lathe tool sensor setup , who's done it ?

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 655

- Thank you received: 109

25 Apr 2023 22:21 - 25 Apr 2023 22:22 #269910

by smc.collins

lathe tool sensor setup , who's done it ? was created by smc.collins

has anyone actually made a working lathe tool sensor, a x- x+ z- z+ for setting tools ? if so, how did you implement it ? I tried googlefu, came up empty, and I was considering a hal component, not sure how I would implement the offsets though. but I am investigating it.

Last edit: 25 Apr 2023 22:22 by smc.collins.

Please Log in or Create an account to join the conversation.

28 Apr 2023 16:33 #270115

by JPL

Replied by JPL on topic lathe tool sensor setup , who's done it ?

Do you mean something like this : www.haascnc.com/video/tips/s4xeo5gcxhk.html

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 655

- Thank you received: 109

28 Apr 2023 17:57 - 28 Apr 2023 18:05 #270118

by smc.collins

Replied by smc.collins on topic lathe tool sensor setup , who's done it ?

yes, 4 sided tool setting sensor. I'm working through the variables of a hal component for this. mostly trying to figure out how to send the events and store them. thinking a macro with tool position, via halui.

kinda complicated, setting tools manually is obviously les complicated and i intend to start from there.

the sensor measure's tools a specific distance z- z+ x- x+, and those offsets need to be associated when the sensor is triggered.

it would also be nice to have a homing type routine to measure the tool once it's close. long term, be able to enter a approximate tool length and have lcnc handle the entire transaction, that's more complicated however.

but for now, triggering a tool offset measurement in a touch off, that's a start.

kinda complicated, setting tools manually is obviously les complicated and i intend to start from there.

the sensor measure's tools a specific distance z- z+ x- x+, and those offsets need to be associated when the sensor is triggered.

it would also be nice to have a homing type routine to measure the tool once it's close. long term, be able to enter a approximate tool length and have lcnc handle the entire transaction, that's more complicated however.

but for now, triggering a tool offset measurement in a touch off, that's a start.

Last edit: 28 Apr 2023 18:05 by smc.collins.

Please Log in or Create an account to join the conversation.

18 Jun 2023 20:49 #273803

by JR1050

Replied by JR1050 on topic lathe tool sensor setup , who's done it ?

Yes, I set up the tool probe on my Cincinnati. You will need to create an input for the probe signal in Hal.

You then need a macro to measure the tools based on their orientation.

I wrote the macro as a custom M code. and. assigned positions based on tool orientation and clock direction. To touch off an od turning tool:

Type in MDI

M275 P12, as the top button of the probe is at 12 o’clock.

You have to measure the distance from spindle center to the probe and add it to the probed value, then write it to the tool table using G10.

I can share the Macro. You will have to write some plc code to put the probe up and down.

You then need a macro to measure the tools based on their orientation.

I wrote the macro as a custom M code. and. assigned positions based on tool orientation and clock direction. To touch off an od turning tool:

Type in MDI

M275 P12, as the top button of the probe is at 12 o’clock.

You have to measure the distance from spindle center to the probe and add it to the probed value, then write it to the tool table using G10.

I can share the Macro. You will have to write some plc code to put the probe up and down.

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 655

- Thank you received: 109

19 Jun 2023 00:39 #273819

by smc.collins

Replied by smc.collins on topic lathe tool sensor setup , who's done it ?

maybe we can collaborate here, I'll write a hal component, for the mechanics, please share the macro, I'd like to see it

Please Log in or Create an account to join the conversation.

20 Jun 2023 06:29 #273899

by GuiHue

Replied by GuiHue on topic lathe tool sensor setup , who's done it ?

I am not a lathe user and have never worked with those sensors. However, it appears to me that they create a trigger signal all the same. I thus fail to see the difference to a normal probe input. As JR1050 writes, I would expect to handle the entire tool probing in a GCode macro, potentially triggering and reading external actors or sensors using M6x commands. I fail to see the need for a hal comp, thinking this makes it even more complex.The mechanics look like it is triggered through one or maybe a few inputs. Should not require anything but M6x commands.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 655

- Thank you received: 109

20 Jun 2023 16:41 #273945

by smc.collins

Replied by smc.collins on topic lathe tool sensor setup , who's done it ?

the lathe tool sensor has 4 inputs and has 4 offsets 1 per input. so that's why a hal component is needed, lcnc only allows for a single probe input and it's not specifically designed to be a lathe tool sensor.

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

20 Jun 2023 21:28 #273966

by spumco

Replied by spumco on topic lathe tool sensor setup , who's done it ?

@GuiHue

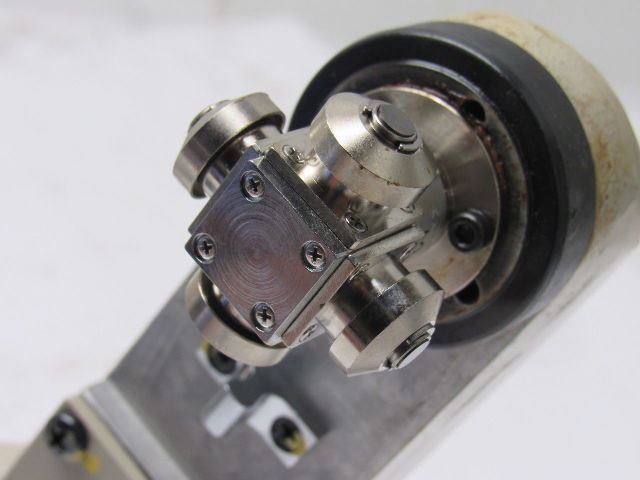

Some lathe tool probes are basically a spindle probe with square sides (instead of a ball stylus).

However, some are 4-sided jobs.

Some (older) machines required the operator to lower the probe arm manually (or bolt it on). Newer machines generally deploy the arm automatially... meaning up sensor and deployed sensors, plus safety logic in case it doesn't make it down all the way.

Pretty sure you could do everything in M-codes, but it'd get messy and hard to follow or debug. A dedicated comp to handle all of the backstage stuff would be sweet.

Some lathe tool probes are basically a spindle probe with square sides (instead of a ball stylus).

However, some are 4-sided jobs.

Some (older) machines required the operator to lower the probe arm manually (or bolt it on). Newer machines generally deploy the arm automatially... meaning up sensor and deployed sensors, plus safety logic in case it doesn't make it down all the way.

Pretty sure you could do everything in M-codes, but it'd get messy and hard to follow or debug. A dedicated comp to handle all of the backstage stuff would be sweet.

Attachments:

Please Log in or Create an account to join the conversation.

15 Jul 2023 19:14 #275537

by foxington

Replied by foxington on topic lathe tool sensor setup , who's done it ?

hello gentelmen,

I am hooking up pin for this topic because I am curently tring to solve same problem.

I found some ways of putting it on lathe, placement connection and probing subroutine but feedback from real user should be better then my own dreams. Have anybody experiences with implementation of that and what should do and what avoid please?

Regards F.

I am hooking up pin for this topic because I am curently tring to solve same problem.

- Where to place metrol probe to flatbed lathe - small free space volume

- how to start probing - by some marco from MDI screen probably

I found some ways of putting it on lathe, placement connection and probing subroutine but feedback from real user should be better then my own dreams. Have anybody experiences with implementation of that and what should do and what avoid please?

Regards F.

Please Log in or Create an account to join the conversation.

22 Aug 2023 19:38 #278733

by JR1050

Replied by JR1050 on topic lathe tool sensor setup , who's done it ?

This is my tool setting macro.

od tool 12 oclock P12

front of any tool 3 oclock P3

id tool 6 oclock P6

left hand tool 09 oclocl P9

set tool about .2 from the probe

Probe front of any tool

M275 P3 in MDI

G54 is ALWAYS machine zero, #101, #102 ect are the variables you have to figure out. #101 would be the difference from the triggered probe to the center of your spindle. #104 in my case is the distance from the front of the chuck to the face of the probe.

o<m275> sub

G90G49G54

(PROBE OD TURNING TOOL-THISONE WORKS)

o101 if[#<P> EQ 12]

#102=-1.7501

G49G94

G91

G38.2 X-.2 F5.

G0X.15

G38.2 X-.2 F5.

#101=[[#5061+#102]*2]

G0X.2

G90G49

G10 L1 P#5400 X#101

G49

(PROBE ID TOOL)

o101 elseif[#<P> EQ 6]

#103=-.1585

G49G94

G91

G38.2 X.2 F5.

G0X-.15

G38.2 X.2F5.

#101=[[#5061+#103]*2]

G0X-.2

G90G49

G10 L1 P#5400 X#101

(PROBE FRONT OF ANY TOOL)

o101 elseif[#<P> EQ 3]

#104=-9.6783

G49G94

G91

G38.2 Z-.2F5.

G0Z.15

G38.2 Z-.2F5.

#101=[#5063+#104]

G0Z.2

G90G49

G10 L1 P#5400 Z#101

(PROBE LEFT HAND TOOL)

o101 elseif[#<P> EQ 9]

#105=-4.674

G49G94

G91

G38.2 Z.2F5.

G0Z-.2

G38.2 Z.2F5.

#101=[#5063+#105]

G0Z-.2

G90G49

G10 L1 P#5400 Z#101

o101 endif

#<P>=0

o<m275> endsub

M30

od tool 12 oclock P12

front of any tool 3 oclock P3

id tool 6 oclock P6

left hand tool 09 oclocl P9

set tool about .2 from the probe

Probe front of any tool

M275 P3 in MDI

G54 is ALWAYS machine zero, #101, #102 ect are the variables you have to figure out. #101 would be the difference from the triggered probe to the center of your spindle. #104 in my case is the distance from the front of the chuck to the face of the probe.

o<m275> sub

G90G49G54

(PROBE OD TURNING TOOL-THISONE WORKS)

o101 if[#<P> EQ 12]

#102=-1.7501

G49G94

G91

G38.2 X-.2 F5.

G0X.15

G38.2 X-.2 F5.

#101=[[#5061+#102]*2]

G0X.2

G90G49

G10 L1 P#5400 X#101

G49

(PROBE ID TOOL)

o101 elseif[#<P> EQ 6]

#103=-.1585

G49G94

G91

G38.2 X.2 F5.

G0X-.15

G38.2 X.2F5.

#101=[[#5061+#103]*2]

G0X-.2

G90G49

G10 L1 P#5400 X#101

(PROBE FRONT OF ANY TOOL)

o101 elseif[#<P> EQ 3]

#104=-9.6783

G49G94

G91

G38.2 Z-.2F5.

G0Z.15

G38.2 Z-.2F5.

#101=[#5063+#104]

G0Z.2

G90G49

G10 L1 P#5400 Z#101

(PROBE LEFT HAND TOOL)

o101 elseif[#<P> EQ 9]

#105=-4.674

G49G94

G91

G38.2 Z.2F5.

G0Z-.2

G38.2 Z.2F5.

#101=[#5063+#105]

G0Z-.2

G90G49

G10 L1 P#5400 Z#101

o101 endif

#<P>=0

o<m275> endsub

M30

Please Log in or Create an account to join the conversation.

Time to create page: 0.098 seconds