- Hardware & Machines

- Driver Boards

- How do you pass shielded servo motor cables through the cabinet wall/panel?

How do you pass shielded servo motor cables through the cabinet wall/panel?

03 Aug 2022 00:10 #248884

by arvidb

How do you pass shielded servo motor cables through the cabinet wall/panel?

In an ideal world there would be a connector that:

* Is rated for at least 250 VAC and with a choice of different sizes/current ratings

* Has 4-pin female panel connector and male cable connector

* Doesn't require soldering (since not recommended for mains voltage)

* Doesn't require €1000 in tools for crimping, inserting, and extracting pins

* Clamps the shield braid all around (no pigtail connection of shield)

* For the panel connector: securely connects the shield to the panel

I guess as hobbyists we are out of luck? So how do you do this? Pass cables through without connectors, perhaps without connecting the shield to the cabinet? Soldered connectors and no shield? Or did you invest in a crimping tool? Some other more clever solution?

It would be great to see pictures too.

In an ideal world there would be a connector that:

* Is rated for at least 250 VAC and with a choice of different sizes/current ratings

* Has 4-pin female panel connector and male cable connector

* Doesn't require soldering (since not recommended for mains voltage)

* Doesn't require €1000 in tools for crimping, inserting, and extracting pins

* Clamps the shield braid all around (no pigtail connection of shield)

* For the panel connector: securely connects the shield to the panel

I guess as hobbyists we are out of luck? So how do you do this? Pass cables through without connectors, perhaps without connecting the shield to the cabinet? Soldered connectors and no shield? Or did you invest in a crimping tool? Some other more clever solution?

It would be great to see pictures too.

Please Log in or Create an account to join the conversation.

03 Aug 2022 05:11 #248899

by arvidb

Replied by arvidb on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

Maybe using EMC glands is a good idea? I did find some reasonably priced ones:

LAPP SKINTOP MS-SC-M

+

nut

- although the glands are out of stock.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 18101

- Thank you received: 6006

03 Aug 2022 07:49 #248908

by tommylight

Replied by tommylight on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

Drill a bigger hole?

That is what i usually do, or sometimes re-route the cables if they are long enough, do not cause issues, no risk of interference, etc.

That is what i usually do, or sometimes re-route the cables if they are long enough, do not cause issues, no risk of interference, etc.

Please Log in or Create an account to join the conversation.

03 Aug 2022 08:49 #248909

by arvidb

Replied by arvidb on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

So you thread the cable through with the connector(s) still on and leave them loose? No strain relief or shield connection?

Curious, how does re-routing help?

Curious, how does re-routing help?

Please Log in or Create an account to join the conversation.

03 Aug 2022 10:04 #248913

by rodw

Replied by rodw on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

I feel your pain and want to find a solution too. On a little mill I retrofitted, I justpassed them through a cable gland that worked pretty well.

Then the next enclosure I went back to GX16 connectors but the soldering really got to me so I paid a mate who had been trained in soldering to NASA standards to do it. He did not enjoy it either.

Andy suggested the neutrik powercon connectors www.neutrik.com/en/products/power but I still see that awful word solder!

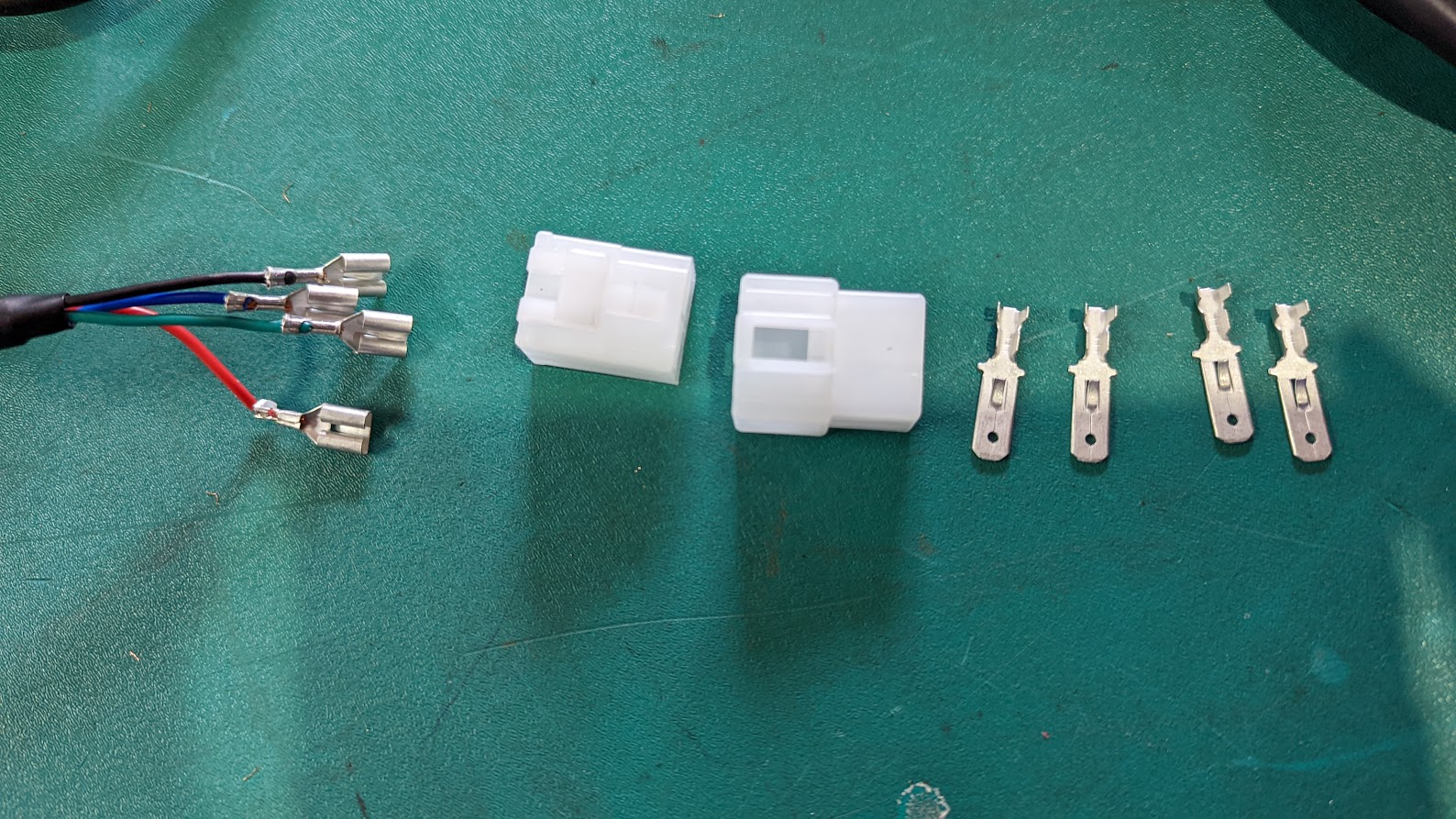

At the motor end, I have been using automotive QC connectors. These do require crimping but I was able to use a crimper I bought for about $40 from Amazon for JST connectors.

I like these because they are nice and light so OK suspended in the air. Note they are not compatible with the more familiar red/blue/yellow automotove crimp terminals (which I also use for some applications

Any Ideas, please let me know... Lets get rid of soldering!

Then the next enclosure I went back to GX16 connectors but the soldering really got to me so I paid a mate who had been trained in soldering to NASA standards to do it. He did not enjoy it either.

Andy suggested the neutrik powercon connectors www.neutrik.com/en/products/power but I still see that awful word solder!

At the motor end, I have been using automotive QC connectors. These do require crimping but I was able to use a crimper I bought for about $40 from Amazon for JST connectors.

I like these because they are nice and light so OK suspended in the air. Note they are not compatible with the more familiar red/blue/yellow automotove crimp terminals (which I also use for some applications

Any Ideas, please let me know... Lets get rid of soldering!

Attachments:

The following user(s) said Thank You: arvidb

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 18101

- Thank you received: 6006

03 Aug 2022 10:35 #248916

by tommylight

Replied by tommylight on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

I just put those plastic/pvc round thingies to protect wires from scratching.So you thread the cable through with the connector(s) still on and leave them loose? No strain relief or shield connection?

Curious, how does re-routing help?

The following user(s) said Thank You: arvidb

Please Log in or Create an account to join the conversation.

03 Aug 2022 12:35 #248925

by andypugh

I use Lemo quite a bit, though I tend to scavenge them or buy used from eBay.

M23 are good, but expensive. Mouser seem most reasonable:

www.mouser.co.uk/ProductDetail/Amphenol-...%252BmAEXCHfDw%3D%3D

Bear in mind that often you have to buy shell, backshell, insert ans terminals separetely. That's a kit.

I used M23 to pass the power and feedback for the 4th axis through the mill to allow it to be disconnected.

I swapped the unobtainable connectors on a servo motor for SpeakCON and salvaged Lemo:

Before: photos.app.goo.gl/HqjLvfHWQpqkuHzg8

After: photos.app.goo.gl/s8ecWDui7QaZDpJj8

Then after buying a bigger Lemo from ebay: photos.app.goo.gl/P5sz9dqDLwavKatG7

The solder Lemos are vacuum-tight. Crimp ones are not, and the crimping tools are very expensive. However I have found that this style tool (I have two sizes now) work for D-sub, Lemo and M23: www.amazon.co.uk/Laser-7533-Indent-Crimping-Tool/dp/B07NDVC3VS

And, that mention of D-sub brings me to the real point of this reply. Ordinary D-sub have a higher current and voltage rating than you might guess:

docs.rs-online.com/869a/A700000007669880.pdf

750V and 5A, and it's not a fancy one.

But, you might want to look at the actual fancy ones, with mixed terminals so that you can run signal and power (40A) high voltage (2800V), pneumatic, optical or coax through the same connector:

uk.rs-online.com/web/c/connectors/usb-d-...imensions=4292006345

Drop-down the "contact type" option here to see the supported contact types: uk.rs-online.com/web/c/connectors/usb-d-...tors/d-sub-contacts/

Replied by andypugh on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

You mention "shielded" so my favoured Neutrik (SpeakCON and PowerCON) won't work.How do you pass shielded servo motor cables through the cabinet wall/panel?

I use Lemo quite a bit, though I tend to scavenge them or buy used from eBay.

M23 are good, but expensive. Mouser seem most reasonable:

www.mouser.co.uk/ProductDetail/Amphenol-...%252BmAEXCHfDw%3D%3D

Bear in mind that often you have to buy shell, backshell, insert ans terminals separetely. That's a kit.

I used M23 to pass the power and feedback for the 4th axis through the mill to allow it to be disconnected.

I swapped the unobtainable connectors on a servo motor for SpeakCON and salvaged Lemo:

Before: photos.app.goo.gl/HqjLvfHWQpqkuHzg8

After: photos.app.goo.gl/s8ecWDui7QaZDpJj8

Then after buying a bigger Lemo from ebay: photos.app.goo.gl/P5sz9dqDLwavKatG7

The solder Lemos are vacuum-tight. Crimp ones are not, and the crimping tools are very expensive. However I have found that this style tool (I have two sizes now) work for D-sub, Lemo and M23: www.amazon.co.uk/Laser-7533-Indent-Crimping-Tool/dp/B07NDVC3VS

And, that mention of D-sub brings me to the real point of this reply. Ordinary D-sub have a higher current and voltage rating than you might guess:

docs.rs-online.com/869a/A700000007669880.pdf

750V and 5A, and it's not a fancy one.

But, you might want to look at the actual fancy ones, with mixed terminals so that you can run signal and power (40A) high voltage (2800V), pneumatic, optical or coax through the same connector:

uk.rs-online.com/web/c/connectors/usb-d-...imensions=4292006345

Drop-down the "contact type" option here to see the supported contact types: uk.rs-online.com/web/c/connectors/usb-d-...tors/d-sub-contacts/

The following user(s) said Thank You: arvidb

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4967

- Thank you received: 1370

03 Aug 2022 16:24 #248947

by Todd Zuercher

Replied by Todd Zuercher on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

Andy, the servo motor connectors you replaced in the above photos look like the mil spec Amphenol type connectors that seem to be common on servo motors. They are generally available, but come in a myriad of options and configurations that can be difficult to discern exactly what you have to match with. (They are also often a bit pricey but very high quality.)

Please Log in or Create an account to join the conversation.

03 Aug 2022 22:39 #248980

by arvidb

While soldering connectors is a PITA that's not the main reason I want to avoid soldering: with the contacts carrying hundreds of volts and multiple amps, any bad connection will cause heating, which could make the solder melt and release the cable. At these voltages you really want a physical connection of the cable that is unaffected by heat.

Those automotive QC connectors look interesting. As long as their voltage rating is okay... I will keep them in mind!

Replied by arvidb on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

Yeah, passing them through a cable gland sounds more and more like a good solution.I feel your pain and want to find a solution too. On a little mill I retrofitted, I justpassed them through a cable gland that worked pretty well.

While soldering connectors is a PITA that's not the main reason I want to avoid soldering: with the contacts carrying hundreds of volts and multiple amps, any bad connection will cause heating, which could make the solder melt and release the cable. At these voltages you really want a physical connection of the cable that is unaffected by heat.

Those automotive QC connectors look interesting. As long as their voltage rating is okay... I will keep them in mind!

Please Log in or Create an account to join the conversation.

03 Aug 2022 22:44 #248982

by arvidb

Easy, and if it works then why not? How do you connect any cable shields though? Do you clamp them to some ground bar or something? Or just use a pigtail at the drive?

Easy, and if it works then why not? How do you connect any cable shields though? Do you clamp them to some ground bar or something? Or just use a pigtail at the drive?

Replied by arvidb on topic How do you pass shielded servo motor cables through the cabinet wall/panel?

This sounds pretty tempting!I just put those plastic/pvc round thingies to protect wires from scratching.

Please Log in or Create an account to join the conversation.

- Hardware & Machines

- Driver Boards

- How do you pass shielded servo motor cables through the cabinet wall/panel?

Time to create page: 0.248 seconds