about scara joint 3 issue ...

02 Sep 2016 11:53 - 02 Sep 2016 12:00 #79901

by bkt

Replied by bkt on topic about scara joint 3 issue ...

the image .... of belt drive C axis ..... the other machine is equal but gear driven C axis ....

Over the "cilindrical carter" there are a motor directly connected to a planetary gearbox ... direct connected on joint0 .... under the second "carter" there is another engine and gearbox connected by belts or gears ( depending on model ) to the joint1 .... joint3 / C axis is seen and is without housing ... has a gearbox that connects to the pipe ( end effector ) that runs ....

With image is more clear I think ...

Regards

Giorgio

Over the "cilindrical carter" there are a motor directly connected to a planetary gearbox ... direct connected on joint0 .... under the second "carter" there is another engine and gearbox connected by belts or gears ( depending on model ) to the joint1 .... joint3 / C axis is seen and is without housing ... has a gearbox that connects to the pipe ( end effector ) that runs ....

With image is more clear I think ...

Regards

Giorgio

Last edit: 02 Sep 2016 12:00 by bkt.

Please Log in or Create an account to join the conversation.

02 Sep 2016 20:32 #79932

by andypugh

Perhaps with a more-clear image

Is that the C-axis motor on the bottom of the second joint?

Is it possible you simply have the sense of rotation of the C axis motor wrong? (Or, at least, not the direction Scarakins expects)

Replied by andypugh on topic about scara joint 3 issue ...

With image is more clear I think

Perhaps with a more-clear image

Is that the C-axis motor on the bottom of the second joint?

Is it possible you simply have the sense of rotation of the C axis motor wrong? (Or, at least, not the direction Scarakins expects)

Please Log in or Create an account to join the conversation.

03 Sep 2016 11:45 - 03 Sep 2016 12:04 #79968

by bkt

I think scarakins expects that if joint0 go to ++ and joint1 go to ++ ... joint3(C axis) go to ++/++/+joint3 .... what you means for??

the problem:

pheraps at every velocity (proportionally .. less at slow motion ... more at hight motion .... F5000 = slow F90000 = hight)...

regards

Giorgio

Replied by bkt on topic about scara joint 3 issue ...

Yes...Is that the C-axis motor on the bottom of the second joint?

Is it possible you simply have the sense of rotation of the C axis motor wrong? (Or, at least, not the direction Scarakins expects)

I think scarakins expects that if joint0 go to ++ and joint1 go to ++ ... joint3(C axis) go to ++/++/+joint3 .... what you means for??

the problem:

pheraps at every velocity (proportionally .. less at slow motion ... more at hight motion .... F5000 = slow F90000 = hight)...

regards

Giorgio

Last edit: 03 Sep 2016 12:04 by bkt.

Please Log in or Create an account to join the conversation.

03 Sep 2016 14:12 #79974

by andypugh

Replied by andypugh on topic about scara joint 3 issue ...

C-axis scaling? Have you checked that 1 revolution is exactly one revolution?

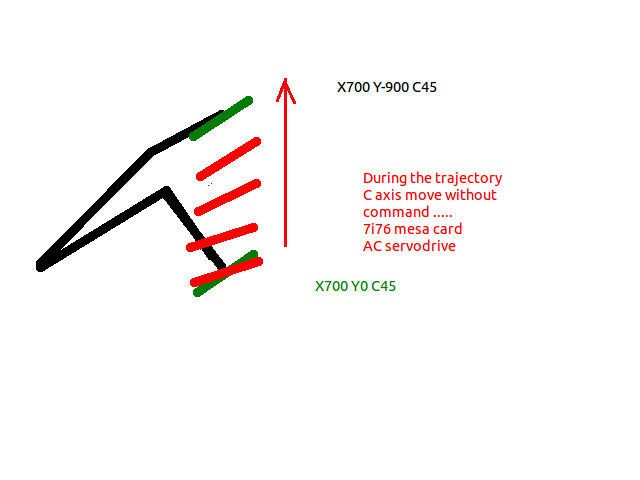

If green is what you want and red is what you get, then it seems that scarakins is compensating, but not quite by the right amount.

If I have misinterpreted the diagram, then perhaps you could explain it?

If green is what you want and red is what you get, then it seems that scarakins is compensating, but not quite by the right amount.

If I have misinterpreted the diagram, then perhaps you could explain it?

The following user(s) said Thank You: bkt

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17828

- Thank you received: 5928

03 Sep 2016 15:03 #79979

by tommylight

Replied by tommylight on topic about scara joint 3 issue ...

Not my forte, but, if the black are the robot joints, green is what you need it to do and red is what you get, that is a sign of proportions and lengths not being set properly, also the geometry of the arms and position in regards to one another, and moving angles.

From that drawing, for moving Y axis at +, it has to move the C axis ( if C is the farthest left one ).

Take this with a grain (or two) of salt, as i am not familiar with scara, but i do a lot of KUKA installation and wiring external hardware and programming ( well teaching, not actual programming), so i am familiar with the complications of moving a 6 axis machine in a 3 dimensional space.

From that drawing, for moving Y axis at +, it has to move the C axis ( if C is the farthest left one ).

Take this with a grain (or two) of salt, as i am not familiar with scara, but i do a lot of KUKA installation and wiring external hardware and programming ( well teaching, not actual programming), so i am familiar with the complications of moving a 6 axis machine in a 3 dimensional space.

The following user(s) said Thank You: bkt

Please Log in or Create an account to join the conversation.

05 Sep 2016 07:22 - 05 Sep 2016 09:14 #80040

by bkt

Replied by bkt on topic about scara joint 3 issue ...

UPDATE 1: I replaced # DEFINE PM_PI with #DEFINE PI = 3.xxxxxxxxxx of scarakins ...... the situation has improved slightly but little by little ...

At these point I think the problem is max step acceleration problem related .... correct me if I'm wrong , but if I have a closed loop , any error ( acceleration and speed ) the error is corrected from the closed loop in LCNC / JA .... but if I have an open loop ... if the acceleration of ' axis " C " was too different from acceleration of joint1 + joint0 ???? What happen??

I do not know the answer to this ... but I figured LCNC / JA could have problems ... I try to play with these parameters now ...

UPDATE2: joint0 and joint1 is set STEPGEN_MAXACC = 9000 ... in the old test I set C axes STEPGEN_MAXACC = 9000 .... now I set C axes STEPGEN_MAXACC =300 STEPGEN_MAXVEL =200 MAX_ACCELERATION = 220 MAX_VELOCITY = 180 ..... same error on the same situation .... Now I'm sure lLCNC / JA adjusts the acceleration and deceleration even in the step / dir without any type of error according to the kinematic choice .... so it is not the problem ....

Regards

Giorgio

This is right ......If green is what you want and red is what you get

This is just check ... it's all ok.C-axis scaling? Have you checked that 1 revolution is exactly one revolution?

you're right , it's the first thing I thought of me as well ... but the parts are manufactured in our workshops and the error is +/- 0.02mm ... while I see an error of 4-12 ° depending on the speed .... only for test 3week ago I try to insert an erron on leght of arm .... on a 10mm error on arm off 500mm, it is barely visible to the naked eye on the axis " C " while you see a lot regarding the joint and joint 0 1 ....Not my forte, but, if the black are the robot joints, green is what you need it to do and red is what you get, that is a sign of proportions and lengths not being set properly, also the geometry of the arms and position in regards to one another, and moving angles.

At these point I think the problem is max step acceleration problem related .... correct me if I'm wrong , but if I have a closed loop , any error ( acceleration and speed ) the error is corrected from the closed loop in LCNC / JA .... but if I have an open loop ... if the acceleration of ' axis " C " was too different from acceleration of joint1 + joint0 ???? What happen??

I do not know the answer to this ... but I figured LCNC / JA could have problems ... I try to play with these parameters now ...

UPDATE2: joint0 and joint1 is set STEPGEN_MAXACC = 9000 ... in the old test I set C axes STEPGEN_MAXACC = 9000 .... now I set C axes STEPGEN_MAXACC =300 STEPGEN_MAXVEL =200 MAX_ACCELERATION = 220 MAX_VELOCITY = 180 ..... same error on the same situation .... Now I'm sure lLCNC / JA adjusts the acceleration and deceleration even in the step / dir without any type of error according to the kinematic choice .... so it is not the problem ....

Regards

Giorgio

Last edit: 05 Sep 2016 09:14 by bkt.

Please Log in or Create an account to join the conversation.

Time to create page: 0.472 seconds