[ Vfdmod ] An easy VFD control over MODBUS RTU

10 Jan 2024 17:33 #290386

by COFHAL

Replied by COFHAL on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

I have the complete ini of my machine on github. Here you find the ini of the vfd:

github.com/ModuloFS/LCNC_RatRig_KillerBe...ee/vfd_h1_config.ini

Be aware of the P01.47 parameter in the vfd, because at the standard configuration you are not able to set the max output frequency with the 16 Bit register values.

THANK

Please Log in or Create an account to join the conversation.

10 Jan 2024 18:16 #290388

by CNC_Tux

Replied by CNC_Tux on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

Hello Friends of LinuxCNC,

i think i am here in the right address, about VFD and Modbus RTU

I use LinuxCNC 2.9.2 and i try to get to run a VFD ( Powtran PI500) on the Modbus RTU.

I found something about PI500 in the description, but i think thats isnt the driver.

linuxcnc.org/docs/2.9/html/man/man1/pi500_vfd.1.html

My goal is to get to work the first one, then i get 2 others in modbus RTU as well ( 3 Spindle = slave 1; slave 2; slave 3 )

Has anybody an idea, how is to do for a PI500 VFD?

Thank you so much in advance

Best regards

Reinhard

i think i am here in the right address, about VFD and Modbus RTU

I use LinuxCNC 2.9.2 and i try to get to run a VFD ( Powtran PI500) on the Modbus RTU.

I found something about PI500 in the description, but i think thats isnt the driver.

linuxcnc.org/docs/2.9/html/man/man1/pi500_vfd.1.html

My goal is to get to work the first one, then i get 2 others in modbus RTU as well ( 3 Spindle = slave 1; slave 2; slave 3 )

Has anybody an idea, how is to do for a PI500 VFD?

Thank you so much in advance

Best regards

Reinhard

Please Log in or Create an account to join the conversation.

18 Mar 2024 21:12 #296254

by COFHAL

Replied by COFHAL on topic [ Vfdmod ] problems

I have found several problems with this component. First, it takes as feedback to the spindle the values reported by the control, but not by an encoder, for example from the spindle of a lathe, therefore the pyvcp is designed to obtain information from the readings via RS-485 but not from an encoder. external, therefore some files have to be modified so that spindle at speed is used with this feedback and not the original one. Another problem that I found is that the override control of the Axis GUI no longer responds, when the speed of the spindle is varied with this control in Axis, to vary its speed it does not respond even though the values in HAL do vary between what has been set in the ini file, the spindle speed only responds to G code commands or + or - in the Axis GUI, but not to the slider in the Axis GUI. Finally, when I controlled the VFD with +10 volts, the G96 code worked in CSS mode, now with control by 485 the speed of the spindle is always the same and the spindle does not accelerate as it does. diameter is smaller, nor does the feed increase.

Please Log in or Create an account to join the conversation.

18 Mar 2024 23:15 #296262

by rodw

Replied by rodw on topic [ Vfdmod ] problems

Nothing is ever plug and play, why would an example config demonstrating vfd use include encoder feedback? You need to adapt it to include your encoder.

Linuxcnc tells the vfd what speed it wants so if its not getting that right in g96, you may not have set the spindle up correctly

Ref linuxcnc.org/docs/stable/html/man/man9/m....html#SPINDLE%20PINS

I don't have an encoder or lathe, Everything works perfectly for me but I migrated to qtdragon long ago.

I know I had problems initially because I did not fully understand how to set up the spindle.

On my VFD voltage and rs485 control are mutually exclusive.

Linuxcnc tells the vfd what speed it wants so if its not getting that right in g96, you may not have set the spindle up correctly

Ref linuxcnc.org/docs/stable/html/man/man9/m....html#SPINDLE%20PINS

I don't have an encoder or lathe, Everything works perfectly for me but I migrated to qtdragon long ago.

I know I had problems initially because I did not fully understand how to set up the spindle.

On my VFD voltage and rs485 control are mutually exclusive.

Please Log in or Create an account to join the conversation.

19 Mar 2024 14:08 - 19 Mar 2024 14:12 #296321

by COFHAL

Replied by COFHAL on topic [ Vfdmod ] problems

The spindle.0.speed-in pin, which is necessary to use G96 (constant surface speed) and G95 (feed per revolution) modes, is connected to my HAL through the spindle encoder at:

net spindle-velocity-feedback-rps encoder_SPD.velocity => spindle.0.speed-in.

The custom.hal file that is automatically generated by Vfdmod connects the vfdmod pin vfdmod.spindle.rpm-in to splindle-cmd-rps. I don't know if I'm wrong but the problem would be that the spindle.0.speed-in pin is not connected to splindle-cmd-rps.

I attach my hal files. and custom hal.

net spindle-velocity-feedback-rps encoder_SPD.velocity => spindle.0.speed-in.

The custom.hal file that is automatically generated by Vfdmod connects the vfdmod pin vfdmod.spindle.rpm-in to splindle-cmd-rps. I don't know if I'm wrong but the problem would be that the spindle.0.speed-in pin is not connected to splindle-cmd-rps.

I attach my hal files. and custom hal.

Attachments:

Last edit: 19 Mar 2024 14:12 by COFHAL.

Please Log in or Create an account to join the conversation.

19 Mar 2024 19:30 #296338

by rodw

Replied by rodw on topic [ Vfdmod ] problems

Yes, the config creates the signal and its up to you to connect it to the right pin in your hal

You are almost on the right track except vfdmod supplies revs per minute and linuxcnc requires revs per second.

The solution is to use the scale component to scale rpm to rps

linuxcnc.org/docs/stable/html/man/man9/scale.9.html

I do this in a custom gearbox component so don't have an example

You are almost on the right track except vfdmod supplies revs per minute and linuxcnc requires revs per second.

The solution is to use the scale component to scale rpm to rps

linuxcnc.org/docs/stable/html/man/man9/scale.9.html

I do this in a custom gearbox component so don't have an example

The following user(s) said Thank You: COFHAL

Please Log in or Create an account to join the conversation.

29 Mar 2024 16:23 #297120

by COFHAL

Replied by COFHAL on topic [ Vfdmod ] problems

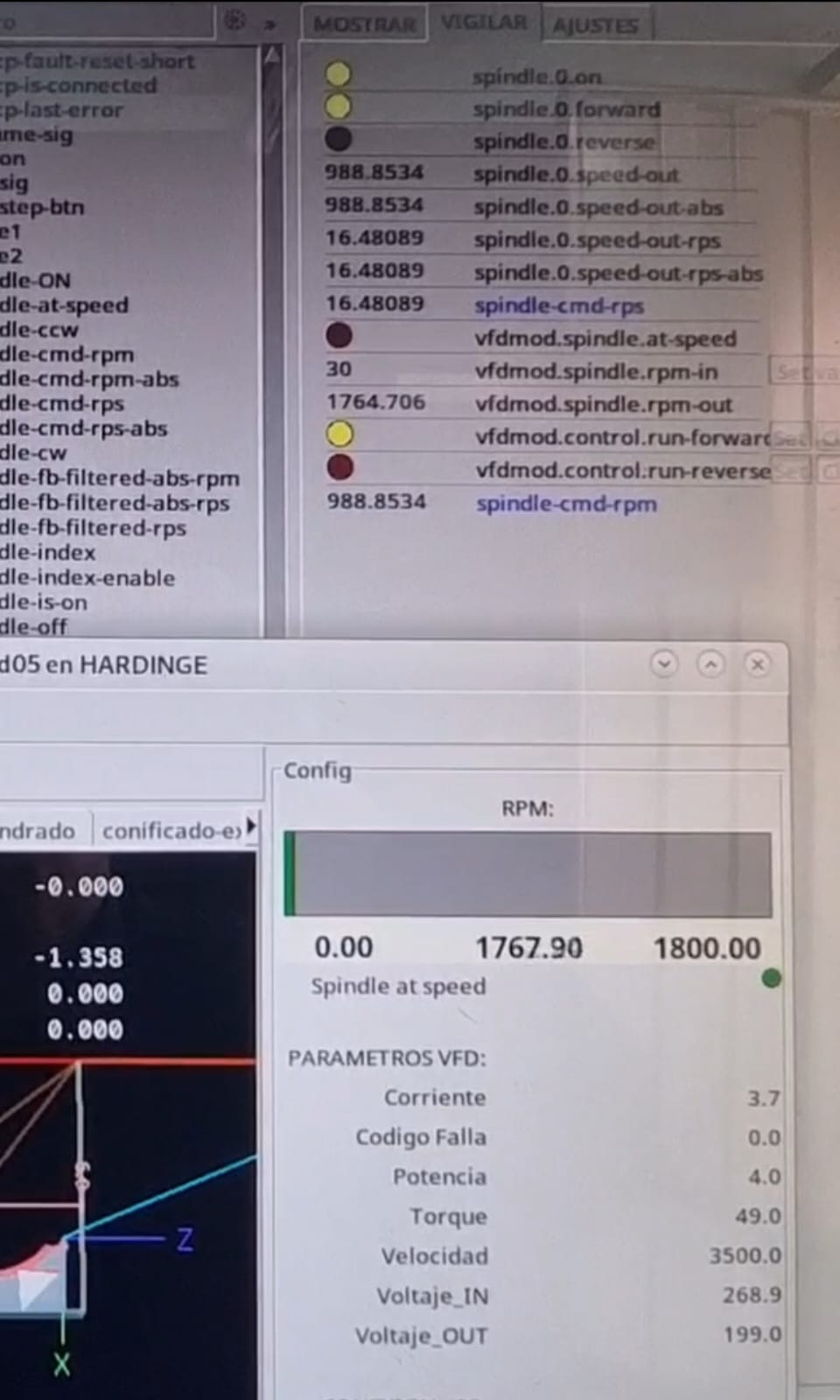

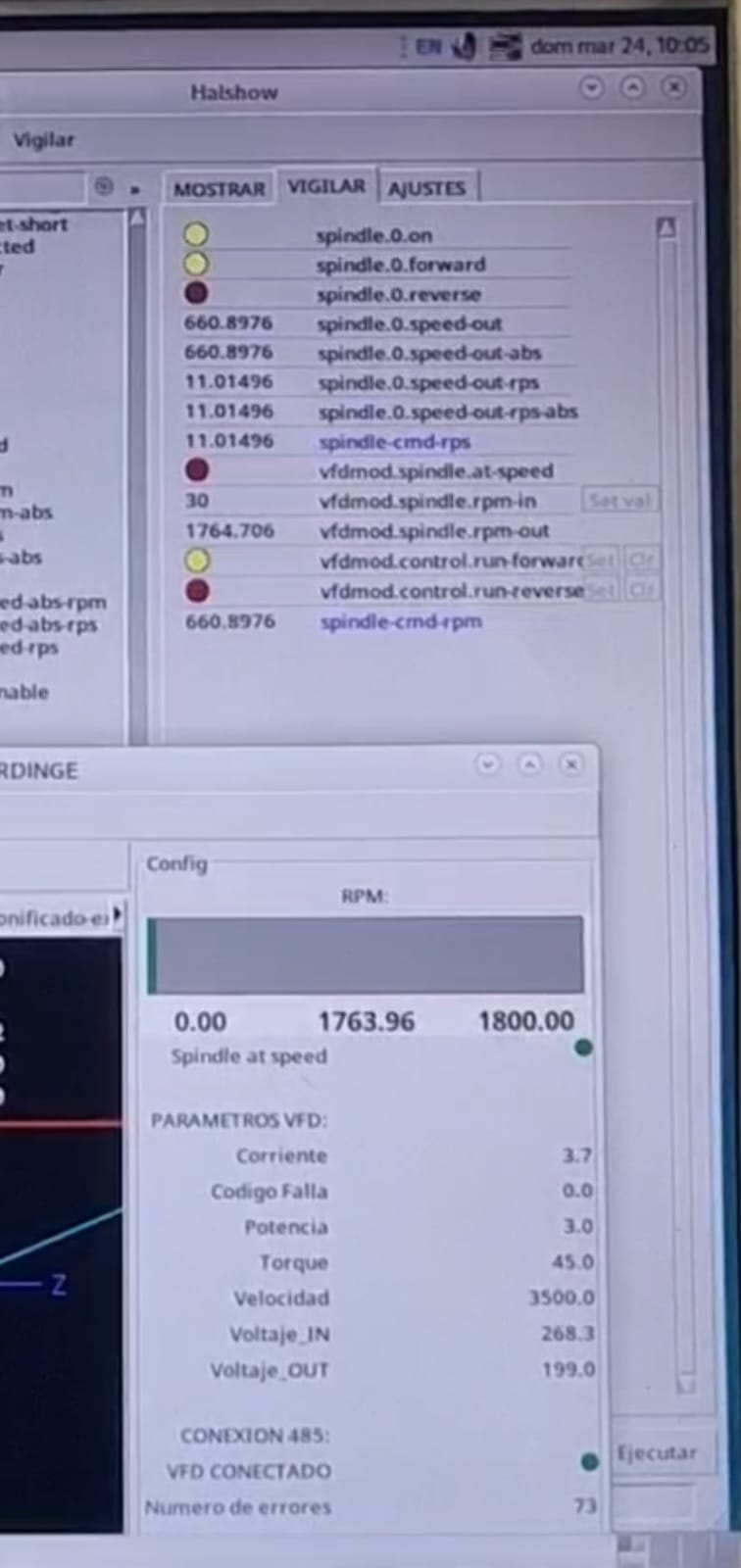

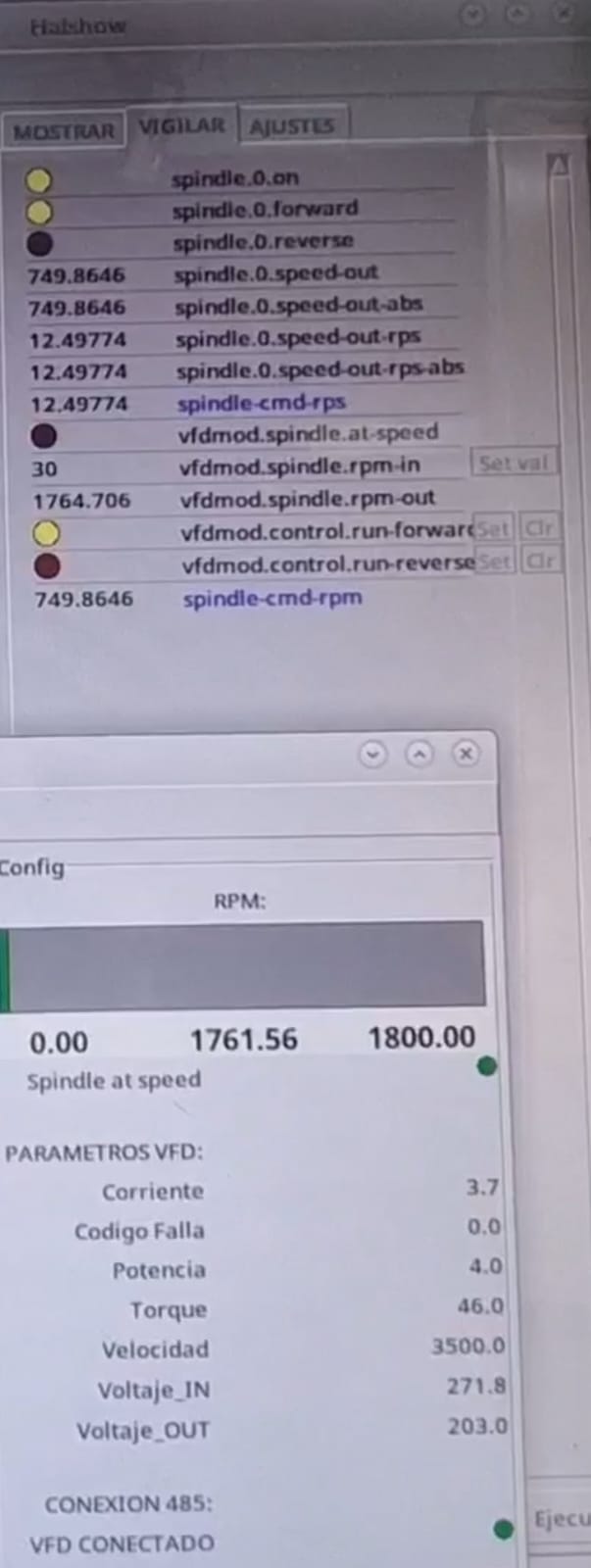

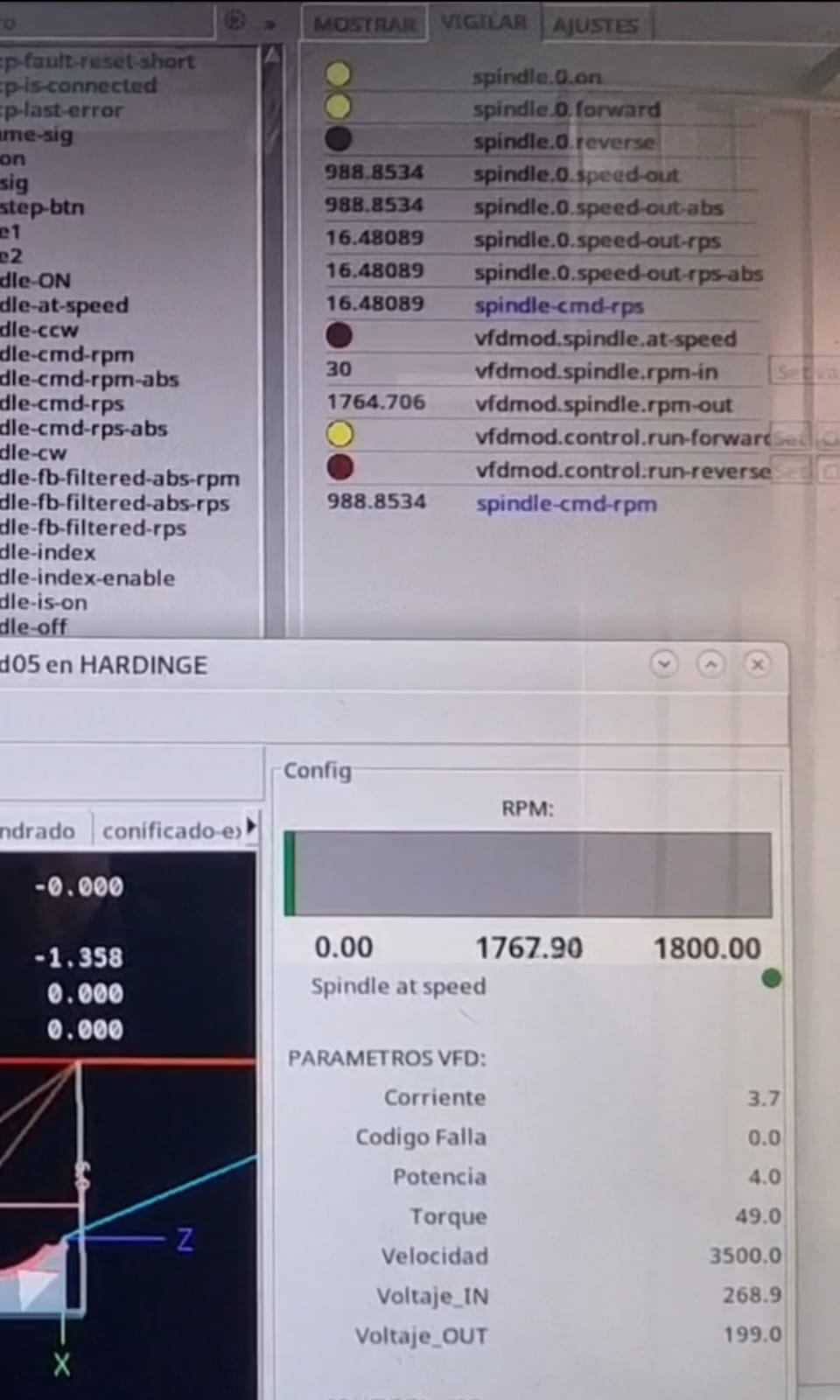

The VFDMOD component does not work with g code G96. When a code that contains that G code is executed, it automatically writes to the vfdmod.speed-in PIN the value declared in parameter D of G96. While in the other pins the speed change is reflected, which indicates that CSS is working. I think that since this component is designed for VDF of milling machines where lCSS is not used, for that reason it is not very useful when used to control the speed of a lathe motor. In the photos you can see that the commanded speed is different from the commanded output of the component, which always adjusts it to the maximum of parameter D of G96. I don't know if the same thing happens with the MB2HAL component.

Attachments:

Please Log in or Create an account to join the conversation.

29 Mar 2024 18:26 #297129

by rodw

Replied by rodw on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

I'm not convinced vfdmod won't work. Linuxcnc is controlling the spindle speed so it does not care about G96 or what kind of machine you have or even how you control your VFD. A spindle is a spindle. As long as your X axis is touched off on the centre line of the spindle, G96 should work if your config is correct.

I found this thread helpful when I set up mine. Please review the first post on page 2

forum.linuxcnc.org/qtvcp/45552-need-help...-qtdragon-hd?start=0

I found this thread helpful when I set up mine. Please review the first post on page 2

forum.linuxcnc.org/qtvcp/45552-need-help...-qtdragon-hd?start=0

The following user(s) said Thank You: COFHAL

Please Log in or Create an account to join the conversation.

29 Mar 2024 22:00 #297149

by Pickle

Replied by Pickle on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

Hi

Relative newcomer though I am, I have implemented a couple of 3-axis machines interfaced via parallel port to the stepper drivers and RS485 to the vfds. The first used the HY-01 vfd and the associated inbuilt LinuxCNC driver. The second system uses the H100 vfd, with VFDMOD as the driver. These systems used old 64 bit AMD based PCs. I have decided to upgrade to MESA 7i92T and purchased one a month or so back, I also received a RPi5 in the post around the same time and decided it would be a more compact solution and could be fun to implement RPi5 + MESA 7i92. The interfacing to the steppers/switches was straightforward once the manual had been decoded (!) and the CNC is now functional. The modbus interface to the pi is causing me problems - as RPi5 is 64 bit only, and the VFDMOD release for the pi is 32 bit armhf. Can anyone give me pointers on implementation of VFDMOD on the RPi5? Is anyone else out there doing a similar thing?

Relative newcomer though I am, I have implemented a couple of 3-axis machines interfaced via parallel port to the stepper drivers and RS485 to the vfds. The first used the HY-01 vfd and the associated inbuilt LinuxCNC driver. The second system uses the H100 vfd, with VFDMOD as the driver. These systems used old 64 bit AMD based PCs. I have decided to upgrade to MESA 7i92T and purchased one a month or so back, I also received a RPi5 in the post around the same time and decided it would be a more compact solution and could be fun to implement RPi5 + MESA 7i92. The interfacing to the steppers/switches was straightforward once the manual had been decoded (!) and the CNC is now functional. The modbus interface to the pi is causing me problems - as RPi5 is 64 bit only, and the VFDMOD release for the pi is 32 bit armhf. Can anyone give me pointers on implementation of VFDMOD on the RPi5? Is anyone else out there doing a similar thing?

Please Log in or Create an account to join the conversation.

30 Mar 2024 20:16 #297232

by COFHAL

Replied by COFHAL on topic [ Vfdmod ] problems

You were right, VFDmod works with G96, it's all in how the different spindle and vfdmod pins are connected, unfortunately there are no clear examples of lathe configurations with this component.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.187 seconds