Grizzly G1006 with Servos

- marked23

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

06 Jul 2025 06:16 #331370

by marked23

Grizzly G1006 with Servos was created by marked23

(my first post here)

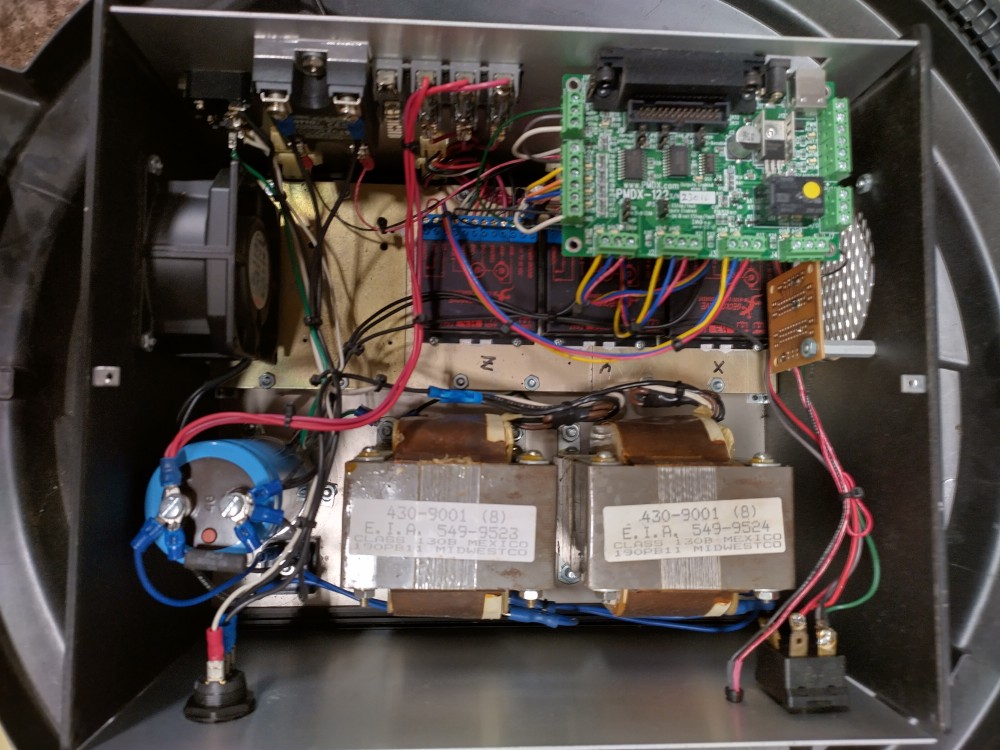

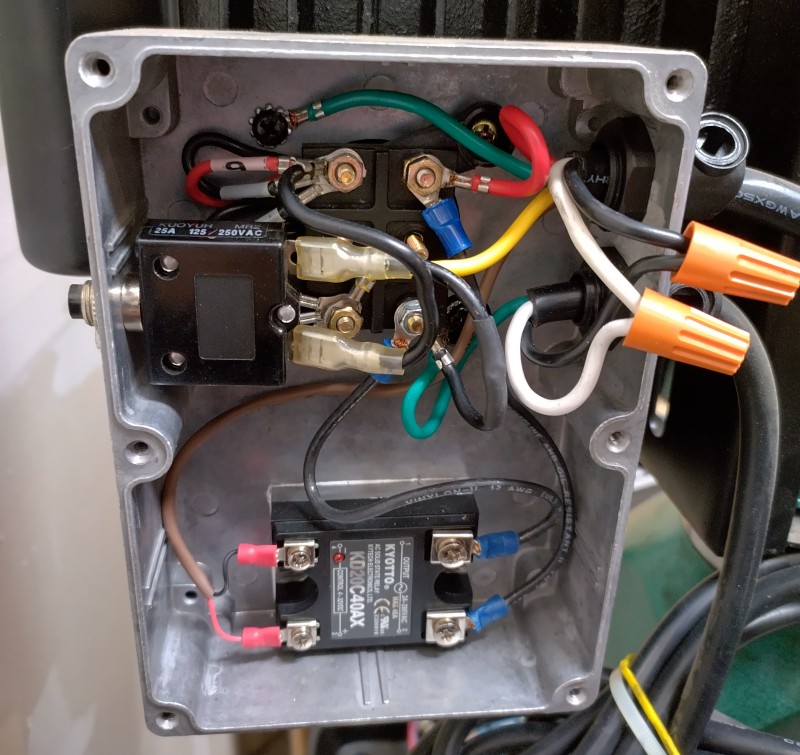

I was given a Grizzly G1006 with a CNC kit. The previous owner bought the mill new, and did the CNC conversion himself. And he built the servo control box himself, including the power supply. And he built the pendant control box. And he built the pendant.

Of course, I didn't know how any of this worked, but I knew I had all the cabling, and the computer. So I plugged in the things that were obvious. Then I had to reverse engineer the purpose of the cables that were not obvious.

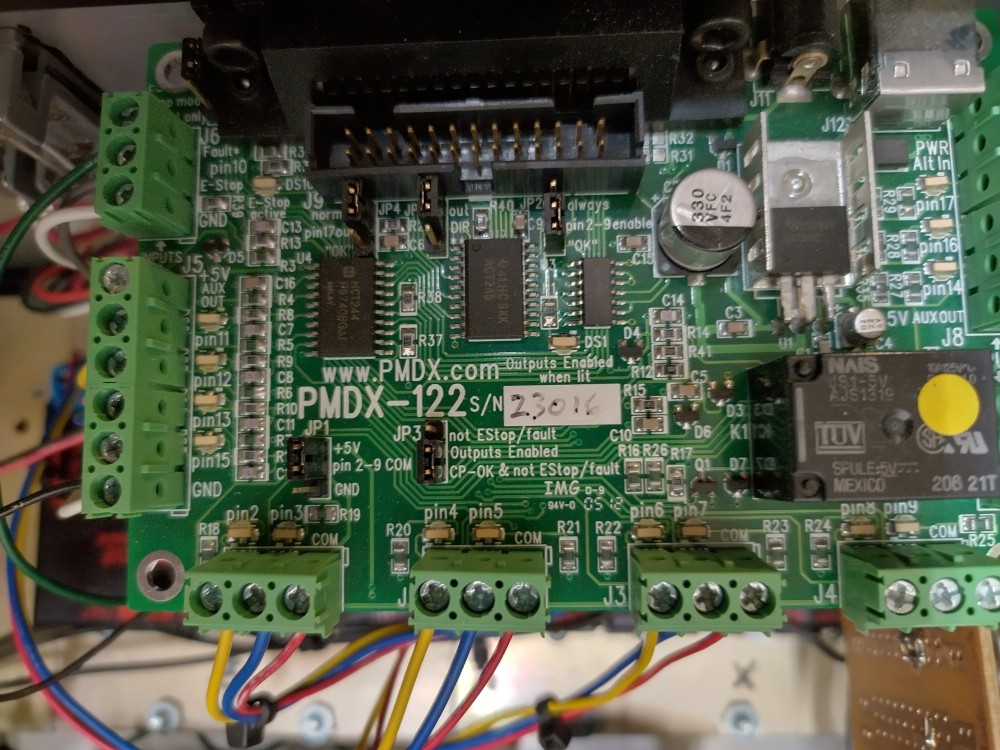

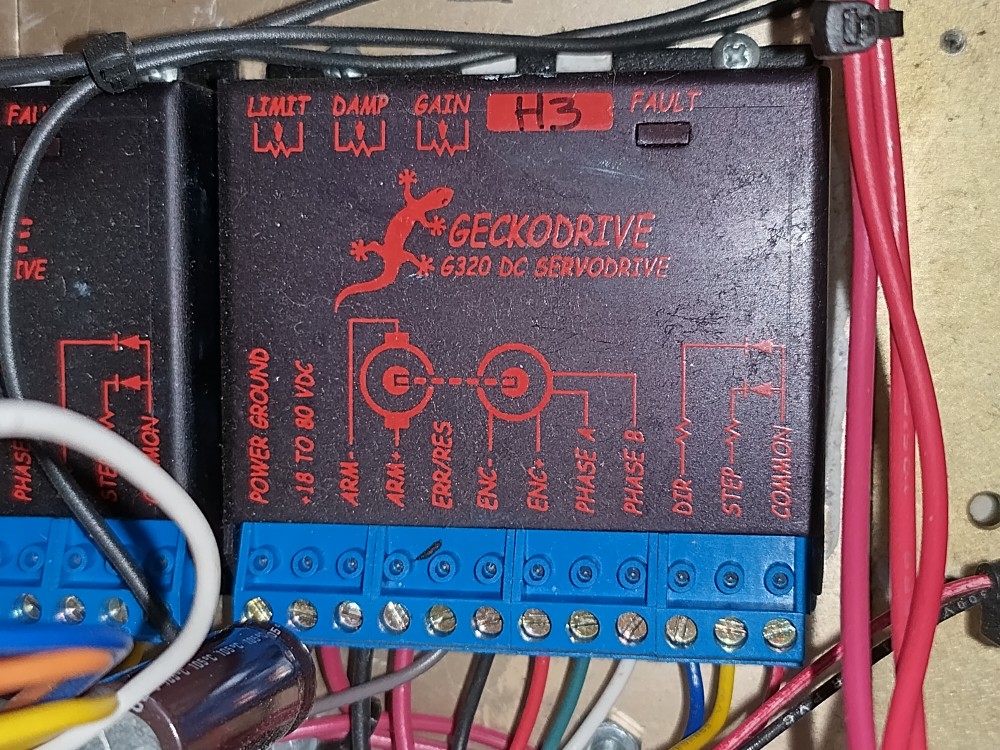

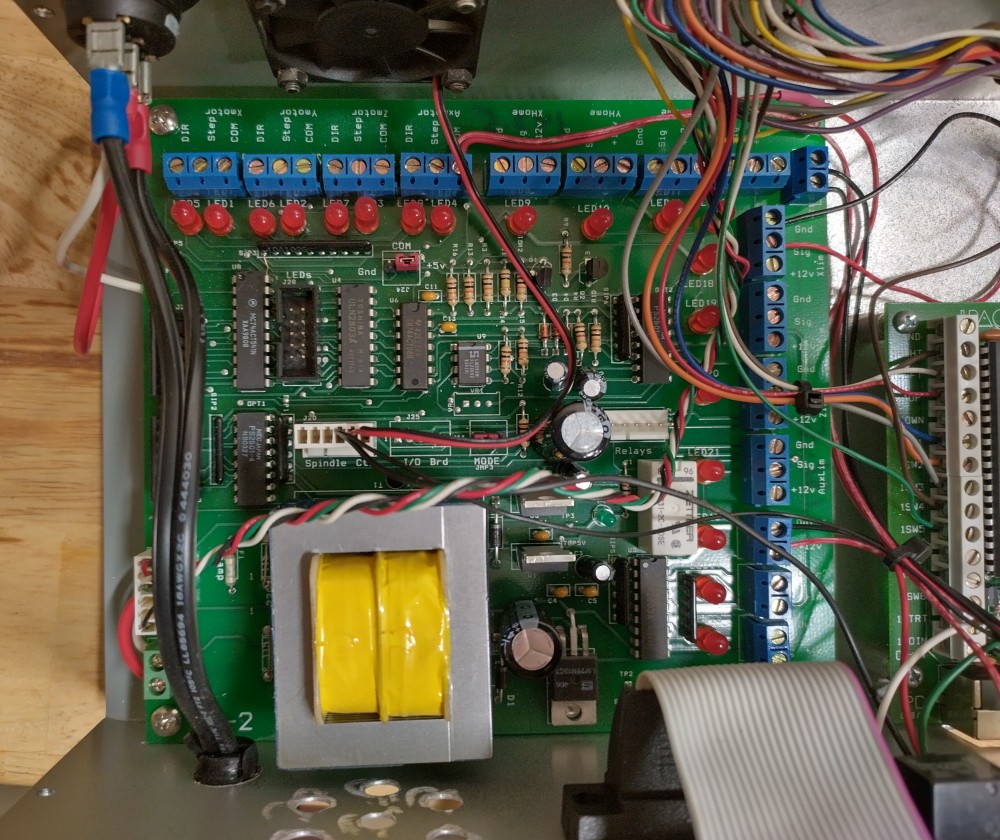

It was controlled from a 2003 era computer running Windows 10, and Mach 3. The parallel port sent commands to a PMDX-122, which sent steps to three Geckodrive G320s.

Anyway... I got it to move.

youtube.com/shorts/TgeZ-A3zM6M

Now I'm converting it to LinuxCNC.

I have a Mesa 7i96s, that will be replacing the PMDX-122. I have a USB game controller that will be replacing the pendant.

I'm going to try to keep his original servo control box, with his bespoke power supply.

Grizzly G1006 Mill/Drill

Ballscrew conversion (unknown source)

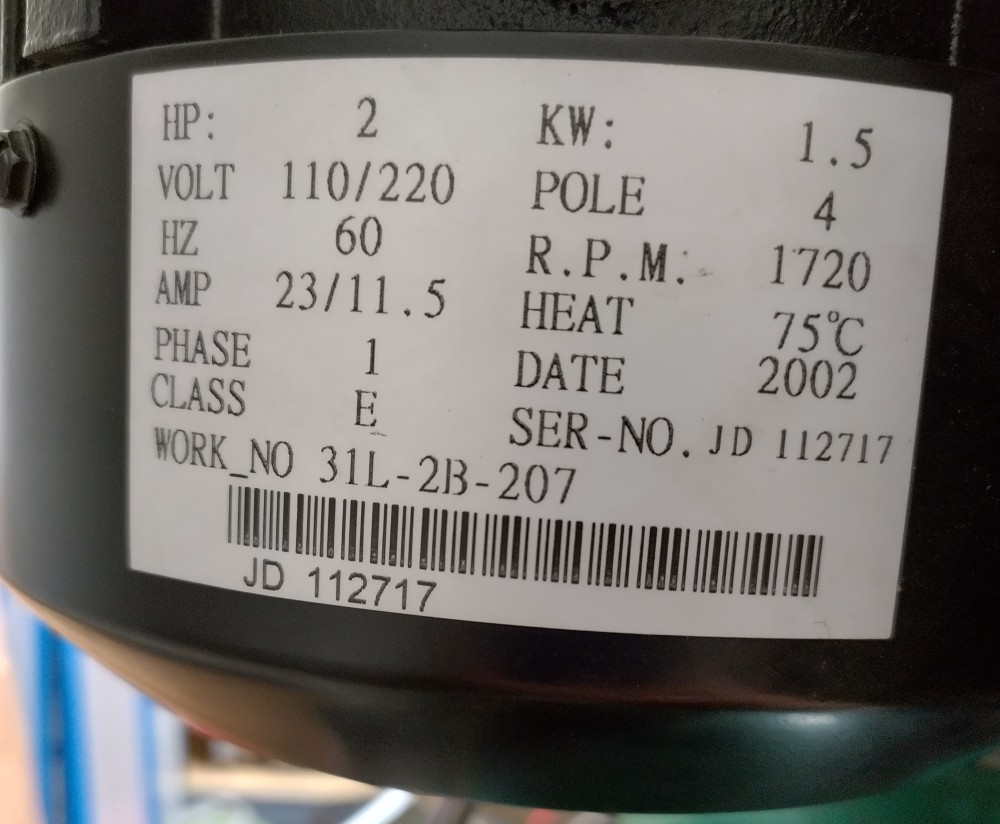

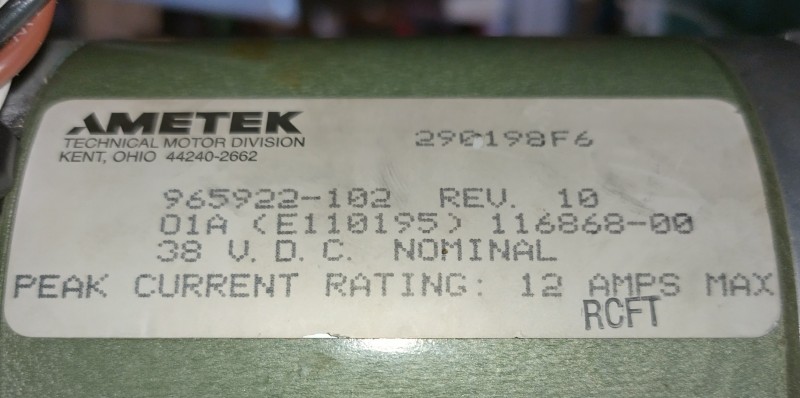

Ametek 38v 12A servo motors

USDigital encoders (250 step)

Mesa 7i96s Ethernet stepper controller

Geckodrive G320 x3

Thanks to all of you who are building and supporting LinuxCNC. I have found many resources to help get me started. I'm sure I'll have some questions, and probably a build thread.

Just wanted to say hi.

I was given a Grizzly G1006 with a CNC kit. The previous owner bought the mill new, and did the CNC conversion himself. And he built the servo control box himself, including the power supply. And he built the pendant control box. And he built the pendant.

Of course, I didn't know how any of this worked, but I knew I had all the cabling, and the computer. So I plugged in the things that were obvious. Then I had to reverse engineer the purpose of the cables that were not obvious.

It was controlled from a 2003 era computer running Windows 10, and Mach 3. The parallel port sent commands to a PMDX-122, which sent steps to three Geckodrive G320s.

Anyway... I got it to move.

youtube.com/shorts/TgeZ-A3zM6M

Now I'm converting it to LinuxCNC.

I have a Mesa 7i96s, that will be replacing the PMDX-122. I have a USB game controller that will be replacing the pendant.

I'm going to try to keep his original servo control box, with his bespoke power supply.

Grizzly G1006 Mill/Drill

Ballscrew conversion (unknown source)

Ametek 38v 12A servo motors

USDigital encoders (250 step)

Mesa 7i96s Ethernet stepper controller

Geckodrive G320 x3

Thanks to all of you who are building and supporting LinuxCNC. I have found many resources to help get me started. I'm sure I'll have some questions, and probably a build thread.

Just wanted to say hi.

Please Log in or Create an account to join the conversation.

- marked23

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

06 Jul 2025 19:09 - 06 Jul 2025 19:28 #331409

by marked23

Replied by marked23 on topic Grizzly G1006 with Servos

Attachments:

Last edit: 06 Jul 2025 19:28 by marked23. Reason: added pendant picture

Please Log in or Create an account to join the conversation.

- marked23

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

06 Jul 2025 19:20 #331411

by marked23

Replied by marked23 on topic Grizzly G1006 with Servos

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21243

- Thank you received: 7252

07 Jul 2025 00:20 #331427

by tommylight

Replied by tommylight on topic Grizzly G1006 with Servos

You can wire the drives directly to Mesa and get rid of the parallel port boards.

Please Log in or Create an account to join the conversation.

- marked23

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

07 Jul 2025 20:25 #331486

by marked23

Replied by marked23 on topic Grizzly G1006 with Servos

> Why not just use it as-is?

> Maybe just put a mesa board in place of the PMDX

> ... wire the drives directly to Mesa

Yes. That's the idea. I have a 7i96s already mostly wired. I spent much of this weekend working on getting the configuration setup, using pncconf. Only to find that Claude (online AI) led me astray. I should have been using stepconf. Or even better... MesaCT.

> Does it work fine right now?

Who knows? It was working fine in 2009, when it was last used. Yes, the servos move. I can't yet try the spindle until I put in a new electrical circuit. My garage has one outlet, shared with the lighting and garage doors. And my breaker panel is full.

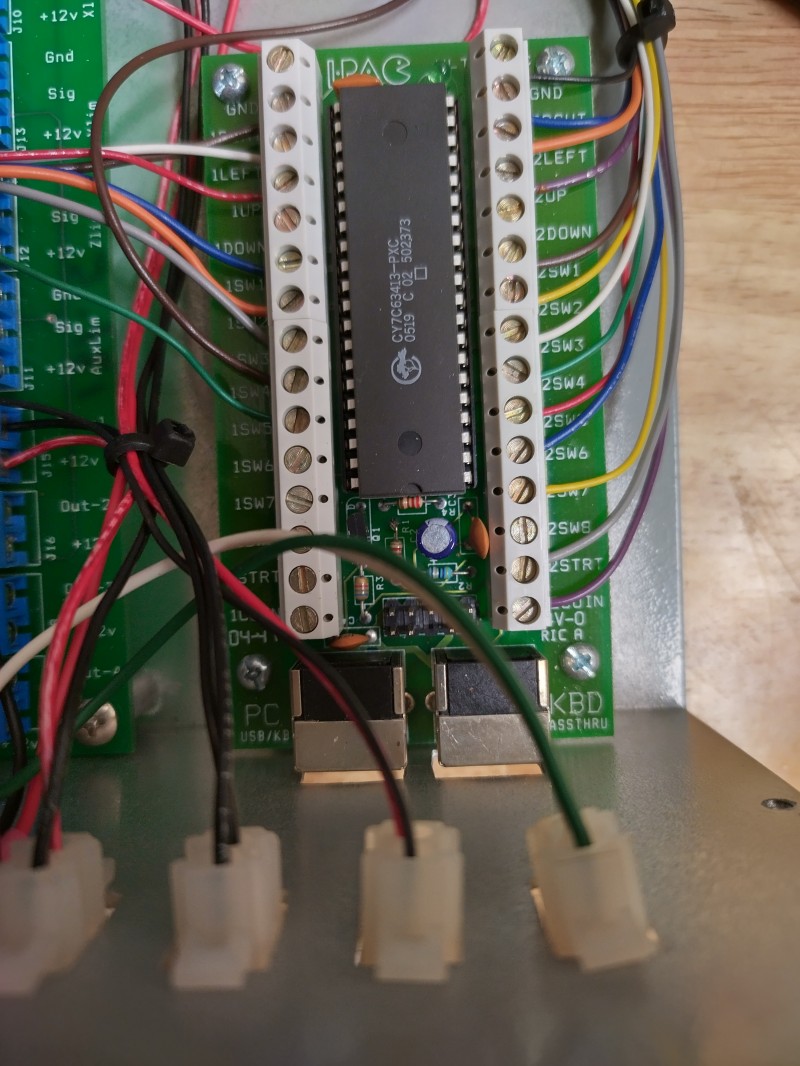

> What is that IPAC board?

It takes commands from button presses on the pendant, and injects them into the keyboard communication. Then you run Mach3 with keygrabber so that the pendant buttons are captured and sent to Mach3. There are two ps/2 keyboard ports on the IPAC. One goes to the computer, the other to the keyboard. (Which is a real IBM M1... precious metal to me.)

> He obviously took pride in his work.

Yeah. I was surprised he didn't use more off-the-shelf options. Learning and building was his joy, so that makes sense.

>Why change something so neatly and carefully made?

I can't make use of the pendant because the new computer doesn't have any parallel ports, and the pendant needs its own parallel port.

The servo control box will look exactly as it does, except the PMDX board will be swapped out for a Mesa 7i96s.

- I don't have a license for Mach3

- I prefer to use Ethernet

- I'm removing Windows from all my computers, before October.

- LinuxCNC does not fit on the old computer.

> Maybe just put a mesa board in place of the PMDX

> ... wire the drives directly to Mesa

Yes. That's the idea. I have a 7i96s already mostly wired. I spent much of this weekend working on getting the configuration setup, using pncconf. Only to find that Claude (online AI) led me astray. I should have been using stepconf. Or even better... MesaCT.

> Does it work fine right now?

Who knows? It was working fine in 2009, when it was last used. Yes, the servos move. I can't yet try the spindle until I put in a new electrical circuit. My garage has one outlet, shared with the lighting and garage doors. And my breaker panel is full.

> What is that IPAC board?

It takes commands from button presses on the pendant, and injects them into the keyboard communication. Then you run Mach3 with keygrabber so that the pendant buttons are captured and sent to Mach3. There are two ps/2 keyboard ports on the IPAC. One goes to the computer, the other to the keyboard. (Which is a real IBM M1... precious metal to me.)

> He obviously took pride in his work.

Yeah. I was surprised he didn't use more off-the-shelf options. Learning and building was his joy, so that makes sense.

>Why change something so neatly and carefully made?

I can't make use of the pendant because the new computer doesn't have any parallel ports, and the pendant needs its own parallel port.

The servo control box will look exactly as it does, except the PMDX board will be swapped out for a Mesa 7i96s.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17657

- Thank you received: 5164

07 Jul 2025 20:38 #331488

by PCW

Replied by PCW on topic Grizzly G1006 with Servos

Yes. That's the idea. I have a 7i96s already mostly wired. I spent much of this weekend working on getting the configuration setup, using pncconf. Only to find that Claude (online AI) led me astray. I should have been using stepconf. Or even better... MesaCT.

pncconf and MesaCT can both create 7I96S configurations, stepconf cannot (stepconf is for parallel port hardware)

pncconf and MesaCT can both create 7I96S configurations, stepconf cannot (stepconf is for parallel port hardware)

The following user(s) said Thank You: marked23

Please Log in or Create an account to join the conversation.

Time to create page: 0.249 seconds