Re:CHNC-1 Retrofit & Upgrades

- robh

- Offline

- Premium Member

-

- Posts: 102

- Thank you received: 22

old control was Simens 810T , plc on it fell over with a memory problem so EMC will take over

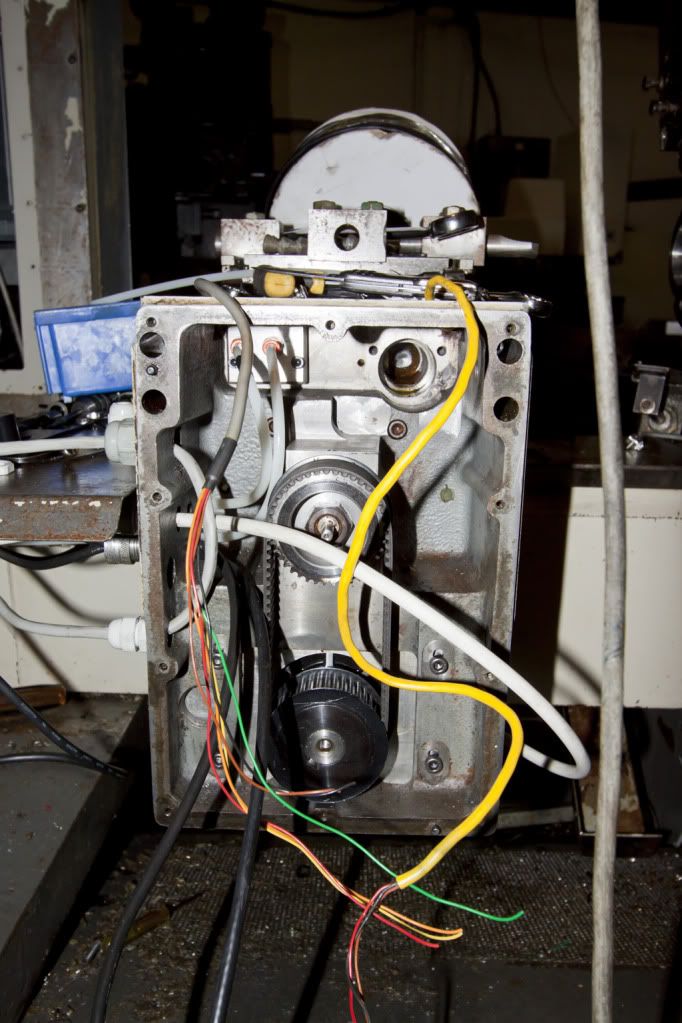

we are chaning the old DC motors to AC 1kw setup and upping its speed alittle also on X and Z

also chanign the turret from Air motor to servo driven so quite abit of mods etc to happen on the turret side

machine with new monitor fitting 17"

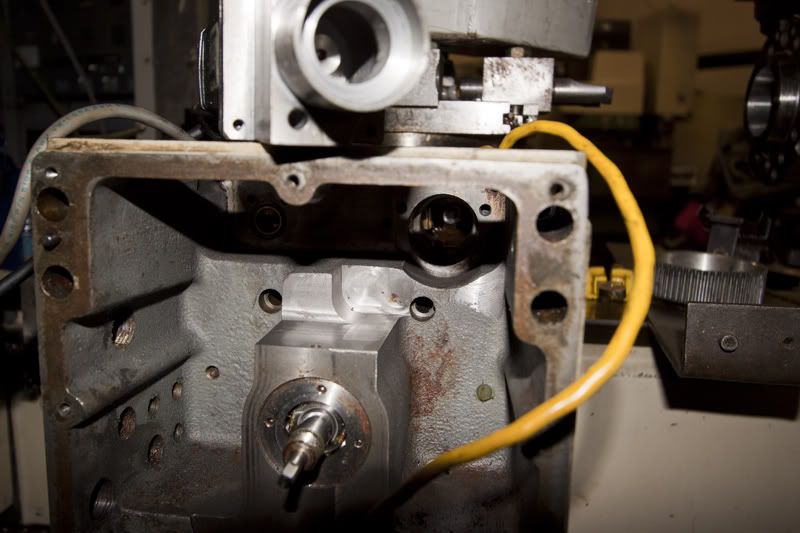

Photo of the servo that will drive the turret when finished, mounting housing made

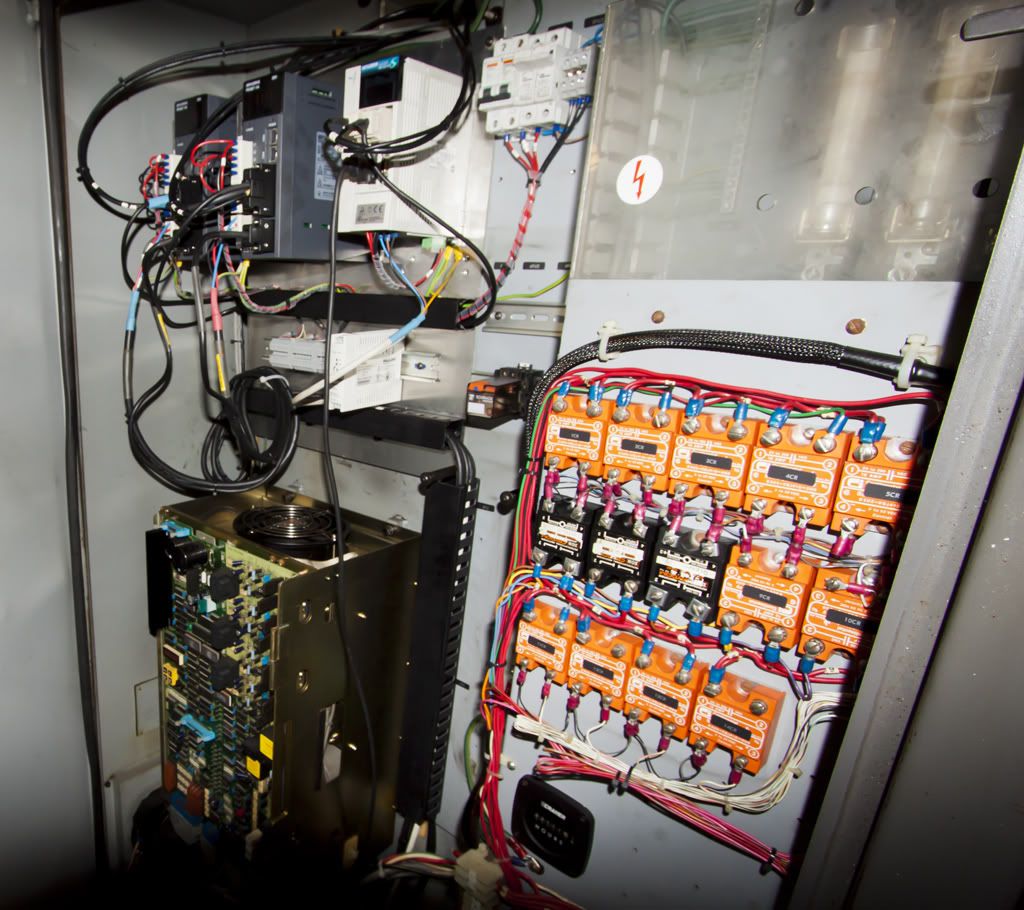

PC & Mesa hardware nearly finished mounting

Spindle , relays etc

rob

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

Nice! Be making chips soon on that one.

John

Please Log in or Create an account to join the conversation.

- robh

- Offline

- Premium Member

-

- Posts: 102

- Thank you received: 22

PC Board fitted, Mesa brakeouts and made a IO panel for all wires coming in

after abit of modding and making brackets X motor Fitted, Air feed pipes fitted to new block for turret lift.

1:1 belt gearing

much more todo yet

Close fit on X motor but we got it in there.. had to modd the Lube feed block to get full travel

fitted all drives and nearly finished up doing the interface wiring now

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

Looking real good, be in production soon I'd bet.

John

Please Log in or Create an account to join the conversation.

- robh

- Offline

- Premium Member

-

- Posts: 102

- Thank you received: 22

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

John

Please Log in or Create an account to join the conversation.

- Alloy Craft

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- bobinater

- Offline

- New Member

-

- Posts: 19

- Thank you received: 0

How much different is the chnc from the hnc other than the enclosure ?

Your machine is very impressive, love the coolant. and is it set up for constant surface speed?

Please Log in or Create an account to join the conversation.

- robh

- Offline

- Premium Member

-

- Posts: 102

- Thank you received: 22

Looks pretty smooth, very nice. With all that work you did to get the turret servo on there, I was hoping to see the turret index. Anyway where did you get the pulleys and belts for the axis drives? Also what Mesa cards are you using on this one?

this is one thing i do keep meaning to make a video off

but as CHNC is used for 2nd opp work 99% of the time, i never realy have a good video to make of turret index's as we allways gang up 2 or more tools on the square turret you see.

but turret is working perfect, it does realy want a new gear in there tho. to make it truly zero backlash on the worm and 3 gears..

we are so bussy tho we dont realy have time or urgent need for it. only thing we need to fix is the collet coloser as that thing just eats air now. looking to put a new hydrolic unit on.

rob

Please Log in or Create an account to join the conversation.

- robh

- Offline

- Premium Member

-

- Posts: 102

- Thank you received: 22

Hey rob

How much different is the chnc from the hnc other than the enclosure ?

Your machine is very impressive, love the coolant. and is it set up for constant surface speed?

hi

the main difference is the 16C collets over the 5C collets..

a HNC is grate machine for 2nd opps and small parts.. the CHNC is also but for us not very offten we find we need the 16C size range.. as 5C would cover 80% of work gets put on it.

travels are the same on X and Y, some dont have the top parting slide with them but they both take same unit, its just Air over hydrolic tho so it eats air and can be a pain if not used for awhile, we very rarly use outs beacsue of that.

yes

constant surface speed, Rigid tapping, etc etc

anything EMC can do it can do and more.

rob

Please Log in or Create an account to join the conversation.