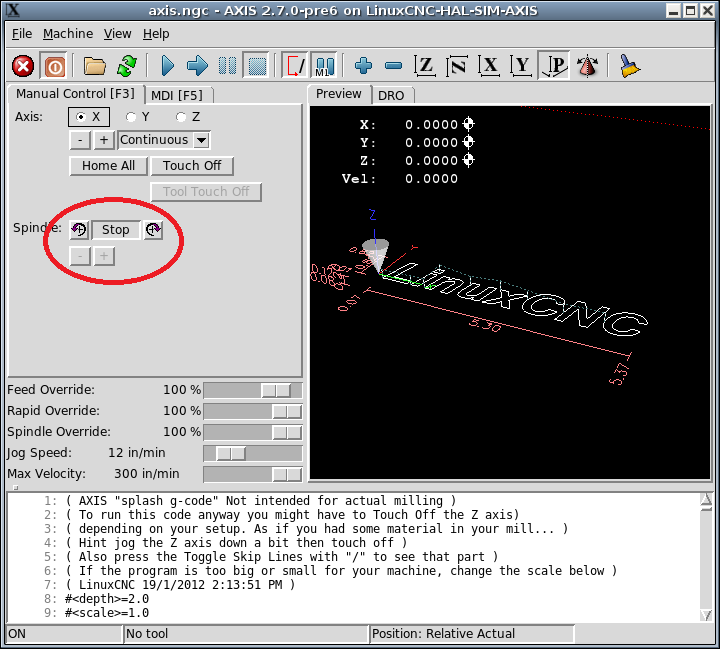

p.s. silly as this sounds, how does one turn on the spindle in linuxcnc? i have never given it a thought as this was part of the generated gcode....

jacques

jacques

p.s. silly as this sounds, how does one turn on the spindle in linuxcnc? i have never given it a thought as this was part of the generated gcode....

jacques

Last edit: 21 Sep 2017 21:41 by jlroch.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4962

- Thank you received: 1369

22 Sep 2017 02:36 #99234

by Todd Zuercher

Replied by Todd Zuercher on topic how can i use my linuxcnc router manually?

The following user(s) said Thank You: jlroch

Please Log in or Create an account to join the conversation.

Time to create page: 0.127 seconds