Closing the servo loop with HAL mesa 7i76

Please Log in or Create an account to join the conversation.

Those pertain to tuning the position loop in the drive (something that may need done). But not directly to the velocity or acceleration limits.

I have changed the PD113 to 10 then 20 then 30 and 30 seems to have improved I upped the acc to 1100 now I can move at vel 1490 with G0 X500 X0 without the following error.

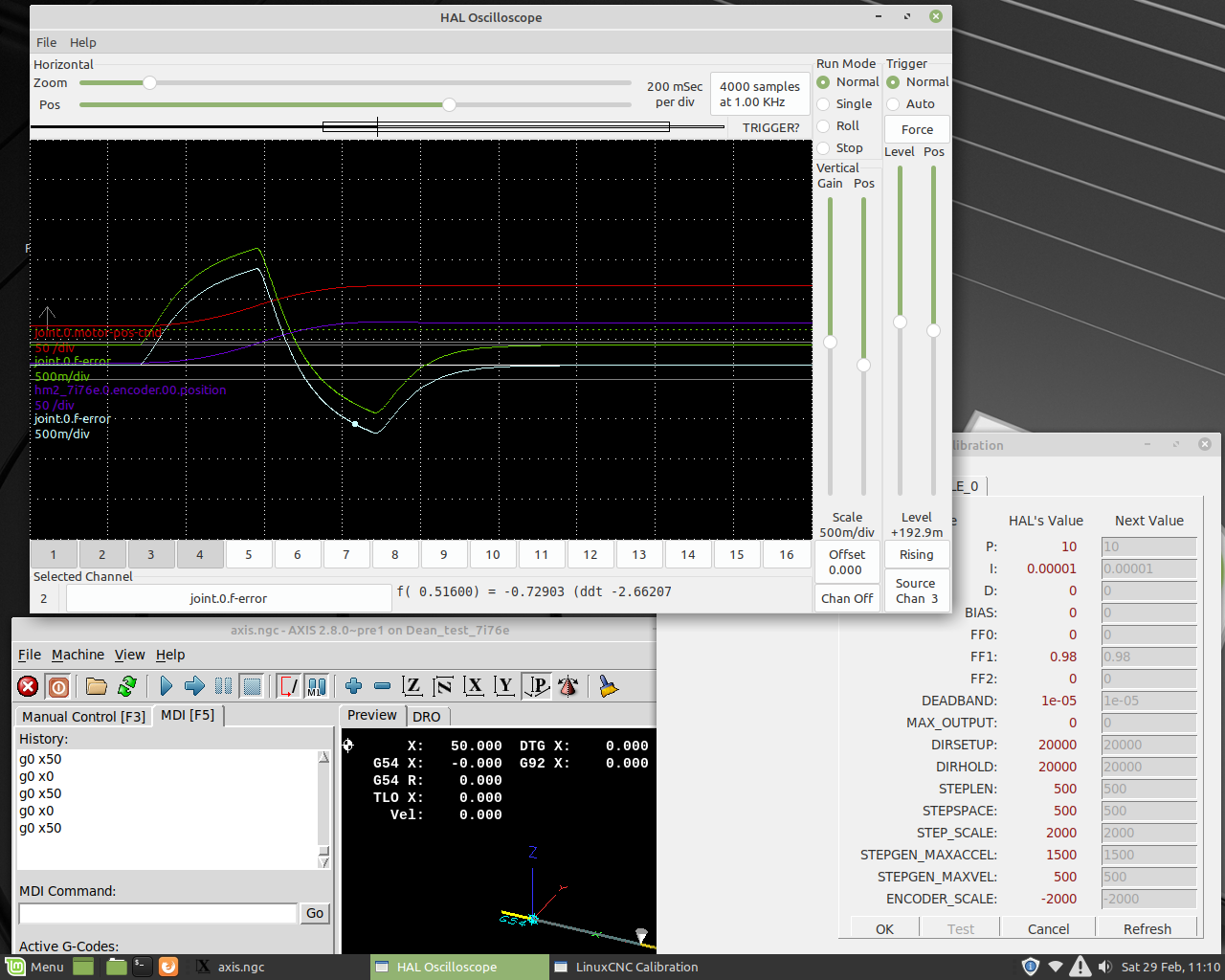

I will post the halscope plot tomorrow. Still not to sure how to use it properly yet

Please Log in or Create an account to join the conversation.

Attachments:

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1130

- Thank you received: 533

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

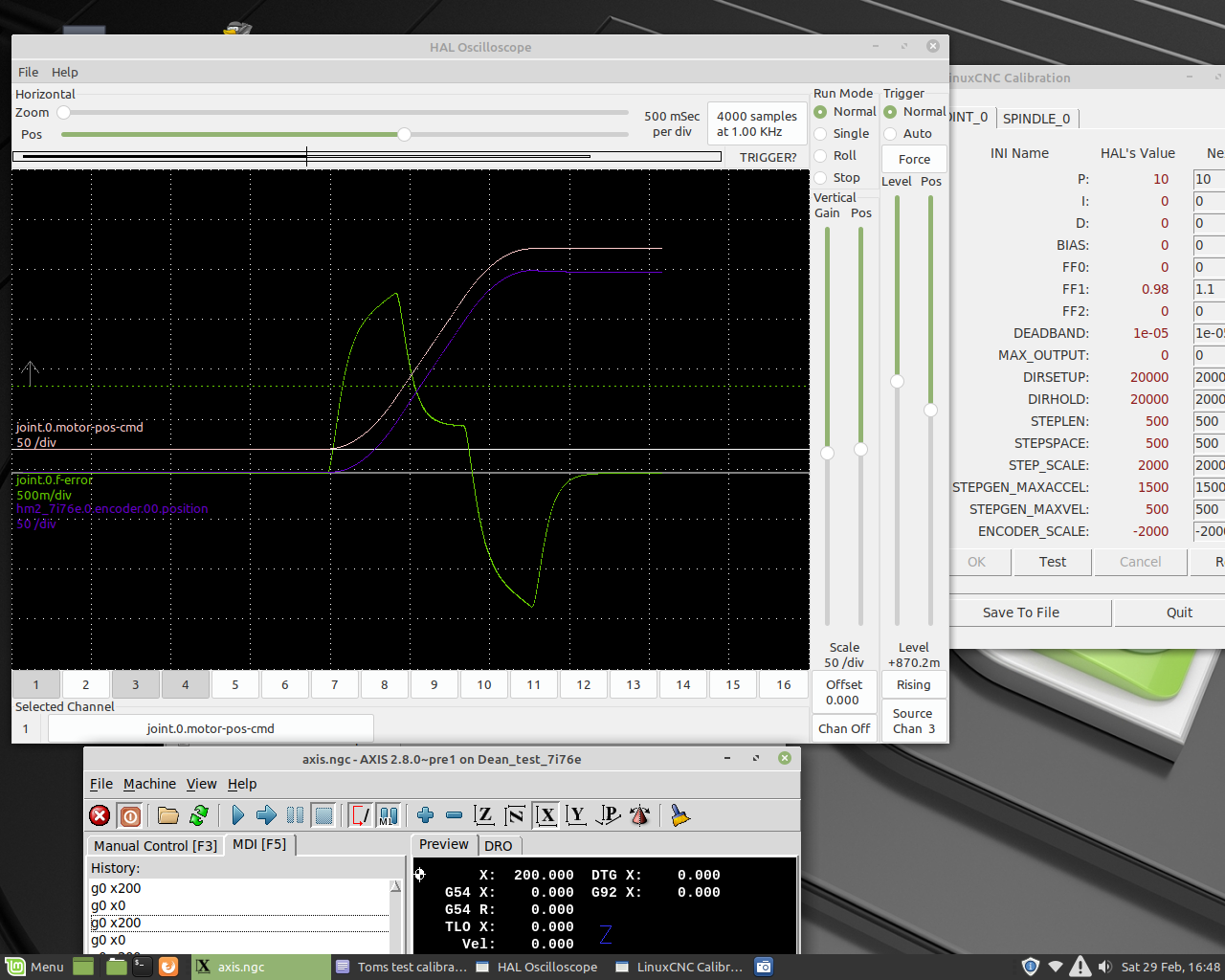

At that speed you are still getting about 400ms of total delay.

Have a look at the first post here, where the wiring ends and the tuning starts, right above the :fine tuning: part.

That should get you very close to acceptable very fast.

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Please Log in or Create an account to join the conversation.

Did you set all the drives filter time constants to their minimums?

Please Log in or Create an account to join the conversation.

Yes . I have now changed them back. Thanks for taking an interestSince changing the settings in the drive, are you still getting following errors?

At that speed you are still getting about 400ms of total delay.

Have a look at the first post here, where the wiring ends and the tuning starts, right above the :fine tuning: part.

That should get you very close to acceptable very fast.

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

I am not sure how to read the plot. I have been studying the tutorial. (mine is step/dir)

Thanks Peter I have tried to fathom the manual but not sure which parameters to change.The fact that you are getting huge errors (> 1.5 mm) means the drive tuning is still way off

Did you set all the drives filter time constants to their minimums?

manual: www.dropbox.com/s/jp7t9hcszjcg6na/1.8Kw%...vo%20manual.pdf?dl=0

New plot over 200mm

Attachments:

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

- Posts: 1130

- Thank you received: 533

Yes . I have now changed them back. Thanks for taking an interestSince changing the settings in the drive, are you still getting following errors?

I am about to start a project with up to 9 motors, some closed loop steppers and some servos. I plan on doing what you are doing and closing the loop within LinuxCNC. I am sure the issues and responses here will be very relevant to my situation when I get started.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

I would set Pn110,111,112,114 to their minimums and see if that improves the tracking

Peter many thanks for looking into this.

Pn109 is set for zero which I think disables Pn110,111,112 not sure if it affects 114.

But I will of course try those settings.

My Naz drives MB has failed and I am trying to get the data off the raid HD's which is going to take me some time.

Please Log in or Create an account to join the conversation.