Fehlmann Picomax 100 Retrofit

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

23 Jul 2023 18:38 #276099

by anfänger

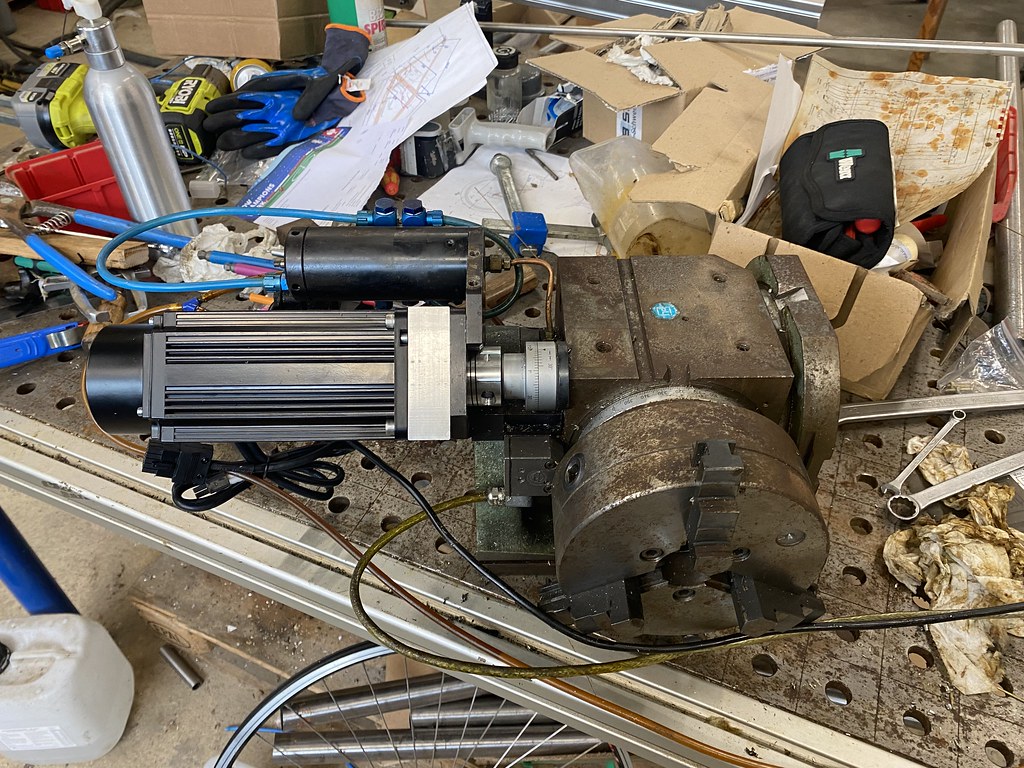

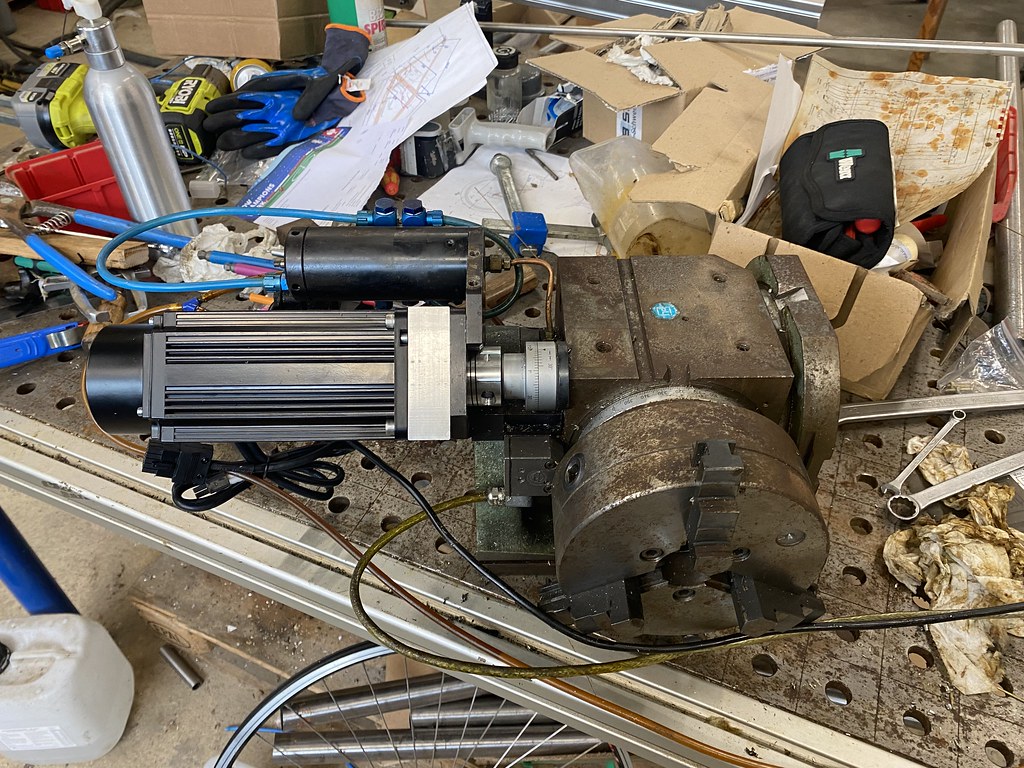

last the 4th axis is a bit more trouble, I needed a while to figure out how to disassemble it:

here I transferred the hole pattern from the mounting plate the to new spacer:

and the new servo can be mounted:

but here it ended while widening the bore of the new coupler to fit the new servo shaft I scrapped the part:

with this I decided to stop for now and wat of a new coupler to arrive. When It's here I will continue and start ti figure out How I will route the wired for the new servos. I don't think I will us the same paths as the old ones, cars the connectors won't fit.

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

last the 4th axis is a bit more trouble, I needed a while to figure out how to disassemble it:

here I transferred the hole pattern from the mounting plate the to new spacer:

and the new servo can be mounted:

but here it ended while widening the bore of the new coupler to fit the new servo shaft I scrapped the part:

with this I decided to stop for now and wat of a new coupler to arrive. When It's here I will continue and start ti figure out How I will route the wired for the new servos. I don't think I will us the same paths as the old ones, cars the connectors won't fit.

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

06 Aug 2023 16:25 #277121

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

With the new shaft coupling arrives, I was able to fit it to the A-Axis:

Next is to figure out how to protect servo an brake from chips, the old housing won't fit anymore.

Maybe I'll simply print something and cover it with Aluminium if needed.

I rerouted the Z-Axis wire, cause there was no way I could route it through the old duct ways, so I made a small cut in the casting and printed a cable guide. Maybe I' make a cover in the Machinehead later to protect the cables from a ripping belt.

Last was some cleaning before preparing to route the X-, Y- and A-Axis cable through the machine base:

And I wonder if I should use the encoder signals from the servos. Having glas scales I didn't need them.

But maybe they give me a finer resolution 0.0016 mm vs 0.005 mm for X and Y, for A I need to use the new servo anyway and Z I actually don't know the difference, cause I don't know the gear reduction.

Next is to figure out how to protect servo an brake from chips, the old housing won't fit anymore.

Maybe I'll simply print something and cover it with Aluminium if needed.

I rerouted the Z-Axis wire, cause there was no way I could route it through the old duct ways, so I made a small cut in the casting and printed a cable guide. Maybe I' make a cover in the Machinehead later to protect the cables from a ripping belt.

Last was some cleaning before preparing to route the X-, Y- and A-Axis cable through the machine base:

And I wonder if I should use the encoder signals from the servos. Having glas scales I didn't need them.

But maybe they give me a finer resolution 0.0016 mm vs 0.005 mm for X and Y, for A I need to use the new servo anyway and Z I actually don't know the difference, cause I don't know the gear reduction.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

13 Aug 2023 18:24 #277852

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

Lets find out if someone is reading here...

I've got the servo drives setup an did some first test. The encoders will give me a better resolution than the old glas scales. so I connected the encoder output from the drives to the mesa cards.

So far so good.

now I've got a problem, the first drive is just oscillating when controlled by linuxcnc

the drives work with +- 10V

My hal setting:

setp hm2_7i97.0.pwmgen.00.output-type 2 #PWM up on pin0, #PWM down on pin1

setp hm2_7i97.0.pwmgen.00.offset-mode 0 # offset mode so 50% = 0

setp hm2_7i97.0.pwmgen.00.scale [JOINT_0]OUTPUT_SCALE

# PID tuning params

DEADBAND = 0.000015

P = 100

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

now I disconnected the motor and when I turn the the spindle, can look at the output:

pwmgen.00.value -50 -> 50mv on drive

pwmgen.00.value -100 -> 9750mv on drive

pwmgen.00.value 100 -> -9750mv on drive

is this OK / normal O do I have something misconfigured here?

I've got the servo drives setup an did some first test. The encoders will give me a better resolution than the old glas scales. so I connected the encoder output from the drives to the mesa cards.

So far so good.

now I've got a problem, the first drive is just oscillating when controlled by linuxcnc

the drives work with +- 10V

My hal setting:

setp hm2_7i97.0.pwmgen.00.output-type 2 #PWM up on pin0, #PWM down on pin1

setp hm2_7i97.0.pwmgen.00.offset-mode 0 # offset mode so 50% = 0

setp hm2_7i97.0.pwmgen.00.scale [JOINT_0]OUTPUT_SCALE

# PID tuning params

DEADBAND = 0.000015

P = 100

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

now I disconnected the motor and when I turn the the spindle, can look at the output:

pwmgen.00.value -50 -> 50mv on drive

pwmgen.00.value -100 -> 9750mv on drive

pwmgen.00.value 100 -> -9750mv on drive

is this OK / normal O do I have something misconfigured here?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21088

- Thank you received: 7201

13 Aug 2023 18:56 #277855

by tommylight

Replied by tommylight on topic Fehlemann Picomax 100 Retrofit

For the first issue see here:

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

For the second, it seems the scaling is not right, and you can change the direction of the output by simply putting a - in front of the SCALE value.

-

Oh yes, we are reading...

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

For the second, it seems the scaling is not right, and you can change the direction of the output by simply putting a - in front of the SCALE value.

-

Oh yes, we are reading...

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17502

- Thank you received: 5116

14 Aug 2023 00:25 #277893

by PCW

Replied by PCW on topic Fehlemann Picomax 100 Retrofit

Your PWM setup is not correct for the 7I97, these are the correct settings:

# ---PWM Generator signals/setup---

setp hm2_7i97.0.pwmgen.00.output-type 1 #PWM pin0

setp hm2_7i97.0.pwmgen.00.offset-mode 1 # offset mode so 50% = 0

# ---PWM Generator signals/setup---

setp hm2_7i97.0.pwmgen.00.output-type 1 #PWM pin0

setp hm2_7i97.0.pwmgen.00.offset-mode 1 # offset mode so 50% = 0

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

14 Aug 2023 09:48 #277938

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

Thanks I‘ll give it a try.

Made this Hal a while ago, and now not sure if I modified my lathe file or used another base to start.

Scale is not finally set, cause I don’t know it yet, after I switched from glasscales to encoder feedback.

But wrong direction of scales usually results in a runaway axis…

Made this Hal a while ago, and now not sure if I modified my lathe file or used another base to start.

Scale is not finally set, cause I don’t know it yet, after I switched from glasscales to encoder feedback.

But wrong direction of scales usually results in a runaway axis…

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

19 Aug 2023 14:42 #278465

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

I measured all the axis and corrected all input and output scale parameters, so they should be right.

and PCW was right... All my other hal files use the same settings he mentioned, so I adjusted them.

but Ist didn't fix my problem in total.

It's still oscillating, but I can jog now.

and PCW was right... All my other hal files use the same settings he mentioned, so I adjusted them.

but Ist didn't fix my problem in total.

It's still oscillating, but I can jog now.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21088

- Thank you received: 7201

19 Aug 2023 15:17 #278472

by tommylight

Replied by tommylight on topic Fehlemann Picomax 100 Retrofit

Might be time to have a look here, skip the wiring section:

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

19 Aug 2023 18:13 #278483

by anfänger

Replied by anfänger on topic Fehlemann Picomax 100 Retrofit

Hi, I know this tuning tutorial and used it before, my problem is.

My servo system is oscillating right away.

Even with 0.00001 Deadband and P at 10.

When using a potentiometer for as analog input the servo runs smooth ans stable.

Sot it something that comes in interaction with linuxcnc.

Maybe the PID from the drive and linuxcnc don't work well together.

The oscillation range is +- 40 increments,

but there is something else odd,

the DRO is running at a different scale than the encoder position.

My servo system is oscillating right away.

Even with 0.00001 Deadband and P at 10.

When using a potentiometer for as analog input the servo runs smooth ans stable.

Sot it something that comes in interaction with linuxcnc.

Maybe the PID from the drive and linuxcnc don't work well together.

The oscillation range is +- 40 increments,

but there is something else odd,

the DRO is running at a different scale than the encoder position.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17502

- Thank you received: 5116

19 Aug 2023 18:36 #278485

by PCW

Replied by PCW on topic Fehlemann Picomax 100 Retrofit

Are the encoders rotary or linear encoders?

Is the analog out scale set for full speed (in machine units per second) at +10V?

(if not, the units for FF1 and P are unknown)

I would get the encoder and analog scaling right,

FF1 right and then worry about fine tuning

Is the analog out scale set for full speed (in machine units per second) at +10V?

(if not, the units for FF1 and P are unknown)

I would get the encoder and analog scaling right,

FF1 right and then worry about fine tuning

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.211 seconds