Refit Kitamura MyCenter Zero

26 Apr 2017 17:29 #92158

by Rescue35

Refit Kitamura MyCenter Zero was created by Rescue35

Hello all, I've been lurking and reading for awhile. Now I need some advice. I recently purchased a 1989 Kitamura MyCenter Zero With Fanuc O Mate and Sanyo Denki drives (BA030-04) and servos (65BM004) with a Z axis fault. I was told it was the encoder. The problem was the brake not disengaging. Once that was fixed the Z axis drive faulted with no load, the solution per the manual is to replace the drive.

Instead of fighting this thing through all the problems it may have that I haven't even gotten to yet, I would like to do replace the axis drives and steppers and use LinuxCNC as the controller. I would like to keep the spindle servo and drive so that I can use it to ridged tap and index for tool changes. I found this thread regarding setup of the spindle. forum.linuxcnc.org/30-cnc-machines/29530...center-spindle-motor The 12 position ATC and its controls can wait for phase 2. My main goal is to get the axis, spindle, and drawbar operational.

Here is the hardware that has stuck itself in my brain.

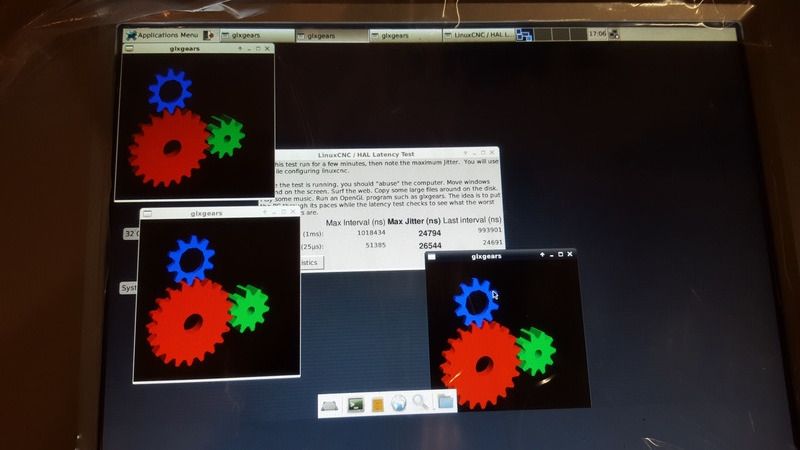

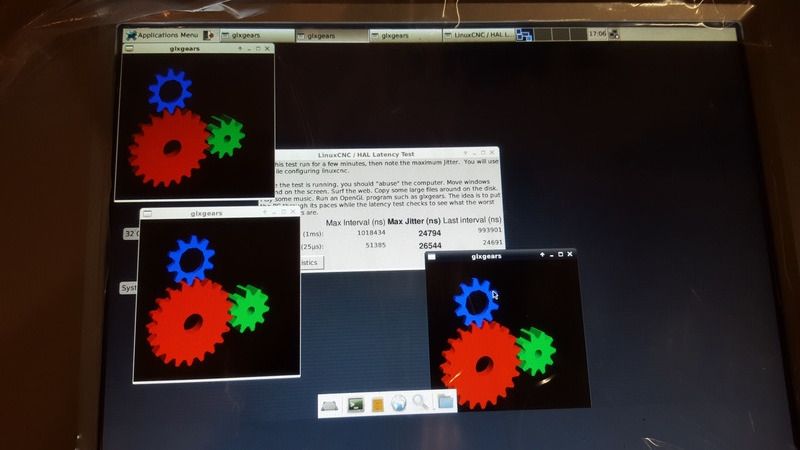

Panel mount touchscreen PC (need to load Linux and check latency)

Mesa7I76E

Clearpath SD servos on X, Y, and Z

Optionally I could reuse the amplifier and servos that work with a Mesa 7I77. Any suggestions on a reliable amp for use with the stock servos?

What would you do? Any help is greatly appreciated.

I have built a couple of small, stepper driven, CNC machines before and ran them with Mach3. I was very disappointed in the control and rigidity. I have installed linuxcnc on a couple of computers in the past to try it out. I have never ran a machine with it.

I tried to link some photos of the machine but recived an error stating I have too many links. I'll try more once I prove Im not a spammer

Bad Z Amplifier

Instead of fighting this thing through all the problems it may have that I haven't even gotten to yet, I would like to do replace the axis drives and steppers and use LinuxCNC as the controller. I would like to keep the spindle servo and drive so that I can use it to ridged tap and index for tool changes. I found this thread regarding setup of the spindle. forum.linuxcnc.org/30-cnc-machines/29530...center-spindle-motor The 12 position ATC and its controls can wait for phase 2. My main goal is to get the axis, spindle, and drawbar operational.

Here is the hardware that has stuck itself in my brain.

Panel mount touchscreen PC (need to load Linux and check latency)

Mesa7I76E

Clearpath SD servos on X, Y, and Z

Optionally I could reuse the amplifier and servos that work with a Mesa 7I77. Any suggestions on a reliable amp for use with the stock servos?

What would you do? Any help is greatly appreciated.

I have built a couple of small, stepper driven, CNC machines before and ran them with Mach3. I was very disappointed in the control and rigidity. I have installed linuxcnc on a couple of computers in the past to try it out. I have never ran a machine with it.

I tried to link some photos of the machine but recived an error stating I have too many links. I'll try more once I prove Im not a spammer

Bad Z Amplifier

Please Log in or Create an account to join the conversation.

26 Apr 2017 17:32 #92159

by Rescue35

Replied by Rescue35 on topic Refit Kitamura MyCenter Zero

Please Log in or Create an account to join the conversation.

26 Apr 2017 17:32 #92160

by Rescue35

Replied by Rescue35 on topic Refit Kitamura MyCenter Zero

Please Log in or Create an account to join the conversation.

28 Apr 2017 12:06 #92254

by andypugh

Replied by andypugh on topic Refit Kitamura MyCenter Zero

Do you have any specs for motor type, current and voltage? (and feedback type, too)

There are lots of drive possibilities, which need to be whittled down a bit.

There are lots of drive possibilities, which need to be whittled down a bit.

Please Log in or Create an account to join the conversation.

28 Apr 2017 16:51 #92285

by Rescue35

Replied by Rescue35 on topic Refit Kitamura MyCenter Zero

Thanks for the help.

The spindle is 230v 3 phase AC 2.2 kw continuous (3.7kw for 30min). It is a brushless servo with position control through a D/A converter.

Sanyo Deinki

Controler 65BA030dxt

Encoder 1000 p/r

Scale of velocity command voltage Ei=3V/Krpm

The axis motors are 3 phase brushless servos. 230v

Sanyo Deinki

X&Y 65BL014HXE01 (14kg/cm or 194 oz/in)

Encoder 2500 P/R

3000 rpm

Z 65BL030HBE08 (30kg/cm or 416 oz/in)

Encoder 1500 P/R

3000 rpm

Axis controllers are 3 phase full wave 30 amp

Sanyo Deinki

X&Y 65BA030DXT04

Z 65BA030DXT06

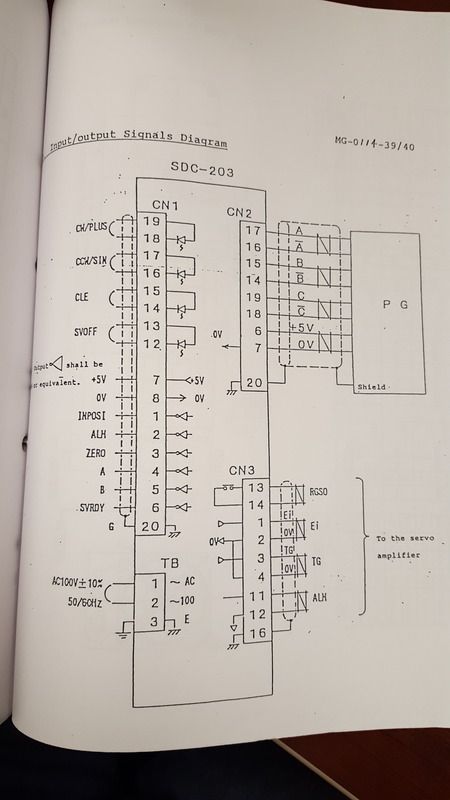

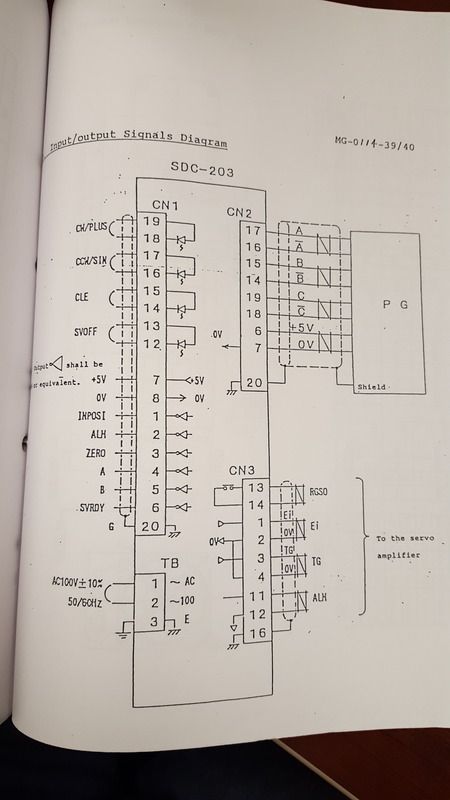

The axis encoders use A+-, B+-, C+-, U+-, V+-, W+-, 5V+,5V-.

D/A Converter I/O

I will work on getting the manual scanned.

The spindle is 230v 3 phase AC 2.2 kw continuous (3.7kw for 30min). It is a brushless servo with position control through a D/A converter.

Sanyo Deinki

Controler 65BA030dxt

Encoder 1000 p/r

Scale of velocity command voltage Ei=3V/Krpm

The axis motors are 3 phase brushless servos. 230v

Sanyo Deinki

X&Y 65BL014HXE01 (14kg/cm or 194 oz/in)

Encoder 2500 P/R

3000 rpm

Z 65BL030HBE08 (30kg/cm or 416 oz/in)

Encoder 1500 P/R

3000 rpm

Axis controllers are 3 phase full wave 30 amp

Sanyo Deinki

X&Y 65BA030DXT04

Z 65BA030DXT06

The axis encoders use A+-, B+-, C+-, U+-, V+-, W+-, 5V+,5V-.

D/A Converter I/O

I will work on getting the manual scanned.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 17815

- Thank you received: 5927

28 Apr 2017 23:23 #92313

by tommylight

Replied by tommylight on topic Refit Kitamura MyCenter Zero

That about encoders using UVW is not right.

They are incremental encoders with A/A, B/B, and C/C that should be index.

The servos seem to use cv/ccv signals, as far as i know 7i77 can do that, but you should wait for PCW or Andy to confirm that.

They are incremental encoders with A/A, B/B, and C/C that should be index.

The servos seem to use cv/ccv signals, as far as i know 7i77 can do that, but you should wait for PCW or Andy to confirm that.

The following user(s) said Thank You: Rescue35

Please Log in or Create an account to join the conversation.

29 Apr 2017 09:19 #92323

by andypugh

Replied by andypugh on topic Refit Kitamura MyCenter Zero

The UVW will be commutation signals for the drives. (brushless motors are commutated in the drives, not in the motor).

If those signals exist then the choice of drives is much expanded.

Is there a DC power supply in the system, or do the axis drives take AC input?

I suspect that the easiest solution would be Granite Drives though cheaper options include the Mesa 8i20 (requires separate DC power supply) and "Whatever turns up on eBay at a good price"

It might well be simplest just to find a stock of spares of the original drives.

If those signals exist then the choice of drives is much expanded.

Is there a DC power supply in the system, or do the axis drives take AC input?

I suspect that the easiest solution would be Granite Drives though cheaper options include the Mesa 8i20 (requires separate DC power supply) and "Whatever turns up on eBay at a good price"

It might well be simplest just to find a stock of spares of the original drives.

The following user(s) said Thank You: Rescue35

Please Log in or Create an account to join the conversation.

30 Apr 2017 15:18 #92349

by Rescue35

Replied by Rescue35 on topic Refit Kitamura MyCenter Zero

Thanks for the education. Servos and their drives are new to me. The UVW does exist in the encoders, I've seen the connections with my own eyes. These drives take 200V AC +-10%. I checked them yesterday and they are receiving 189V. I'll research those options. I have to go back through and troubleshoot it again as I keep getting different faults depending on my jog speed settings. It always faults out while trying to reference the machine so I have no idea what shape the x and y drives are in.

On the upside, I have a reasonable candidate for LinuxCNC. 17" Touchscreen panel mount w/serial port.

On the upside, I have a reasonable candidate for LinuxCNC. 17" Touchscreen panel mount w/serial port.

Please Log in or Create an account to join the conversation.

Time to create page: 0.127 seconds