G71, G70 cycle for lathes (first tests)

- jlviloria

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 9

27 Sep 2013 01:13 - 29 Sep 2013 01:15 #39228

by jlviloria

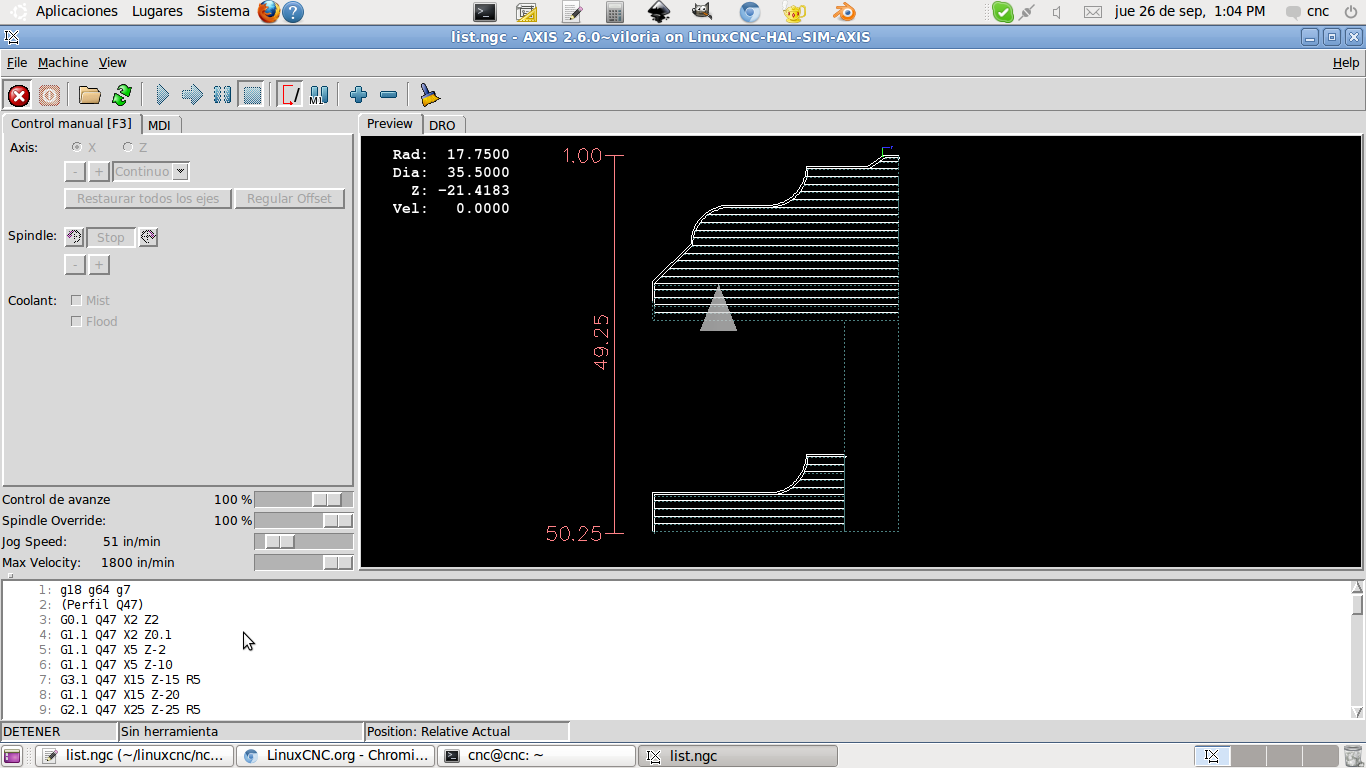

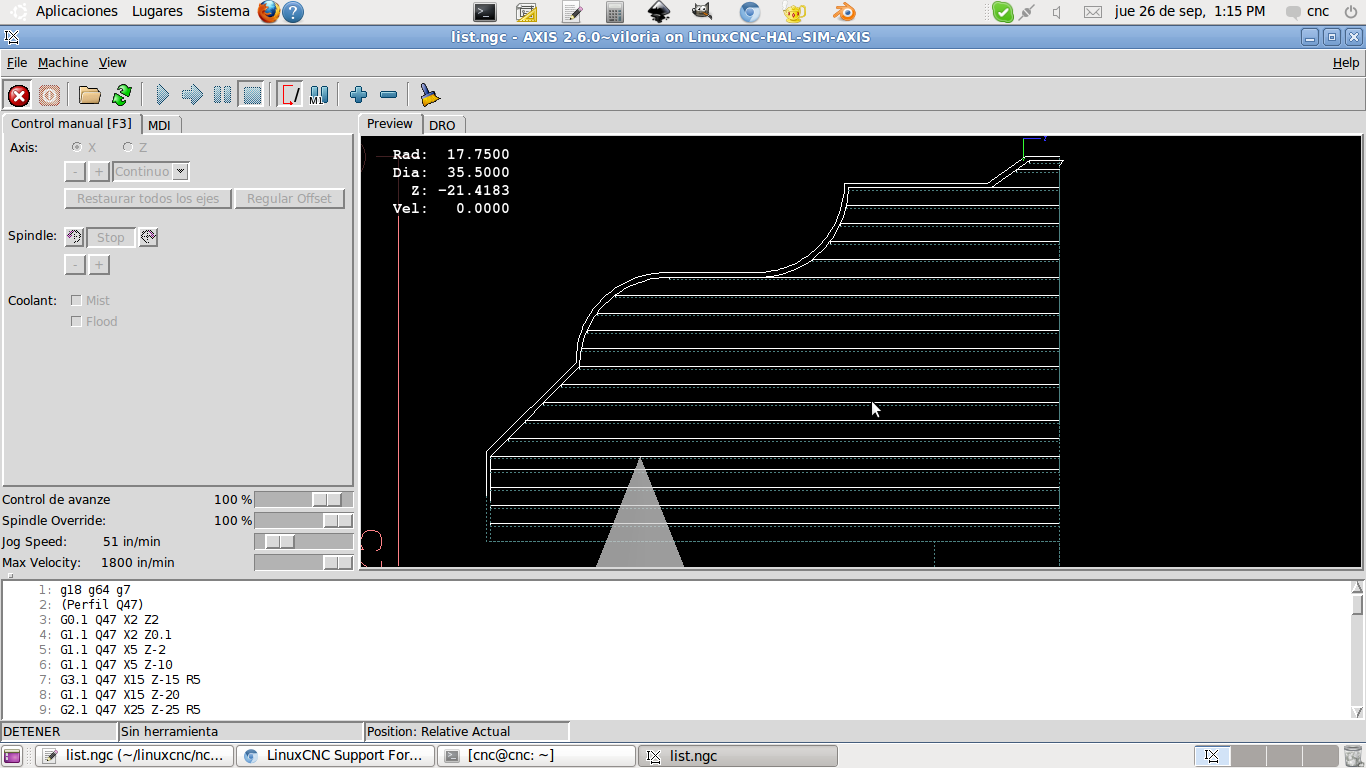

G71, G70 cycle for lathes (first tests) was created by jlviloria

Regards,

Continuing the search for the solution to the problems of my lathe.

The posting for inspection, test, criticize or improve.

At the moment only for external profiles, unfortunately not modal, for now.

The constant cutting depth, the depth varies agree programmed cutting.

I have some concerns that I could not solve,

1) when an error in the programming and chasten the program does not take change well, I have to close and reopen LinuxCNC, so assume correctly.

2) how I can make modal coordinates??? they are not repeated in each block.

3) I hope some suggestions to get better work.

Example=

g18 g64 g7

(Perfil Q47)

G0.1 Q47 X2 Z2

G1.1 Q47 X2 Z0.1

G1.1 Q47 X5 Z-2

G1.1 Q47 X5 Z-10

G3.1 Q47 X15 Z-15 R5

G1.1 Q47 X15 Z-20

G2.1 Q47 X25 Z-25 R5

G1.1 Q47 X35 Z-30

G1.1 Q47 X40 Z-30

(Ciclo de desbaste Q47)

G0 X45

Z2

G71 Q47 P1 R0.3 i0.5 k0.2 F1500

(Perfil Q48)

G0.1 Q48 X80 Z-5

G1.1 Q48 X80 Z-10

G3.1 Q48 X90 Z-15 R5

G1.1 Q48 X90 Z-30

G1.1 Q48 X100 Z-30

(Ciclo de desbaste Q47)

G0 X100

Z-5

G71 Q48 P1 R0.3 I0.5 K0.2 F1500

(Ciclo de acabado Q47)

G0 X45

Z2

G70 Q47 F1500

Continuing the search for the solution to the problems of my lathe.

The posting for inspection, test, criticize or improve.

At the moment only for external profiles, unfortunately not modal, for now.

The constant cutting depth, the depth varies agree programmed cutting.

I have some concerns that I could not solve,

1) when an error in the programming and chasten the program does not take change well, I have to close and reopen LinuxCNC, so assume correctly.

2) how I can make modal coordinates??? they are not repeated in each block.

3) I hope some suggestions to get better work.

Example=

g18 g64 g7

(Perfil Q47)

G0.1 Q47 X2 Z2

G1.1 Q47 X2 Z0.1

G1.1 Q47 X5 Z-2

G1.1 Q47 X5 Z-10

G3.1 Q47 X15 Z-15 R5

G1.1 Q47 X15 Z-20

G2.1 Q47 X25 Z-25 R5

G1.1 Q47 X35 Z-30

G1.1 Q47 X40 Z-30

(Ciclo de desbaste Q47)

G0 X45

Z2

G71 Q47 P1 R0.3 i0.5 k0.2 F1500

(Perfil Q48)

G0.1 Q48 X80 Z-5

G1.1 Q48 X80 Z-10

G3.1 Q48 X90 Z-15 R5

G1.1 Q48 X90 Z-30

G1.1 Q48 X100 Z-30

(Ciclo de desbaste Q47)

G0 X100

Z-5

G71 Q48 P1 R0.3 I0.5 K0.2 F1500

(Ciclo de acabado Q47)

G0 X45

Z2

G70 Q47 F1500

Last edit: 29 Sep 2013 01:15 by jlviloria.

Please Log in or Create an account to join the conversation.

- jlviloria

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 9

27 Sep 2013 01:14 #39229

by jlviloria

Replied by jlviloria on topic G71, G70 cycle for lathes (first tests)

The following user(s) said Thank You: fixer

Please Log in or Create an account to join the conversation.

- fixer

- Offline

- Premium Member

-

Less

More

- Posts: 132

- Thank you received: 27

06 Jun 2016 20:20 #75582

by fixer

Replied by fixer on topic G71, G70 cycle for lathes (first tests)

This looks interesting. Have you done some more work on it? Have you solved the bugs? How do you handle pockets?

Please Log in or Create an account to join the conversation.

- nkp

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 39

09 Jun 2016 03:58 #75706

by nkp

Replied by nkp on topic G71, G70 cycle for lathes (first tests)

I tried to solve the same problem

github.com/nkp2169/G71

www.cnc-club.ru/forum/viewtopic.php?f=15...955&p=265717#p265717

github.com/nkp2169/G71

www.cnc-club.ru/forum/viewtopic.php?f=15...955&p=265717#p265717

The following user(s) said Thank You: andypugh, dinkata

Please Log in or Create an account to join the conversation.

- fixer

- Offline

- Premium Member

-

Less

More

- Posts: 132

- Thank you received: 27

09 Jun 2016 14:30 #75731

by fixer

Replied by fixer on topic G71, G70 cycle for lathes (first tests)

Nice work! And maybe an even better idea to tell controller about profile shape!

I think every lathe user should take a look at this, it generates roughing and finishing paths directly from DWG file, really nice work there! Thank you for sharing this!

I think every lathe user should take a look at this, it generates roughing and finishing paths directly from DWG file, really nice work there! Thank you for sharing this!

Please Log in or Create an account to join the conversation.

Time to create page: 0.109 seconds