Stepper with encoder feedback plus BOOST feature.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 18083

- Thank you received: 5997

15 May 2020 17:37 #167883

by tommylight

Stepper with encoder feedback plus BOOST feature. was created by tommylight

This article pertains to Lam Technologies stepper drives, namely the DSxxxx series of them that feature a "Boost" input, giving the possibility of adding more current to stepper motors when the f-error passes a certain settable threshold.

Note : Lam drives come factory set to invert the boost pin, so when that pin goes high the current is lowered to the motor by a value preset in the drive, the default is 50%.

In this example i used a DS1044 set at 2A, so with the boost active that drops to 1A. In the config attached, the output pin that controls the boost feature is inverted, so in normal use there is 1A going to the motor at standstill and while moving and the f-error is under the preset value, while it jumps to 2A as soon as that threshold is exceeded, offering more power for the motor to correct the position.

The f-error value is sent through an ABS component to have only positive values derived from f-error values, then to in1 of a COMP (comparator) with the in0 set to a value of 0.06 (that reflects to 0.06mm of positional error) and the hysteresis set to 0.05. The output of the comparator activates the physical output on the Mesa 7i92, consequently the Boost input on the DS1044 goes low, resulting in 2A going to the motor till f-error drops below the set value of 0.06 when the output is pulled high and the motor current drops to 1A.

Other settings and equipment used for this test:

Drive microstepping 16, 2A Nema23 stepper motor with a 2500PPR encoder slapped to it giving 10000 counts per motor revolution, Mesa 7i92, encoder wired directly to 7i92 inputs, Linuxcnc V2.9.

The attached config has only X axis using encoder as a general idea.

Note the P value for the PID loop sets how fast the motor will try to correct it's possition, so the lower it is set, the better chances of restoring position. At default 1000 P value the motor will not be able to correct the position due to high speed, but that value is very dependant on the scale used, so a bit of testing is required.

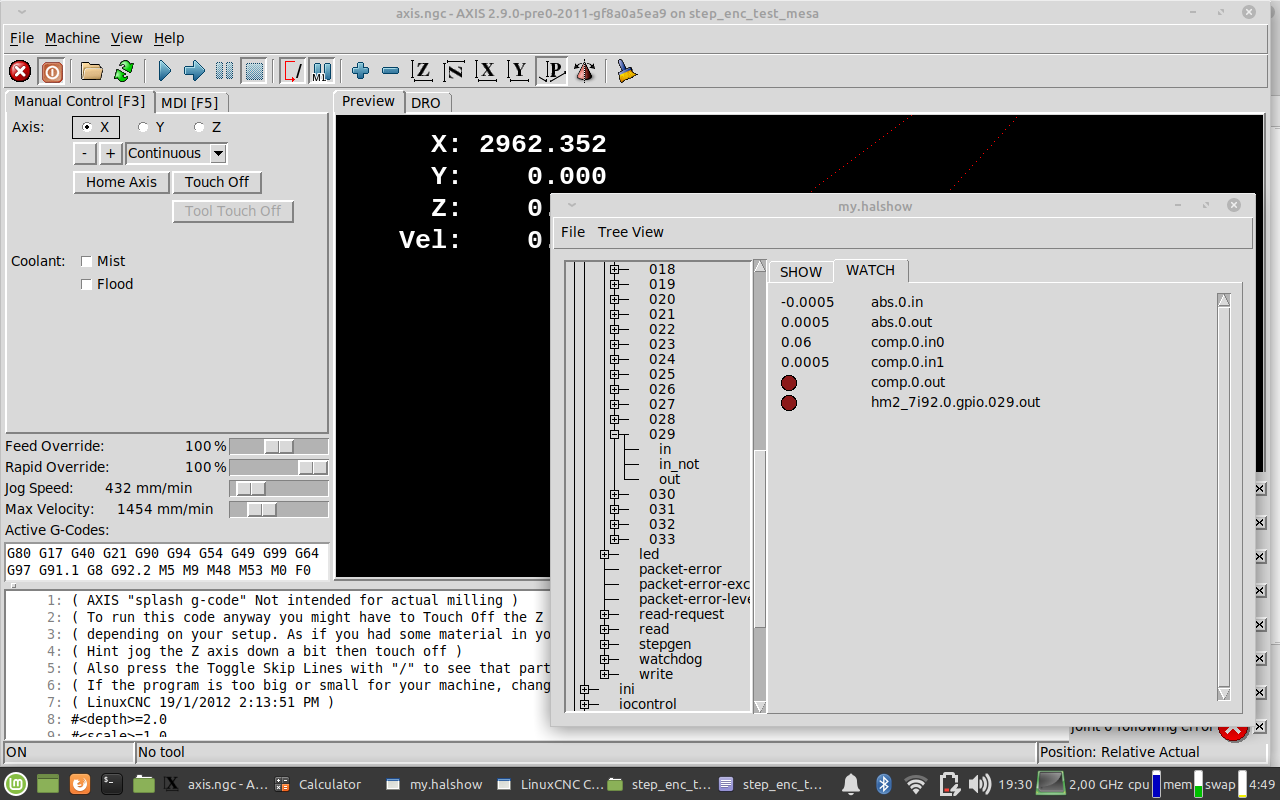

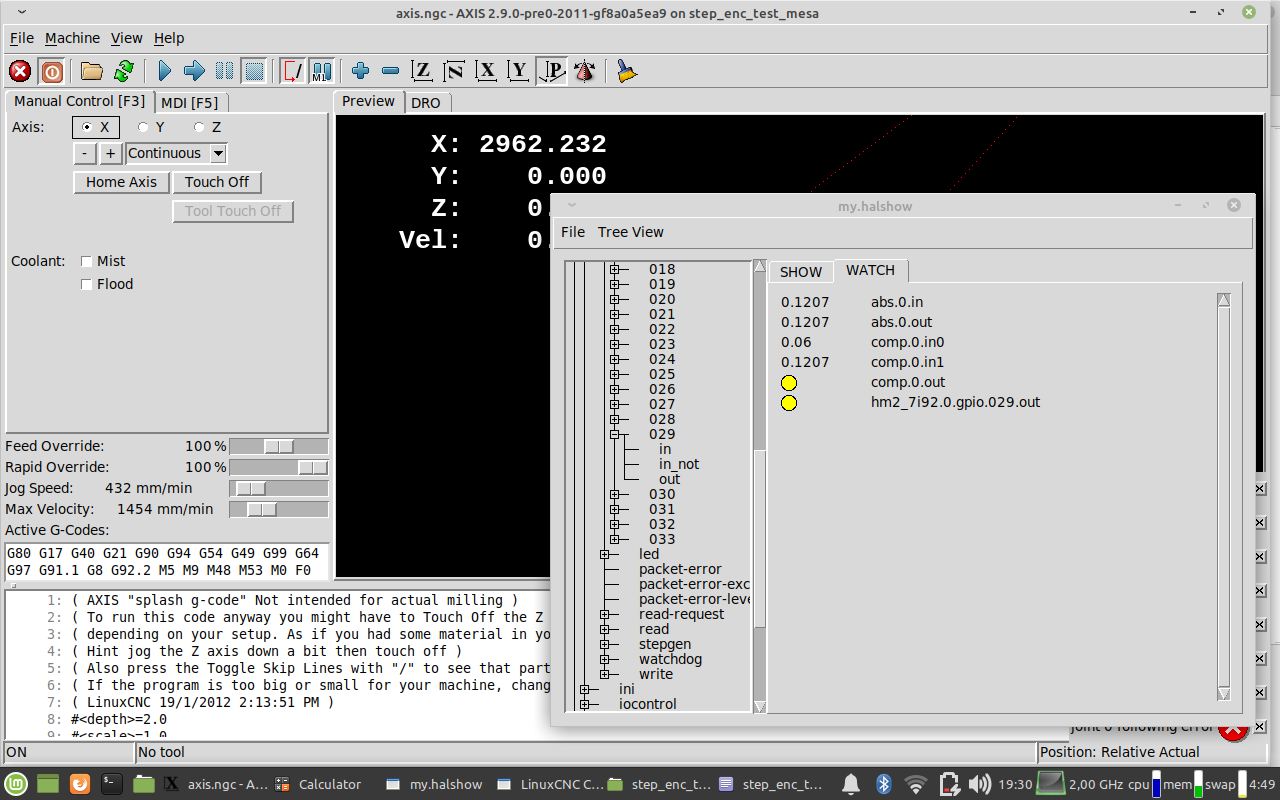

On the below pictures:

Motor at standstill, error is under the threshold, Boost output is not active:

Motor forced out of position, error over the threshold, Boost output is active:

Regards,

Tom.

Note : Lam drives come factory set to invert the boost pin, so when that pin goes high the current is lowered to the motor by a value preset in the drive, the default is 50%.

In this example i used a DS1044 set at 2A, so with the boost active that drops to 1A. In the config attached, the output pin that controls the boost feature is inverted, so in normal use there is 1A going to the motor at standstill and while moving and the f-error is under the preset value, while it jumps to 2A as soon as that threshold is exceeded, offering more power for the motor to correct the position.

The f-error value is sent through an ABS component to have only positive values derived from f-error values, then to in1 of a COMP (comparator) with the in0 set to a value of 0.06 (that reflects to 0.06mm of positional error) and the hysteresis set to 0.05. The output of the comparator activates the physical output on the Mesa 7i92, consequently the Boost input on the DS1044 goes low, resulting in 2A going to the motor till f-error drops below the set value of 0.06 when the output is pulled high and the motor current drops to 1A.

Other settings and equipment used for this test:

Drive microstepping 16, 2A Nema23 stepper motor with a 2500PPR encoder slapped to it giving 10000 counts per motor revolution, Mesa 7i92, encoder wired directly to 7i92 inputs, Linuxcnc V2.9.

The attached config has only X axis using encoder as a general idea.

Note the P value for the PID loop sets how fast the motor will try to correct it's possition, so the lower it is set, the better chances of restoring position. At default 1000 P value the motor will not be able to correct the position due to high speed, but that value is very dependant on the scale used, so a bit of testing is required.

On the below pictures:

Motor at standstill, error is under the threshold, Boost output is not active:

Motor forced out of position, error over the threshold, Boost output is active:

Regards,

Tom.

Please Log in or Create an account to join the conversation.

16 May 2020 06:29 #167922

by bbsr_5a

Replied by bbsr_5a on topic Stepper with encoder feedback plus BOOST feature.

Thank You another Step forward to get a Cheep Closed loop Stepper system without HSxx performence

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 18083

- Thank you received: 5997

16 May 2020 09:40 #167937

by tommylight

Replied by tommylight on topic Stepper with encoder feedback plus BOOST feature.

I use those drives a lot, they are by far the best stepper drives i ever used, and www.mechapro.de has the DS1044 and DS1076 on discount for quite some time now.

They also manufacture other types of stepper drives, from the ones using AC power supplies to the ones with encoder feedback, and many , many more features. But a bit pricey, as for the same price you can get a servo motor and drive from china, and spend days trying to tune that !

All the inputs and outputs are programmable, even the waveform can be changed, and have built in oscillators with settable frequency for testing the drive and motor without any controller attached.

They also manufacture other types of stepper drives, from the ones using AC power supplies to the ones with encoder feedback, and many , many more features. But a bit pricey, as for the same price you can get a servo motor and drive from china, and spend days trying to tune that !

All the inputs and outputs are programmable, even the waveform can be changed, and have built in oscillators with settable frequency for testing the drive and motor without any controller attached.

Please Log in or Create an account to join the conversation.

16 May 2020 10:02 #167942

by rodw

Replied by rodw on topic Stepper with encoder feedback plus BOOST feature.

Tommy, thanks for blazing the way with this. I've been reading up on the Lam products and had made a note of the boost function and was going to sit down to work out how to implement it but you saved me the effort! Lam have a distributor in Australia but not in the US. Their guy Ron here is a very knowledgeable chap and Lam in Italy is very responsive with questions. I have to say after working with an engineer with a complex motor selection model, LAM really do get it.

Have you used their AC drives? It seems to me that you need to use a toroid power supply . Normally you would need to add a DC rectification module after the toroid but with Lam you can skip that part.

Have you used their AC drives? It seems to me that you need to use a toroid power supply . Normally you would need to add a DC rectification module after the toroid but with Lam you can skip that part.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 18083

- Thank you received: 5997

16 May 2020 10:18 #167945

by tommylight

The AC drives are a bit more expensive, the transformers are a bit more expensive, so overall the price goes up.

The nice thing with transformers is the power reserve as you can overload them for short periods of time without issues, by quite a lot. The bad thing is no current limiting, so if something down the line goes belly up, the mess is .... interesting !

Replied by tommylight on topic Stepper with encoder feedback plus BOOST feature.

Not yet, they can be powered directly from a transformer, be it toroidal or the normal square "EI" one.

Have you used their AC drives? It seems to me that you need to use a toroid power supply . Normally you would need to add a DC rectification module after the toroid but with Lam you can skip that part.

The AC drives are a bit more expensive, the transformers are a bit more expensive, so overall the price goes up.

The nice thing with transformers is the power reserve as you can overload them for short periods of time without issues, by quite a lot. The bad thing is no current limiting, so if something down the line goes belly up, the mess is .... interesting !

Please Log in or Create an account to join the conversation.

16 May 2020 10:58 #167947

by rodw

Replied by rodw on topic Stepper with encoder feedback plus BOOST feature.

Tommy thanks.

I'm looking at a situation where I have a Z axis 1.6 amp stepper potentially on a 3 amp Lam driver where the maths says it only needs 1 amp to get the job done (Cutting corrugated Iron at 6100 mm/min - a fun target to aspire to). So this is a good example where a Boost could be good insurance. So a bost form 1.0 amp to 1.6 amp make ssense but I wonder if a quality 1.6 amp motor is likley to be damaged if it is sometimes fed 3.0 amps for short periods on boost!

I'm looking at a situation where I have a Z axis 1.6 amp stepper potentially on a 3 amp Lam driver where the maths says it only needs 1 amp to get the job done (Cutting corrugated Iron at 6100 mm/min - a fun target to aspire to). So this is a good example where a Boost could be good insurance. So a bost form 1.0 amp to 1.6 amp make ssense but I wonder if a quality 1.6 amp motor is likley to be damaged if it is sometimes fed 3.0 amps for short periods on boost!

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 18083

- Thank you received: 5997

16 May 2020 11:39 #167952

by tommylight

Replied by tommylight on topic Stepper with encoder feedback plus BOOST feature.

All of those can be set on the drive, current in 0.1A increments, boost in 10% increments.

This example was for use with encoder, using the boost feature for your idea should be even simpler, in multiple ways:

Setting as another spindle and activating it when doing corrugated stuff,

Setting it as flood or coolant and adding Mn to the start of the cut or manually,

Setting it with a digital pin and adding it to gcode or in post processor,

-

Another very important piece of information regarding these drives, they do output the rated RMS current, not peak, so setting 2A for a 2A chinese motor will most probably burn the motor to a crisp in about 10 minutes.

Currently i have them set at 2A and using 2,4A Sanyo-Denki motors, they do get pretty hot when in use, but not burning your fingers hot.

Need to do some more tests, like, setting the drive to 10000 steps per rev since i have a 2500 PPR encoder so in Linuxcnc that would be 10000 for step scale and 10000 for encoder scale and see how it behaves,

And setting the machines to use 25600 steps per rev, most probably will be silent while moving.

Even at 1600 PPR i can hear the bearings on the linear rails moving much more than the motor noise.

This example was for use with encoder, using the boost feature for your idea should be even simpler, in multiple ways:

Setting as another spindle and activating it when doing corrugated stuff,

Setting it as flood or coolant and adding Mn to the start of the cut or manually,

Setting it with a digital pin and adding it to gcode or in post processor,

-

Another very important piece of information regarding these drives, they do output the rated RMS current, not peak, so setting 2A for a 2A chinese motor will most probably burn the motor to a crisp in about 10 minutes.

Currently i have them set at 2A and using 2,4A Sanyo-Denki motors, they do get pretty hot when in use, but not burning your fingers hot.

Need to do some more tests, like, setting the drive to 10000 steps per rev since i have a 2500 PPR encoder so in Linuxcnc that would be 10000 for step scale and 10000 for encoder scale and see how it behaves,

And setting the machines to use 25600 steps per rev, most probably will be silent while moving.

Even at 1600 PPR i can hear the bearings on the linear rails moving much more than the motor noise.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 1.035 seconds