Search Results (Searched for: raspberry)

- PCW

30 Oct 2025 19:11

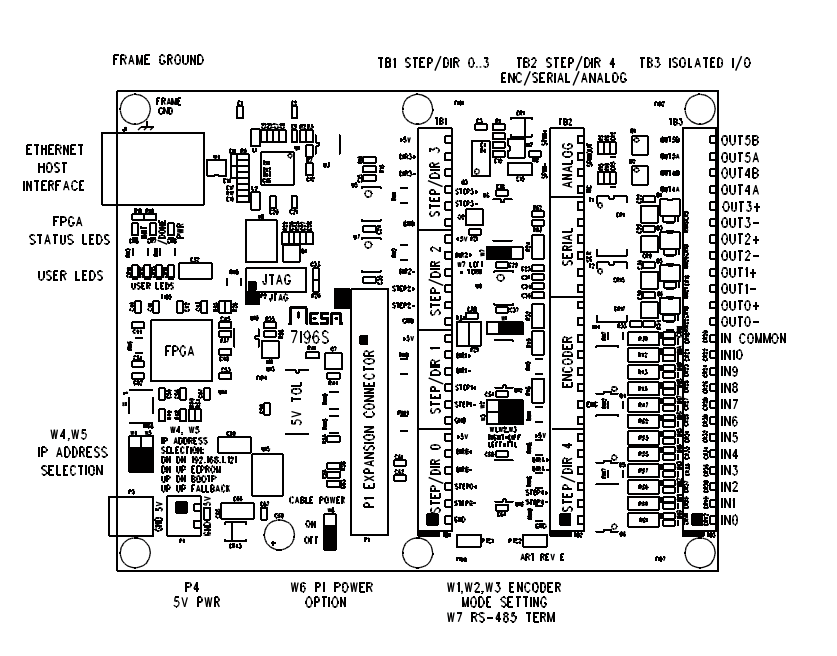

Replied by PCW on topic 7i96s Pinout/Wiring Help

7i96s Pinout/Wiring Help

Category: General LinuxCNC Questions

- maruf1777

- maruf1777

30 Oct 2025 18:39

7i96s Pinout/Wiring Help was created by maruf1777

7i96s Pinout/Wiring Help

Category: General LinuxCNC Questions

- Will_cnc

- Will_cnc

30 Oct 2025 11:00

Replied by Will_cnc on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

- tommylight

30 Oct 2025 00:18

Replied by tommylight on topic Raspberry PI4/5 I2C support for non realtime IO/ADC/LCD

Raspberry PI4/5 I2C support for non realtime IO/ADC/LCD

Category: General LinuxCNC Questions

- nanowhat

- nanowhat

29 Oct 2025 04:28

Replied by nanowhat on topic Loading 32 bit shared library with GladeVCP/python on a Raspberry Pi

Loading 32 bit shared library with GladeVCP/python on a Raspberry Pi

Category: General LinuxCNC Questions

- nanowhat

- nanowhat

29 Oct 2025 02:27

- Chad

- Chad

26 Oct 2025 10:12

- unknown

- unknown

24 Oct 2025 06:41 - 24 Oct 2025 10:14

- eoverton

- eoverton

24 Oct 2025 05:18

Replied by eoverton on topic Remora with STM32H753ZI

Remora with STM32H753ZI

Category: Computers and Hardware

- unknown

- unknown

23 Oct 2025 17:56

- Will_cnc

- Will_cnc

23 Oct 2025 08:09

Leadshine EL8 Servo motor clonking sound and motion was created by Will_cnc

Leadshine EL8 Servo motor clonking sound and motion

Category: EtherCAT

- unknown

- unknown

22 Oct 2025 21:44

- unknown

- unknown

22 Oct 2025 21:41

- Ingo

22 Oct 2025 20:31

- unknown

- unknown

21 Oct 2025 12:27

Replied by unknown on topic fixing "raspi firmware" errors on the official amd64 ISO

fixing "raspi firmware" errors on the official amd64 ISO

Category: Installing LinuxCNC

Time to create page: 0.522 seconds