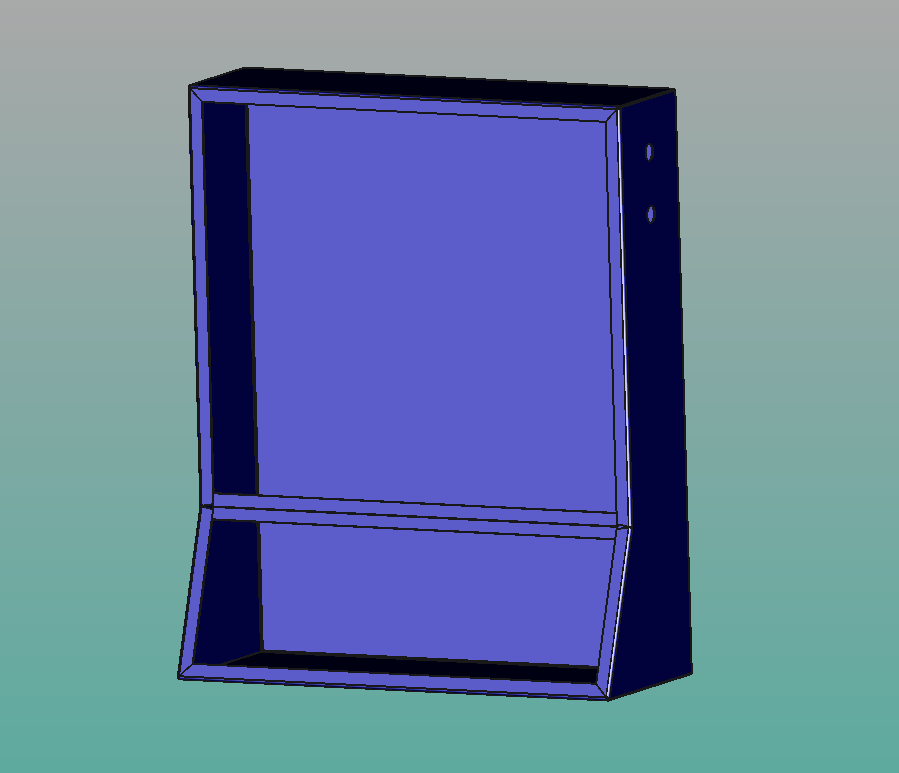

looking for sheetmetal Plasma/laser cut and bending service

Attachments:

Please Log in or Create an account to join the conversation.

I've got a plasma that can handle it no sweat, but no finger-break. I've found that if you're going to be welding, intermittent slots along the bend lines makes it easy to bend and then run over it with the tig.

Please Log in or Create an account to join the conversation.

Folding is expensive vs laser cutting. Look for a sheet metal shop near you.

A press brake is a better option to a pan brake for that

Please Log in or Create an account to join the conversation.

What's your location?

I've got a plasma that can handle it no sweat, but no finger-break. I've found that if you're going to be welding, intermittent slots along the bend lines makes it easy to bend and then run over it with the tig.

I'm in PA.

I suppose that's a possibility. I can machine a 1/2" aluminum chill bars that sit inside the cavities that make that go a bit easier. I suppose it comes down to the cost difference of having to do alot more welding and grinding vs getting it all properly bent. Any guidance on the slot dimensions for a minimal gap on 18gauge?

Can you plasma 1/8" aluminum clean?

Please Log in or Create an account to join the conversation.

I'm in NE OH (Ashtabula). I'd prefer not to deal with shipping, so if you're close enough to Erie for a drive I could meet you there.

I'm in PA.

I suppose that's a possibility. I can machine a 1/2" aluminum chill bars that sit inside the cavities that make that go a bit easier. I suppose it comes down to the cost difference of having to do alot more welding and grinding vs getting it all properly bent. Any guidance on the slot dimensions for a minimal gap on 18gauge?

Can you plasma 1/8" aluminum clean?

Regarding the slot, it'd just be a kerf width - say 0.040" wide using the fine-cut tip. I just clamp some stiff bars on both sides of the section to be bent and go to town with channies. A 2" slot by 2" uncut segment makes for easy bending and not a miserable amount of welding.

Yes, I can plasma 1/8" aluminum clean. My enclosure is made from 0.040" alu panels (circle track body panel drops) and they came out nice. Small holes are not super-clean, but I just pierced those and drilled them out.

I have a bender, but it's a light-weight thing for circle track car panels with no fingers. If you change your design to have a frame with a skin (rather than a self-supporting steel weldment) we can do most of the bending here with no slot welding.

If you're up for it, labor and machine time are free.

If you're close enough to drive here you can show up with material and walk out with parts. And if you want to use the 040" aluminum, I've got all the material on hand you could want.

Please Log in or Create an account to join the conversation.

If that doesn't work out I'll see if we can work something out, I appreciate the offer.

Please Log in or Create an account to join the conversation.

Good luck, and let me know if you can't sort out anything at a reasonable price.

BTW, Automation Direct has 4" deep 16x12 enclosures pretty cheap. Get free shipping if you buy a few.

Add a keyboard tray below and it wouldn't look total hacky.

www.automationdirect.com/adc/shopping/ca...nction_boxes/cs16124

Please Log in or Create an account to join the conversation.

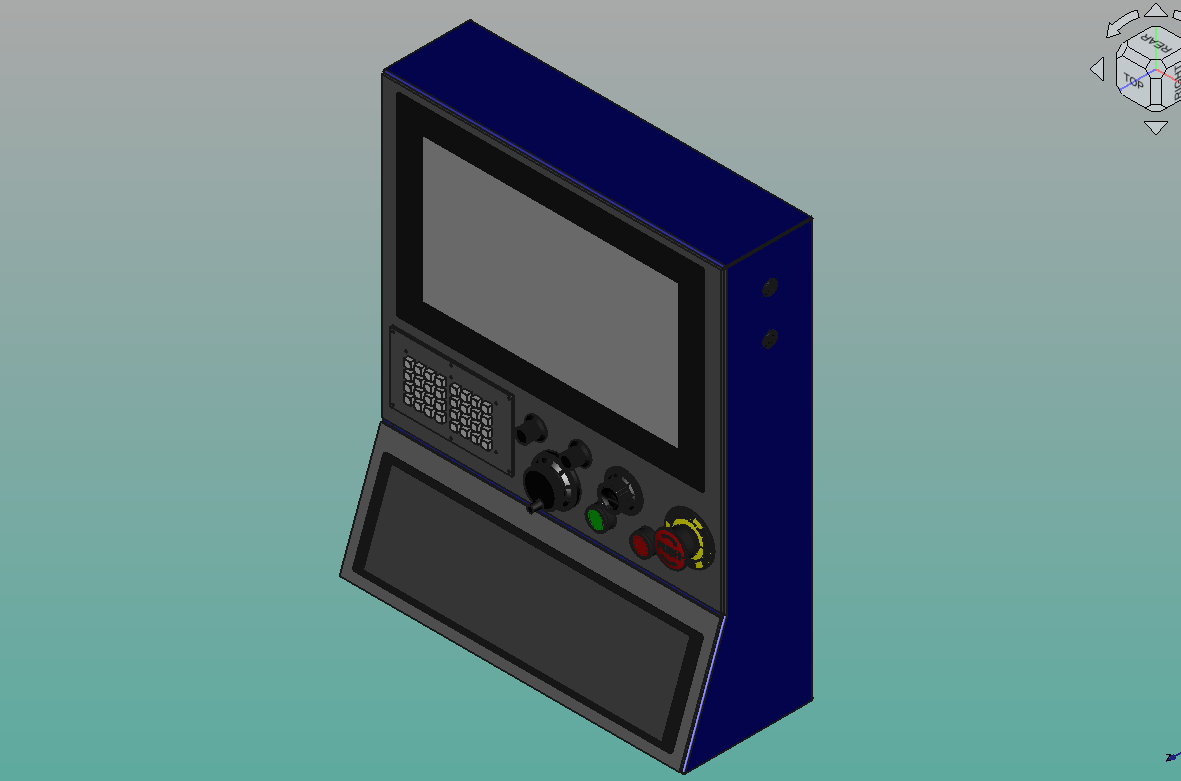

If it were like a one off thing I'd just cut up a sheet of 1/8" aluminum....I can tig 1/8" aluminum like nobodies business lol. I wanna make a few of these as like a standard controller for any machine I might do in the future. I'm going through the effort of making specific PCBs for key matrix's and stuff so it's not a huge wiring project to get one going.

Still working on it but the end goal is something like this:

Attachments:

Please Log in or Create an account to join the conversation.

Offer is still open if you run out of patience with the commercial options.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.