Lichuan AC servos for axes and spindle

27 Apr 2024 09:18 - 27 Apr 2024 09:23 #299173

by EddySPalm

Lichuan AC servos for axes and spindle was created by EddySPalm

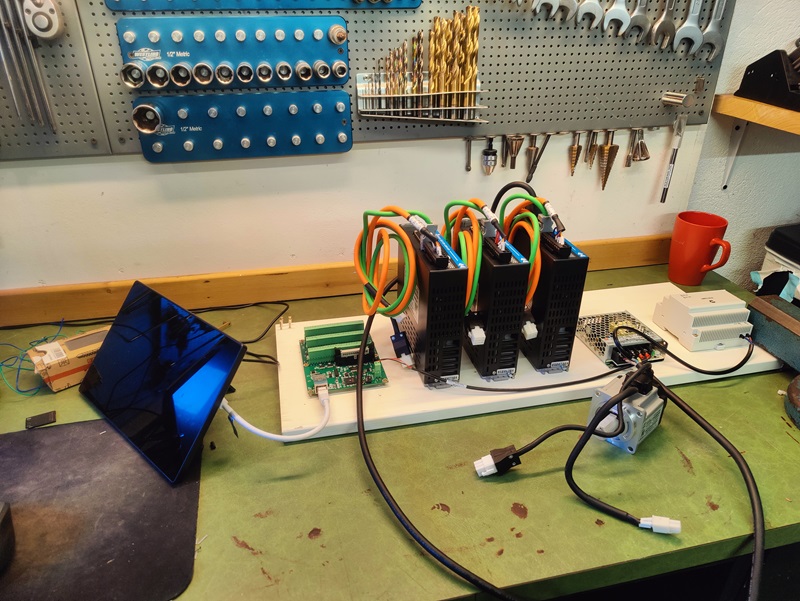

Hello,My setup for a re-retrofit (from Mach3 to LinuxCNC) of an old EMCO Compact 5 CNC lathe is as follows:

- RPI 5 with Linuxcnc 2.9.2 on Debian bookworm

- Mesa 7i96s

- 2x 200W AC servos with A5 drives from Lichuan, for X and Z. Encoders are 17bit incremental type (why on earth did I not get the absolute ones when they were like 20 dollars more....)

- 1x 1000W AC servo with A5 drive from Lichuan, for spindle. Same encoder as for the 200W motors.

As far as I've understood, normal lathe use would indicate that i run the axis drives in position mode with step/dir inputs, and the spindle drive in speed mode, with -10- 10V analog input.

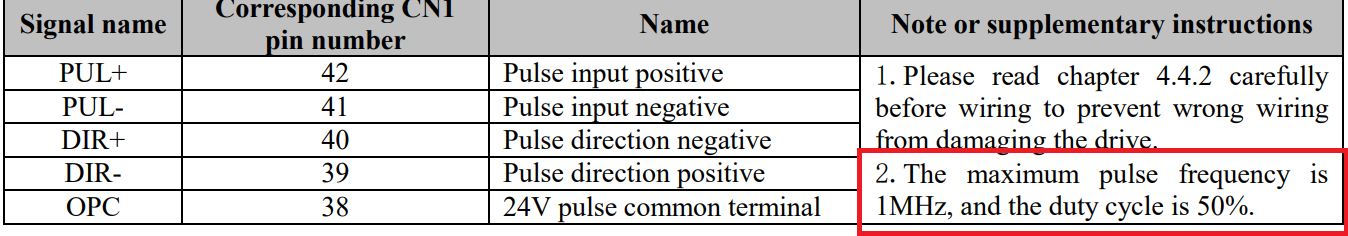

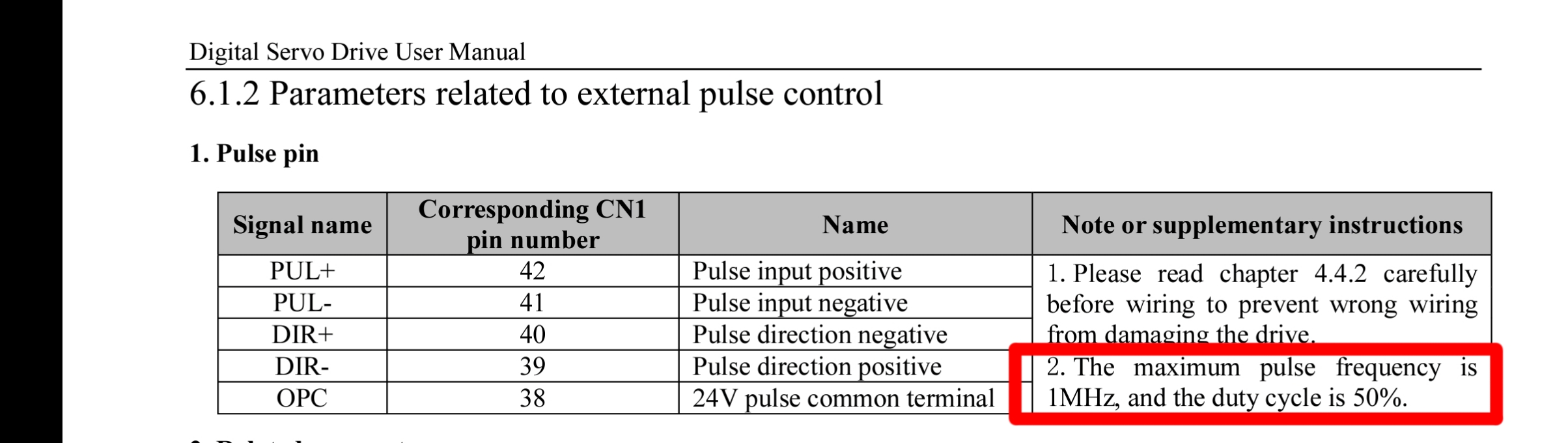

I believe that is what will be relevant info for the questions in this thread?- In the axis section of the pncconf wizard I am faced with some settings I have never encountered before, namely "step-on time", "space", "direction hold" and "direction setup". I have tried to read up on what they mean and how it relates to the information I am given in the servo drive manual. Among the numerous settings and points of information for the servo drives, I cannot find anything which is called the same or remotely the same as those parameters. Can I assume that my step high/low and pulse high/low times are identical, and that I can simply use the drives' maximum step frequency as a base for step-on time and space? It is stated as 1MHz in the manual. What about direction hold and direction setup, could someone please explain what they are? I am anxious of doing something bad to my new precious drivers and motors, so in case any wrong settings can hurt my drives, i just want to be on the safe side...

- Is there anything else I need to pay special attention to when using AC servos with step/dir inputs, instead of stepper motors? I see there are some unseleactable/uneditable tuning parameters (PID info) on the left; I thought I would be tuning the servos internally on the drives?

Link to servo motor with drive (200W version):

www.aliexpress.com/item/1005005440028771...ain.5.76c81802WfkwiM

Attachments:

Last edit: 27 Apr 2024 09:23 by EddySPalm. Reason: tidied up some more...

Please Log in or Create an account to join the conversation.

30 Apr 2024 13:44 #299397

by EddySPalm

Replied by EddySPalm on topic Lichuan AC servos for axes and spindle

I felt brave yesterday and gave it a go with one of the axis motors.

- I connected the step/direction outputs to the mesa card

- I set the driver to default to enabled as long as its powered on. it then turned the fans on and set "run" in the display, which should be a good sign

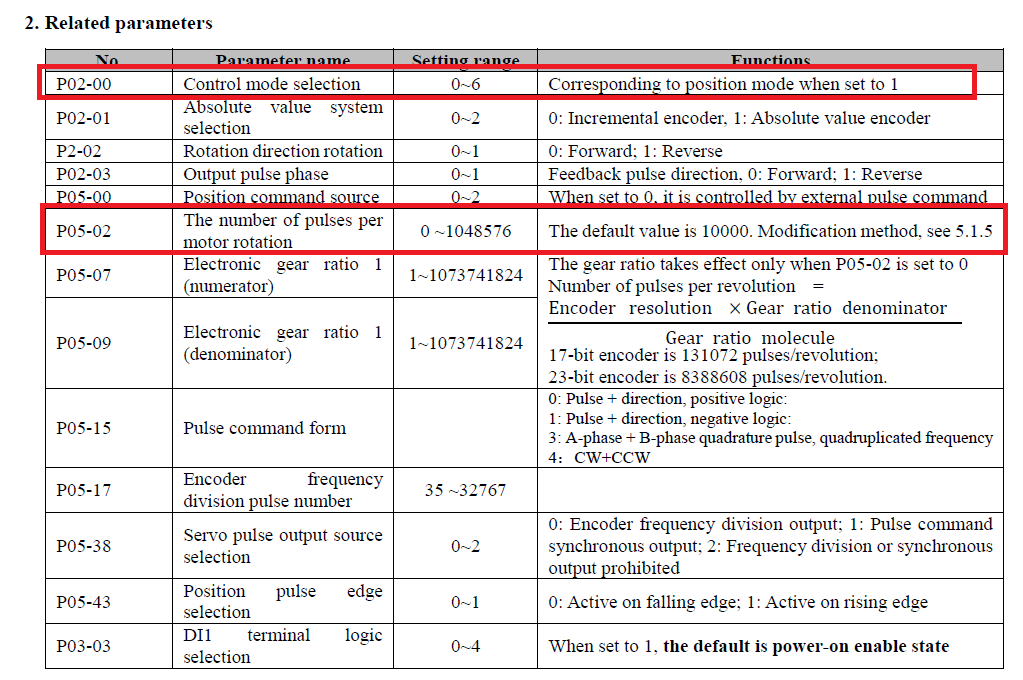

- I made sure the servo drive was in position mode

- I set the "pulses pr rev" in pncconf to 10000, which is the default in the servo drive when in position mode

- I left all the step time settings as is.

And I went into the simulation window to hopefully do some jogging. But nothing happened.

I Played around a little with the "step-on time", "space", "direction hold" and "direction setup" settings, with no real thought behind what I did (i still really don't understand what they do), to no avail.

- I connected the step/direction outputs to the mesa card

- I set the driver to default to enabled as long as its powered on. it then turned the fans on and set "run" in the display, which should be a good sign

- I made sure the servo drive was in position mode

- I set the "pulses pr rev" in pncconf to 10000, which is the default in the servo drive when in position mode

- I left all the step time settings as is.

And I went into the simulation window to hopefully do some jogging. But nothing happened.

I Played around a little with the "step-on time", "space", "direction hold" and "direction setup" settings, with no real thought behind what I did (i still really don't understand what they do), to no avail.

Attachments:

Please Log in or Create an account to join the conversation.

30 Apr 2024 14:24 #299399

by PCW

Replied by PCW on topic Lichuan AC servos for axes and spindle

Wrong step/dir settings cannot hurt your drive.

Too long step time and step space settings will limit the maximum step rate

For example, if you set the step time and step space to 5 usec (5000 and 5000)

the maximum step rate would be 100 KHz, that is 1/(5usec+5usec)

I would try running LinuxCNC rather than the pncconf test as it will indicate if there

are other issues preventing normal operation.

Too long step time and step space settings will limit the maximum step rate

For example, if you set the step time and step space to 5 usec (5000 and 5000)

the maximum step rate would be 100 KHz, that is 1/(5usec+5usec)

I would try running LinuxCNC rather than the pncconf test as it will indicate if there

are other issues preventing normal operation.

The following user(s) said Thank You: EddySPalm

Please Log in or Create an account to join the conversation.

30 Apr 2024 21:08 #299420

by EddySPalm

Replied by EddySPalm on topic Lichuan AC servos for axes and spindle

I have to come clean... I didn't have the mesa card powered up when trying to jog the motor

I am now jogging! only tried in the "machine", but probably also in pncconf, and that's a nice step forward.

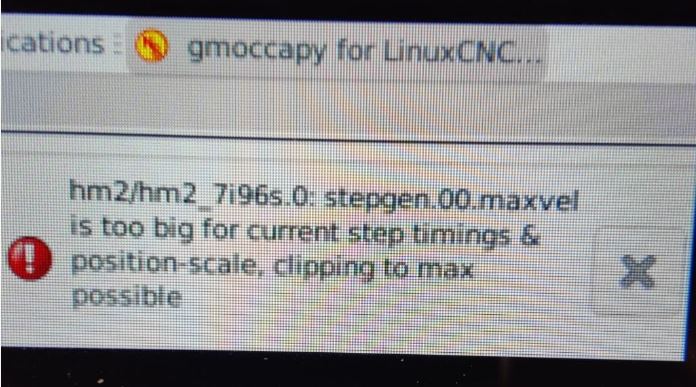

I get the error message in the attached picture though, which I suspect is because I am close to the limit of what my step time/space settings allow for.

If my max step rate is 100kHz at the moment, then with 10 000 pulses pr. rev, my limit will be around 600rpm? It sounds about right, and sure enough, Linuxcnc stalls if I try to jog faster for more than a few seconds.

I will most probably not need all 3000rpm's of my axis motors, but say I did; is there anything keeping me from just lowering the step time/space settings by a factor of 5, to be able to go from 600rpm limit to 3000rpm?

I am now jogging! only tried in the "machine", but probably also in pncconf, and that's a nice step forward.

I get the error message in the attached picture though, which I suspect is because I am close to the limit of what my step time/space settings allow for.

If my max step rate is 100kHz at the moment, then with 10 000 pulses pr. rev, my limit will be around 600rpm? It sounds about right, and sure enough, Linuxcnc stalls if I try to jog faster for more than a few seconds.

I will most probably not need all 3000rpm's of my axis motors, but say I did; is there anything keeping me from just lowering the step time/space settings by a factor of 5, to be able to go from 600rpm limit to 3000rpm?

Please Log in or Create an account to join the conversation.

30 Apr 2024 21:18 #299421

by EddySPalm

Replied by EddySPalm on topic Lichuan AC servos for axes and spindle

Attachments:

Please Log in or Create an account to join the conversation.

30 Apr 2024 21:21 - 30 Apr 2024 21:21 #299422

by PCW

Replied by PCW on topic Lichuan AC servos for axes and spindle

Yes, the step rate limit is only 100 KHz if you have the step time and step space set to 5000 ns each.

If the drive will actually accept a 1 MHz input signal, you can set the step time and step space

to 500 ns each and get a maximum step rate of 1 MHz (6000 RPM at 10000 steps/turn).

If the drive will actually accept a 1 MHz input signal, you can set the step time and step space

to 500 ns each and get a maximum step rate of 1 MHz (6000 RPM at 10000 steps/turn).

Last edit: 30 Apr 2024 21:21 by PCW.

Please Log in or Create an account to join the conversation.

30 Apr 2024 22:04 #299426

by EddySPalm

Replied by EddySPalm on topic Lichuan AC servos for axes and spindle

Attachments:

Please Log in or Create an account to join the conversation.

01 May 2024 07:18 #299444

by Tinine

Replied by Tinine on topic Lichuan AC servos for axes and spindle

Please Log in or Create an account to join the conversation.

03 May 2024 14:43 - 03 May 2024 14:46 #299636

by EddySPalm

Replied by EddySPalm on topic Lichuan AC servos for axes and spindle

Hey Tinine,

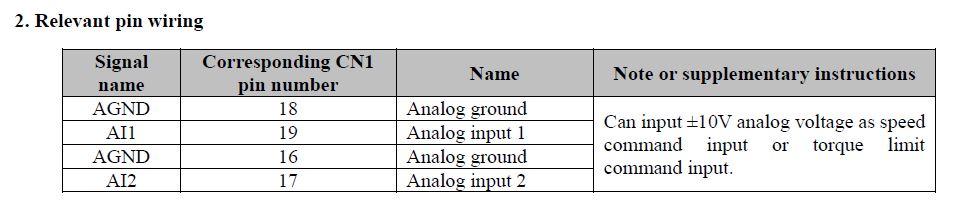

Actually, I could use some of your input, as I am about to connect up my spindle motor to the analog input on the servo driver. Do you also have the A5 servo driver? Being Lichuan, the connections might be the same as mine anyway.

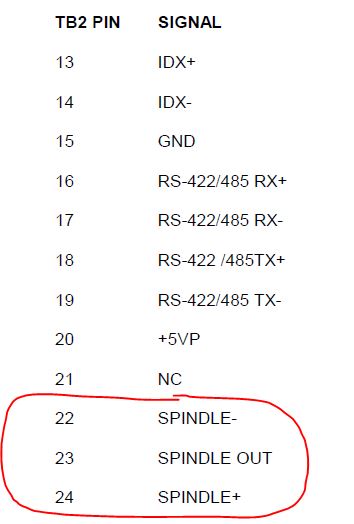

I am wondering how to connect my 7i96s to my servo drive. The relevant pins on the 7i96s are in one of the pictures below, while the relevant pins on the servo drives are in the other picture.

Just to get going on the discussion, I am guessing:

1. I only need one of the AGND pins on the servo drive, and either AI1 or AI2 (not both). Say I opt for AI1

2. SPINDLE OUT connects to AI1

3. SPINDLE + and SPINDLE - are left unconnected

4. I connect an available ground from somewhere on the 7i96s to one of the AGND pins on the servo drive

Servo drive input pins:

7i96s spindle output pins:

Really looking forward to anyones feedback on this. I have been searching quite a bit, but strangely enough haven't found a 100% relevant case.

PS: I have a really good impression of the Lichuan products and company so far also. the drives seem like a really good quilty build, the manuals are not at all hard to read, there's hardly a typo in them, and no sense of "chinglish" while reading them.

Actually, I could use some of your input, as I am about to connect up my spindle motor to the analog input on the servo driver. Do you also have the A5 servo driver? Being Lichuan, the connections might be the same as mine anyway.

I am wondering how to connect my 7i96s to my servo drive. The relevant pins on the 7i96s are in one of the pictures below, while the relevant pins on the servo drives are in the other picture.

Just to get going on the discussion, I am guessing:

1. I only need one of the AGND pins on the servo drive, and either AI1 or AI2 (not both). Say I opt for AI1

2. SPINDLE OUT connects to AI1

3. SPINDLE + and SPINDLE - are left unconnected

4. I connect an available ground from somewhere on the 7i96s to one of the AGND pins on the servo drive

Servo drive input pins:

7i96s spindle output pins:

Really looking forward to anyones feedback on this. I have been searching quite a bit, but strangely enough haven't found a 100% relevant case.

PS: I have a really good impression of the Lichuan products and company so far also. the drives seem like a really good quilty build, the manuals are not at all hard to read, there's hardly a typo in them, and no sense of "chinglish" while reading them.

Attachments:

Last edit: 03 May 2024 14:46 by EddySPalm. Reason: typo, and added some

Please Log in or Create an account to join the conversation.

03 May 2024 14:48 #299637

by PCW

Replied by PCW on topic Lichuan AC servos for axes and spindle

I would probably use step and direction for the spindle

The 7I96S analog output is more intended for VFD

potentiometer replacement use.

The 7I96S analog output is more intended for VFD

potentiometer replacement use.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.192 seconds