Tool wear in tool table ?

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

25 Aug 2016 09:44 #79402

by dinkata

Tool wear in tool table ? was created by dinkata

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

25 Aug 2016 14:43 #79429

by andypugh

Yes, look at the sample config sim/axis/lathe-fanucy

That uses a remapped Tnnnn command, details in the README:

github.com/LinuxCNC/linuxcnc/blob/master.../lathe-fanucy/README

Replied by andypugh on topic Tool wear in tool table ?

We use Linuxcnc v.2.7 Lathe . Uncomfortably correction offset ( maybe we do not know how )

Is it possible to build a tool table wherein to introduce correction wear.

Yes, look at the sample config sim/axis/lathe-fanucy

That uses a remapped Tnnnn command, details in the README:

github.com/LinuxCNC/linuxcnc/blob/master.../lathe-fanucy/README

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

25 Aug 2016 16:47 - 25 Aug 2016 16:49 #79436

by dinkata

there is a problem when you start not first N1 ,

Start for example N13 ,then

toolchange : command T6 , perform Т7 !!!!

then run and during the movement began changing tool without command !!!???

we do not wait, press stop .

I like Linuxcnc,but why CNC , for example Fanuc ,from 40 years ago

there is a possibility introduced corection wear ,

a in Linuxcnc must be make remap etc.

Replied by dinkata on topic Tool wear in tool table ?

I tried a similar remap ,but it is also inconvenient .look at the sample config sim/axis/lathe-fanucy

there is a problem when you start not first N1 ,

Start for example N13 ,then

toolchange : command T6 , perform Т7 !!!!

then run and during the movement began changing tool without command !!!???

we do not wait, press stop .

%

N1 G18 G21 G7 G40 G61 G90

N2 G49 M09

N3 T7

N4 S120 M3

N5 M08

N6 G0 X180. Z40.

N7 Z30.

N8 X0.

N9 G1 Z-13. F4.0

N10 G0 Z30.

N11 X180.

N12 Z40.

N13 G49 M09

N14 T6

N15 S200 M3

N16 M08

N17 G0 X180. Z40.

N18 Z28.1

N19 X104.03

N20 G1 Z27.6 F25.0

.............

....

N140 M2

%I like Linuxcnc,but why CNC , for example Fanuc ,from 40 years ago

there is a possibility introduced corection wear ,

a in Linuxcnc must be make remap etc.

Last edit: 25 Aug 2016 16:49 by dinkata.

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

05 Sep 2016 08:16 #80043

by dinkata

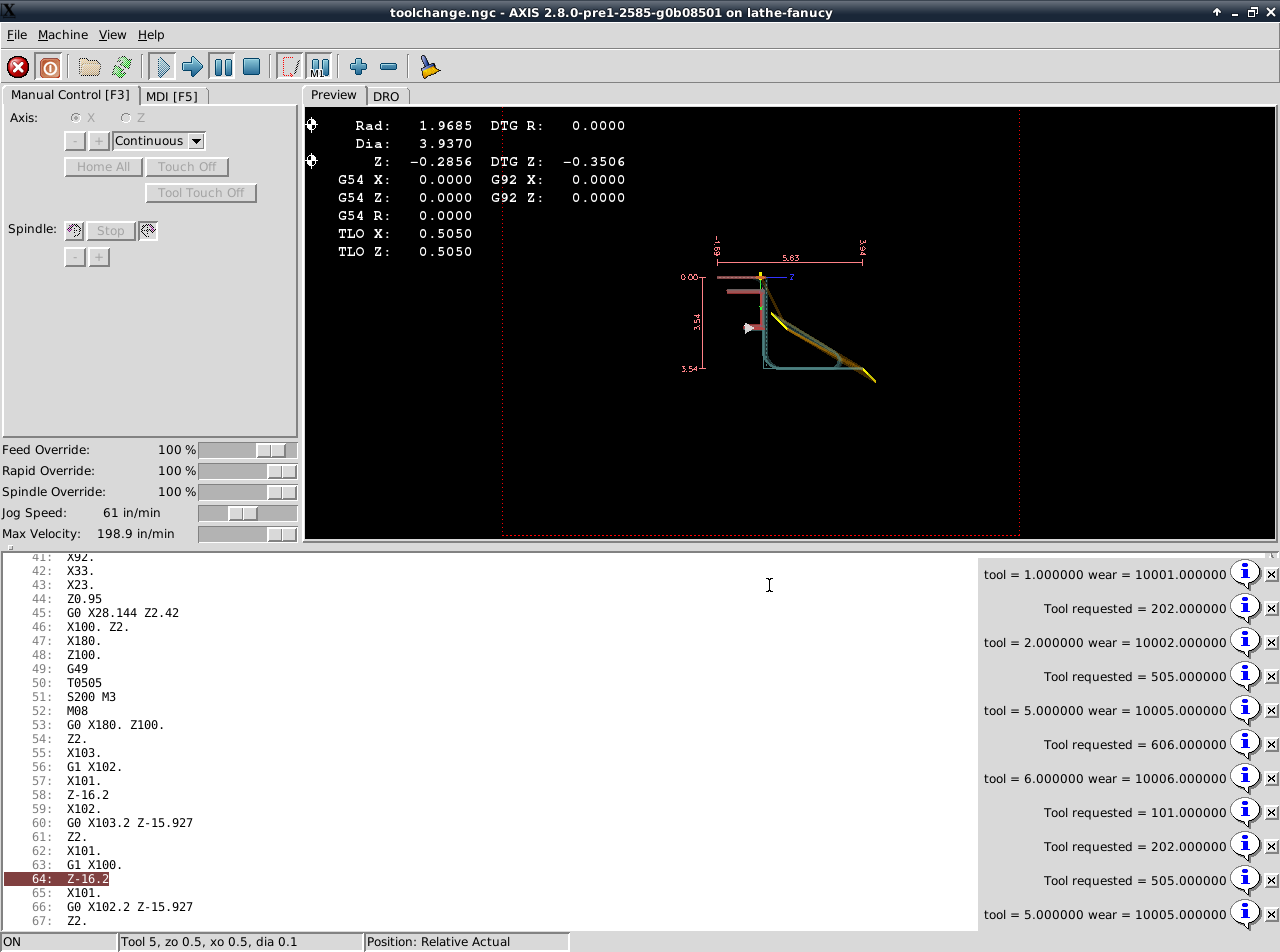

I tried config sim/axis/lathe-fanucy ,

1. - program start and finish normal .

2. -chosen row 49 ,

3.-Run_from selected line

....info tool requested=101 .. !!!??? why ?

....info tool requested=202 .. !!!??? why ?

....info tool requested=505 .. this should only !!!!!

............

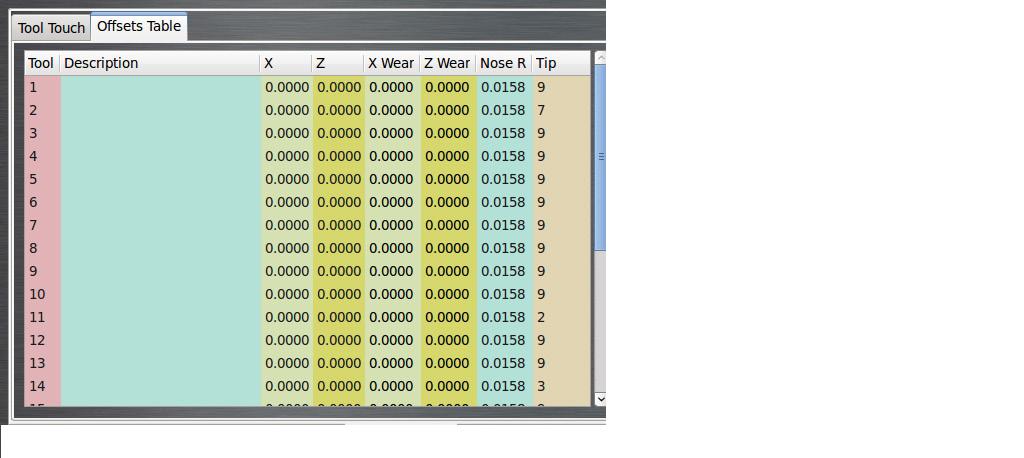

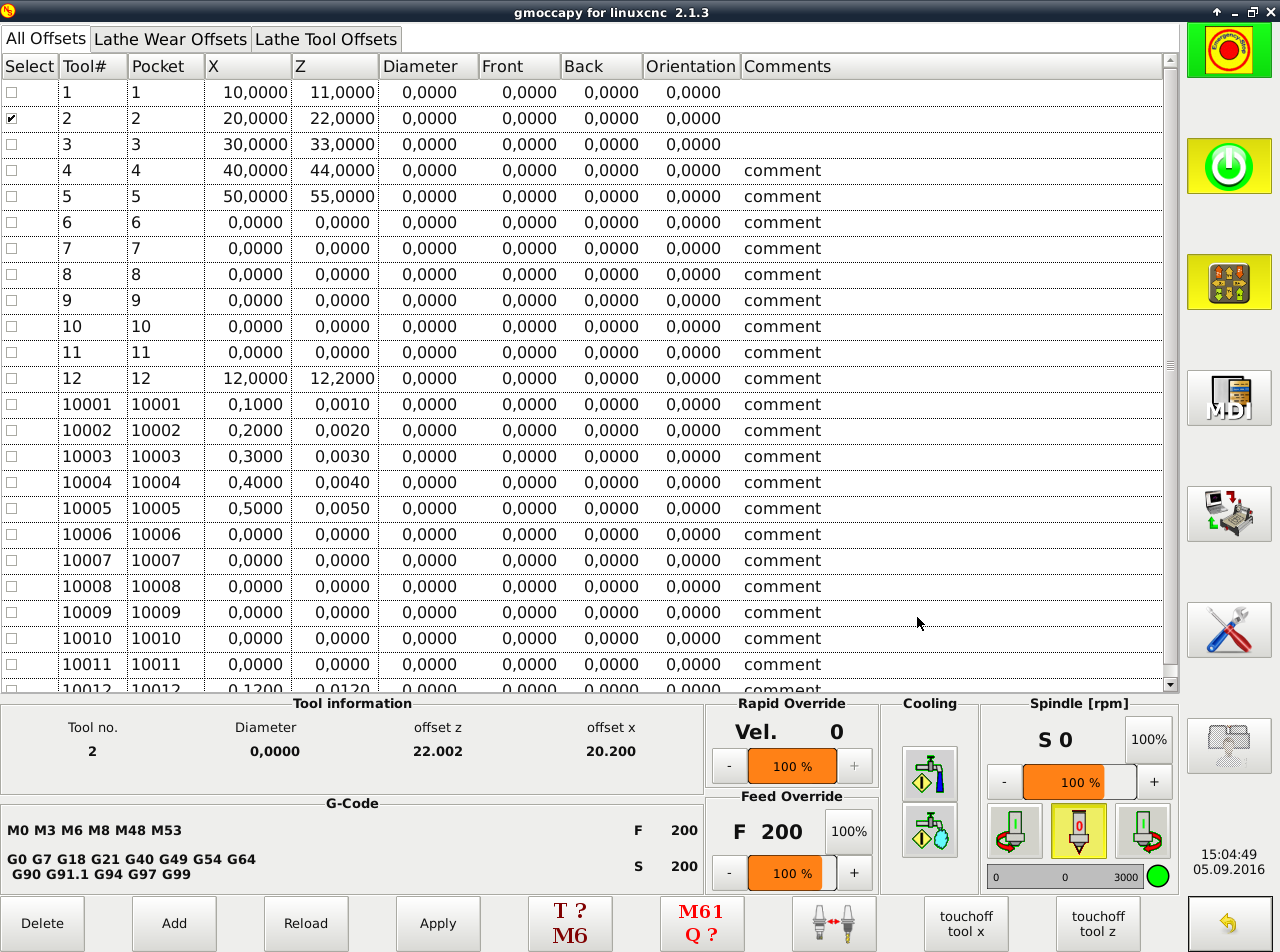

How should I fill tooltable

Tool 1 wear 10001

Tool 2 wear 10002

...................................

Tool 12 wear 12012 ????

..

Thanks advance

Replied by dinkata on topic Tool wear in tool table ?

We use Linuxcnc v.2.7 Lathe . Uncomfortably correction offset ( maybe we do not know how )

Is it possible to build a tool table wherein to introduce correction wear.

Yes, look at the sample config sim/axis/lathe-fanucy

That uses a remapped Tnnnn command, details in the README:

github.com/LinuxCNC/linuxcnc/blob/master.../lathe-fanucy/README

I tried config sim/axis/lathe-fanucy ,

1. - program start and finish normal .

2. -chosen row 49 ,

3.-Run_from selected line

....info tool requested=101 .. !!!??? why ?

....info tool requested=202 .. !!!??? why ?

....info tool requested=505 .. this should only !!!!!

............

How should I fill tooltable

Tool 1 wear 10001

Tool 2 wear 10002

...................................

Tool 12 wear 12012 ????

..

Thanks advance

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

05 Sep 2016 08:18 - 05 Sep 2016 12:16 #80044

by dinkata

Replied by dinkata on topic Tool wear in tool table ?

Last edit: 05 Sep 2016 12:16 by dinkata.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7275

- Thank you received: 2119

06 Sep 2016 03:19 #80063

by cmorley

Replied by cmorley on topic Tool wear in tool table ?

yes this is right.

tool 12 wear would be 10012

As for the run-at-line problem. I'm not sure.

Run-at-line is implemented badly in linuxcnc - it may be run-at-line is changing tools not sure...

could you post your program?

Chris M

tool 12 wear would be 10012

As for the run-at-line problem. I'm not sure.

Run-at-line is implemented badly in linuxcnc - it may be run-at-line is changing tools not sure...

could you post your program?

Chris M

Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

06 Sep 2016 06:13 #80065

by dinkata

Replied by dinkata on topic Tool wear in tool table ?

Of course :could you post your program?

%

G18 G21 G7 G40

G49

T0101

S150 M3

M08

G0 X180. Z100.

Z5.

X0.

G1 Z-43. F200.0

G0 Z5.

X180.

Z100.

G49

T0202

S200 M3

M08

G0 X180. Z100.

Z2.35

X100.

G1 Z2. F200.0

Z1.65

X23.

Z2.

G0 X24.47 Z2.42

X100.

Z1.65

G1 Z1.3

X23.

Z1.65

G0 X24.47 Z2.07

X100.

Z1.3

G1 Z0.95

X23.

Z1.3

G0 X24.47 Z1.72

X100.

Z0.95

G1 Z0.8

X92.

X33.

X23.

Z0.95

G0 X28.144 Z2.42

X100. Z2.

X180.

Z100.

G49

T0505

S200 M3

M08

G0 X180. Z100.

Z2.

X103.

G1 X102.

X101.

Z-16.2

X102.

G0 X103.2 Z-15.927

Z2.

X101.

G1 X100.

Z-16.2

X101.

G0 X102.2 Z-15.927

Z2.

X100.

G1 X99.

Z-16.2

X100.

G0 X101.2 Z-15.927

Z2.

X99.

G1 X98.

Z-16.2

X99.

G0 X100.2 Z-15.927

Z2.

X98.

G1 X97.

Z-16.2

X98.

G0 X99.2 Z-15.927

Z2.

X97.

G1 X96.

Z-16.2

X97.

G0 X98.2 Z-15.927

Z2.

X96.

G1 X95.

Z-0.369

X95.131 Z-0.434

G03 X95.6 Z-1. K-0.566 I-0.566

G1 Z-16.2

X96.

G0 X97.2 Z-15.927

Z2.

X95.

G1 X94.

Z0.131

X95. Z-0.369

G0 X96.2 Z-0.095

Z2.

X94.

G1 X93.6

Z0.331

X94. Z0.131

G0 X102.201 Z2.

X103.2

X102.

X180.

Z100.

G49

T0606

S200 M3

M08

G0 X180. Z100.

Z2.

X26.7

G1 X26. F250.0

X26.7

Z-32.996

X26.

G0 X25.16 Z-32.075

Z2.

X26.7

G1 X27.4

Z-32.996

X26.7

G0 X25.86 Z-32.075

Z2.

X27.4

G1 X28.1

Z-32.996

X27.4

G0 X26.56 Z-32.075

Z2.

X28.1

G1 X28.8

Z-32.996

X28.1

G0 X27.26 Z-32.075

Z2.

X28.8

G1 X29.5

Z-1.184

X29.434 Z-1.217

G02 X29.2 Z-1.5 K-0.283 I0.283

G1 Z-32.996

X28.8

G0 X27.96 Z-32.075

Z2.

X29.5

G1 X30.2

Z-0.834

X29.5 Z-1.184

G0 X28.66 Z-0.263

Z2.

X30.2

G1 X30.9

Z-0.484

X30.2 Z-0.834

G0 X29.36 Z0.087

Z2.

X30.9

G1 X31.6

Z-0.134

X30.9 Z-0.484

G0 X30.06 Z0.437

Z2.

X31.6

G1 X32.2

Z0.166

X31.6 Z-0.134

G0 X29.655 Z2.

X25.16

X26.

X180.

Z100.

M5

M9

M2

%Please Log in or Create an account to join the conversation.

- dinkata

- Offline

- Premium Member

-

Less

More

- Posts: 101

- Thank you received: 1

06 Sep 2016 06:29 - 06 Sep 2016 06:43 #80066

by dinkata

Replied by dinkata on topic Tool wear in tool table ?

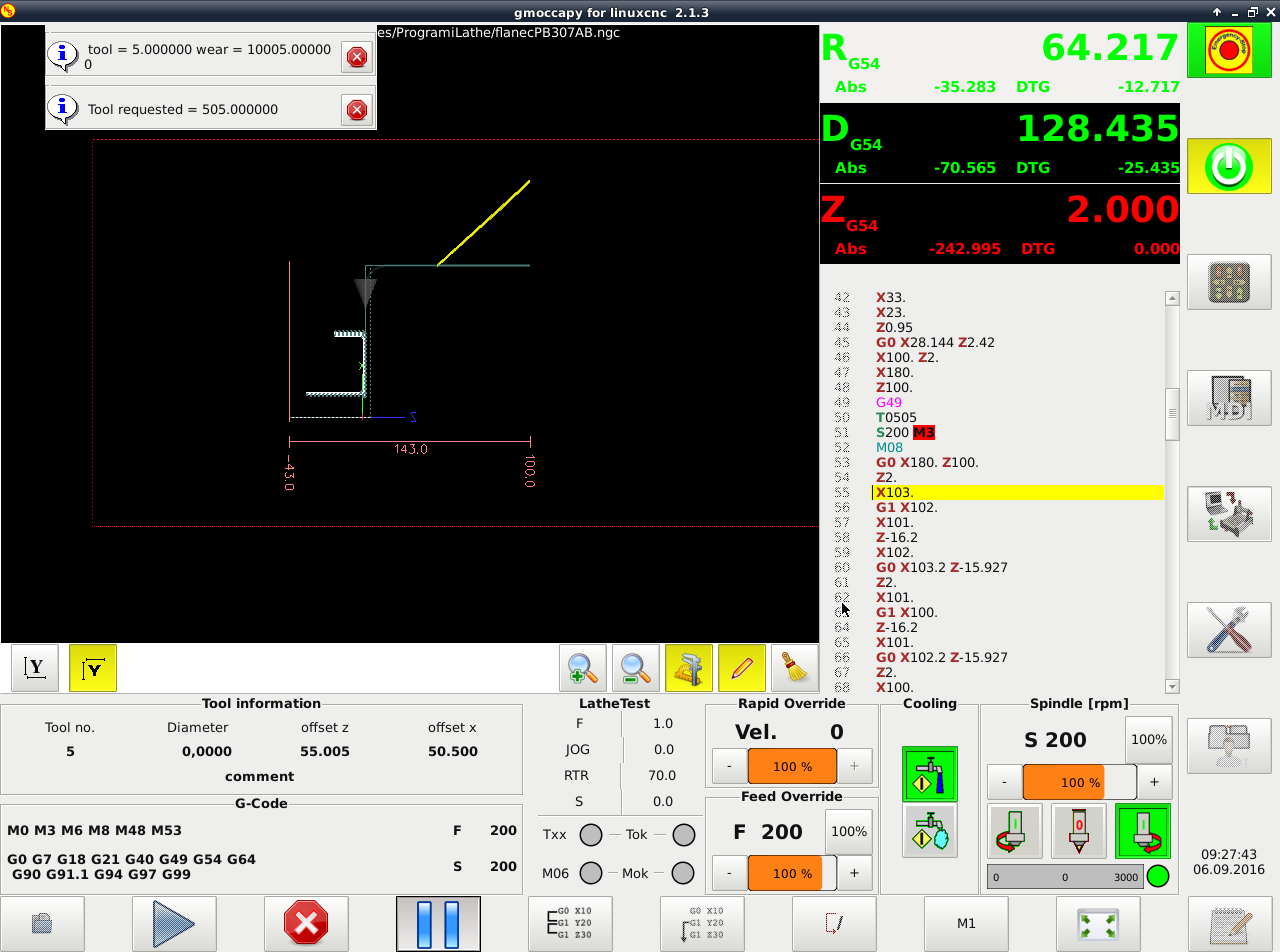

1.If we start from the beginning - no problem

2.Very useful tool wear in tooltable !

3.But we need when setting program use " run-at-line "

..If we start from line

.....G49

T0505 ..

remap wants to put previous tools

4.If I hide previous tools

.........

( T0101 )

.........

( T0202 )...

.......

and start from line

.....G49

T0505 ..

Then remap work properly

Is it possible to avoid hiding previous instruments?

2.Very useful tool wear in tooltable !

3.But we need when setting program use " run-at-line "

..If we start from line

.....G49

T0505 ..

remap wants to put previous tools

4.If I hide previous tools

.........

( T0101 )

.........

( T0202 )...

.......

and start from line

.....G49

T0505 ..

Then remap work properly

Is it possible to avoid hiding previous instruments?

Last edit: 06 Sep 2016 06:43 by dinkata.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7275

- Thank you received: 2119

06 Sep 2016 06:58 #80067

by cmorley

Replied by cmorley on topic Tool wear in tool table ?

I confirm the problem.

I'll try to look into it tomorrow

Chris M

I'll try to look into it tomorrow

Chris M

The following user(s) said Thank You: dinkata

Please Log in or Create an account to join the conversation.

- nkp

- Offline

- Premium Member

-

Less

More

- Posts: 143

- Thank you received: 39

07 Sep 2016 04:15 - 07 Sep 2016 04:18 #80112

by nkp

Replied by nkp on topic Tool wear in tool table ?

I think that "the bug" in remap.

The following code works fine:ini:

#REMAP = T prolog=get_T_number ngc=toolchange

The following code works fine:

%

G18 G21 G7 G40

;------------------------tool 1, wear 1

G49

T1 M6

G43

G43.2 H10001

;------------------------

S150 M3

M08

G0 X180. Z100.

Z5.

X0.

G1 Z-43. F200.0

G0 Z5.

X180.

Z100.

;------------------------tool 2, wear 2

G49

T2 M6

G43

G43.2 H10002

;------------------------

S200 M3

M08

G0 X180. Z100.

Z2.35

X100.

G1 Z2. F200.0

Z1.65

X23.

Z2.

G0 X24.47 Z2.42

X100.

Z1.65

G1 Z1.3

X23.

Z1.65

G0 X24.47 Z2.07

X100.

Z1.3

G1 Z0.95

X23.

Z1.3

G0 X24.47 Z1.72

X100.

Z0.95

G1 Z0.8

X92.

X33.

X23.

Z0.95

G0 X28.144 Z2.42

X100. Z2.

X180.

Z100.

;------------------------tool 5, wear 5

G49

T5 M6

G43

G43.2 H10005

;------------------------

S200 M3

M08

G0 X180. Z100.

Z2.

X103.

G1 X102.

X101.

Z-16.2

X102.

G0 X103.2 Z-15.927

Z2.

X101.

G1 X100.

Z-16.2

X101.

G0 X102.2 Z-15.927

Z2.

X100.

G1 X99.

Z-16.2

X100.

G0 X101.2 Z-15.927

Z2.

X99.

G1 X98.

Z-16.2

X99.

G0 X100.2 Z-15.927

Z2.

X98.

G1 X97.

Z-16.2

X98.

G0 X99.2 Z-15.927

Z2.

X97.

G1 X96.

Z-16.2

X97.

G0 X98.2 Z-15.927

Z2.

X96.

G1 X95.

Z-0.369

X95.131 Z-0.434

G03 X95.6 Z-1. K-0.566 I-0.566

G1 Z-16.2

X96.

G0 X97.2 Z-15.927

Z2.

X95.

G1 X94.

Z0.131

X95. Z-0.369

G0 X96.2 Z-0.095

Z2.

X94.

G1 X93.6

Z0.331

X94. Z0.131

G0 X102.201 Z2.

X103.2

X102.

X180.

Z100.

;------------------------tool 6, wear 6

G49

T6 M6

G43

G43.2 H10006

;------------------------

S200 M3

M08

G0 X180. Z100.

Z2.

X26.7

G1 X26. F250.0

X26.7

Z-32.996

X26.

G0 X25.16 Z-32.075

Z2.

X26.7

G1 X27.4

Z-32.996

X26.7

G0 X25.86 Z-32.075

Z2.

X27.4

G1 X28.1

Z-32.996

X27.4

G0 X26.56 Z-32.075

Z2.

X28.1

G1 X28.8

Z-32.996

X28.1

G0 X27.26 Z-32.075

Z2.

X28.8

G1 X29.5

Z-1.184

X29.434 Z-1.217

G02 X29.2 Z-1.5 K-0.283 I0.283

G1 Z-32.996

X28.8

G0 X27.96 Z-32.075

Z2.

X29.5

G1 X30.2

Z-0.834

X29.5 Z-1.184

G0 X28.66 Z-0.263

Z2.

X30.2

G1 X30.9

Z-0.484

X30.2 Z-0.834

G0 X29.36 Z0.087

Z2.

X30.9

G1 X31.6

Z-0.134

X30.9 Z-0.484

G0 X30.06 Z0.437

Z2.

X31.6

G1 X32.2

Z0.166

X31.6 Z-0.134

G0 X29.655 Z2.

X25.16

X26.

X180.

Z100.

M5

M9

M2

%#REMAP = T prolog=get_T_number ngc=toolchange

Last edit: 07 Sep 2016 04:18 by nkp.

The following user(s) said Thank You: jo_key, dinkata

Please Log in or Create an account to join the conversation.

Time to create page: 0.187 seconds