Search Results (Searched for: raspberry)

- nichtAlex

- nichtAlex

27 Feb 2026 05:05

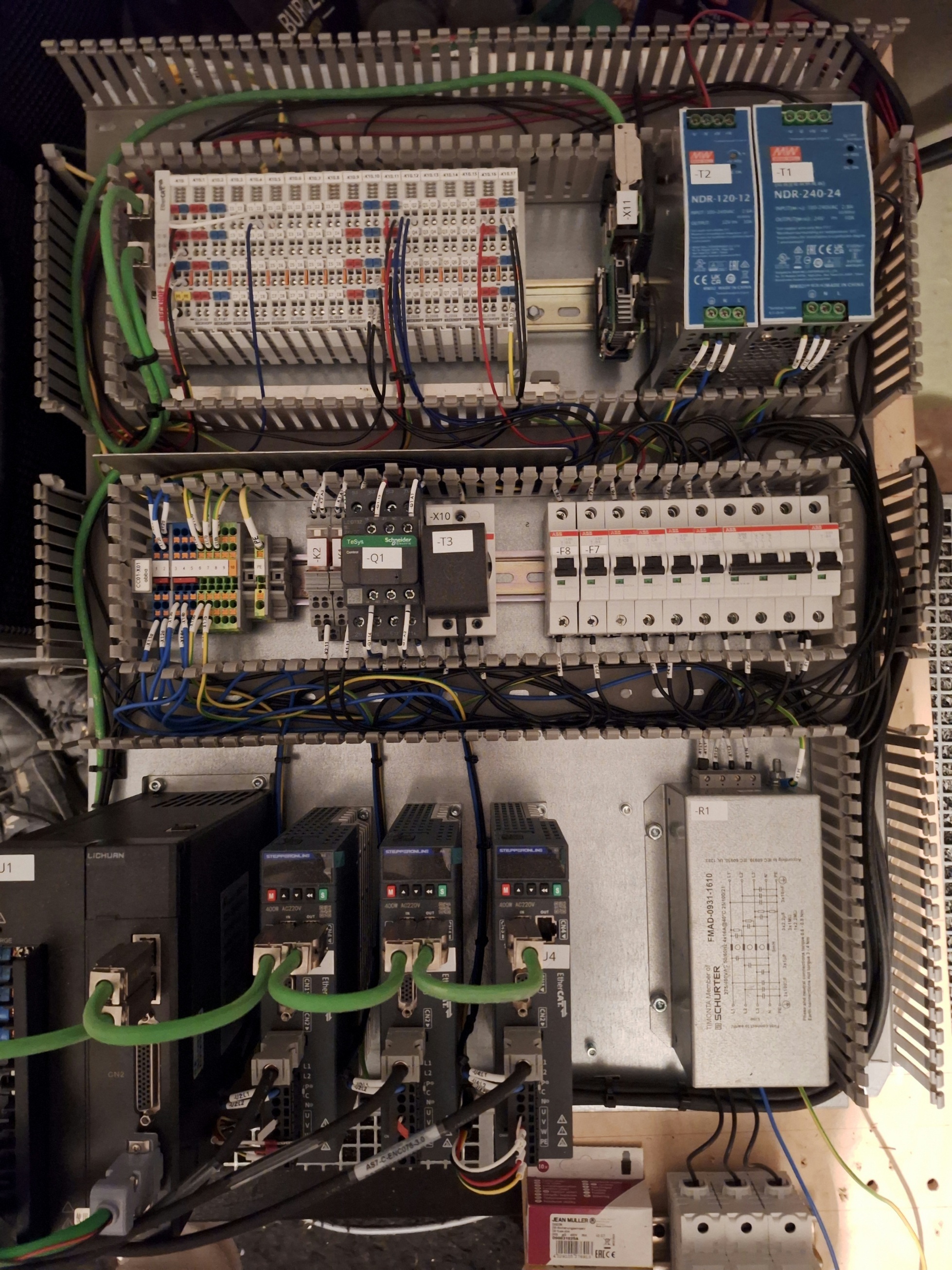

Replied by nichtAlex on topic Umstieg von LinuxCNC + Mesa auf EtherCAT (Leadshine EL8 / Beckhoff) – Erfahrunge

Umstieg von LinuxCNC + Mesa auf EtherCAT (Leadshine EL8 / Beckhoff) – Erfahrunge

Category: Deutsch

- nichtAlex

- nichtAlex

26 Feb 2026 05:17

Replied by nichtAlex on topic Umstieg von LinuxCNC + Mesa auf EtherCAT (Leadshine EL8 / Beckhoff) – Erfahrunge

Umstieg von LinuxCNC + Mesa auf EtherCAT (Leadshine EL8 / Beckhoff) – Erfahrunge

Category: Deutsch

- masawee

- masawee

21 Feb 2026 13:04

Replied by masawee on topic Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Category: Installing LinuxCNC

- MRx

- MRx

12 Feb 2026 15:52 - 12 Feb 2026 15:54

- krille

- krille

10 Feb 2026 13:35

Replied by krille on topic Raspberry pi 5 freze

Raspberry pi 5 freze

Category: General LinuxCNC Questions

- Massimo148

- Massimo148

06 Feb 2026 18:23 - 06 Feb 2026 22:59

Retrofitting an old industrial CNC Plasma table was created by Massimo148

Retrofitting an old industrial CNC Plasma table

Category: Plasmac

- unknown

- unknown

05 Feb 2026 11:44

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- fenton06

- fenton06

05 Feb 2026 04:37 - 05 Feb 2026 04:38

Replied by fenton06 on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- tar_san

- tar_san

05 Feb 2026 02:46

Replied by tar_san on topic initramfs-tools error (sudo apt upgrade)

initramfs-tools error (sudo apt upgrade)

Category: Installing LinuxCNC

- tommylight

02 Feb 2026 18:23

Replied by tommylight on topic Raspberry pi 5 freze

Raspberry pi 5 freze

Category: General LinuxCNC Questions

- krille

- krille

02 Feb 2026 18:08

Raspberry pi 5 freze was created by krille

Raspberry pi 5 freze

Category: General LinuxCNC Questions

- nicklego

31 Jan 2026 21:27 - 01 Feb 2026 18:45

Maxnc15CL Motor timing help was created by nicklego

Maxnc15CL Motor timing help

Category: General LinuxCNC Questions

- RNZ

- RNZ

30 Jan 2026 22:23

Replied by RNZ on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- meister

- meister

30 Jan 2026 17:31

Remote - Camera - Touch - MPG was created by meister

Remote - Camera - Touch - MPG

Category: Other User Interfaces

- amanker

- amanker

30 Jan 2026 14:11

How to update QtDragon_HD to latest version? was created by amanker

How to update QtDragon_HD to latest version?

Category: Qtvcp

Time to create page: 0.711 seconds