Odd AC servo motors - how to test

01 Dec 2017 12:12 #102559

by tecno

Odd AC servo motors - how to test was created by tecno

Got my hands on a box with AC servo motors where I do not know if these are functional.

So my questions is can I use following to test these motors or will they be damaged?

goo.gl/HdPeiz

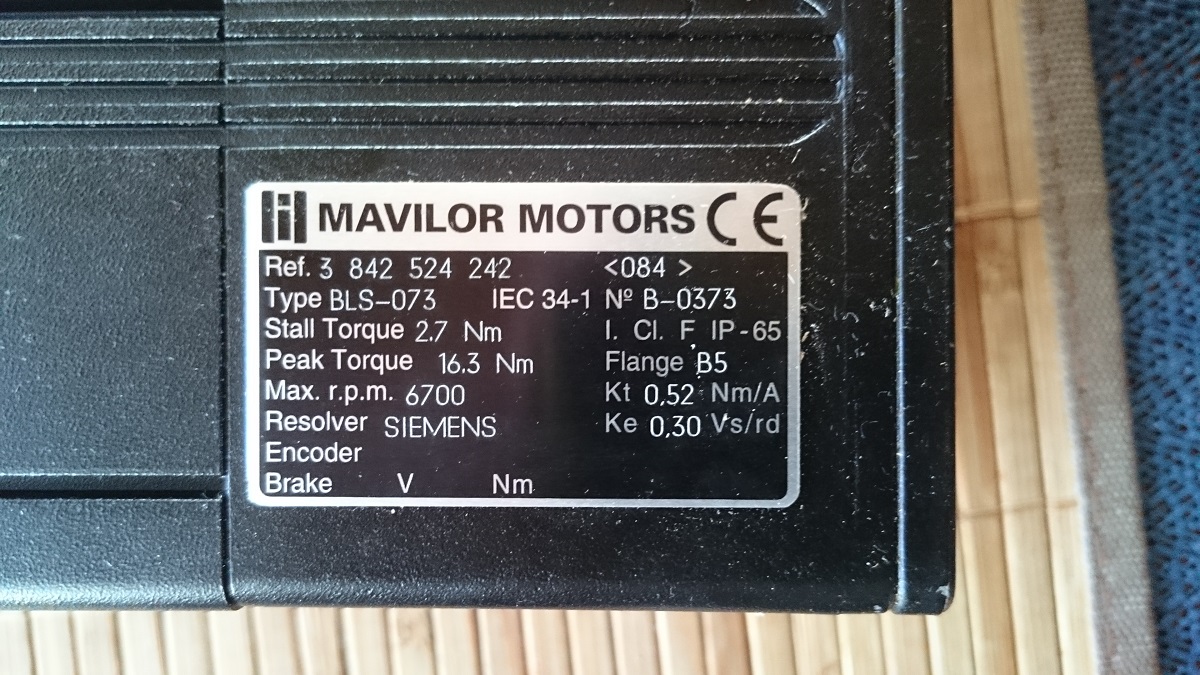

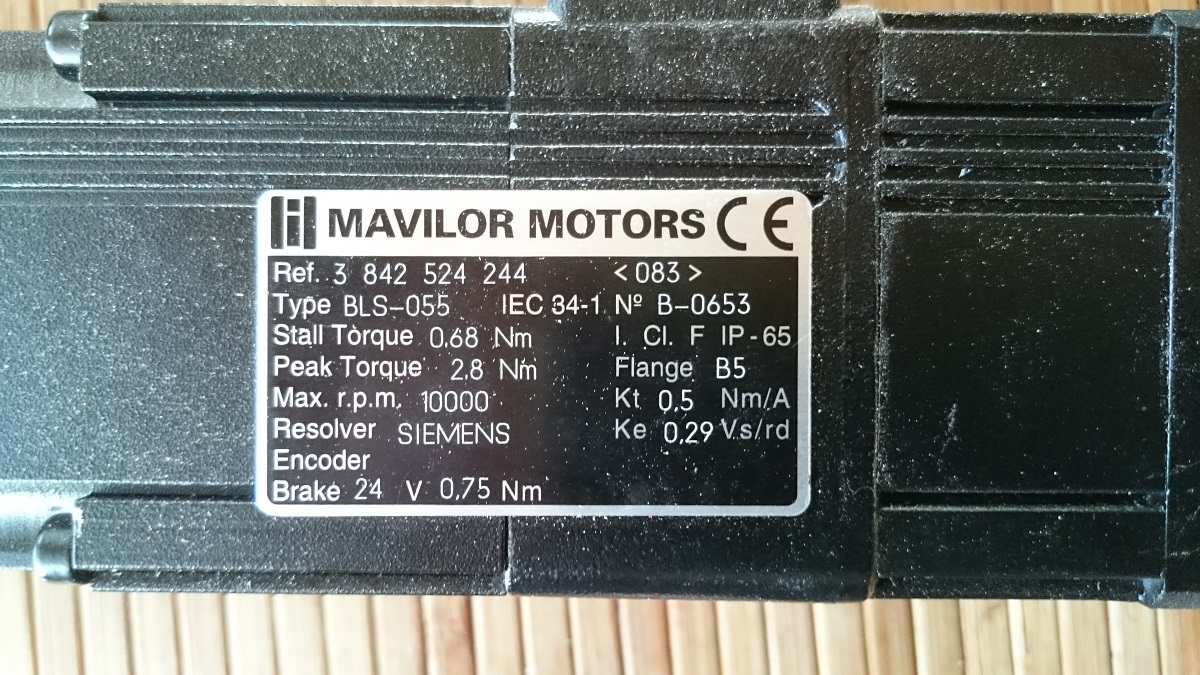

AC motors in question are these. 220VAC

So my questions is can I use following to test these motors or will they be damaged?

goo.gl/HdPeiz

AC motors in question are these. 220VAC

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5007

- Thank you received: 1441

01 Dec 2017 16:11 #102568

by Todd Zuercher

Replied by Todd Zuercher on topic Odd AC servo motors - how to test

I would think, if they spin freely, and the winding's arn't shorted and all have similar resistance, there is probably nothing wrong with them. I do not know a good way to test them short of connecting them to a proper drive.

Please Log in or Create an account to join the conversation.

01 Dec 2017 17:21 #102570

by tecno

Replied by tecno on topic Odd AC servo motors - how to test

What I would like to 'hear' is the condition of the bearings, resistance and turning freely looks OK.

At the moment I do not have any proper drive only this test/lab VFD board but I assume it will destroy motors.

Maybe I dare to put these out for sale

At the moment I do not have any proper drive only this test/lab VFD board but I assume it will destroy motors.

Maybe I dare to put these out for sale

Please Log in or Create an account to join the conversation.

01 Dec 2017 23:30 #102576

by andypugh

Replied by andypugh on topic Odd AC servo motors - how to test

What do you want to know about them? I am confident that they could be made to run with LinuxCNC without to much trouble.

Mesa 8i20 + 7i49 is one way, or the STMBL drive.

Do you have an application in mind for them?

Mesa 8i20 + 7i49 is one way, or the STMBL drive.

Do you have an application in mind for them?

Please Log in or Create an account to join the conversation.

02 Dec 2017 10:21 #102591

by tecno

Replied by tecno on topic Odd AC servo motors - how to test

Well on a long time wanted list is a plasma table but it has been put on back-burner due to lack of space.

Much of the mechanic parts I already have but need to tinker how to build the table as it has to be fast/easy setup and tear down build. Main idea is to have a *cutting* frame easily manageable that I fix on material to be cut and store this frame hanging in garage roof when not in use. Size of this frame is still unknown but somewhere around a 1/4 plate (2000x1000 nominal size)

Is STMBL mature and what kind of cost are we looking at, assuming it has to be assembled by me?

The Mesa route is appealing as I have 7i90HD already but it is always a price tag on everything that I have to look for.

Much of the mechanic parts I already have but need to tinker how to build the table as it has to be fast/easy setup and tear down build. Main idea is to have a *cutting* frame easily manageable that I fix on material to be cut and store this frame hanging in garage roof when not in use. Size of this frame is still unknown but somewhere around a 1/4 plate (2000x1000 nominal size)

Is STMBL mature and what kind of cost are we looking at, assuming it has to be assembled by me?

The Mesa route is appealing as I have 7i90HD already but it is always a price tag on everything that I have to look for.

Please Log in or Create an account to join the conversation.

02 Dec 2017 11:40 #102592

by andypugh

wholesaler.alibaba.com/product-detail/ch...ter_60301320562.html

The design fits you requirements quite well.

Replied by andypugh on topic Odd AC servo motors - how to test

Have you seen these?Main idea is to have a *cutting* frame easily manageable that I fix on material to be cut and store this frame hanging in garage roof when not in use.

wholesaler.alibaba.com/product-detail/ch...ter_60301320562.html

The design fits you requirements quite well.

There are a number of machines running (and running well) with them. But building by hand (392 surface mount components) is not something I have managed to persuade myself to do. Component cost is about $100 and I think that someone is selling assembled ones for $250 (but I don't know how many he has). And you still ideally need a Mesa card to drive one (step and direction is an option, but smart-serial is a lot better). You would want to add a 7i44 to the 7i90 to connect the smart-serial.Is STMBL mature and what kind of cost are we looking at, assuming it has to be assembled by me?

Please Log in or Create an account to join the conversation.

02 Dec 2017 11:58 #102593

by tecno

Replied by tecno on topic Odd AC servo motors - how to test

Yes I have been looking at that one but the total price landed here is way too much 4700US+import tax and fees + VAT.

Still pondering if I go that design route or if I make a frame for this, time will tell.

As I already have some Mesa boards that is the most economical for me, but it is still in planning stage.

Maybe I put these motors for sale and make my other projects ready up and running. Been off line again due to health reasons but now I need to get my lathe functional. Need to fix some relays between 7i76e and lathes original AC-coil relays and do some rewiring.

Still pondering if I go that design route or if I make a frame for this, time will tell.

As I already have some Mesa boards that is the most economical for me, but it is still in planning stage.

Maybe I put these motors for sale and make my other projects ready up and running. Been off line again due to health reasons but now I need to get my lathe functional. Need to fix some relays between 7i76e and lathes original AC-coil relays and do some rewiring.

Please Log in or Create an account to join the conversation.

04 Dec 2017 09:52 #102653

by rodw

There are some commercial vertical tables and I did think of building one like that as space is an issue for me. It would have just stood up against the wall. The material just needs to be on a bit of an angle (eg not quite perpendicular to the floor). One of the ones I saw tabbed parts so they did not fall out. That is actually supported in Sheetcam. For casual use, I think I'd sell your servos and invest in a 7i76e and a few stepper motors. I'm using 269 Oz NEMA 23's on the X and Z axis. I was going to use the same size on the joint axis (Y axis) but I found some nice NEMA 34 5:1 timing belt reduction drives so I upgraded to small NEMA 34's that I could still run with my 3.5 amp stepper drives. The drives I am using are Longs Motor DM542a from eBay and my steppers came from steppers online so they are nothing special. $35 for a stepper drive and $50 for a stepper motor vs $250 for a servo drive would make a big difference to the total cost. I am getting 21 m/min rapids and say 1.5 m/s/s acceleration with 20 x micro stepping. The 5mm/rev ball screw on the Z is good for about 5.5 m/min so there will be no constraints that will affect your plasma cutting.

If you did use a servo, Keep the smallest and put it on your Z axis to get maximum acceleration for torch height control. I think Dewey calculated that you needed 2219 mm/s/s acceleration to cut corrugated iron (if you want to show off). I did get that in testing but found in real cutting, it was too fast and I lost steps (I think - things happen very fast with plasma)

Replied by rodw on topic Odd AC servo motors - how to test

Well on a long time wanted list is a plasma table but it has been put on back-burner due to lack of space.

Much of the mechanic parts I already have but need to tinker how to build the table as it has to be fast/easy setup and tear down build. Main idea is to have a *cutting* frame easily manageable that I fix on material to be cut and store this frame hanging in garage roof when not in use. Size of this frame is still unknown but somewhere around a 1/4 plate (2000x1000 nominal size)

There are some commercial vertical tables and I did think of building one like that as space is an issue for me. It would have just stood up against the wall. The material just needs to be on a bit of an angle (eg not quite perpendicular to the floor). One of the ones I saw tabbed parts so they did not fall out. That is actually supported in Sheetcam. For casual use, I think I'd sell your servos and invest in a 7i76e and a few stepper motors. I'm using 269 Oz NEMA 23's on the X and Z axis. I was going to use the same size on the joint axis (Y axis) but I found some nice NEMA 34 5:1 timing belt reduction drives so I upgraded to small NEMA 34's that I could still run with my 3.5 amp stepper drives. The drives I am using are Longs Motor DM542a from eBay and my steppers came from steppers online so they are nothing special. $35 for a stepper drive and $50 for a stepper motor vs $250 for a servo drive would make a big difference to the total cost. I am getting 21 m/min rapids and say 1.5 m/s/s acceleration with 20 x micro stepping. The 5mm/rev ball screw on the Z is good for about 5.5 m/min so there will be no constraints that will affect your plasma cutting.

If you did use a servo, Keep the smallest and put it on your Z axis to get maximum acceleration for torch height control. I think Dewey calculated that you needed 2219 mm/s/s acceleration to cut corrugated iron (if you want to show off). I did get that in testing but found in real cutting, it was too fast and I lost steps (I think - things happen very fast with plasma)

Please Log in or Create an account to join the conversation.

Time to create page: 0.184 seconds