Linuxcnc creates unwanted radii

18 Jan 2021 16:52 #195811

by algier

Linuxcnc creates unwanted radii was created by algier

Hi all, I'm having an issue where my shop's cnc is giving me larger radii than the toolpath calls for.

I'm cutting a simple rectangle pocket with a 3/8 tool and it's resulting in 1"+ radius. In Fusion 360, the simulation shows the tool traveling correctly, and the toolpath preview in linuxcnc confirms this. However, when I run the file, it gives me these big round corners. The attached file shows the red lines that indicate how the tool traveled during the toolpath.

help!

The first image is of the program preview, and the second is of my part. I first ran a pocket that had consistent radii all around, and I ran a contour afterwards that gave me the correct radii in the top left corner.

I'm cutting a simple rectangle pocket with a 3/8 tool and it's resulting in 1"+ radius. In Fusion 360, the simulation shows the tool traveling correctly, and the toolpath preview in linuxcnc confirms this. However, when I run the file, it gives me these big round corners. The attached file shows the red lines that indicate how the tool traveled during the toolpath.

help!

The first image is of the program preview, and the second is of my part. I first ran a pocket that had consistent radii all around, and I ran a contour afterwards that gave me the correct radii in the top left corner.

Please Log in or Create an account to join the conversation.

18 Jan 2021 17:28 - 18 Jan 2021 17:31 #195812

by PCW

Replied by PCW on topic Linuxcnc creates unwanted radii

That may be expected behavior unless you have specified a

path following tolerance with G64 PXX QYY

linuxcnc.org/docs/html/user/user-concepts.html#_path_following

path following tolerance with G64 PXX QYY

linuxcnc.org/docs/html/user/user-concepts.html#_path_following

Last edit: 18 Jan 2021 17:31 by PCW.

Please Log in or Create an account to join the conversation.

18 Jan 2021 18:46 #195816

by Michael

Replied by Michael on topic Linuxcnc creates unwanted radii

If the contour is correct and the roughing operation is not, look at your smoothing and tolerance settings in fusion for the roughing operation.

It is most likely a combination of both the fusion settings and your G61 or G64 setting

Fusion smoothing and tolerance will try to make as few moves as possible. In combination with G64 and no P variable then Linuxcnc is going to optimize the tool path even more to make smooth arcs/transitions.

As far as what all these settings should be depends on what you are making and your cutter size.

G61 will read the code exactly as given. I usually run a G64 P.003 with 1/4" and up cutters. Tighter tolerance with smaller more precise work. You can add this parameter to your g code file manually, I usually do the first line after the stuff in ()

It is most likely a combination of both the fusion settings and your G61 or G64 setting

Fusion smoothing and tolerance will try to make as few moves as possible. In combination with G64 and no P variable then Linuxcnc is going to optimize the tool path even more to make smooth arcs/transitions.

As far as what all these settings should be depends on what you are making and your cutter size.

G61 will read the code exactly as given. I usually run a G64 P.003 with 1/4" and up cutters. Tighter tolerance with smaller more precise work. You can add this parameter to your g code file manually, I usually do the first line after the stuff in ()

Please Log in or Create an account to join the conversation.

18 Jan 2021 19:54 #195817

by algier

Replied by algier on topic Linuxcnc creates unwanted radii

thanks, PCW and Michael. I'm afraid I'm not experienced enough to know how to modify G61/64 settings yet. However, I went ahead and slowed my toolpath speed by a third and got a much better corner. I went further and added feed optimization to the toolpath and got an even better corner. It still isn't making a full unrounded right turn but it's very close now. I assume this won't be fully remedied until I make this manual G-# code modification?

Please Log in or Create an account to join the conversation.

18 Jan 2021 20:25 #195820

by Michael

Replied by Michael on topic Linuxcnc creates unwanted radii

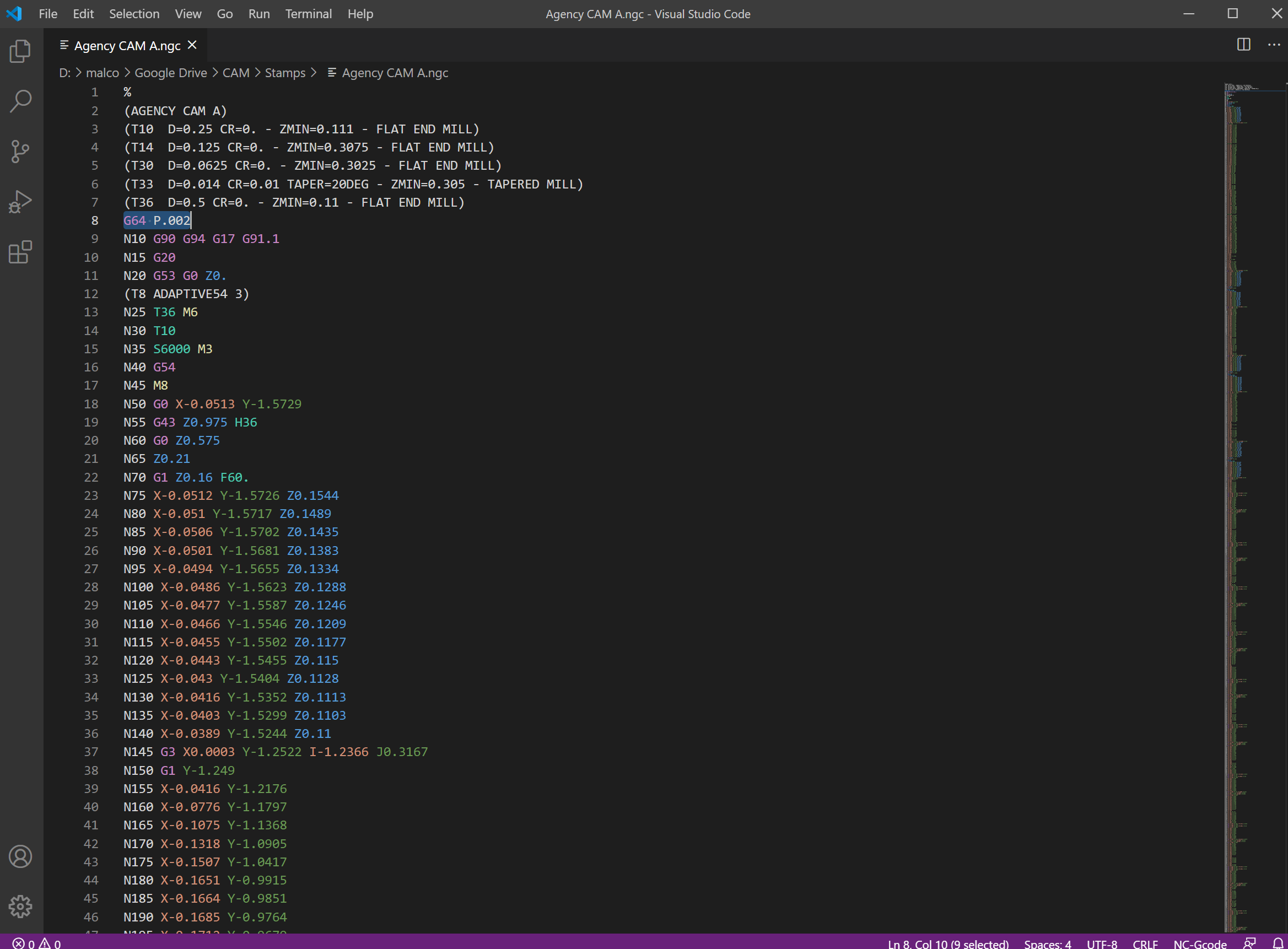

Here is a screen shot of my g code. When you enter the fusion post processor to output g code, the screen that pops up has an ooption in the lower left to "Open NC File in Editor". Make sure that is checked and it should bring up the g code file after you pick a save location. Look at line 8 on this picture. The setting should stay that way until its changed or the machine is powered off.

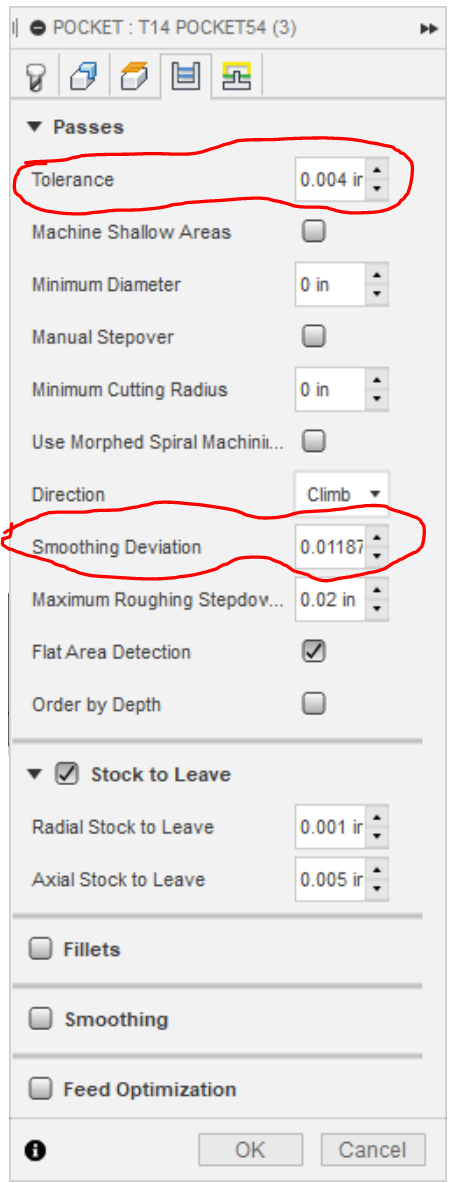

In addition what are the settings you have for the pocket operation in fusion? The contour operation is not as affected because its basically a line to an arc to a line. Both fusion and LinuxCNC will optimize the transition between those moves. On the pocket operation, depending on settings, the code would probably be more like line to short arc to short arc to short arc to short arc..... finally back to a straight line as it try's to maintain a certain tool load or feed optimization. So it will have a lot more transitions where linuxCNC in its default G64 (with no P.nnn variable) will trry and shorten them to make a smooth arc/transition. You are basically smoothing (shortening) the tool path multiple times through fusion and LinuxCNC. What are your variables in fusion?

In addition what are the settings you have for the pocket operation in fusion? The contour operation is not as affected because its basically a line to an arc to a line. Both fusion and LinuxCNC will optimize the transition between those moves. On the pocket operation, depending on settings, the code would probably be more like line to short arc to short arc to short arc to short arc..... finally back to a straight line as it try's to maintain a certain tool load or feed optimization. So it will have a lot more transitions where linuxCNC in its default G64 (with no P.nnn variable) will trry and shorten them to make a smooth arc/transition. You are basically smoothing (shortening) the tool path multiple times through fusion and LinuxCNC. What are your variables in fusion?

Attachments:

Please Log in or Create an account to join the conversation.

18 Jan 2021 21:31 #195836

by andypugh

Replied by andypugh on topic Linuxcnc creates unwanted radii

When you configured your machine, how did you decide your acceleration limits?

Those are, fundamentally, what define corner sharpness. If you give your car very slippy tyres it won't turn sharply. The same is true of a CNC machine with high speeds and low acceleration.

Those are, fundamentally, what define corner sharpness. If you give your car very slippy tyres it won't turn sharply. The same is true of a CNC machine with high speeds and low acceleration.

Please Log in or Create an account to join the conversation.

Time to create page: 0.215 seconds