Low budget plasma setup, what do I need?

25 Jun 2019 12:47 #137798

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

OK, will have to read up on Plasmac.

Please Log in or Create an account to join the conversation.

25 Jun 2019 13:09 #137799

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Please Log in or Create an account to join the conversation.

25 Jun 2019 13:30 #137800

by rodw

Replied by rodw on topic Low budget plasma setup, what do I need?

Maybe. Do you have any analog inputs on your mesa cards ? (7i76e has some).Its coming back to me. I think the sensor I used is an on/off

This was probably it www.jaycar.com.au/ugn3503ua-hall-effect-sensor/p/ZD1902

Find the datasheet. It has a diagram similar to what I used. I machined a plastic ring to protect it.

Can't remember where I got the idea from.

This was probably it www.jaycar.com.au/ugn3503ua-hall-effect-sensor/p/ZD1902

Find the datasheet. It has a diagram similar to what I used. I machined a plastic ring to protect it.

Can't remember where I got the idea from.

Please Log in or Create an account to join the conversation.

25 Jun 2019 14:06 #137801

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Maybe it all is simplified by setting like this in Plasmac?

plasmac uses one of three different operating modes.

Mode Description

0 Use external arc voltage in to calculate Arc Voltage and Arc OKPlease Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 17767

- Thank you received: 5905

26 Jun 2019 00:42 #137843

by tommylight

Replied by tommylight on topic Low budget plasma setup, what do I need?

Use PlasmaC built in feature to generate ArcOK signal, dealing with plasma cutter guts is not healthy, it does not forgive mistakes.

It should work properly with some fine adjustment, in about 2 to 5 minutes of your time.

It should work properly with some fine adjustment, in about 2 to 5 minutes of your time.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

26 Jun 2019 19:27 #137924

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

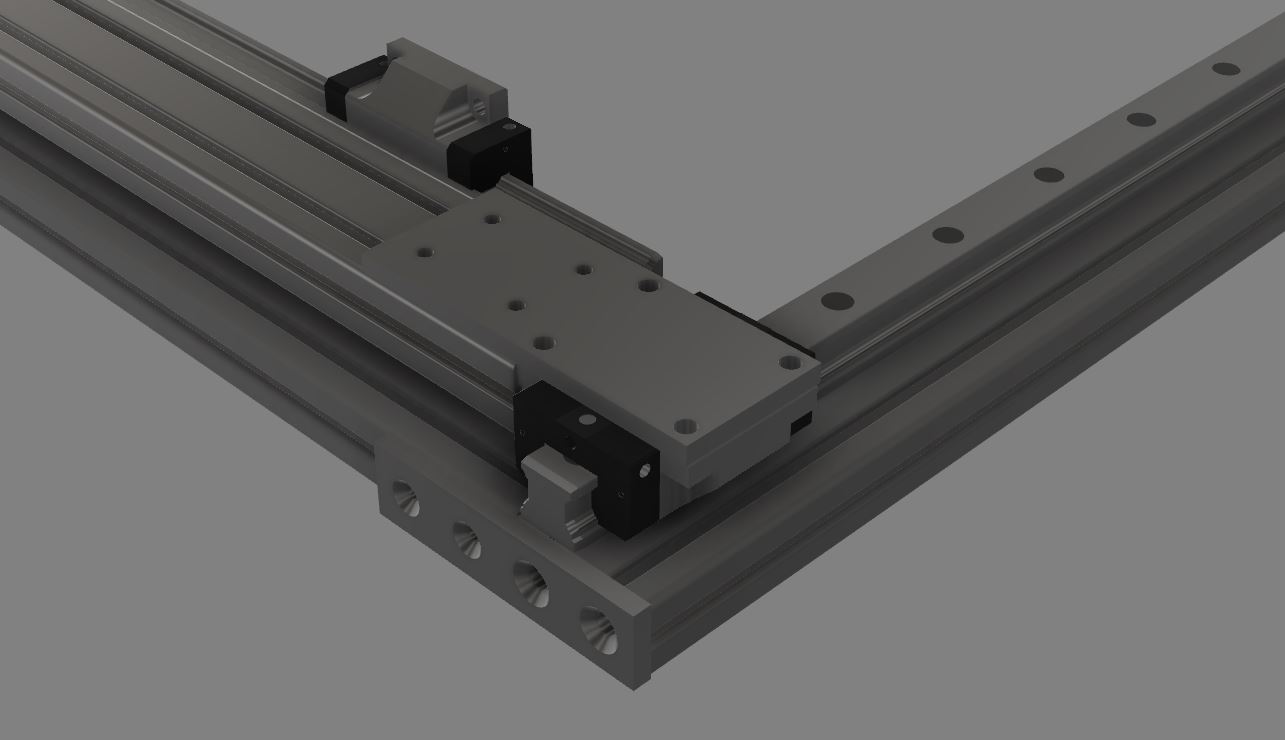

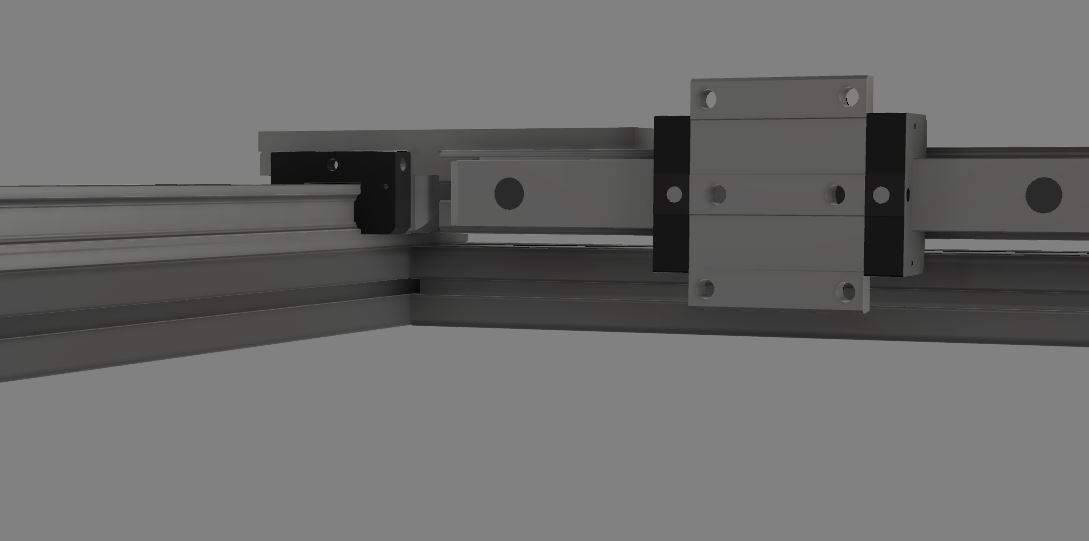

Attachments:

Please Log in or Create an account to join the conversation.

26 Jun 2019 20:25 #137925

by rodw

Replied by rodw on topic Low budget plasma setup, what do I need?

Remember to allow at least 50mm for material warpage below the torch tip and that is barely enough.

Please Log in or Create an account to join the conversation.

26 Jun 2019 20:30 #137926

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Thanks for the tip, will take that in designing the main stand with eventual waterpan and grating or whatever it is called.

I assume that amount of warping occurs on very thin materials?

I assume that amount of warping occurs on very thin materials?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 17767

- Thank you received: 5905

26 Jun 2019 23:19 #137940

by tommylight

Replied by tommylight on topic Low budget plasma setup, what do I need?

If you plan on using water table, it will have to be more than 50mm above, then again without water table it should also be more than 50mm. The dust from cutting ( or water ) can easily reach 100mm or more, that is very fine dust that will end up on those rails and soon enough it will make them lock due to tight tolerances.

If at all possible make the table at least 200 to 250mm above cutting surface, make the torch holder so it can be 70 to 100mm above cutting surface. That is easy to do and it will prolong the life of the rails a lot. One carriage is enough to hold the torch and floating head and cables, and a lot more.

If at all possible make the table at least 200 to 250mm above cutting surface, make the torch holder so it can be 70 to 100mm above cutting surface. That is easy to do and it will prolong the life of the rails a lot. One carriage is enough to hold the torch and floating head and cables, and a lot more.

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

Less

More

- Posts: 1130

- Thank you received: 531

26 Jun 2019 23:37 #137941

by thefabricator03

Replied by thefabricator03 on topic Low budget plasma setup, what do I need?

Also to add to what Tom said,

The torch airflow will be left on for a period after the torch has been fired. This causes water to be sprayed all over the place from the airflow.

I would allow a min 100mm for the torch to be parked about the water level at the end of a cut.

The torch airflow will be left on for a period after the torch has been fired. This causes water to be sprayed all over the place from the airflow.

I would allow a min 100mm for the torch to be parked about the water level at the end of a cut.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.128 seconds