Developing Retrofit Plan for Mori Seiki SL2

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 04:37 #70141

by Dale Lusby

Developing Retrofit Plan for Mori Seiki SL2 was created by Dale Lusby

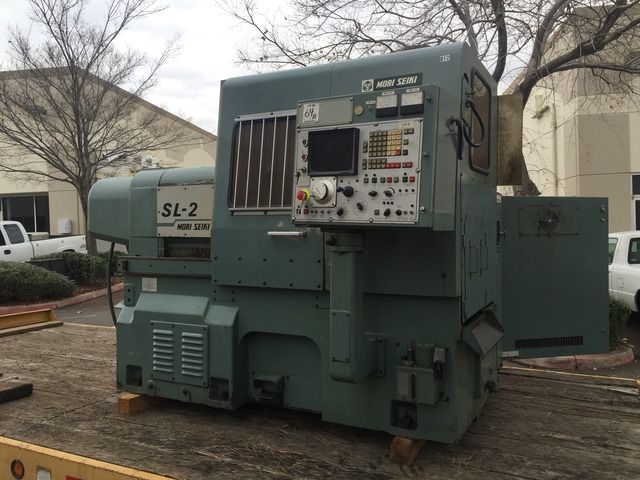

I recently acquired a Mori Seiki SL2 at auction and although I was assured it was working I was a little bummed to find out the spindle power supply and driver were removed recently. I'm working with the auction company to come up with a resolution but honestly I don't expect much to happen there. As such I am looking at doing what is likely a better option anyways and retrofitting to LinuxCNC.

First I want to figure out what boards I should be looking at. I assume Mesa and Pico are good choices. Any specific recommendation and if so why? The lathe runs a Fanuc 6t controller currently and the spindle motor is a Fanuc DC servo. I haven't dug too deep but it will be either a 7.5 or 15 hp motor. Once I figure the cards out i'll need to start looking at connecting them. Also if anyone has ideas on how to power and control the spindle I would appreciate the advice. My experience is with the Shizuoka AN-S retrofit but it used stepper motors and I assume will be quite simple compared to this.

First I want to figure out what boards I should be looking at. I assume Mesa and Pico are good choices. Any specific recommendation and if so why? The lathe runs a Fanuc 6t controller currently and the spindle motor is a Fanuc DC servo. I haven't dug too deep but it will be either a 7.5 or 15 hp motor. Once I figure the cards out i'll need to start looking at connecting them. Also if anyone has ideas on how to power and control the spindle I would appreciate the advice. My experience is with the Shizuoka AN-S retrofit but it used stepper motors and I assume will be quite simple compared to this.

Please Log in or Create an account to join the conversation.

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

15 Feb 2016 21:29 #70190

by emcPT

Replied by emcPT on topic Developing Retrofit Plan for Mori Seiki SL2

Hello,

Are the motors red cap or yellow cap?

Are the motors red cap or yellow cap?

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

15 Feb 2016 23:52 #70203

by Dale Lusby

Replied by Dale Lusby on topic Developing Retrofit Plan for Mori Seiki SL2

Please Log in or Create an account to join the conversation.

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

16 Feb 2016 07:08 #70224

by emcPT

Replied by emcPT on topic Developing Retrofit Plan for Mori Seiki SL2

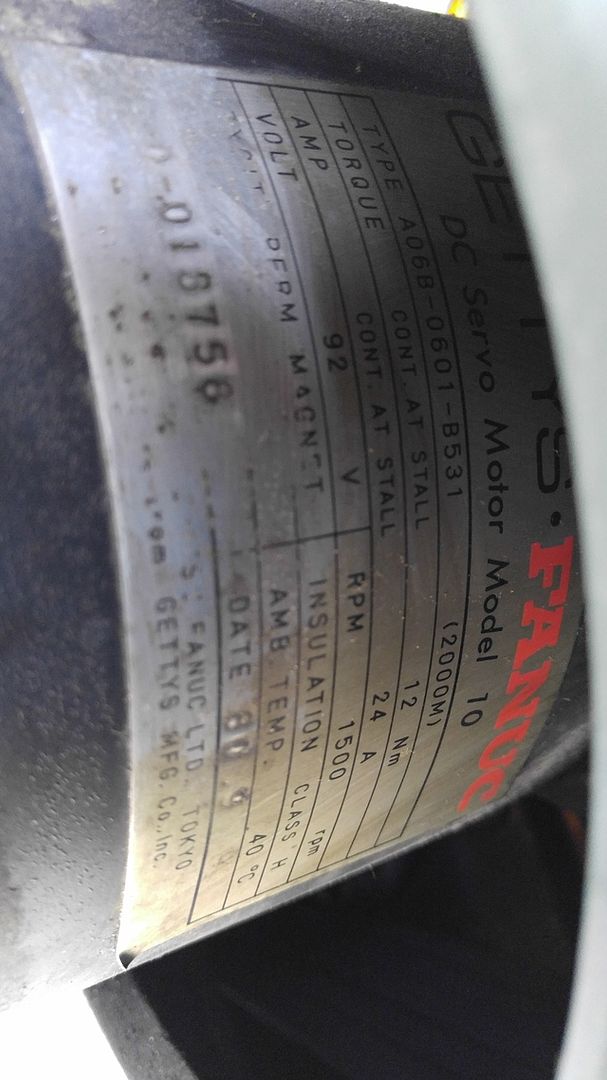

I was thinking that the motors were Fanuc. They would then be red cap oy yellow cap. Yours are BLACK cap

The point is that they are DC servos. This mean that they are easy to control.

Where are you located?

The point is that they are DC servos. This mean that they are easy to control.

Where are you located?

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

16 Feb 2016 07:28 #70226

by Dale Lusby

Replied by Dale Lusby on topic Developing Retrofit Plan for Mori Seiki SL2

I'm located in northern California. I emailed Jon at Pico and he's helping me to come up with some ideas on the axis servos. Biggest issue is likely going to be the spindle as they pulled the entire power unit and control board out of the machine. The used boards range from $4-13k which would be a little pricey to get it back to its 1980's glory. Any ideas on finding a way to power and control it? I'm sure I could always move to a 3 phase motor and VfD but I'd rather keep the one in it if possible.

I know someone with a Yasnac SL2 that he parted out and he may still have his spindle motor and Yasnac board. Perhaps I could have a Yasnac spindle and fanuc axis.

I know someone with a Yasnac SL2 that he parted out and he may still have his spindle motor and Yasnac board. Perhaps I could have a Yasnac spindle and fanuc axis.

Please Log in or Create an account to join the conversation.

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

16 Feb 2016 07:58 #70228

by emcPT

Replied by emcPT on topic Developing Retrofit Plan for Mori Seiki SL2

I have one (removed from a equal machine):

www.ebay.com/itm/321918559072?ssPageName...id=p3984.m1555.l2649

www.ebay.com/itm/321918559072?ssPageName...id=p3984.m1555.l2649

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Elite Member

-

Less

More

- Posts: 284

- Thank you received: 31

26 Feb 2016 17:33 #70679

by JR1050

Replied by JR1050 on topic Developing Retrofit Plan for Mori Seiki SL2

That is a good solid piece of iron. The control is 6ta, the 2nd 6t. The black cap motors were used on the Fanuc 2000 ,3000,5 series and up to the 6ta. I believe the drives for the black motors are scr, the yellow cap are transistor. Any way, check to see who makes the spindle motor. Fanuc never made a dc spindle motor, it would probably be Fuji or Mistubishi, as that what my mori had on it. If it's Fanuc, it is ac. The dc motor and drive are usually of the same manufacturer, so Fuji -Fuji ect. Dc systems usually will have a fwd and rvs contractor and the drive will have simple signal like 0-10v command , up to speed and enable.

If the control works, it wouldn't be bad idea to run it with the Fanuc , as there is no real inherit advantage to retofitting it. Lcnc doesn't have all the cool Fanuc cycles and you will have to rewrite all the logic that makes it a mori, which is a huge undertaking, in the end you still have to put a drive in it. Try Warren at uptime electronics in the LA area, he may be able to help.

If the control works, it wouldn't be bad idea to run it with the Fanuc , as there is no real inherit advantage to retofitting it. Lcnc doesn't have all the cool Fanuc cycles and you will have to rewrite all the logic that makes it a mori, which is a huge undertaking, in the end you still have to put a drive in it. Try Warren at uptime electronics in the LA area, he may be able to help.

Please Log in or Create an account to join the conversation.

- Iron-Man

-

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 1

27 Feb 2016 16:53 #70709

by Iron-Man

Have you thought about changing out all of the electronics, placing AC servos and running PathPilot?

Iron-Man

Replied by Iron-Man on topic Developing Retrofit Plan for Mori Seiki SL2

I recently acquired a Mori Seiki SL2 at auction and although I was assured it was working I was a little bummed to find out the spindle power supply and driver were removed recently. I'm working with the auction company to come up with a resolution but honestly I don't expect much to happen there. As such I am looking at doing what is likely a better option anyways and retrofitting to LinuxCNC.

First I want to figure out what boards I should be looking at. I assume Mesa and Pico are good choices. Any specific recommendation and if so why? The lathe runs a Fanuc 6t controller currently and the spindle motor is a Fanuc DC servo. I haven't dug too deep but it will be either a 7.5 or 15 hp motor. Once I figure the cards out i'll need to start looking at connecting them. Also if anyone has ideas on how to power and control the spindle I would appreciate the advice. My experience is with the Shizuoka AN-S retrofit but it used stepper motors and I assume will be quite simple compared to this.

Have you thought about changing out all of the electronics, placing AC servos and running PathPilot?

Iron-Man

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

27 Feb 2016 18:07 #70713

by Dale Lusby

Replied by Dale Lusby on topic Developing Retrofit Plan for Mori Seiki SL2

I've been working closely with Jon at Pico and I can't say enough about how much he is willing to help. His service and willingness to help would be tough to surpass. I will be going with Pico for the boards (his servo amps aren't big enough) and currently am deciding on the servo amps to use. Probably will be AMC for them. I've thought long and hard about just getting the spindle drive replaced but the hard thing is spending the money on something that will still be a 30+ year old tech. Nothing wrong with it but I worry that I'll be spending money for years to come to keep it running instead of biting the bullet and doing the retrofit. I believe in the end and thinking long term it is best to go ahead and change it out.

I haven't looked much into PathPilot. My plan is to use the motors the machine has. For my needs they should be good.

I haven't looked much into PathPilot. My plan is to use the motors the machine has. For my needs they should be good.

Please Log in or Create an account to join the conversation.

- Iron-Man

-

- Offline

- Senior Member

-

Less

More

- Posts: 70

- Thank you received: 1

27 Feb 2016 18:49 - 27 Feb 2016 18:53 #70716

by Iron-Man

Dale let me know if you change your mind. I am currently finishing up a Denford NovaTurn converted to AC servos/PathPilot, and have started a stepper to AC Servo update for a EMCO Concept Turn 105 which will be running PathPilot.

The AMC drives are great for DC servos, I am using one for the SEM DC spindle motor on the NovaTurn. Take a look at the the Mesa boards, 6i25 / 7i77 etc., they will provide a better expansion and interface capability.

Iron-Man

Replied by Iron-Man on topic Developing Retrofit Plan for Mori Seiki SL2

I've been working closely with Jon at Pico and I can't say enough about how much he is willing to help. His service and willingness to help would be tough to surpass. I will be going with Pico for the boards (his servo amps aren't big enough) and currently am deciding on the servo amps to use. Probably will be AMC for them. I've thought long and hard about just getting the spindle drive replaced but the hard thing is spending the money on something that will still be a 30+ year old tech. Nothing wrong with it but I worry that I'll be spending money for years to come to keep it running instead of biting the bullet and doing the retrofit. I believe in the end and thinking long term it is best to go ahead and change it out.

I haven't looked much into PathPilot. My plan is to use the motors the machine has. For my needs they should be good.

Dale let me know if you change your mind. I am currently finishing up a Denford NovaTurn converted to AC servos/PathPilot, and have started a stepper to AC Servo update for a EMCO Concept Turn 105 which will be running PathPilot.

The AMC drives are great for DC servos, I am using one for the SEM DC spindle motor on the NovaTurn. Take a look at the the Mesa boards, 6i25 / 7i77 etc., they will provide a better expansion and interface capability.

Iron-Man

Last edit: 27 Feb 2016 18:53 by Iron-Man. Reason: Additional Info.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.226 seconds