spindle sync trouble

- systemslave

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

09 Dec 2014 07:53 - 09 Dec 2014 08:31 #53837

by systemslave

spindle sync trouble was created by systemslave

I am having an issue with the synchronized motion using G76 and G33. I have the speed connected for manual control. When issuing G76 and G33 commands I note that changing the speed has no effect on the Z axis speed. Does LinuxCNC monitor the shaft encoder for synchronized movement or assume the stated spindle speed? If the shaft encoder is monitored, why don't I see Z axis speed change with shaft speed?

Last edit: 09 Dec 2014 08:31 by systemslave.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 25

- Thank you received: 758

09 Dec 2014 17:57 #53845

by ArcEye

Replied by ArcEye on topic spindle sync trouble

Hi

You will have to expand upon what you are doing and why you want to manually change speed during the cutting of a thread,

or select a speed which is different from the one in your code?

Also upon what encoder you have and how it is connected.

The Z feed IS synchronised to spindle speed, but how well this is done depends upon what spindle encoder you have.

A Z index is basically good for positional use, getting the thread started in the right place each time, but you cannot cut good threads without at least an A pulse.

It is this that allows the adjustment of feed to match the fluctuations of spindle speed caused by tool drag etc

The optimum number of pulses and the accuracy you can get in speed matching, is largely governed by your ability to read them.

With a hardware encoder interface, you could go very high, but with the software encoders, anything much above 200 tends to quickly go haywire as speed increases,

because they cannot keep up.

regards

You will have to expand upon what you are doing and why you want to manually change speed during the cutting of a thread,

or select a speed which is different from the one in your code?

Also upon what encoder you have and how it is connected.

The Z feed IS synchronised to spindle speed, but how well this is done depends upon what spindle encoder you have.

A Z index is basically good for positional use, getting the thread started in the right place each time, but you cannot cut good threads without at least an A pulse.

It is this that allows the adjustment of feed to match the fluctuations of spindle speed caused by tool drag etc

The optimum number of pulses and the accuracy you can get in speed matching, is largely governed by your ability to read them.

With a hardware encoder interface, you could go very high, but with the software encoders, anything much above 200 tends to quickly go haywire as speed increases,

because they cannot keep up.

regards

Please Log in or Create an account to join the conversation.

- systemslave

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

13 Dec 2014 00:24 - 13 Dec 2014 00:27 #53968

by systemslave

Replied by systemslave on topic spindle sync trouble

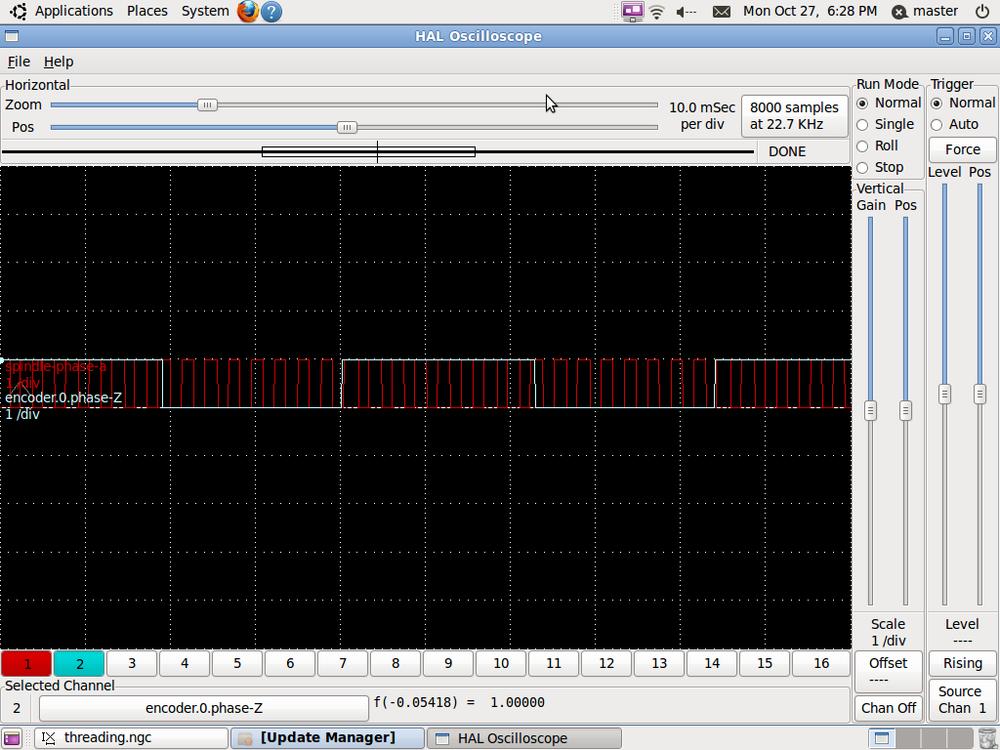

I built a low resolution shaft encoder. Here is a screen from HAL scope.

I am using manual speed control because I haven't gotten the VFD hooked up yet.

I don't want to change speed during the cutting of a thread. I only did that to test the system during an air cut. It should have compensated the feed rate, but the feed rate was unaffected.

I am using manual speed control because I haven't gotten the VFD hooked up yet.

I don't want to change speed during the cutting of a thread. I only did that to test the system during an air cut. It should have compensated the feed rate, but the feed rate was unaffected.

Last edit: 13 Dec 2014 00:27 by systemslave.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 23517

- Thank you received: 5000

16 Dec 2014 08:02 #54050

by andypugh

G33 and G76 use spindle _position_ not speed. (motion.spindle-revs). So manually changing the speed will have no effect unless that also changes the rate at which the encoder position feedback changes.

Replied by andypugh on topic spindle sync trouble

I don't want to change speed during the cutting of a thread. I only did that to test the system during an air cut. It should have compensated the feed rate, but the feed rate was unaffected.

G33 and G76 use spindle _position_ not speed. (motion.spindle-revs). So manually changing the speed will have no effect unless that also changes the rate at which the encoder position feedback changes.

Please Log in or Create an account to join the conversation.

- systemslave

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

16 Dec 2014 09:55 #54054

by systemslave

I don't think I followed that. The shaft encoder is physically connected to the shaft, so changing the speed in any way would also change the rate at which the encoder position feedback changes - right? We are talking about A and sync pulses here aren't we? What did I miss?

Replied by systemslave on topic spindle sync trouble

G33 and G76 use spindle _position_ not speed. (motion.spindle-revs). So manually changing the speed will have no effect unless that also changes the rate at which the encoder position feedback changes.

I don't think I followed that. The shaft encoder is physically connected to the shaft, so changing the speed in any way would also change the rate at which the encoder position feedback changes - right? We are talking about A and sync pulses here aren't we? What did I miss?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 23517

- Thank you received: 5000

16 Dec 2014 18:49 #54058

by andypugh

Yes, sorry, for some reason I interpreted what you said as that you were manually changing HAL pin values from the command prompt, rather than that you were manually changing the spindle speed with a knob on the VFD.

Yes, the change in spindle speed should change the Z speed.

Is it possible that the Z speed is maxed-out? As far as I know there are no checks, so it might be running at max speed and lagging. If it is lagging it will try to catch up so will still run at max speed when the spindle slows.

Replied by andypugh on topic spindle sync trouble

The shaft encoder is physically connected to the shaft, so changing the speed in any way would also change the rate at which the encoder position feedback changes - right?

Yes, sorry, for some reason I interpreted what you said as that you were manually changing HAL pin values from the command prompt, rather than that you were manually changing the spindle speed with a knob on the VFD.

Yes, the change in spindle speed should change the Z speed.

Is it possible that the Z speed is maxed-out? As far as I know there are no checks, so it might be running at max speed and lagging. If it is lagging it will try to catch up so will still run at max speed when the spindle slows.

Please Log in or Create an account to join the conversation.

- systemslave

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

17 Dec 2014 14:44 #54084

by systemslave

Replied by systemslave on topic spindle sync trouble

Thanks Andy. Yes, I have a pot tied to the VFD for speed control.

About maxing out - I don't think so. When I have the spindle speed turned up high LinuxCNC won't take a pass. I assume that this is because it cannot make the pass at the maximum Z travel speed (though I am guessing). That leads me to think it IS monitoring the spindle speed and matching the Z speed (actually following the surface I know). However, when I have the speed set low enough to take passes I can change the spindle speed around and the Z feed rate does not change. It does not even change between passes. If it is 83 (mm) it remains at 83.

As you can see from the HAL Scope capture I posted, LinuxCNC clearly sees both A phase and Z phase. I know this works for other people, so I am pretty sure the mistake is in something I have done. I just can't figure out what.

About maxing out - I don't think so. When I have the spindle speed turned up high LinuxCNC won't take a pass. I assume that this is because it cannot make the pass at the maximum Z travel speed (though I am guessing). That leads me to think it IS monitoring the spindle speed and matching the Z speed (actually following the surface I know). However, when I have the speed set low enough to take passes I can change the spindle speed around and the Z feed rate does not change. It does not even change between passes. If it is 83 (mm) it remains at 83.

As you can see from the HAL Scope capture I posted, LinuxCNC clearly sees both A phase and Z phase. I know this works for other people, so I am pretty sure the mistake is in something I have done. I just can't figure out what.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 23517

- Thank you received: 5000

17 Dec 2014 20:23 #54093

by andypugh

Is "counter_mode" set to true?

If you stop the spindle, does the movement stop (it should).

Attach your HAL and INI files, we can have a look for anything obvious.

Replied by andypugh on topic spindle sync trouble

As you can see from the HAL Scope capture I posted, LinuxCNC clearly sees both A phase and Z phase. I know this works for other people, so I am pretty sure the mistake is in something I have done. I just can't figure out what.

Is "counter_mode" set to true?

If you stop the spindle, does the movement stop (it should).

Attach your HAL and INI files, we can have a look for anything obvious.

The following user(s) said Thank You: systemslave

Please Log in or Create an account to join the conversation.

- systemslave

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

18 Dec 2014 10:12 #54107

by systemslave

Replied by systemslave on topic spindle sync trouble

Andy totally rocks!

I got to step 2 and stopped the spindle in the middle of a thread run. As I approached 0 the Z speed dropped off and stopped. I ran the speed up and down in the very low ranges and the Z speed (feedrate) followed the surface. Without a readout I just had the spindle speed too high before. I had assumed incorrectly that when the machine took a run at the threads it meant that it could match the feedrate to the spindle speed. It couldn't keep up at that speed. Andy had considered that possibility earlier. He was right! It works perfectly but at a lower speed than I had "eyeballed" with my manual speed control tied across the VFD.

SOLVED (thank you Andy Pugh)

I got to step 2 and stopped the spindle in the middle of a thread run. As I approached 0 the Z speed dropped off and stopped. I ran the speed up and down in the very low ranges and the Z speed (feedrate) followed the surface. Without a readout I just had the spindle speed too high before. I had assumed incorrectly that when the machine took a run at the threads it meant that it could match the feedrate to the spindle speed. It couldn't keep up at that speed. Andy had considered that possibility earlier. He was right! It works perfectly but at a lower speed than I had "eyeballed" with my manual speed control tied across the VFD.

SOLVED (thank you Andy Pugh)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 23517

- Thank you received: 5000

18 Dec 2014 20:20 #54123

by andypugh

It is possible that your encoder scale is wrong, which might explain the miss-match.

It is definitely worth opening a halmeter (in the "machine" menu) and looking at motion.spindle-revs to make sure that it increases by exactly 1.0 as you rotate the spindle by hand with the VFD turned off.

Replied by andypugh on topic spindle sync trouble

It works perfectly but at a lower speed than I had "eyeballed" with my manual speed control tied across the VFD.

It is possible that your encoder scale is wrong, which might explain the miss-match.

It is definitely worth opening a halmeter (in the "machine" menu) and looking at motion.spindle-revs to make sure that it increases by exactly 1.0 as you rotate the spindle by hand with the VFD turned off.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 2.060 seconds