- Other Stuff

- User Exchange

- Trying to avoid learning by asking if someone can be paid (very little) to help

Trying to avoid learning by asking if someone can be paid (very little) to help

- rudy

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

30 May 2019 19:59 #135419

by rudy

Trying to avoid learning by asking if someone can be paid (very little) to help was created by rudy

What I want to do is put the image of a buffalo in 3d on a panel that's 84" high and 118" wide. It will actually consist of 6 doors fitted tightly together (they pop out 2" when pushed in, then open on hinges). I have not determined the type of wood - test doors made from solid hickory, poplar, and hemlock are currently hanging to see how much they warp. Test doors are about 3/4" inch. real ones can be thicker. I have a friend who has a 22" wide CNC router who can do the cutting (don't know right now what machine he has, will find out). I have collected some candidate buffalo pictures from the web but have absolutely no artistic sense and would like to avoid the rather steep learning curve between knowing nothing and being able to do at least a half decent job of creating the gcode needed.

Is anyone interested in helping out? if so, please contact me rudy at winface.com

Is anyone interested in helping out? if so, please contact me rudy at winface.com

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

31 May 2019 09:07 #135452

by pl7i92

Replied by pl7i92 on topic Trying to avoid learning by asking if someone can be paid (very little) to help

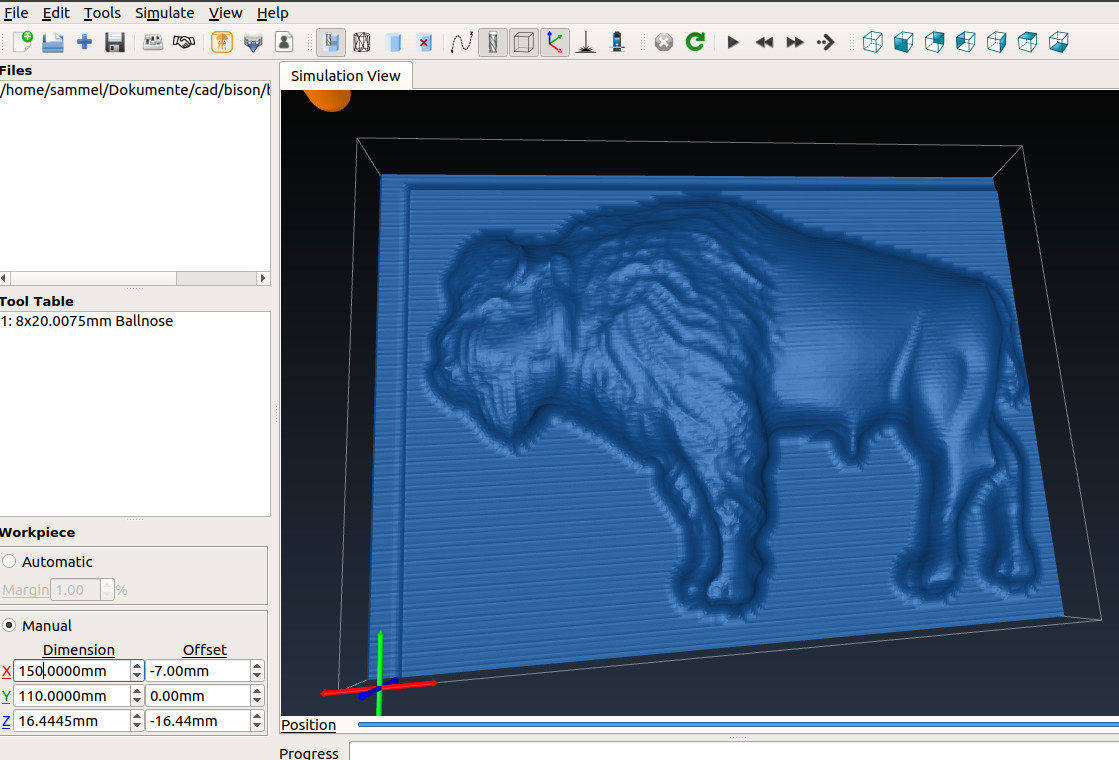

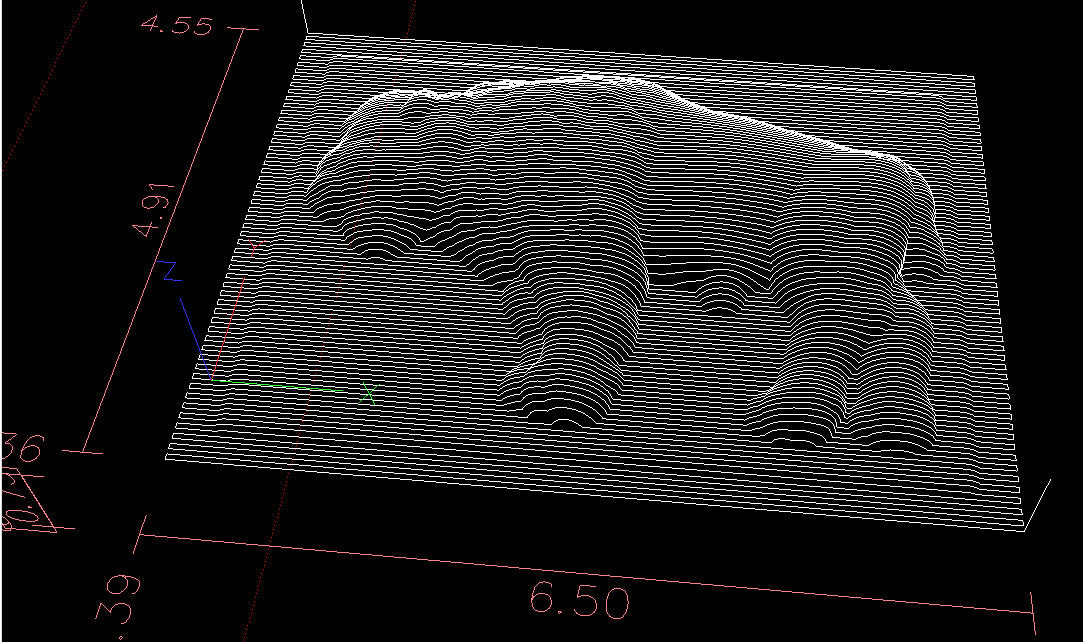

Attachments:

Please Log in or Create an account to join the conversation.

- rudy

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

31 May 2019 13:16 #135465

by rudy

Replied by rudy on topic Trying to avoid learning by asking if someone can be paid (very little) to help

Wow!

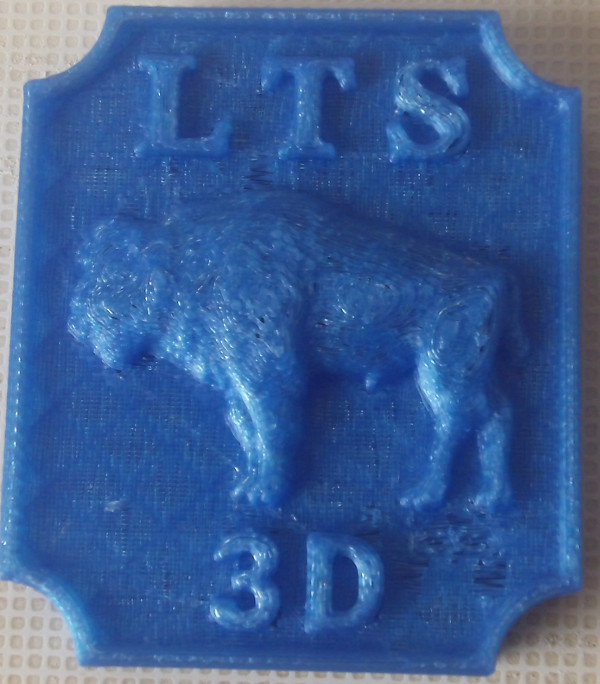

Your buffalo is pretty much exactly what I have in mind - guess that's a "plate 3d sculpt"?

I don't know how big yours is, (particularly in terms of depth) or how scalable the gcode is but that image exemplifies the idea.

Now.. the wall this is going on is 118" (nearly 3M) wide by 90" (about 2.25M) from carpet to ceiling so net about 118 x 82 seems likely. My big issue, other than the gcode, is ensuring that the wood doesn't warp or expand/contract and that will be affected by the depth needed for the image. So, for this to work, how thick do you need the wood to be?

Your buffalo is pretty much exactly what I have in mind - guess that's a "plate 3d sculpt"?

I don't know how big yours is, (particularly in terms of depth) or how scalable the gcode is but that image exemplifies the idea.

Now.. the wall this is going on is 118" (nearly 3M) wide by 90" (about 2.25M) from carpet to ceiling so net about 118 x 82 seems likely. My big issue, other than the gcode, is ensuring that the wood doesn't warp or expand/contract and that will be affected by the depth needed for the image. So, for this to work, how thick do you need the wood to be?

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

31 May 2019 15:14 #135475

by pl7i92

Replied by pl7i92 on topic Trying to avoid learning by asking if someone can be paid (very little) to help

this is all scalable in all axis

Primary wood be to know what your friend can do

the toolsize BALL Cutter

the mashine Rough capability (( ok Feeds can be Changed )))

BUT nit the steps

IS Your friend able to get a G-code from a STL file i guess YES as he ownes a mashine

I will do a Gcode on your Request of the TOP tread

Primary wood be to know what your friend can do

the toolsize BALL Cutter

the mashine Rough capability (( ok Feeds can be Changed )))

BUT nit the steps

IS Your friend able to get a G-code from a STL file i guess YES as he ownes a mashine

I will do a Gcode on your Request of the TOP tread

Please Log in or Create an account to join the conversation.

- rudy

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

31 May 2019 15:48 #135479

by rudy

Replied by rudy on topic Trying to avoid learning by asking if someone can be paid (very little) to help

I have asked Euan for details on his machine. I know he can handle up to 22" in width and can feed whatever length is needed. He has many different cutters, and we can get anything needed.

What thickness should the wood be?

(Ich spreche oder schreibe kein Deutsch, kann es aber gut genug lesen, um zurechtzukommen - insbesondere mit Hilfe von Google Translate. Bitte verwenden Sie Deutsch, wenn es Ihnen leichter fällt.)

What thickness should the wood be?

(Ich spreche oder schreibe kein Deutsch, kann es aber gut genug lesen, um zurechtzukommen - insbesondere mit Hilfe von Google Translate. Bitte verwenden Sie Deutsch, wenn es Ihnen leichter fällt.)

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

31 May 2019 18:30 #135495

by pl7i92

Replied by pl7i92 on topic Trying to avoid learning by asking if someone can be paid (very little) to help

Please Log in or Create an account to join the conversation.

- rudy

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

31 May 2019 19:56 #135499

by rudy

Replied by rudy on topic Trying to avoid learning by asking if someone can be paid (very little) to help

Thank you!

I should find out about machine options and scale during the next week or so and will get back to you (via this site) as soon as I have the info.

I should find out about machine options and scale during the next week or so and will get back to you (via this site) as soon as I have the info.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4599

01 Jun 2019 00:08 #135514

by andypugh

Replied by andypugh on topic Trying to avoid learning by asking if someone can be paid (very little) to help

If the router in question runs LinuxCNC then you can just open the JPEG file in Axis.

That will automatically run the image-to-G-code application.

That will automatically run the image-to-G-code application.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

01 Jun 2019 08:18 #135549

by pl7i92

Replied by pl7i92 on topic Trying to avoid learning by asking if someone can be paid (very little) to help

the image is to Dark for details

Tryed it

Tryed it

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

11 Jun 2019 07:42 - 11 Jun 2019 07:43 #136562

by pl7i92

Replied by pl7i92 on topic Trying to avoid learning by asking if someone can be paid (very little) to help

Attachments:

Last edit: 11 Jun 2019 07:43 by pl7i92.

Please Log in or Create an account to join the conversation.

- Other Stuff

- User Exchange

- Trying to avoid learning by asking if someone can be paid (very little) to help

Time to create page: 0.172 seconds