Hurco BMC30 Retrofit

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

29 Mar 2018 22:04 #108086

by Ozo

Hurco BMC30 Retrofit was created by Ozo

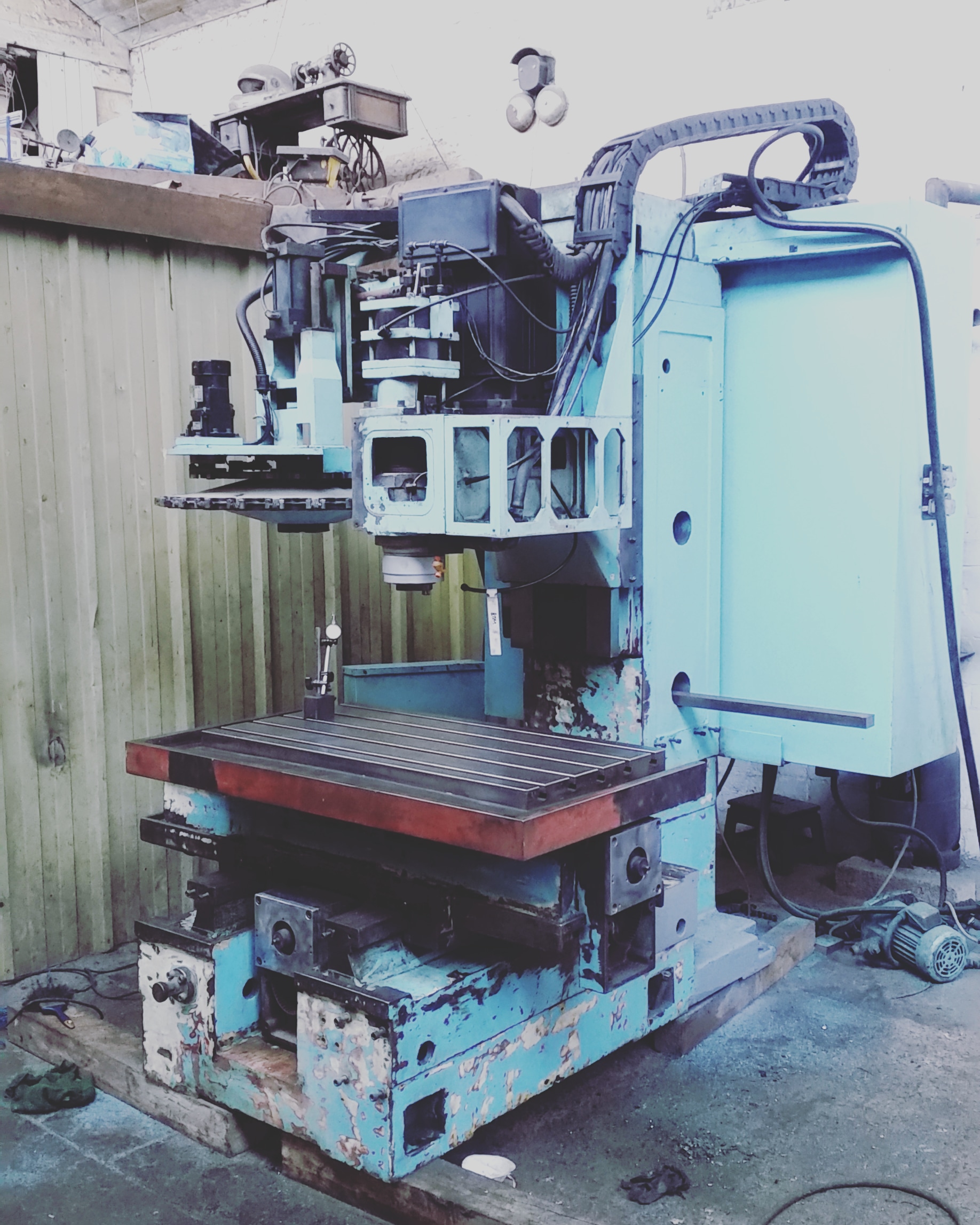

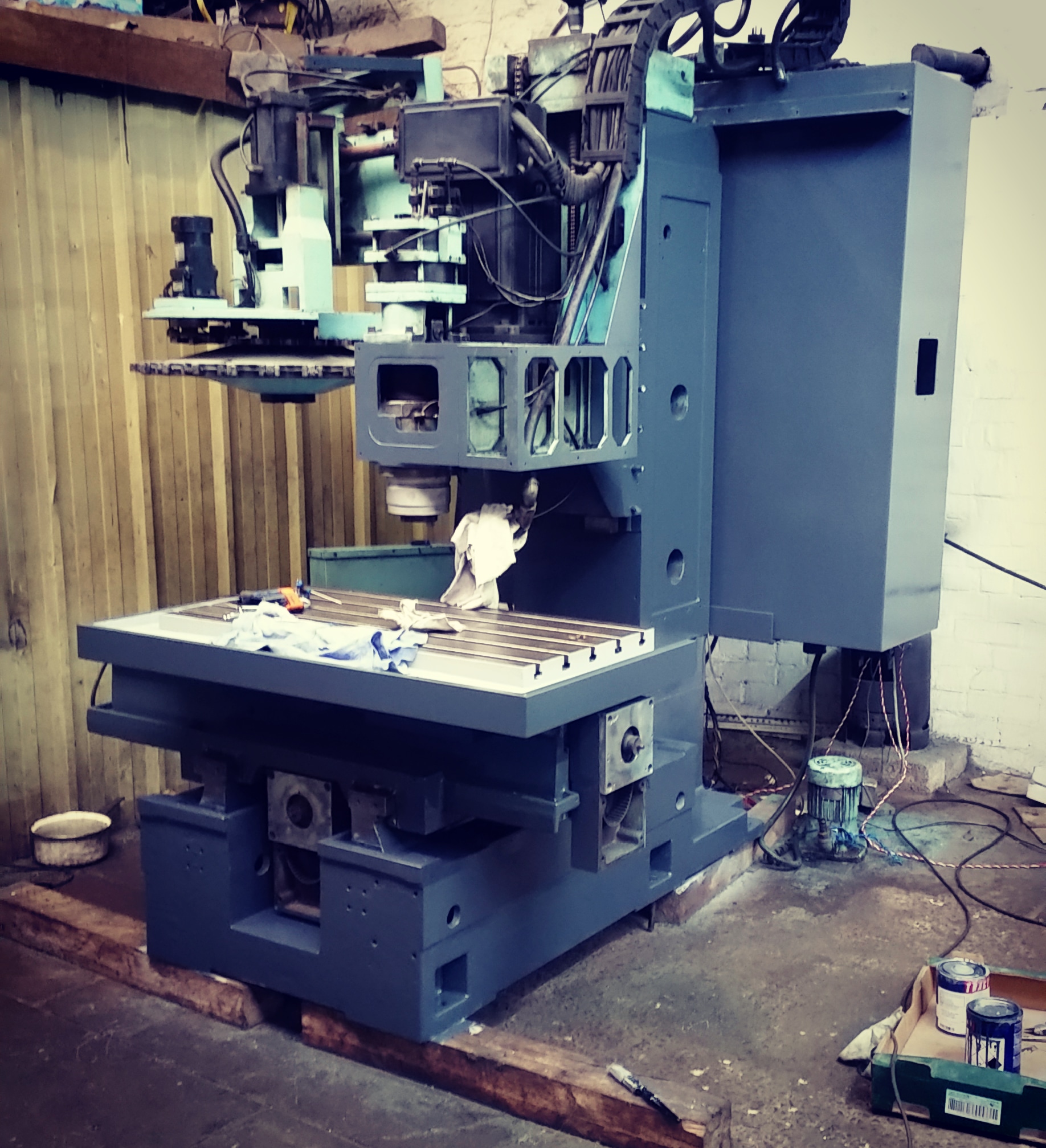

Thought I would share my rebuild of a 1989 vintage Hurco BMC30.

The machine was taken out of the previous owners workshop running however after sitting in another shed for around 6 months before reaching me 2 of the yaskawa servo drives went down. Speaking to several people in the know they all said that the particular drive used didn't like to be powered off for long. Apparently it was a common fault. I needed to sit down when I received the quote for repairing the drives @£1200 each, refurbished drives where quoted from £1200 to over £2000 with most expensive having a generous 30 day warranty! I decided a couldn't justify spending that amount of money on 30 year old electronics for the same or another part to go down in 6 months time so retrofit it is!

I have done a number of retrofits in the past with my last one being a Bridgeport Interact running linuxcnc so I'm fairly confident of getting the machine running however the spindle encoder, and tool changer are still unknowns!

The picture is of the machine the day it arrived.

The machine was taken out of the previous owners workshop running however after sitting in another shed for around 6 months before reaching me 2 of the yaskawa servo drives went down. Speaking to several people in the know they all said that the particular drive used didn't like to be powered off for long. Apparently it was a common fault. I needed to sit down when I received the quote for repairing the drives @£1200 each, refurbished drives where quoted from £1200 to over £2000 with most expensive having a generous 30 day warranty! I decided a couldn't justify spending that amount of money on 30 year old electronics for the same or another part to go down in 6 months time so retrofit it is!

I have done a number of retrofits in the past with my last one being a Bridgeport Interact running linuxcnc so I'm fairly confident of getting the machine running however the spindle encoder, and tool changer are still unknowns!

The picture is of the machine the day it arrived.

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

29 Mar 2018 22:38 #108087

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

I looked into buying second hand drives but none of the modern drives were compatible with the encoders in the motors and to be honest I don't know enough about ac drives and servos to really mess about, I just wanted a working machine. The next plan was to use mesa 8i20 drives and close the loop in linuxcnc however at the time I was trying to buy these OCT- DEC 2017 8i20s were out of stock. I contacted mesa, they were having some issues with component supply for building the drives, they hoped to have some back in stock within the month, the month came and went with no stock, I contacted mesa again and they where still having some issues, after a couple of months I gave up waiting and treated myself to x3 new 1kw motors and drives from DMM Technologies. Typically I received an email a couple of weeks later to says 8i20 were back in stock!

The new 1kw motors are fairly comparable in torque etc to the original 0.85kw yaskawa servos, they have a slightly higher rpm though.

It turns out technology has came on a long way in 30 years as far as servo motors go, I was genuinely worried I had overlooked something in the specs, the new motor is literally half the size of the original one and has more power!

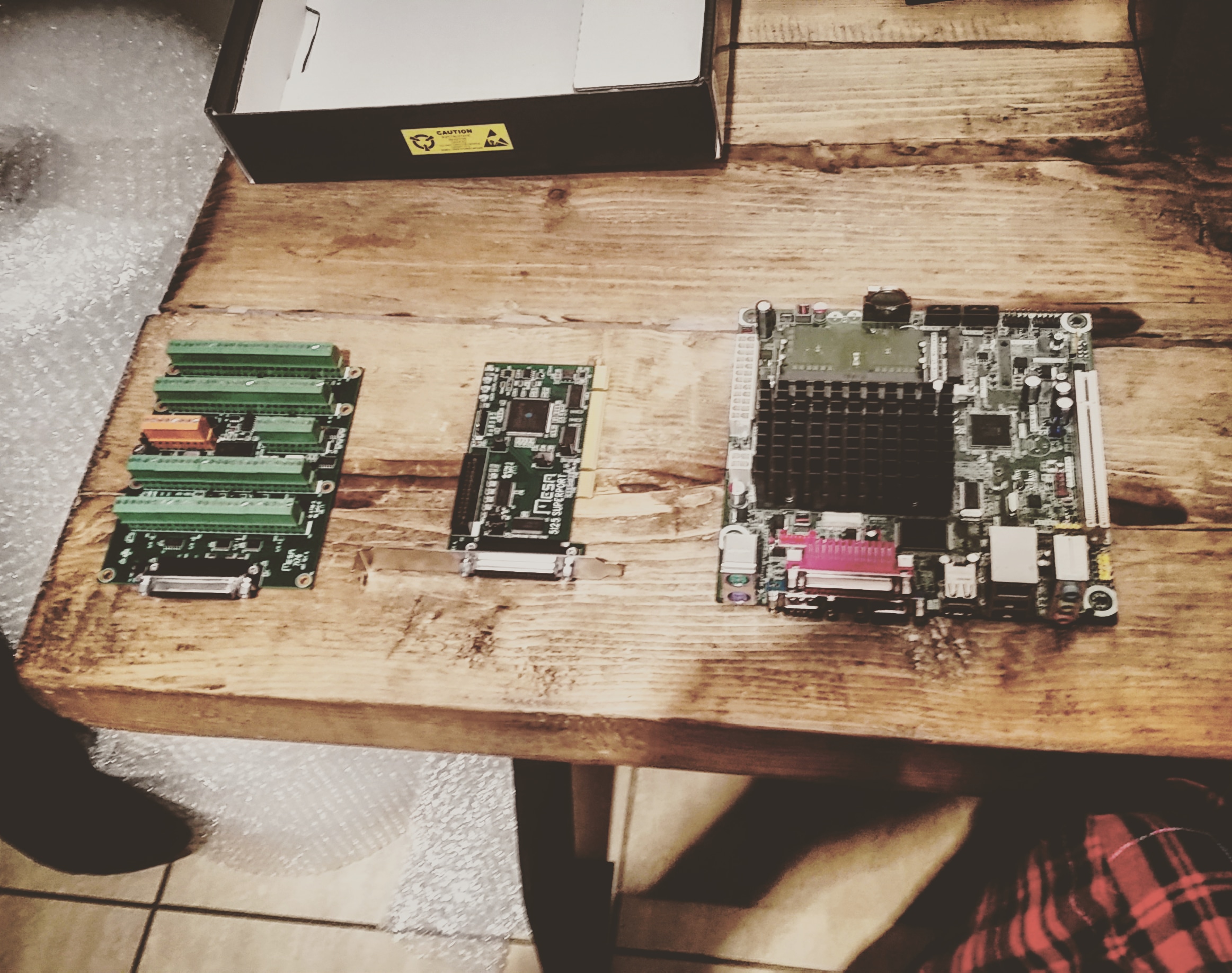

The DMM drives can take a variety of input signals but with the 16bit encoder in the motor and their really nice tuning software I decided to keep it simple by going for a pulse/direction setup and closing the loop between the drive and motor. With that in mind I ordered up a mesa 5i25/7i76 combo.

I decided if I was going to this far I would rather replace the spindle drive also, at least I know what I have and if anything breaks I can lift the phone and have a replacement within a couple of days. The original yaskawa was still working fine, it also housed the orient control for tool change which I'm going to have to work out. The original drive is a beast, it must weigh 40kgs!

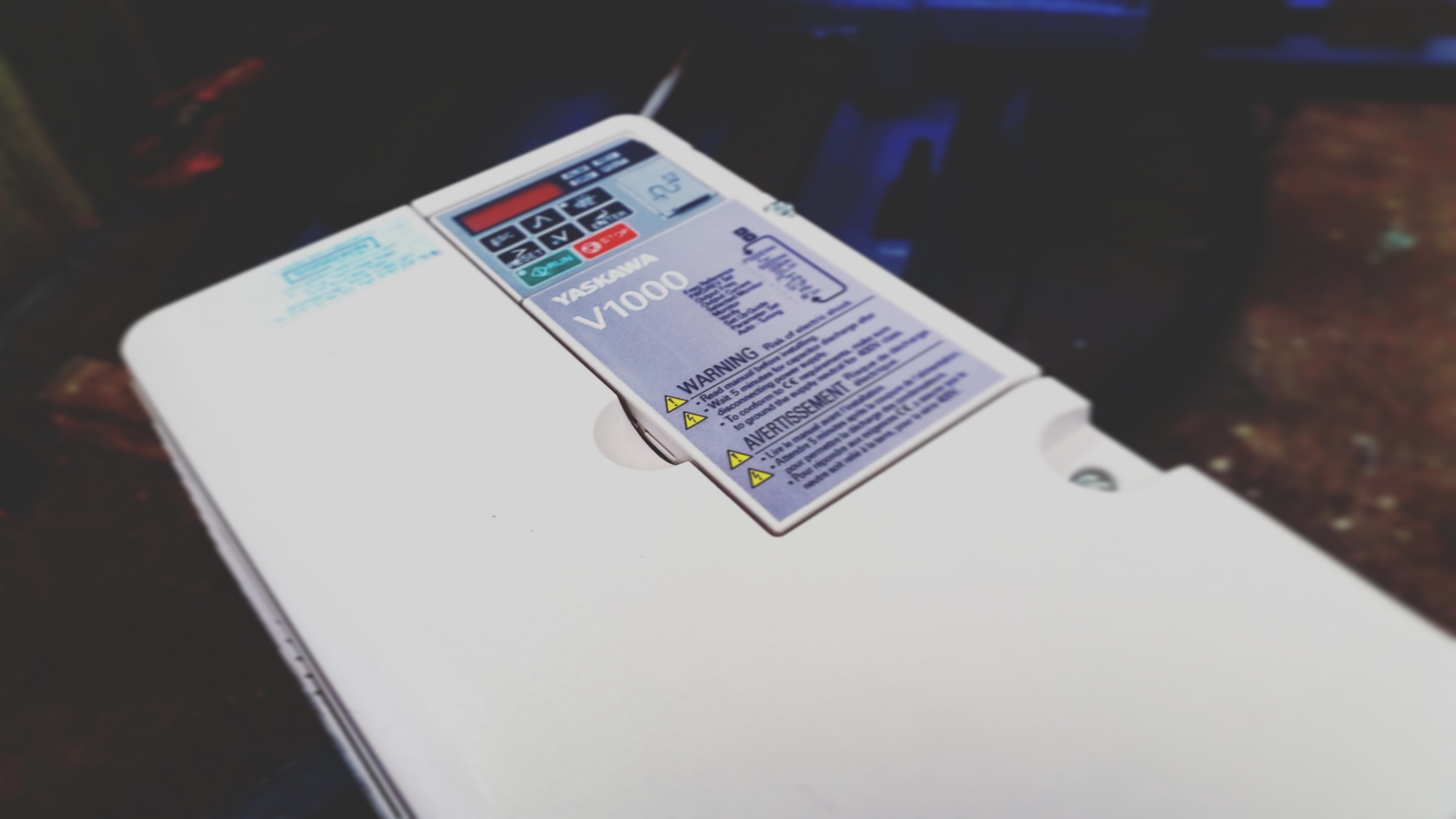

I ended up going for a Yaskawa V1000 Vector drive.

Just a warning, I'm pulling a lot of these images from my instagram so there are some filtered shots!

The new 1kw motors are fairly comparable in torque etc to the original 0.85kw yaskawa servos, they have a slightly higher rpm though.

It turns out technology has came on a long way in 30 years as far as servo motors go, I was genuinely worried I had overlooked something in the specs, the new motor is literally half the size of the original one and has more power!

The DMM drives can take a variety of input signals but with the 16bit encoder in the motor and their really nice tuning software I decided to keep it simple by going for a pulse/direction setup and closing the loop between the drive and motor. With that in mind I ordered up a mesa 5i25/7i76 combo.

I decided if I was going to this far I would rather replace the spindle drive also, at least I know what I have and if anything breaks I can lift the phone and have a replacement within a couple of days. The original yaskawa was still working fine, it also housed the orient control for tool change which I'm going to have to work out. The original drive is a beast, it must weigh 40kgs!

I ended up going for a Yaskawa V1000 Vector drive.

Just a warning, I'm pulling a lot of these images from my instagram so there are some filtered shots!

Attachment not found

Attachment not found

Attachment not found

Attachment not found

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

30 Mar 2018 20:07 #108128

by andypugh

Very filtered (they show "you do not have permissions to access this page")

Replied by andypugh on topic Hurco BMC30 Retrofit

Just a warning, I'm pulling a lot of these images from my instagram so there are some filtered shots!

Attachment not found

Very filtered (they show "you do not have permissions to access this page")

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Mar 2018 20:53 #108138

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Mar 2018 20:54 #108139

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Mar 2018 21:01 #108140

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

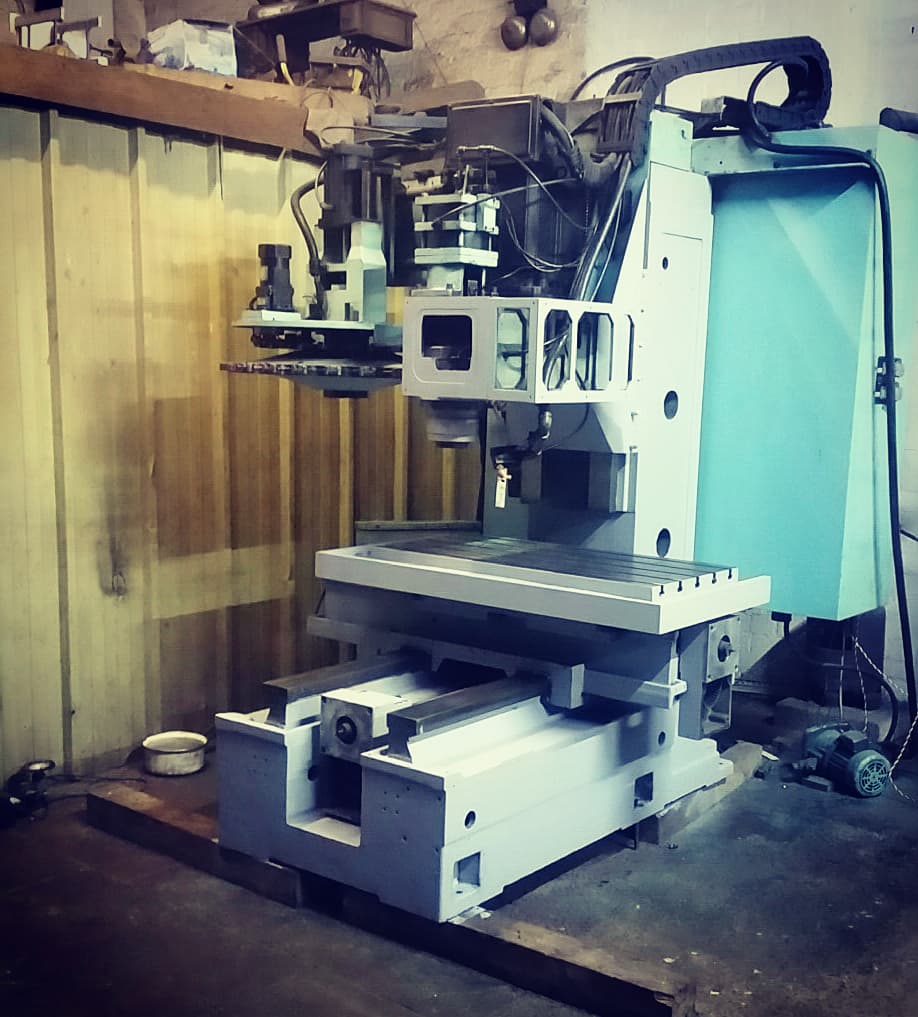

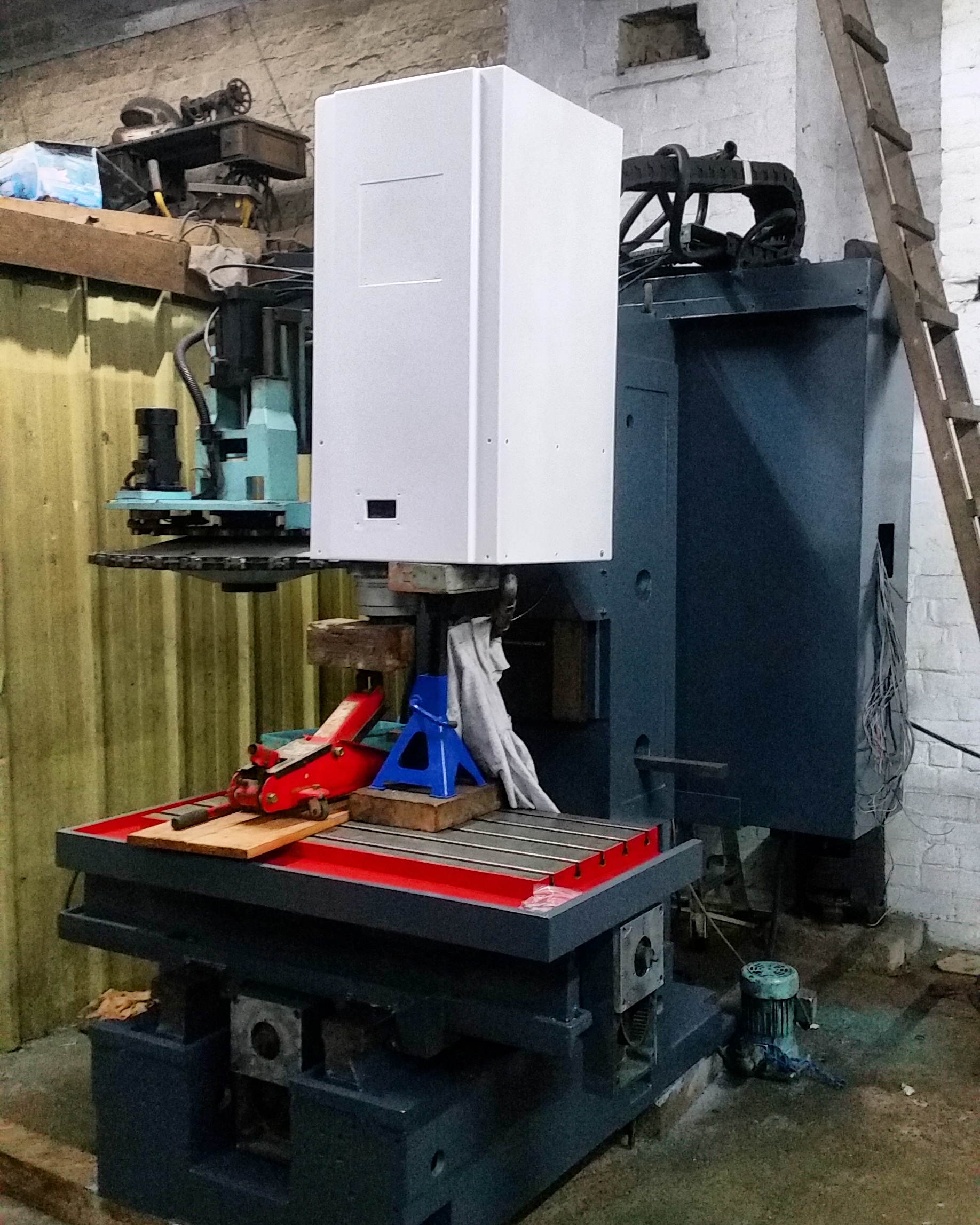

As I'm going so far with the electronics I thought I may as well repaint it at the same time.

I'm using a machinery enamel for the castings and a white 2k paint for all panels.

I stripped back to bare metal where required and back to the primer where I could get away with it. The castings had body fillers in a lot of places to smooth out the castings. Overall the old paint was pretty nasty stuff and I'm sure fairly unhealthy to be working with.

I'm using a machinery enamel for the castings and a white 2k paint for all panels.

I stripped back to bare metal where required and back to the primer where I could get away with it. The castings had body fillers in a lot of places to smooth out the castings. Overall the old paint was pretty nasty stuff and I'm sure fairly unhealthy to be working with.

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Mar 2018 21:03 #108141

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Mar 2018 21:08 #108142

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

30 Mar 2018 21:11 #108143

by andypugh

Working now. My mum has the same sewing machine

Replied by andypugh on topic Hurco BMC30 Retrofit

Lets try the photos again, they look great in the preview!

Working now. My mum has the same sewing machine

Please Log in or Create an account to join the conversation.

- Ozo

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 1

30 Mar 2018 21:34 #108146

by Ozo

Replied by Ozo on topic Hurco BMC30 Retrofit

Andy, Id probably be wiser learning how to use that than messing at cncs

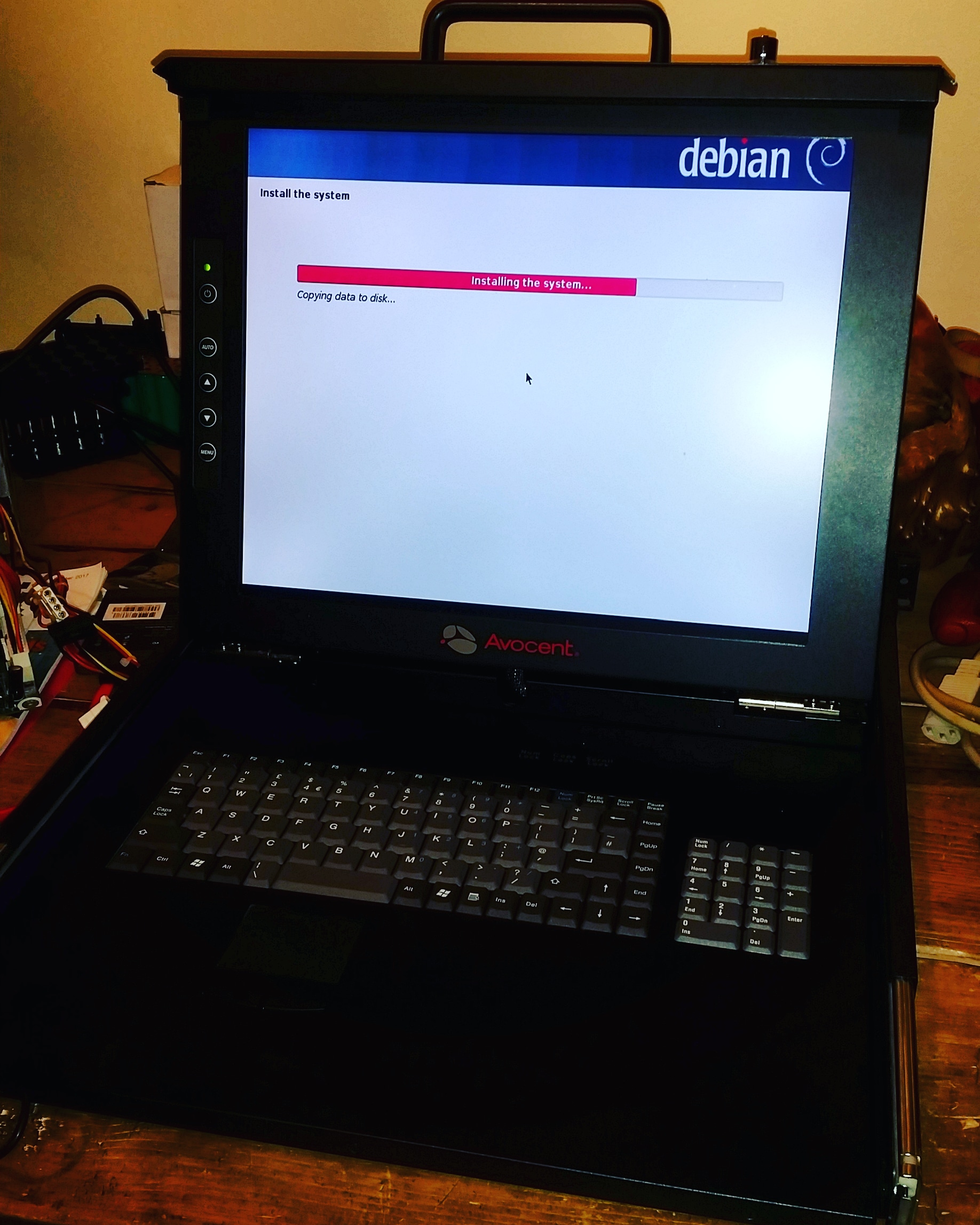

The next thing to do was strip out any of the old wiring i didn't need. The wiring was a complete rats nest not helped by the fact that on a lot of the heavier power cables the outer sheath was falling apart in my hands. I can only assume the older controllers were more resistant to noise than our "modern" controllers as there seems to be quite a few ground loops in the system. This coupled with a noisy transformer that tied neutral to earth has given me a lot of issues. At worst it was enough to glitch the pc or complete shut it off, this also meant I was getting axis drift. I still have a little flickering on my screen and the ps2 wires for keyboard and mouse don't like it however usb connection doesn't seem to be affected at all. Its definitely still a work in progress but if it comes to it I will move the PC outside. At the moment it is mounted with no case inside one of the control enclosures.

The next thing to do was strip out any of the old wiring i didn't need. The wiring was a complete rats nest not helped by the fact that on a lot of the heavier power cables the outer sheath was falling apart in my hands. I can only assume the older controllers were more resistant to noise than our "modern" controllers as there seems to be quite a few ground loops in the system. This coupled with a noisy transformer that tied neutral to earth has given me a lot of issues. At worst it was enough to glitch the pc or complete shut it off, this also meant I was getting axis drift. I still have a little flickering on my screen and the ps2 wires for keyboard and mouse don't like it however usb connection doesn't seem to be affected at all. Its definitely still a work in progress but if it comes to it I will move the PC outside. At the moment it is mounted with no case inside one of the control enclosures.

Please Log in or Create an account to join the conversation.

Time to create page: 0.267 seconds