Is software Estop allowed

- Benb

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 183

- Thank you received: 60

Control regulation rules (common sense) calls for external hardwired red mushroom push button.

Emergency stop push button must be designed to fulfill the following requirements:

- Mushroom-head shape to make it easy to push

- Coloured red and mounted on a bright yellow background

- Push button must remain in latched position after it has been pushed

- Resetting of the Estop by pulling or twisting alone shall not resume operation. A second deliberate action is needed, such as the pressing of a reset button

- Must be located at each operator control station and at any other location where an emergency stop would be required

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4613

- Thank you received: 2042

Software Estop in the form of UI/HMI touchscreen, flat panel display driven by mouse/keyboard, software commands (G code …) and membrane switches are NOT ALLOWED.

I agree but the implementation of proper machine safety standards is first and foremost the responsibility of the machine integrator. Regulations that apply in one country may not apply in another. Also in most countries machine safety regulations will go WAY beyond having a proper emergency stop push button.

Generally I would be willing to bet with anyone building a cnc machine (other than a serious commercial company) that their machine is in breach of code somewhere.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11557

- Thank you received: 3877

So yes, safety is in the hnads of the integrator.

Please Log in or Create an account to join the conversation.

- Benb

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 183

- Thank you received: 60

This discussion is not about machine safety relays, devices, … etc. So, let’s not mix-up things and muddy the discussion.

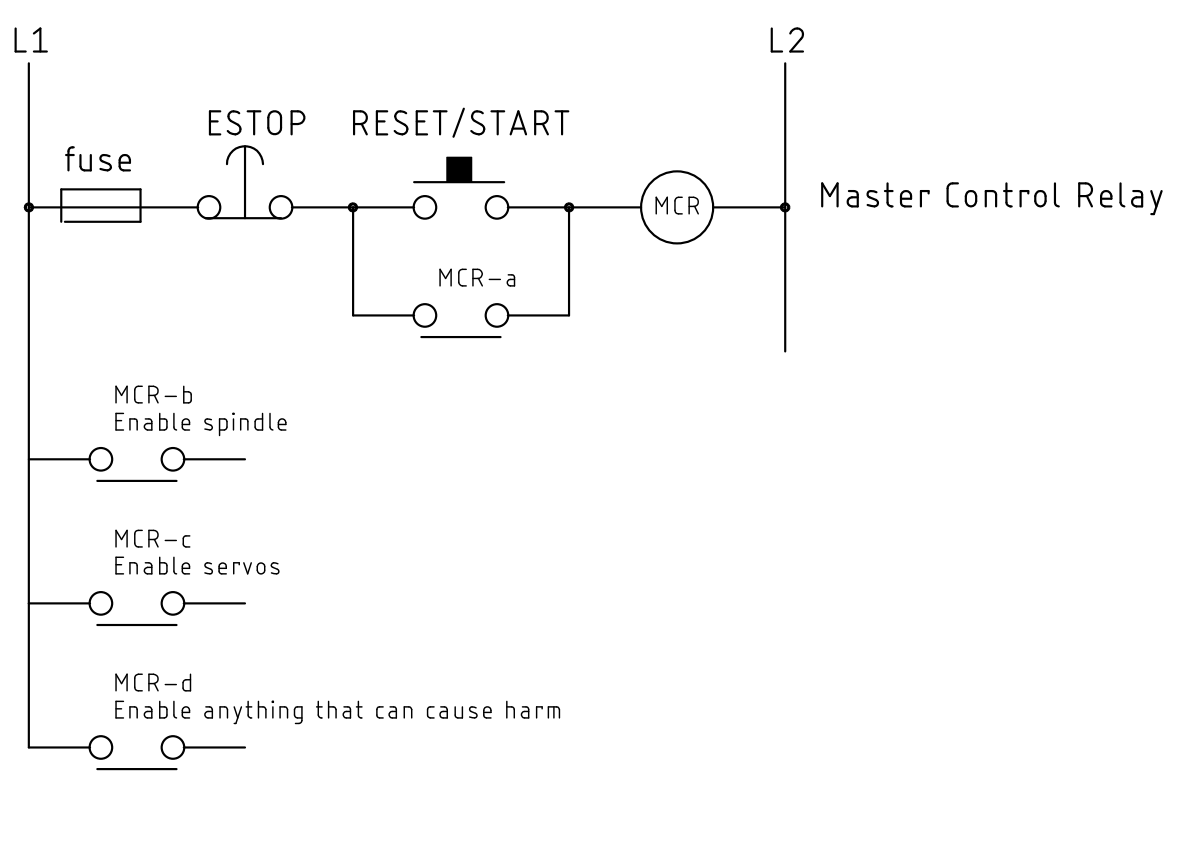

This awareness message is strictly about machine estop/reset only, which require very simple relay circuit. If you cannot read electrical diagrams just google start/stop circuit and you will find several examples showing realistic picture and wiring diagram for non electrical inclined.

To build an estop/reset circuit you need: red mushroom shaped push button, a push button and a relay wired as follows:

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21053

- Thank you received: 7181

Yes, it is a plane, and it is stealth.

No one asked for this info.....

-

Benb is trying to explain, with examples, how e-stop functions and how it should be implemented and why it is very important, so help him.

Thank you Benb.

-

Mentioning related stuff and the multitude of options might add to it, but it is not helping much without actual examples and corresponding info.

-

Another rant:

I have never used e-stop latch, although it does have it's uses for sure, but i have used the normal e-stop in and out even on 16 ton machines, as Aciera so eloquently put it "the implementation of proper machine safety standards is first and foremost the responsibility of the machine integrator" so the e-stop from LinuxCNC is just integrated into the machine e-stop system.

My point being, stop telling people to use e-stop latch unless they actually need it, they wind up wasting days trying to set it up and get frustrated, while the machines using it can be mostly stopped with a single hand and not much effort.

net e-stop-in <=== whatever-input-pin-01

net e-stop-out ===> whatever-output-pin-22Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11557

- Thank you received: 3877

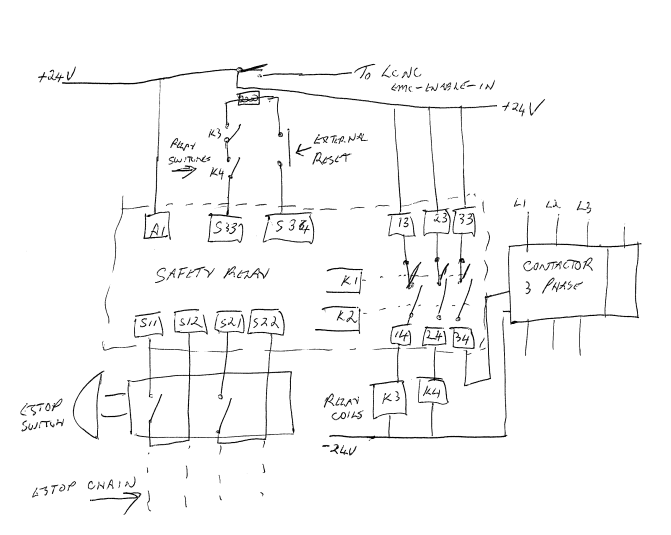

Note that the estop button has two redunant circuits

The main contactor needs both K1 & K2 to be triggered

K3 & K4 are seperate force guided relays. Linuxcnc is not updated with a sucessful power on unless both K3 & K4 are triggered.

Force guided relays have a non conductive pin forced between the contacts to ensure contacts cannot be welded together.

Additional safety switches eg. door switches, guards etc are placed in the S33/S34 loop with the reset button.

With such a wiring layout, it is permissable to use linuxcnc's software power button as a reset latch. In this case, use iocontrol.0.user-request-enable as it receives a pulse to repliciate the external reset button.

BUt the safety relay cost me $250 AUD and another $100 or so for the force guided relays.

Attachments:

Please Log in or Create an account to join the conversation.

- Benb

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 183

- Thank you received: 60

And yes, no one asked me for advice but since Linuxcnc documentation does not address this subject I felt obligated to make hobbits and new Linuxcnc users aware of the use of Estop.

Tommy as Linuxcnc gate keeper do us (Linuxcnc users) favor and add a warning in the Linuxcnc documentation “software estop is not allowed. here is no substitute for an external standalone Estop/reset”.

Please Log in or Create an account to join the conversation.

- Cant do this anymore bye all

-

- Offline

- Platinum Member

-

- Posts: 1200

- Thank you received: 425

Full of good solid advice would be the better description.

Man you are so out of line with that comment.

Up til then it's been a decent discussion.

I'm just hoping there was a bit of confusion into the term "e-stop latch".

Just a little aside.

I've worked a lot of casual labour hire, disposable workers is what we really are, I was at a recycling plant, pulling steel that was missed during separation and wasn't supposed to go into the crusher. The plant wasn't the best safety wise. Anyways they had this dodgy estop setup, was like 2 step away from where you had to work. So after being there for a bit I realised the issue, spoke to the guy on site, no reaction, spoke to my contact at the labour hire mob, all they hid was ring the plant up and were assured yes there is an estop on the machine, tho access wasn't never discussed. So I said "Fuck it" and walked out. Got a call from from the labour hire mob, told them never to call again as their "safety officer was useless". Yeah and they are a major player in concrete recycling in Sydney.

So yeah machine safety is fucking important.

I fully agree a software estop is not the ideal way to go. Ah fuck I've lost my train of thought.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21053

- Thank you received: 7181

-

It is allowed, depends on machine, most hobby machines do not need it as the spindle is not controlled by LinuxCNC, etc etc etcTommy what you saying in your rant is wrong “software estop is not allowed “.

And my rant was about the "e-stop latch", not the "e-stop".

You missed the point, they do have E-stops, big ones at least two, and the proper safety stuff, always.So, do yourself a favor and add an external estop to your 50 kg bench drill press and your 16-ton machine.I also hope you don’t let anyone else uses your software estop equipped machines, they are unsafe and you will not forgive yourself if someone else using them gets hurt.

My small plasma machines do not have any, they do not need it, ever. My Big industrial plasma machines with DC servo motors have at least 2 e-stops and obligatory "extreme limits" on all axis

Never had a single incident on my machines, the biggest incident was braking an end mill.

I already said thank you.And yes, no one asked me for advice but since Linuxcnc documentation does not address this subject I felt obligated to make hobbits and new Linuxcnc users aware of the use of Estop.

Again, as Aciera said above,Tommy as Linuxcnc gate keeper do us (Linuxcnc users) favor and add a warning in the Linuxcnc documentation “software estop is not allowed. here is no substitute for an external standalone Estop/reset”.

the implementation of proper machine safety standards is first and foremost the responsibility of the machine integratorPlease Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4613

- Thank you received: 2042

Linuxcnc ‘gate keepers’ should warn users that - software estops are not allowed - for safety sake.

It's enough of a struggle to try and keep the existing code base and its documentation even halfway updated with the volunteers we have. If you would like to add information about safety then I would invite you to add to the wiki:

wiki.linuxcnc.org/cgi-bin/wiki.pl

Please Log in or Create an account to join the conversation.