Suitable encoder upgrade options

20 Dec 2023 09:46 #288657

by Unlogic

Suitable encoder upgrade options was created by Unlogic

I'm in the process of CNC converting my Optimum MH50V milling machine (

link to build thread

) and as a part of that process I'd like to upgrade the encoder on the machine so that I can do rigid tapping later on.

The encoder that came with the machine looks like this:

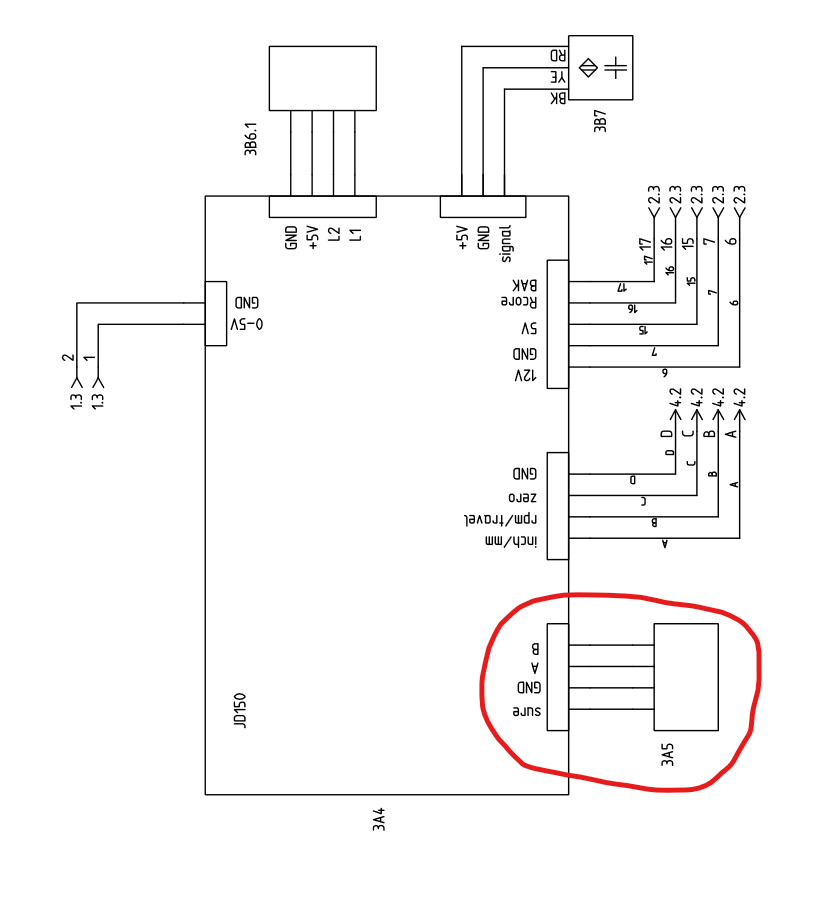

The manual for the machine doesn't say much about the encoder itself, here is a snippet from the schematics:

Given that this encoder most likely doesn't have and index signal I realize it will have to replaced. Does anyone here on the forum have any hints on what could be a suitable upgrade option given the physical layout of the machine?

I've been able to progress pretty far with my CNC conversion without asking too many rookie questions here on the forum by reading up on old threads. However the subject of encoders didn't give too many examples of similar setups so I figured I'd ask the community.

The shaft for the spindle has an OD of 40 mm and the maximum OD which can fit before hitting the supports on the side is 68 mm. Pressing on some kind of gear here shouldn't be much of a problem if that's a suitable way to go.

The encoder that came with the machine looks like this:

The manual for the machine doesn't say much about the encoder itself, here is a snippet from the schematics:

Given that this encoder most likely doesn't have and index signal I realize it will have to replaced. Does anyone here on the forum have any hints on what could be a suitable upgrade option given the physical layout of the machine?

I've been able to progress pretty far with my CNC conversion without asking too many rookie questions here on the forum by reading up on old threads. However the subject of encoders didn't give too many examples of similar setups so I figured I'd ask the community.

The shaft for the spindle has an OD of 40 mm and the maximum OD which can fit before hitting the supports on the side is 68 mm. Pressing on some kind of gear here shouldn't be much of a problem if that's a suitable way to go.

Attachments:

Please Log in or Create an account to join the conversation.

20 Dec 2023 17:27 #288677

by Mecanix

Replied by Mecanix on topic Suitable encoder upgrade options

An incremental rotary encoder with A/B/Z (TTL signals) will be sufficient for sync motions e.g threads and speed/velocity. Assuming you have a vacant input pin for the index signal secured already, it's then just a matter of ensuring that the input VCC of the new encoder is within range of your system output voltage. Apart from the physical mounting aspect.

Another selection factor to consider is the PPR (pulses per revolution). The higher ppr = better sync motion accuracy. However from the schematic you posted it's hard to tell if there are any hardware constraints. Signal input optocoupler max freq/speed (if any mind you) to name one. If there aren't any detailed schematics avail, a hd pic of the board could help with that part.

Curious. What is the S.U.R.E. input (output?) for?

Another selection factor to consider is the PPR (pulses per revolution). The higher ppr = better sync motion accuracy. However from the schematic you posted it's hard to tell if there are any hardware constraints. Signal input optocoupler max freq/speed (if any mind you) to name one. If there aren't any detailed schematics avail, a hd pic of the board could help with that part.

Curious. What is the S.U.R.E. input (output?) for?

Please Log in or Create an account to join the conversation.

20 Dec 2023 17:47 #288678

by Unlogic

Replied by Unlogic on topic Suitable encoder upgrade options

Thanks for your reply Mecanix I'm switching the machine over to a Mesa 7i96S+7i84 based setup so I'm planing to use the encoder input on the 7i96S.

I have not been able to dig up anymore information on the encoder currently mounted on the machine so it would feel better to replace it with a known model and brand.

But so far I'm at a complete loss regarding which type/brand of sensor to get and what the best approach would be for mounting it.

Omron seems to have a lot of very nice encoders but they all have this tiny little shaft so I assume they would have to be belt driven somehow which might be a tight fit on top of the spindle.

A setup with a gear/wheel on the spindle shaft and one or more sensors reading it would probably be a bit simpler to fit. But I'm not sure if there is anything like that available "off the shelf".

I have not been able to dig up anymore information on the encoder currently mounted on the machine so it would feel better to replace it with a known model and brand.

But so far I'm at a complete loss regarding which type/brand of sensor to get and what the best approach would be for mounting it.

Omron seems to have a lot of very nice encoders but they all have this tiny little shaft so I assume they would have to be belt driven somehow which might be a tight fit on top of the spindle.

A setup with a gear/wheel on the spindle shaft and one or more sensors reading it would probably be a bit simpler to fit. But I'm not sure if there is anything like that available "off the shelf".

The following user(s) said Thank You: Mecanix

Please Log in or Create an account to join the conversation.

20 Dec 2023 18:20 #288685

by Mecanix

Replied by Mecanix on topic Suitable encoder upgrade options

Ah I see. Nice base set-up hardware!

Omron does indeed put up great sensors. They'll include a shaft coupler in your kit, it's made out of a composite (damp vibrations and all. Recommend). Mounting will require creativity for sure but I'm pretty sure that's the last of your worry considering your line of expertise.

Fwiw; I'm setup with a E6B2-CWZ3E (2500ppr) with LTV-M601 input signal isolation. Note high-speed opto mandatory...

Omron does indeed put up great sensors. They'll include a shaft coupler in your kit, it's made out of a composite (damp vibrations and all. Recommend). Mounting will require creativity for sure but I'm pretty sure that's the last of your worry considering your line of expertise.

Fwiw; I'm setup with a E6B2-CWZ3E (2500ppr) with LTV-M601 input signal isolation. Note high-speed opto mandatory...

The following user(s) said Thank You: Unlogic

Please Log in or Create an account to join the conversation.

04 Apr 2024 09:10 #297564

by Unlogic

Excuse my lack of experience when it comes to encoders and Mesa card but what makes an high-speed opto mandatory when using the E6B2-CWZ3E encoder?

Replied by Unlogic on topic Suitable encoder upgrade options

I've started looking into the spindle encoder upgrade again now that the machine is up and running with LinuxCNC.Ah I see. Nice base set-up hardware!

Omron does indeed put up great sensors. They'll include a shaft coupler in your kit, it's made out of a composite (damp vibrations and all. Recommend). Mounting will require creativity for sure but I'm pretty sure that's the last of your worry considering your line of expertise.

Fwiw; I'm setup with a E6B2-CWZ3E (2500ppr) with LTV-M601 input signal isolation. Note high-speed opto mandatory...

Excuse my lack of experience when it comes to encoders and Mesa card but what makes an high-speed opto mandatory when using the E6B2-CWZ3E encoder?

Please Log in or Create an account to join the conversation.

04 Apr 2024 11:35 #297570

by spumco

Replied by spumco on topic Suitable encoder upgrade options

@Unlogic,

What is the OD of the encoder magnet carrier you attached in the first post? Asking because it might be possible to bore out a narrow timing pulley and sneak it on that magnet mount thing and run a belt to a small shaft encoder.

I did this on my lathe spindle and it's working well. Bored a GT2 9mm wide pulley out and shrink-fit it on the spindle - there wasn't enough thickness left for a set screw or keyless bushing. Matching pulley on the encoder and everything's all set.

There are slim hollow-shaft encoders (US Digital) that mount directly on the shaft, but I don't think they go much larger than 1". And big-bore hollow shaft encoders from BEI (and similar) get really expensive and bulky.

What is the OD of the encoder magnet carrier you attached in the first post? Asking because it might be possible to bore out a narrow timing pulley and sneak it on that magnet mount thing and run a belt to a small shaft encoder.

I did this on my lathe spindle and it's working well. Bored a GT2 9mm wide pulley out and shrink-fit it on the spindle - there wasn't enough thickness left for a set screw or keyless bushing. Matching pulley on the encoder and everything's all set.

There are slim hollow-shaft encoders (US Digital) that mount directly on the shaft, but I don't think they go much larger than 1". And big-bore hollow shaft encoders from BEI (and similar) get really expensive and bulky.

Please Log in or Create an account to join the conversation.

04 Apr 2024 11:39 #297571

by Unlogic

Replied by Unlogic on topic Suitable encoder upgrade options

Hi Spumco,

The OD of the magnet carrier is 40 mm so your approach might actually be the simplest way to go. I'm currently looking a HTD 3M belt and pulleys which seem to be pretty slim.

The OD of the magnet carrier is 40 mm so your approach might actually be the simplest way to go. I'm currently looking a HTD 3M belt and pulleys which seem to be pretty slim.

Please Log in or Create an account to join the conversation.

04 Apr 2024 20:00 #297588

by spumco

Replied by spumco on topic Suitable encoder upgrade options

If you do go with the approach I mentioned, do yourself a favor and buy pulleys with external (protruding) hubs. Especially if the hub is larger than your target ID.

The hubs make it easy to mount in a lathe and indicate the bore & face. Bore out the pulley while hanging on to the hub, then part it off the hub.

I went with a light shrink fit (~0.001"), but you might just want to bore to a transition fit and use retaining compound as you don't have a shoulder on the existing 40mm magnet carrier to set elevation.

Looks like you might have to remove the magnets as well, unless you slot the new timing pulley and kinda-sorta use the magnets as drive-dogs.

Suggestion #2 - use as small a pulley as possible without boring it in to a beer can. You want the matching encoder pulley to have a low inertia as possible... if you use relatively small pulleys you can skip the intermediate bearing & shaft arrangement and mount the driven pulley directly on the encoder.

If the pulley & belt system are huge/heavy, belt tension and pulley inertia will probably kill your shaft encoder bearings faster than you'd like without isolating the encoder with a pulley & intermediate bearing/shaft.

The hubs make it easy to mount in a lathe and indicate the bore & face. Bore out the pulley while hanging on to the hub, then part it off the hub.

I went with a light shrink fit (~0.001"), but you might just want to bore to a transition fit and use retaining compound as you don't have a shoulder on the existing 40mm magnet carrier to set elevation.

Looks like you might have to remove the magnets as well, unless you slot the new timing pulley and kinda-sorta use the magnets as drive-dogs.

Suggestion #2 - use as small a pulley as possible without boring it in to a beer can. You want the matching encoder pulley to have a low inertia as possible... if you use relatively small pulleys you can skip the intermediate bearing & shaft arrangement and mount the driven pulley directly on the encoder.

If the pulley & belt system are huge/heavy, belt tension and pulley inertia will probably kill your shaft encoder bearings faster than you'd like without isolating the encoder with a pulley & intermediate bearing/shaft.

The following user(s) said Thank You: Unlogic

Please Log in or Create an account to join the conversation.

04 Apr 2024 21:18 #297594

by spumco

Replied by spumco on topic Suitable encoder upgrade options

BTW, I just realized I have an encoder sitting around with a 72T x 6mm GT2 pulley mounted on it.

It's an Automation Direct (Koyo) TRD-SR600VD. 5V differential line driver w/index...works well with Mesa cards; I had it on my lathe during testing until I realized I needed a significantly higher resolution for C-axis use.

If you're in the US I can offer a substantial discount from retail. Like get it out of my shop price.

It's an Automation Direct (Koyo) TRD-SR600VD. 5V differential line driver w/index...works well with Mesa cards; I had it on my lathe during testing until I realized I needed a significantly higher resolution for C-axis use.

If you're in the US I can offer a substantial discount from retail. Like get it out of my shop price.

The following user(s) said Thank You: Unlogic

Please Log in or Create an account to join the conversation.

05 Apr 2024 09:17 #297630

by Unlogic

Replied by Unlogic on topic Suitable encoder upgrade options

Thanks, that's very kind of you!

I'm located on the "wrong" side of the pond (Sweden).

I ordered a Omron E6C2-CWZ1X 2000PPR incremental encoder yesterday just a few minutes before I saw your message...

I suspect that this encoder is not genuine as it was a tenth of the advertised official prices so we'll have to see how it works when it arrives. Bought on eBay from a seller who offers both warranty and returns.

www.ebay.co.uk/itm/335292322601

If the encoder I bought turns out to be a dud then I'm very interested in your Koyo encoder.

In order to drive the encoder I ordered two 48 teeth 9mm wide HTD 3M pulleys and a polyamide belt. I would have preferred 6mm belts and pulleys but the supplier didn't carry those. I'll try to remove as much mass as possible from the pulley that will be connected to the encoder.

I'm located on the "wrong" side of the pond (Sweden).

I ordered a Omron E6C2-CWZ1X 2000PPR incremental encoder yesterday just a few minutes before I saw your message...

I suspect that this encoder is not genuine as it was a tenth of the advertised official prices so we'll have to see how it works when it arrives. Bought on eBay from a seller who offers both warranty and returns.

www.ebay.co.uk/itm/335292322601

If the encoder I bought turns out to be a dud then I'm very interested in your Koyo encoder.

In order to drive the encoder I ordered two 48 teeth 9mm wide HTD 3M pulleys and a polyamide belt. I would have preferred 6mm belts and pulleys but the supplier didn't carry those. I'll try to remove as much mass as possible from the pulley that will be connected to the encoder.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.173 seconds