Learn CAD/CAM or Gcode

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 120

- Thank you received: 1

29 Jan 2013 09:37 #29251

by Sterling

Learn CAD/CAM or Gcode was created by Sterling

Howdy all...

I've constructed my CNC machine, installed PC/software (running the latest Linux version) and cut the LinuxCNC sample file into a board.

My primary reasoning for building the machine is to make cribbage boards. I would like the machine to drill the custom designed peg-hole patterns, (as I'm sure that the machine will drill them precisely where they ought to be, and much faster than I); leaving the artistic designs to me (drawings, custom shapes, and surface designs, etc...)

So - to get the hole-patterns started, I'm planning to try the GUI route first as I have a Windows background and know essentially nothing about Linux. Would it be practical to download CAD / CAM software (such as LibreCAD / SketchUP etc ), import my designs, then export them into the 3D designs for the machine to use?

-or-

I'm thinking the alternative is to try to learn Gcode...and learning any coding is a bit intimidating to me.

I'd be delighted to read any thoughts/inputs/suggestions from you folks...!!

Thanx~!

>>> Sterl

I've constructed my CNC machine, installed PC/software (running the latest Linux version) and cut the LinuxCNC sample file into a board.

My primary reasoning for building the machine is to make cribbage boards. I would like the machine to drill the custom designed peg-hole patterns, (as I'm sure that the machine will drill them precisely where they ought to be, and much faster than I); leaving the artistic designs to me (drawings, custom shapes, and surface designs, etc...)

So - to get the hole-patterns started, I'm planning to try the GUI route first as I have a Windows background and know essentially nothing about Linux. Would it be practical to download CAD / CAM software (such as LibreCAD / SketchUP etc ), import my designs, then export them into the 3D designs for the machine to use?

-or-

I'm thinking the alternative is to try to learn Gcode...and learning any coding is a bit intimidating to me.

I'd be delighted to read any thoughts/inputs/suggestions from you folks...!!

Thanx~!

>>> Sterl

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 758

29 Jan 2013 18:17 #29255

by ArcEye

Replied by ArcEye on topic Learn CAD/CAM or Gcode

Hi

For something as simple as drilling 12 patterns of 10 holes, CAD / CAM would be total overkill.

Also if you do not learn the basics of G Code, you will have great problems correcting the output from CAM or even appreciating what is does.

What you want to do can easily be achieved using a canned drilling cycle, but it might even be best to start by programming it 'longhand' , as a learning exercise.

You simply need to touch off at the first hole in one line, then drill that and move incrementally (G91) by the hole spacing required and drill the next until you have drilled the first 5 holes.

Then move whatever spacing there is between the groups and do it again for the next 5 holes etc etc.

In the process you will become familiar with G90 G91, G01, X Y and Z moves, Feed Spindle speed etc etc

All this can be done in the MDI tab, without having to write a program and then you can cut and paste the relevant bits from the MDI into a file, add a header and footer and you have written your first G Code!

Hands on, doing simple stuff like this is definitely the best way to learn, its what I did years ago, replacing manual movements of the table and quill that I was used to, with MDI commands to do the same thing.

regards

For something as simple as drilling 12 patterns of 10 holes, CAD / CAM would be total overkill.

Also if you do not learn the basics of G Code, you will have great problems correcting the output from CAM or even appreciating what is does.

What you want to do can easily be achieved using a canned drilling cycle, but it might even be best to start by programming it 'longhand' , as a learning exercise.

You simply need to touch off at the first hole in one line, then drill that and move incrementally (G91) by the hole spacing required and drill the next until you have drilled the first 5 holes.

Then move whatever spacing there is between the groups and do it again for the next 5 holes etc etc.

In the process you will become familiar with G90 G91, G01, X Y and Z moves, Feed Spindle speed etc etc

All this can be done in the MDI tab, without having to write a program and then you can cut and paste the relevant bits from the MDI into a file, add a header and footer and you have written your first G Code!

Hands on, doing simple stuff like this is definitely the best way to learn, its what I did years ago, replacing manual movements of the table and quill that I was used to, with MDI commands to do the same thing.

regards

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

29 Jan 2013 19:41 #29256

by BigJohnT

Replied by BigJohnT on topic Learn CAD/CAM or Gcode

I have a medium priced CAM software and almost never use it for drilling holes and prefer to just type in the coordinates and use the canned cycles as it is so much faster. And like ArcEye says if you don't know G code you can't fix the mistakes that the post processor makes.

As a start I'd read my G code tutorial then read the canned cycles section of the user manual.

John

As a start I'd read my G code tutorial then read the canned cycles section of the user manual.

John

Please Log in or Create an account to join the conversation.

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 120

- Thank you received: 1

29 Jan 2013 22:15 #29261

by Sterling

Replied by Sterling on topic Learn CAD/CAM or Gcode

Thanx guys~! I'm thinking you're totally correct. I spent hours yesterday working on stuff.

I downloaded a couple utilities and worked on them...just to try an make a simple board with holes reminded me of when I first used MS Project back in 1998 (It was like driving a finishing nail with a sledgehammer). So, it seemed that if I could get the basis of the Gcode down, it ought to be a simple matter of 'cut-n-paste' the lines of code.

I had bookmarked some Gcode data on-line (including BigJohnT's material) and went over that a few times as well. I typed out some things and I might have the basis of what I need. I'm going to give it a go later today, and if it doesn't work and doesn't make sense, would you gents let me know what I've done wrong? This is a new venture for me, and obviously, I won't ask you folks to do the coding for me-but sometimes the human brain sets up its own roadblocks!

Thanx -

>>> Sterl

I downloaded a couple utilities and worked on them...just to try an make a simple board with holes reminded me of when I first used MS Project back in 1998 (It was like driving a finishing nail with a sledgehammer). So, it seemed that if I could get the basis of the Gcode down, it ought to be a simple matter of 'cut-n-paste' the lines of code.

I had bookmarked some Gcode data on-line (including BigJohnT's material) and went over that a few times as well. I typed out some things and I might have the basis of what I need. I'm going to give it a go later today, and if it doesn't work and doesn't make sense, would you gents let me know what I've done wrong? This is a new venture for me, and obviously, I won't ask you folks to do the coding for me-but sometimes the human brain sets up its own roadblocks!

Thanx -

>>> Sterl

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

29 Jan 2013 23:33 - 29 Jan 2013 23:33 #29265

by BigJohnT

Replied by BigJohnT on topic Learn CAD/CAM or Gcode

Just start simple, sort out what you need for your preamble line then M2 at the end and put some code in the middle to drill the holes.

John

John

Last edit: 29 Jan 2013 23:33 by BigJohnT.

Please Log in or Create an account to join the conversation.

- jaredts

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 2

30 Jan 2013 01:48 #29276

by jaredts

Replied by jaredts on topic Learn CAD/CAM or Gcode

I won't disagree with anything said--you need to start with gcode. I lean toward cad/cam however. I've done a lot of both, and my experience is that cam is not only faster in almost every case, there are less errors and it is associative in most software to changes you make. Just drilling holes--it's a tossup depending on how many you are drilling and how often you need to make a new program. If you don't understand gcode or machining then accepting a program from cam software is a little dangerous.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

30 Jan 2013 01:57 #29277

by BigJohnT

+1 on understanding what your cam post processor spits out.

On my Hardinge CHCN lathe I can do 95% of the ops right at the machine using ngcgui and that is much faster than opening up a cam program. On my mill and plasma the story is quite different. On the plasma I do about 15% of the ops with ngcgui like square and round cuts, the rest I use cam and seldom program by hand for the plasma. On the mill it is about 25% ngcgui, 25% just spinning the MPG, 25% hand coding and 25% cam. So it really depends on your needs what suits the best.

John

Replied by BigJohnT on topic Learn CAD/CAM or Gcode

I won't disagree with anything said--you need to start with gcode. I lean toward cad/cam however. I've done a lot of both, and my experience is that cam is not only faster in almost every case, there are less errors and it is associative in most software to changes you make. Just drilling holes--it's a tossup depending on how many you are drilling and how often you need to make a new program. If you don't understand gcode or machining then accepting a program from cam software is a little dangerous.

+1 on understanding what your cam post processor spits out.

On my Hardinge CHCN lathe I can do 95% of the ops right at the machine using ngcgui and that is much faster than opening up a cam program. On my mill and plasma the story is quite different. On the plasma I do about 15% of the ops with ngcgui like square and round cuts, the rest I use cam and seldom program by hand for the plasma. On the mill it is about 25% ngcgui, 25% just spinning the MPG, 25% hand coding and 25% cam. So it really depends on your needs what suits the best.

John

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 155

30 Jan 2013 20:43 #29307

by Rick G

Replied by Rick G on topic Learn CAD/CAM or Gcode

All good information.

In the real world I spend a lot of time in CAD, so for complicated designs it is a natural choice for me.

However as John has stated many tasks can be accomplished with NGCGUI and I am using that more and more.

When you design your pattern if you know the X and Y coordinates of the holes you might want to look at position.ngc which is a NGCGUI program that you input the coordinates and it will send the machine to the exact location.

www.linuxcnc.org/media/kunena/attachment...y/files/position.ngc

The above version will send the machine to the specified locations and then pause for you to drill, the locations can also be saved to a file for later use.

I have a modified version that instead of pausing also drills holes or bores circles. I can post for you if you want to try this solution.

Rick G

In the real world I spend a lot of time in CAD, so for complicated designs it is a natural choice for me.

However as John has stated many tasks can be accomplished with NGCGUI and I am using that more and more.

When you design your pattern if you know the X and Y coordinates of the holes you might want to look at position.ngc which is a NGCGUI program that you input the coordinates and it will send the machine to the exact location.

www.linuxcnc.org/media/kunena/attachment...y/files/position.ngc

The above version will send the machine to the specified locations and then pause for you to drill, the locations can also be saved to a file for later use.

I have a modified version that instead of pausing also drills holes or bores circles. I can post for you if you want to try this solution.

Rick G

Please Log in or Create an account to join the conversation.

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 120

- Thank you received: 1

31 Jan 2013 03:04 #29329

by Sterling

Replied by Sterling on topic Learn CAD/CAM or Gcode

Howdy gents =

Thank you for the help/input~! I will certainly look into that file Rick G.

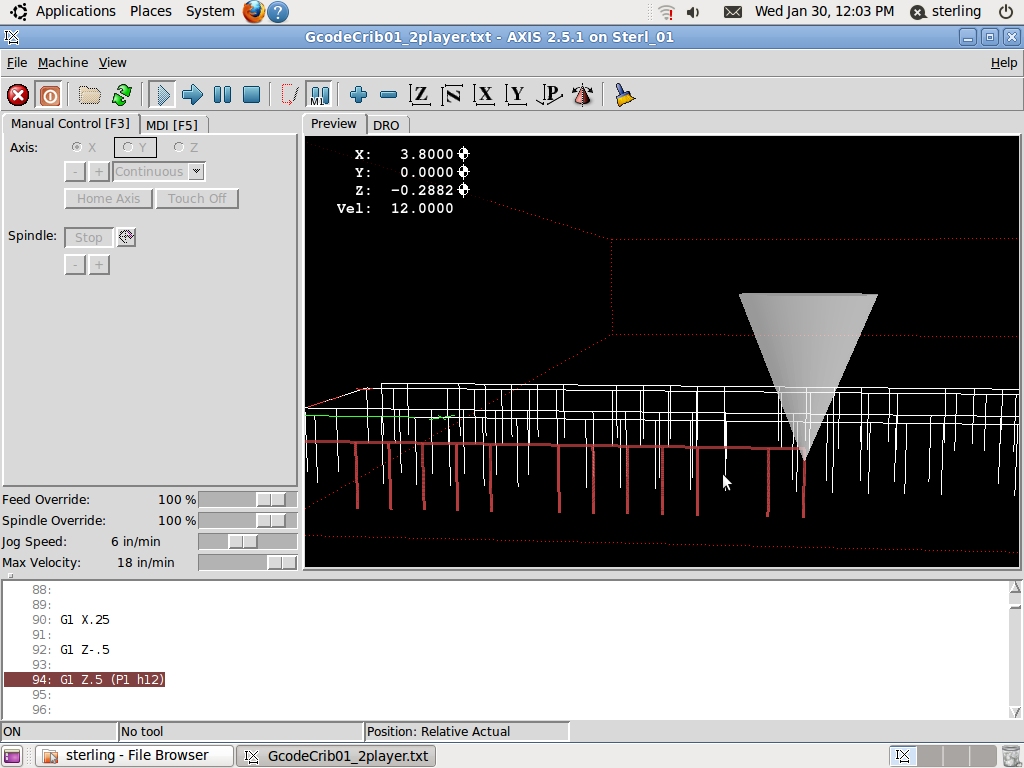

In the interim, I have completed my first Gcode, and it worked (mostly).

The issues that prevented it from being perfect are...

#1) it did not follow the lines precisely

#2) It did not follow the HOME command at the end

#3) It burned the wood (I'm using a Vermont American carbide bit to drill. The router spins at 26k)

Here is my GCode file.

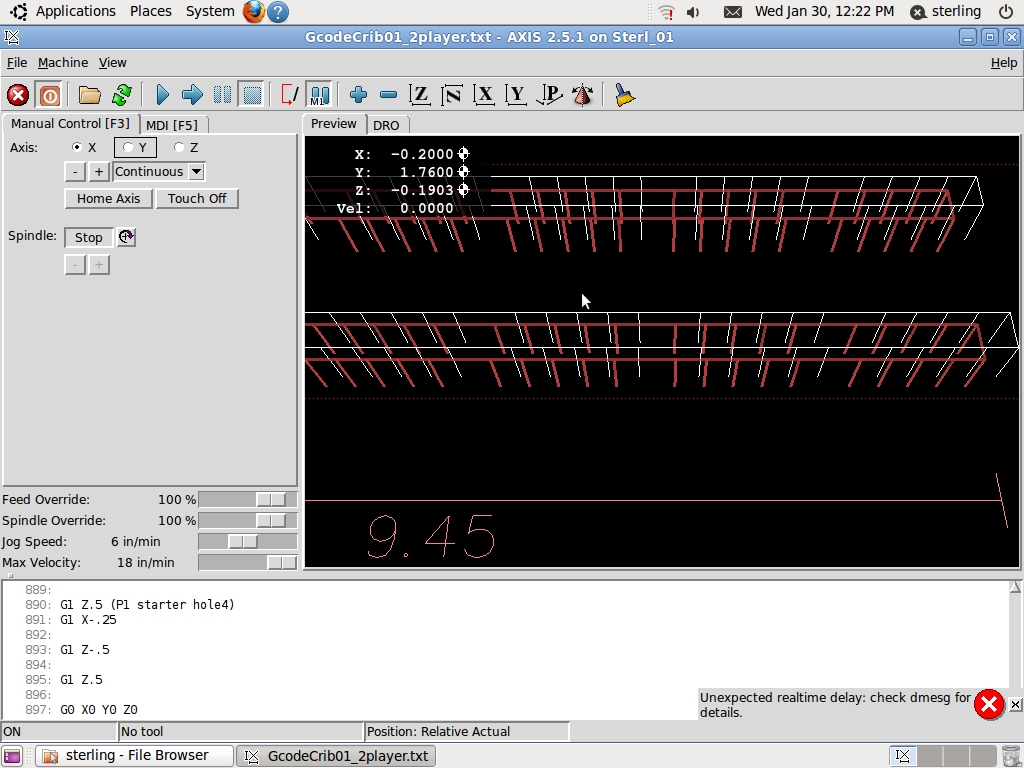

Below are two images of the program, you can see that it 'mirrored' the path, but didn't follow it exactly.

...and...

Thanx again~!

>>> Sterl

Thank you for the help/input~! I will certainly look into that file Rick G.

In the interim, I have completed my first Gcode, and it worked (mostly).

The issues that prevented it from being perfect are...

#1) it did not follow the lines precisely

#2) It did not follow the HOME command at the end

#3) It burned the wood (I'm using a Vermont American carbide bit to drill. The router spins at 26k)

Here is my GCode file.

Below are two images of the program, you can see that it 'mirrored' the path, but didn't follow it exactly.

...and...

Thanx again~!

>>> Sterl

Please Log in or Create an account to join the conversation.

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 120

- Thank you received: 1

31 Jan 2013 03:06 #29330

by Sterling

Replied by Sterling on topic Learn CAD/CAM or Gcode

Oh, the error message in the corner happened when I pressed the [pause] button. I let it sit for a couple minutes to cool it off. I did this when it was half way done with the 2nd path.

Thanx -

>>> Sterl

Thanx -

>>> Sterl

Please Log in or Create an account to join the conversation.

Time to create page: 0.113 seconds