Techno CNC servo motor H50R11-0243 specs help

07 Jul 2023 18:47 - 07 Jul 2023 18:48 #274946

by Fakoep94

Techno CNC servo motor H50R11-0243 specs help was created by Fakoep94

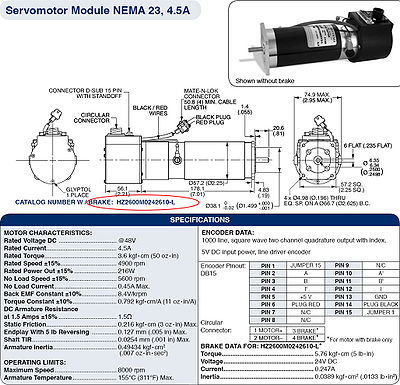

Hello, I'm attempting to retrofit a Techno servo DaVinci CNC mill with a mesa 7i97 and Copley Controls Junus servo amps(model JSP-090-10) running Linux CNC. The problem I'm running into is I can't seem to find a datasheet for the servos that originally came with the mill. I'm still fairly new to working with servos but it seems to me that I won't be able properly set up the amps if I don't have the specs for the servos. In particular I'm looking for the peak force, continuous force, force constant, back emf constant, resistance, and inductance of the servo motors.

The motors for the x,y, and z axis are all the same according to the Techno CNC website although the z axis motor assembly has a different part number due to the inclusion of a brake. The part number for the X/Y axis motor assembly is HZ2600M0243600-L, the part number for the Z motor assembly is HZ2600M0243610-L, and the part number for each individual motor is H50R11-0243.

I've scoured the internet as best as I can and can't find more than a incredibly blurry image of specs for a servo motor that has a slightly different part number(only off by one number). I've also tried contacting Techno CNC by email but have not received a reply.

Kind of at my wits end at this point and just wanted to see if anyone either knew of an online resource I'm not aware of or had more experience with these particular servo motors. If need be I suppose I could get new servos but I would like to try and reuse as much of the original machine as possible.

I'll attach the picture of the blurry specs I found on the Techno CNC support website as well as a picture of the Z axis motor.

Any help or insight would be greatly appreciated!

Thanks!

The motors for the x,y, and z axis are all the same according to the Techno CNC website although the z axis motor assembly has a different part number due to the inclusion of a brake. The part number for the X/Y axis motor assembly is HZ2600M0243600-L, the part number for the Z motor assembly is HZ2600M0243610-L, and the part number for each individual motor is H50R11-0243.

I've scoured the internet as best as I can and can't find more than a incredibly blurry image of specs for a servo motor that has a slightly different part number(only off by one number). I've also tried contacting Techno CNC by email but have not received a reply.

Kind of at my wits end at this point and just wanted to see if anyone either knew of an online resource I'm not aware of or had more experience with these particular servo motors. If need be I suppose I could get new servos but I would like to try and reuse as much of the original machine as possible.

I'll attach the picture of the blurry specs I found on the Techno CNC support website as well as a picture of the Z axis motor.

Any help or insight would be greatly appreciated!

Thanks!

Attachments:

Last edit: 07 Jul 2023 18:48 by Fakoep94. Reason: Need to attach pictures

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17836

- Thank you received: 5932

07 Jul 2023 18:58 #274947

by tommylight

Replied by tommylight on topic Techno CNC servo motor H50R11-0243 specs help

Brushed DC servo motor with 1000 PPR encoder.

That is simple enough, but where or what are the drives?

Or do you need new drives?

That is simple enough, but where or what are the drives?

Or do you need new drives?

Please Log in or Create an account to join the conversation.

07 Jul 2023 19:03 #274948

by Fakoep94

Replied by Fakoep94 on topic Techno CNC servo motor H50R11-0243 specs help

When you say drives do you mean for the servos??? As I understood the terms amplifier and drives were kind of interchangeable when it came to servos, or am I wrong on that???

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17836

- Thank you received: 5932

07 Jul 2023 19:50 #274954

by tommylight

Replied by tommylight on topic Techno CNC servo motor H50R11-0243 specs help

Yes, they are interchangeable, most of the time.

If you want to dwell deeper in the rabbit hole, servo drive is technically a DC power amplifier, so yes you can use an audio amplifier to drive a brushed servo motor, but do not expect much as most amplifiers have capacitors on inputs, hence not DC amplifiers. And no current limiting so easily go up in smoke.

Yes, i meant the drives or amplifiers.

If you want to dwell deeper in the rabbit hole, servo drive is technically a DC power amplifier, so yes you can use an audio amplifier to drive a brushed servo motor, but do not expect much as most amplifiers have capacitors on inputs, hence not DC amplifiers. And no current limiting so easily go up in smoke.

Yes, i meant the drives or amplifiers.

Please Log in or Create an account to join the conversation.

07 Jul 2023 19:55 #274956

by Fakoep94

Replied by Fakoep94 on topic Techno CNC servo motor H50R11-0243 specs help

Ahh okay, I had assumed that was what you meant, I just wanted to double check. I have Copley Controls Junus drives (model JSP-090-10). I will attach the pdf manual for the drives

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17836

- Thank you received: 5932

07 Jul 2023 20:19 #274960

by tommylight

Replied by tommylight on topic Techno CNC servo motor H50R11-0243 specs help

At a minimum you would:

wire encoders to Mesa 7i97

wire analog out from Mesa to drive, beware the polarity, and do not connect analog GND to other GND

wire drive enable from Mesa to drive and the GND <<< not the same as analog GND.

For a lengthy how to with wiring and testing and tuning info, have a look here:

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Do not skip steps, do not wire everything and power stuff on. Step by step, only.

wire encoders to Mesa 7i97

wire analog out from Mesa to drive, beware the polarity, and do not connect analog GND to other GND

wire drive enable from Mesa to drive and the GND <<< not the same as analog GND.

For a lengthy how to with wiring and testing and tuning info, have a look here:

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Do not skip steps, do not wire everything and power stuff on. Step by step, only.

Please Log in or Create an account to join the conversation.

07 Jul 2023 22:39 #274977

by Fakoep94

Replied by Fakoep94 on topic Techno CNC servo motor H50R11-0243 specs help

I have followed your servo wiring and tuning guide and was even able to get the servos to move, however I was not able to get a flat line on the hal scope while looking at 'joint.N.f-error' while tuning FF1. And by the movement of the motor I can tell something isn't right, it is slow stop or start.

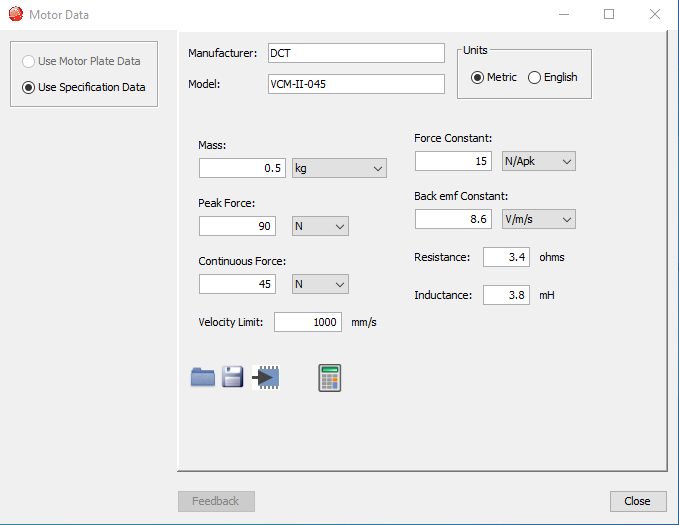

After spending a few days trying to properly get it tuned without luck I decided to look at the configuration of the drives. There is Windows program called CME that alters how the drives function, and within that program there is a page called 'Motor Data'. Ill attach a picture of the page, but where I'm just not sure is what these values should be. Do these values have to be exact or is there someway I could figure them out myself because I cannot find any datasheets on these particular motors. At this point I assume that this page should be properly configured before I start tuning the servos in Linux CNC or is that not necessarily true.

After spending a few days trying to properly get it tuned without luck I decided to look at the configuration of the drives. There is Windows program called CME that alters how the drives function, and within that program there is a page called 'Motor Data'. Ill attach a picture of the page, but where I'm just not sure is what these values should be. Do these values have to be exact or is there someway I could figure them out myself because I cannot find any datasheets on these particular motors. At this point I assume that this page should be properly configured before I start tuning the servos in Linux CNC or is that not necessarily true.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17836

- Thank you received: 5932

07 Jul 2023 23:33 #274978

by tommylight

Replied by tommylight on topic Techno CNC servo motor H50R11-0243 specs help

First, check your hal file and omit the lines containing

setp pid.x.maxerror .0005

for all axis/joints

Then tune P to keep the motor stiff with very little vibration, even after very short jog on both sides.

After this, tuning is pretty easy in later versions of LinuxCNC.

-

About 2 weeks ago i had to tune a machine i moved from LinuxCNC 2.7 to 2.9, could not tune anything till i omitted the above lines, then it all worked easily, much easier than before.

setp pid.x.maxerror .0005

for all axis/joints

Then tune P to keep the motor stiff with very little vibration, even after very short jog on both sides.

After this, tuning is pretty easy in later versions of LinuxCNC.

-

About 2 weeks ago i had to tune a machine i moved from LinuxCNC 2.7 to 2.9, could not tune anything till i omitted the above lines, then it all worked easily, much easier than before.

Please Log in or Create an account to join the conversation.

07 Jul 2023 23:46 #274980

by Fakoep94

Replied by Fakoep94 on topic Techno CNC servo motor H50R11-0243 specs help

Thank you Tommy, I really appreciate the quick and concise responses. I will give that a try and see if that makes any difference.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

08 Jul 2023 00:17 #274982

by Fakoep94

Replied by Fakoep94 on topic Techno CNC servo motor H50R11-0243 specs help

So I looked at my hal file and there isn't any lines that say 'setp pid.x.maxerror .0005'. I will attempt to tune them again by adjusting the P value, but if you wouldn't mind taking a look at my hal file just to make sure everything else looks right. Because pnfconf doesn't support the mesa 7i97 I had to use the basic hal file from the mesa website, it was made in 2021 with Linux CNC 2.9 and has only been slightly modified. I believe the only thing I changed was getting rid of the spindle and adding a pwmgen to convert an analog output signal to a pwm signal to power a laser.

Attachments:

Please Log in or Create an account to join the conversation.

Moderators: cncbasher

Time to create page: 0.224 seconds