The machine is crappy but the HMI is cool!

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11665

- Thank you received: 3930

08 May 2023 06:31 #270904

by rodw

The machine is crappy but the HMI is cool! was created by rodw

I did this mill 12 months ago as an experiment with ethercat drives (which are awesome by the way).

But I only had a1536 x 768 monitor so could not run any if the cool new GUI's

I settled on qtdragon-hd and cmorely has done a lot of fixes bsed on my feedback. Thanks Chris!

Today my industrial paenl mount monitor arrived. I had to do a bit of hacking to make it fit becasue it has a bezel around it.

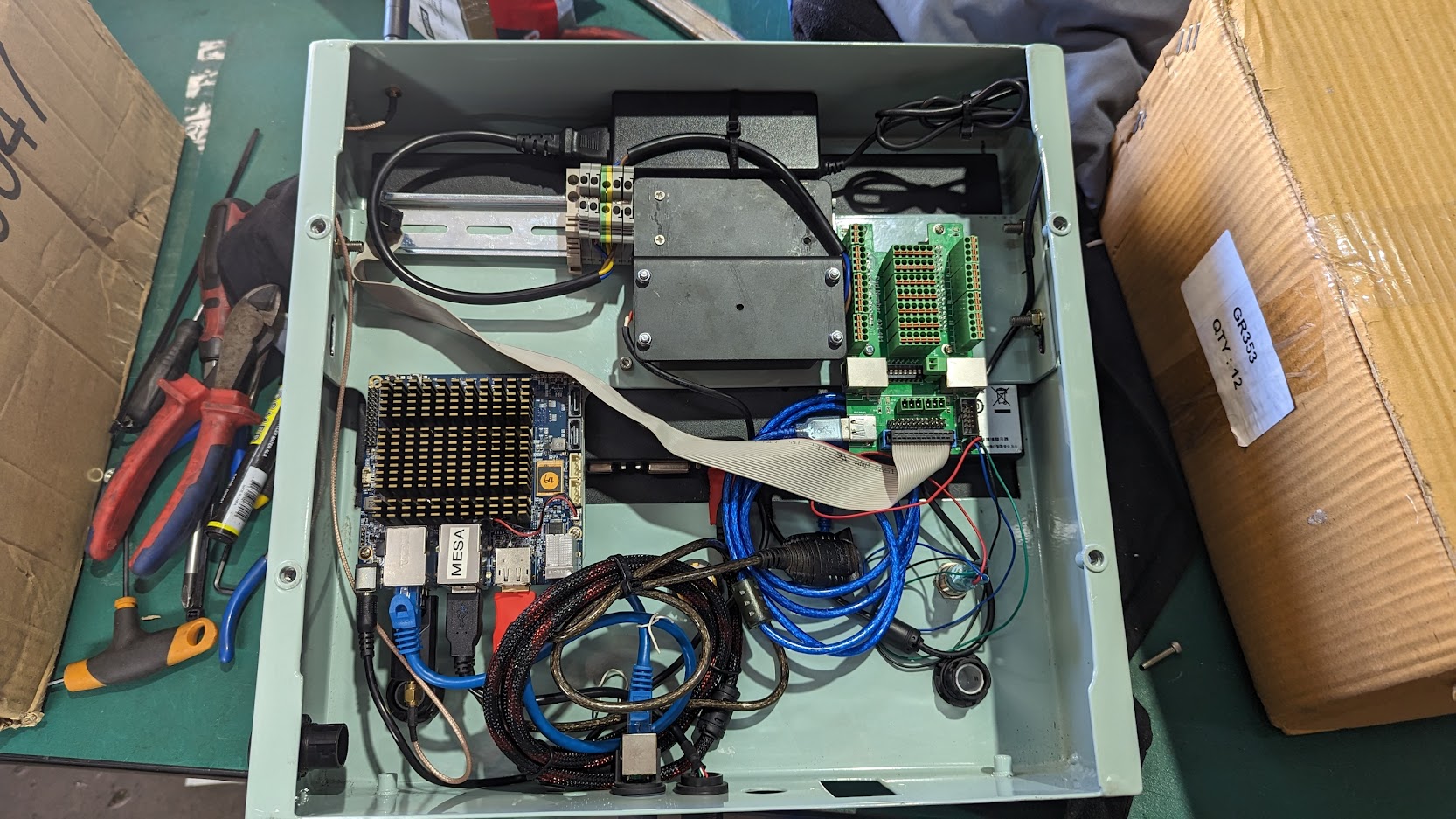

Inside there is a Odroid HM2+ running Bullseye on the left and a custom breakout board originally foe an Odroid and a Mesa 7i73.

It breaks out a few Odroid signals to get an extra USB port

But I only had a1536 x 768 monitor so could not run any if the cool new GUI's

I settled on qtdragon-hd and cmorely has done a lot of fixes bsed on my feedback. Thanks Chris!

Today my industrial paenl mount monitor arrived. I had to do a bit of hacking to make it fit becasue it has a bezel around it.

Inside there is a Odroid HM2+ running Bullseye on the left and a custom breakout board originally foe an Odroid and a Mesa 7i73.

It breaks out a few Odroid signals to get an extra USB port

Attachments:

The following user(s) said Thank You: tommylight, my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 966

- Thank you received: 424

08 May 2023 21:31 #270959

by my1987toyota

Replied by my1987toyota on topic The machine is crappy but the HMI is cool!

Having a working machine is better then none. Making you own break out boards priceless.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- echristley

- Offline

- Premium Member

-

Less

More

- Posts: 99

- Thank you received: 23

12 May 2023 20:00 #271249

by echristley

Replied by echristley on topic The machine is crappy but the HMI is cool!

I cut a lot of metal with a crappy machine like that.

Fill the column and base with portland cement and as much granite cubes as the mix can hold. Improves weight, stiffness and vibration absorbtion.

Put a 2 or 3 Hp motor from a tread mill on there. Watch Craigslist for the free treadmills to show up. Drive it wiith an MC2100 series controller. It take a 20kHz PWM signal for speed control. Keep the belts and gear it low.

It's likely to surprise you with capability. It still won't be a Cincinatti. . . but. . . .

Fill the column and base with portland cement and as much granite cubes as the mix can hold. Improves weight, stiffness and vibration absorbtion.

Put a 2 or 3 Hp motor from a tread mill on there. Watch Craigslist for the free treadmills to show up. Drive it wiith an MC2100 series controller. It take a 20kHz PWM signal for speed control. Keep the belts and gear it low.

It's likely to surprise you with capability. It still won't be a Cincinatti. . . but. . . .

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11665

- Thank you received: 3930

12 May 2023 20:53 #271251

by rodw

Replied by rodw on topic The machine is crappy but the HMI is cool!

Thanks, rounded up a few more photos

Ethercat Control box

We have coolant and mist

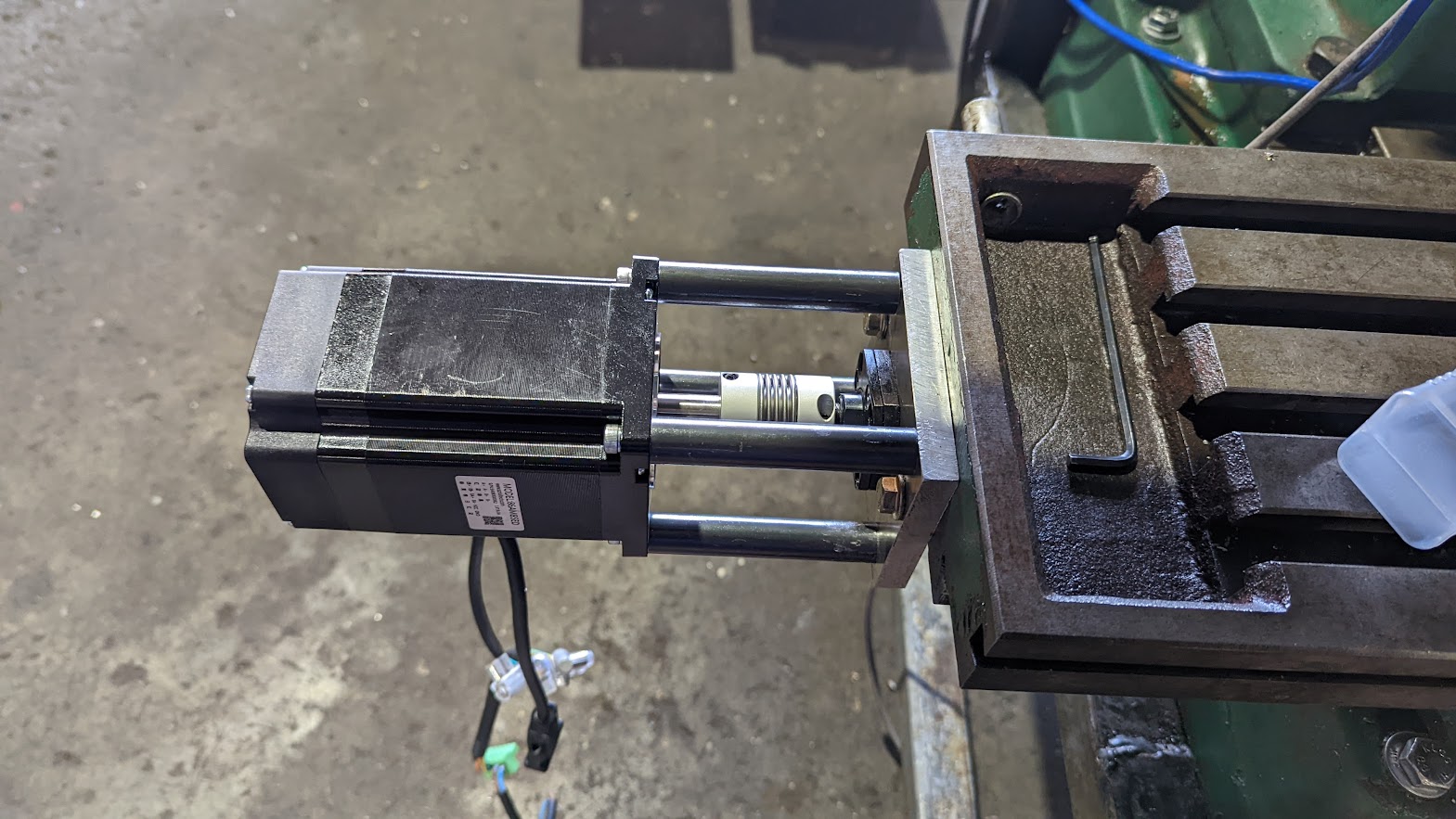

Y Axis ball screw including some adjustments to length  Z axis home switch. The prox sensor failed so I used the Wago connectors when replacing it. This was a cool idea Because when I wired in a probe, I had one spare wire up on thee head so picked the power up here.

The ball screws were pretty easy to mount. Just replaced the lead screw mount.

Z axis home switch. The prox sensor failed so I used the Wago connectors when replacing it. This was a cool idea Because when I wired in a probe, I had one spare wire up on thee head so picked the power up here.

The ball screws were pretty easy to mount. Just replaced the lead screw mount.

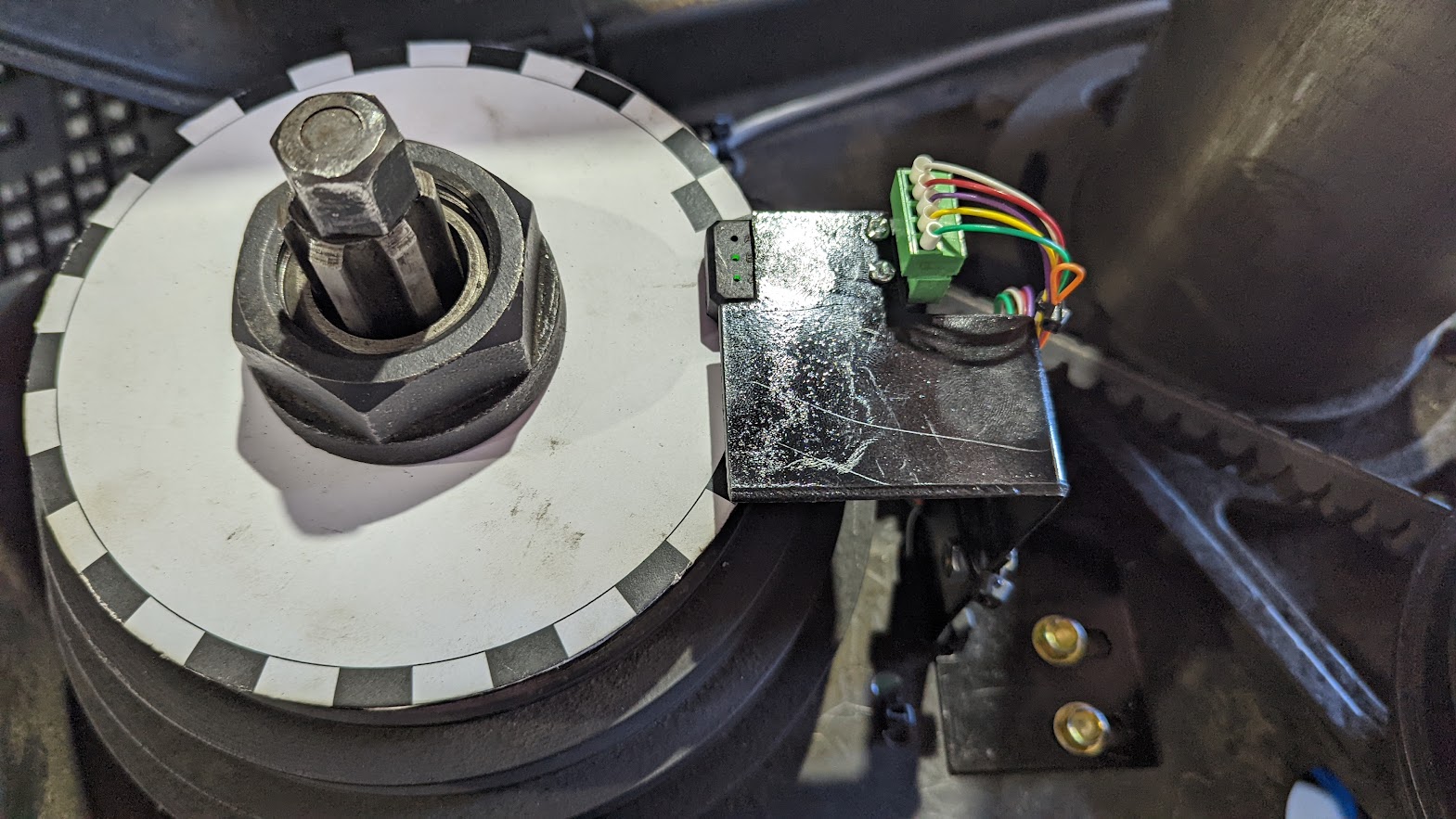

I added a MAsso encoder which uses a paper target mounted on a plasma cut disc.

X axis motor on 16mm dia standoffs.This is my preferred method to mount motors even if it's not pretty! It easy to do with a M6 male thread at one end and a M6 female thread at the motors end. It gives plenty of access to the coupling etc and you can adjust the alignment by winding legs in and out...

I added a MAsso encoder which uses a paper target mounted on a plasma cut disc.

X axis motor on 16mm dia standoffs.This is my preferred method to mount motors even if it's not pretty! It easy to do with a M6 male thread at one end and a M6 female thread at the motors end. It gives plenty of access to the coupling etc and you can adjust the alignment by winding legs in and out...

Attachments:

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11665

- Thank you received: 3930

12 May 2023 21:03 #271252

by rodw

Probe socket wired in. I was a bit annoyed because the Weipu connector uses a M11 thread (who does that?)so it's glued in with sikaflex.

Probe plugged in

New MT3 drawbar I made. (bloody imperial threads!

Genuine Tormach Mt3 collet from Little Machine Shop in the US.

You can't use an ordinary collet. It's too long and if you cut it down, there is not enough room in the collet to hold the TTD Holders.

Ask me how I know this!

One of the many probing tests I've done for cmorley as he cleans up the probing routines in QTdragon_hd.

They are now pretty good. I've only busted one probe so far because I forgot to plug the probe in!

Replied by rodw on topic The machine is crappy but the HMI is cool!

Probe socket wired in. I was a bit annoyed because the Weipu connector uses a M11 thread (who does that?)so it's glued in with sikaflex.

Probe plugged in

New MT3 drawbar I made. (bloody imperial threads!

Genuine Tormach Mt3 collet from Little Machine Shop in the US.

You can't use an ordinary collet. It's too long and if you cut it down, there is not enough room in the collet to hold the TTD Holders.

Ask me how I know this!

One of the many probing tests I've done for cmorley as he cleans up the probing routines in QTdragon_hd.

They are now pretty good. I've only busted one probe so far because I forgot to plug the probe in!

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11665

- Thank you received: 3930

12 May 2023 21:36 #271254

by rodw

Replied by rodw on topic The machine is crappy but the HMI is cool!

Forgot to mention that the VFD is 3 phase as I already had it on hand (5.5kW)

I replaced the single phase motor with a 1.5 kW 3 phase one.

Sold the old motor for $100 in 10 minutes after listing on Facebook Marketplace.

It was gone 10 minutes later! (No Craigs list here )

The two things missing in my Ethercat environment are 0-10 volt spindle control and an encoder interface.

So the enoder I mounted is not in use (one day!) The encoder interface was expensive.

There is not really any need for it because thread milling cuts really nice threads very easily.

Spindle speed is very stable without the encoder.

I did have a PWM output and was just about to set it up but the day I was going to, somebody posted a config to use VFDMOD for my exact BD600 VFD so I grabbed a USB to RS485 interface.

This has worked well.

qtdragon supports a VFD and Chris made a nice tweak to make it obvious if the connection drops out.

Chris also helped me write a custom panel to set the belts in use and to display more VFD info.

This resulted in quite a few bug fixes back into qtdragon.

The final panel is now part of QTvcp.

linuxcnc.org/docs/2.9/html/gui/qtdragon....ed_custom_vcp_panels

To scale the spindle speed, I wrote a custom component. I used a cheap infra red tachometer to measure each belt RPM

and hard coded each value.. It scales the VFD RPM accordingly based on the selected belt

The QTvcp panel has some smarts that disables invalid buttons and saves the values in the qtdragon HMI file

The HMI enclosure was designed in Fusion 360, plasma cut, folded and welded (with lots of grinding)

The main enclosure is 400 x 400mm. I wanted a 500 x 500 mm one but they were not available. This makes it super tight to squeeze stuff in and left no room for any conduit to tidy the wiring up.

All ethercat hardware is from Rtelligent. The toroid power supply is 60 volts AC so there is plenty of grunt (must be up around 90v DC at the motor.

So in summary, the mill might be crappy but there a lot of advanced features under the hood!

I replaced the single phase motor with a 1.5 kW 3 phase one.

Sold the old motor for $100 in 10 minutes after listing on Facebook Marketplace.

It was gone 10 minutes later! (No Craigs list here )

The two things missing in my Ethercat environment are 0-10 volt spindle control and an encoder interface.

So the enoder I mounted is not in use (one day!) The encoder interface was expensive.

There is not really any need for it because thread milling cuts really nice threads very easily.

Spindle speed is very stable without the encoder.

I did have a PWM output and was just about to set it up but the day I was going to, somebody posted a config to use VFDMOD for my exact BD600 VFD so I grabbed a USB to RS485 interface.

This has worked well.

qtdragon supports a VFD and Chris made a nice tweak to make it obvious if the connection drops out.

Chris also helped me write a custom panel to set the belts in use and to display more VFD info.

This resulted in quite a few bug fixes back into qtdragon.

The final panel is now part of QTvcp.

linuxcnc.org/docs/2.9/html/gui/qtdragon....ed_custom_vcp_panels

To scale the spindle speed, I wrote a custom component. I used a cheap infra red tachometer to measure each belt RPM

and hard coded each value.. It scales the VFD RPM accordingly based on the selected belt

The QTvcp panel has some smarts that disables invalid buttons and saves the values in the qtdragon HMI file

The HMI enclosure was designed in Fusion 360, plasma cut, folded and welded (with lots of grinding)

The main enclosure is 400 x 400mm. I wanted a 500 x 500 mm one but they were not available. This makes it super tight to squeeze stuff in and left no room for any conduit to tidy the wiring up.

All ethercat hardware is from Rtelligent. The toroid power supply is 60 volts AC so there is plenty of grunt (must be up around 90v DC at the motor.

So in summary, the mill might be crappy but there a lot of advanced features under the hood!

Attachments:

The following user(s) said Thank You: tommylight, my1987toyota, camb0

Please Log in or Create an account to join the conversation.

- camb0

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 9

20 Jul 2023 00:37 #275841

by camb0

Replied by camb0 on topic The machine is crappy but the HMI is cool!

Great UI, I'll defn be looking into that once most of the hardware on my mill is sorted.

For the BD600 how did you get the RPM into linuxcnc given you don't have the encoder connected, I assume that's coming from the MODBUS via VFDMOD?

If I were to replicate your VFD/MODBUS/VFDMOD setup did you need to buy one of the add-on encoder boards for the BD600 or did it work based off the parameters you configured in the BD600 and VFDMOD? I'm assuming the later.

For the BD600 how did you get the RPM into linuxcnc given you don't have the encoder connected, I assume that's coming from the MODBUS via VFDMOD?

If I were to replicate your VFD/MODBUS/VFDMOD setup did you need to buy one of the add-on encoder boards for the BD600 or did it work based off the parameters you configured in the BD600 and VFDMOD? I'm assuming the later.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11665

- Thank you received: 3930

20 Jul 2023 01:01 #275843

by rodw

Replied by rodw on topic The machine is crappy but the HMI is cool!

VFDMOD is the source of all of our spindle data. Its wired direct to a USB RS485 interface..I've checked the displayed RPM with a hand held tachometer and its very accurate.

I wrote a simple component to scale the RPM based on the belt position after measuring spindle speeds with the tacho in all belt positions.

There is no need for an encoder unless you wish to do rigid tapping.

Rigid tapping is not a must have because threadmilling does it a lot easier and is supported in the F360 post processor. NYCNC has some good tutorials on this.

I wrote a simple component to scale the RPM based on the belt position after measuring spindle speeds with the tacho in all belt positions.

There is no need for an encoder unless you wish to do rigid tapping.

Rigid tapping is not a must have because threadmilling does it a lot easier and is supported in the F360 post processor. NYCNC has some good tutorials on this.

The following user(s) said Thank You: camb0

Please Log in or Create an account to join the conversation.

- camb0

- Offline

- Senior Member

-

Less

More

- Posts: 61

- Thank you received: 9

20 Jul 2023 01:09 #275846

by camb0

Replied by camb0 on topic The machine is crappy but the HMI is cool!

That's great, such a neat and simple solution.

Re rigid tapping I was originally thinking I'd like to be able to do it but as I've thought it over thread milling is a lot easier and potentially needs less tooling esp for larger threads/non production type runs.

I have an encoder (cheap quadrature one) that I may still mount on the motor, I know that's not as good as mounting on the spindle but that will be a lot more work. If it came to that it would be simpler to implement your design given my space constraints (if it's ever needed).

Thx again for your advice.

Re rigid tapping I was originally thinking I'd like to be able to do it but as I've thought it over thread milling is a lot easier and potentially needs less tooling esp for larger threads/non production type runs.

I have an encoder (cheap quadrature one) that I may still mount on the motor, I know that's not as good as mounting on the spindle but that will be a lot more work. If it came to that it would be simpler to implement your design given my space constraints (if it's ever needed).

Thx again for your advice.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11665

- Thank you received: 3930

20 Jul 2023 01:20 #275847

by rodw

Replied by rodw on topic The machine is crappy but the HMI is cool!

If you can mount the encoder to the spindle (not the motor) and you have an encoder input (eg a Mesa Card with one), I would do it.

Ive since purchased a Beckhoff I/O Module so one day I might get the encoder interface for it.

I bought a single M8 threadmill for a specific job. It has a 1.25mm pitch. But in the end, I got 2000 parts made in India so I don't use it.

I also buy M12 x 1.25 and M10 x 1.25 bolts regularly so the single tool will cut all of those threads eg M8 standard pitch, M10 and M12 fine pitch).

I just have to use the fine thread fasteners. A couple more tools from Ali Express and I would have all bolt sizes covered.

Ive since purchased a Beckhoff I/O Module so one day I might get the encoder interface for it.

I bought a single M8 threadmill for a specific job. It has a 1.25mm pitch. But in the end, I got 2000 parts made in India so I don't use it.

I also buy M12 x 1.25 and M10 x 1.25 bolts regularly so the single tool will cut all of those threads eg M8 standard pitch, M10 and M12 fine pitch).

I just have to use the fine thread fasteners. A couple more tools from Ali Express and I would have all bolt sizes covered.

Please Log in or Create an account to join the conversation.

Time to create page: 0.517 seconds