- Configuring LinuxCNC

- Advanced Configuration

- 5 Axis TCP Simultaneous Kinematics Fusion 360 setup Mesa 7i76e

5 Axis TCP Simultaneous Kinematics Fusion 360 setup Mesa 7i76e

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 4

I'm new to LinuxCNC, but I have a lot of CNC experience, 3 axis or less (lathe). I have built my own CNC machines, but mostly using grbl controller on arduino. I'm very intrigued by LinuxCNC and want to add A and C axis to one of my CNC routers. I'll build a LinuxCNC machine on a RPi or something with a little more horse power. I have a Mesa 7i76e card. I want to do simultaneous (TCP kinematics?) machining.

So, now for questions:

1. Can I output from Fusion 360 CAM for LinuxCNC TCP (my vastly preferred creation tool)? If so, is there a post processor ready to go for this. I see a Linux EMC and EMC2 PP in Fusion 360, but there are no details listed regarding continuous 5 axis, etc. Has anyone done this successfully?

2. Is the 7i76e Mesa card an appropriate controller for simultaneous 5 axis?

3. How difficult is it to install and configure TCP/kinematics for this setup? I'm not a programmer, but do understand editing configuration files, etc. Is there sufficient documentation?

4. Is there anyone out there using this configuration willing to help me if I get stuck?

5. I've seen a few videos of this working on youtube, but there isn't a lot of support documentation for setting the configuration files, etc. Maybe I just haven't found it? If you know a good repository of this knowledge, please share.

These are my questions so for before I take the $570 plunge and purchase a harmonic drive (zero backlash?) AC unit.

I want to become a penguin adopter and look forward to a more editable and powerful software interface. I'm hoping to make this work! Any help would be greatly appreciated. I'm happy to create videos documenting this process for future 5 axis peeps.

Thanks in advance,

Tyler

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2077

2. Yes

3. Have a look at the simulation config under 'axis/vismach/5axis/table-rotary-tilting/xyzac'. You can set the axis offsets in the 'ini' file. You might want to start with this and see how the fusion work flow is working out for you.

4. I'm happy to help with the linuxcnc side of things but can't help you with fusion360. I know there are users here that do exactly what you want to do but feedback to 5axis TCP questions is not exactly abundant.

5. Documentation is somewhat scant. Make sure you read the 'README.txt' in the sim config mentioned above. 5axis TCP is very much a CAM exercise so you might also want to look on other forums that cover the topic in Fusion360.

Generally you need to be aware that 5axis TCP will require fast moves in all axes with high rigidity and smooth movments. Depending on your expectations using those 'cheap' rotary assemblies on a machine can be disappointing.

Maybe check these videos out. He has got several covering the XYZAC setup and modifying his rotary assembly. It's in german but covers almost exactly what you want.

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 4

I know the rigidity/holding power of these cheap harmonic drive AC tables is not stellar, but I will be cutting fairly soft material, so I'm not entirely concerned. They have little backlash and repeatability seems to be decent based on a few tests I've seen on YouTube. Plus, it's a USA shipper who has already agreed to honor a return if I deem the backlash to be too excessive for my purposes. I have also looked at the belt driven versions of AC tables, (ratio 6:1 and 8:1) and I may go that route as I'm more familiar with belt drives than harmonic drives.

I appreciate the offer to help me through the LinuxCNC setup. I'm fairly computer savvy and am very familiar with editing .ini files to change configuration, etc. What I don't know much about are the LinuxCNC plugins (?) like the kinematics, which allows TCP. And I'll have to learn the LinuxCNC nomenclature, axis are referred to as "joints," for example.

I've also learned that true 5th axis continuous tool paths CAM abilities in Fusion comes as a paid extension (add on), which runs a very steep $1200 or so a year to use. Ug!

Does anyone know of a reasonably priced 5 continuous axis CAM software that I can import a mesh object into and create both CAM and post processing which LinuxCNC will happily ingest?

Phew, it's a lot. Thanks for humoring me as I dip my toe into both the 5 axis continuous world, LinuxCNC world and I'm sure there's something else!

Cheers,

Tyler

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11705

- Thank you received: 3958

Instead use a 4 core CPU X86 machine. eg. Celeron J1900 or newer in small form factor but i3 and i5 Pc's work well

To use the 5 axis kinematics modules you need to run Versoin 2.9 or above.

The easiset way on a X86 machine is to install Debian Bookworm. Its pretty easy if you follow my how to

docs.google.com/document/d/1jeV_4VKzVmOI...diY/edit?usp=sharing

Good luck!

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 4

I'll see what PCs I have lying around that could fit the bill. Version 2.9 isn't listed, that's the current build? I'll look through your notes. I really appreciate you sharing them with me.

Do you have direct experience with 5 axis continuous machining? Or do you know anyone who does? I'd love to pick somebody's brain regarding what I'm trying to accomplish.

Cheers,

Tyler

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4650

- Thank you received: 2077

In your case you should not have to do anything in the kinematics file at all. (If you are curious it involves two files for the 'trt' kinematics, '/src/emc/kinematics/trtfuncs.c' and '/src/emc/kinematics/xyzac-trt-kins.c') All the custom kinematic does is map the cartesian XYZ position to the joint position and the other way around. There is a paper on the mathematics behind the xyzac-trt kinematics in the documentation.What I don't know much about are the LinuxCNC plugins (?) like the kinematics, which allows TCP.

Note that while in usual cartesian machines there is indeed not much of a difference between 'joint' and 'axis'. However when non-trivial custom kinematics (like your xyzac-trt) are used the concept is important because the cartesian axes (ie XYZ) are then often not aligned with the physical direction of the machine ways. A move along the X axis might involve one, two or even three directions of travel on the machine (ie joints). It is this relationship that is defined in the custom kinematic file.And I'll have to learn the LinuxCNC nomenclature, axis are referred to as "joints," for example.

Also note that the motion planner in LinuxCNC is totally ignorant of any custom kinematics, it lives exclusively in trivial cartesian space where an axis is always parallel to it's corresponding joint. This means that 'axis' limits, as set in the ini file, will only be of limited use. Because of the complex relations of joints and axes the axes limits depend on the joint position. Practically this means that axis limit checks done by the gcode preview in Linuxcnc when loading a file will be pointless and might give false errors and will also not be able to detect violations at runtime. So you may have to set the axis limits in the ini to large values.

Joint limits will be checked and respected, but only during gcode execution.

In short, check your limits in the CAM.

Disclaimer: I have no practical 5axis machining experience.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11705

- Thank you received: 3958

I'll see what PCs I have lying around that could fit the bill. Version 2.9 isn't listed, that's the current build? I'll look through your notes. I really appreciate you sharing them with me.

Do you have direct experience with 5 axis continuous machining? Or do you know anyone who does? I'd love to pick somebody's brain regarding what I'm trying to accomplish.

</quote>

Version 2.8 is the current release version and is pretty long in the tooth. 2.9 has been hived off pending release. 2.10 is the current development branch (master). Linuxcnc was accepted into the Debian repsitories last year but it is only by perodic snapshots of version 2.9. The last one was in about November.

There is an unofficial buildbot of 2.9 and 2.10 so updates are available for bookworm on an ongoing basis. I need to experiment with it and update my instructions.

I have no experience with 5 axis. Aceira is the expert with the kinematics mathematics. I have enough trouble moving from 2D plasma cutting to a 3 Axis CNC Mill I converted. But 2.9/2.10 have some really nice kinematics modules using a method called switchkins which allows swapping between conventional 5 axis cnc mode and 5 axis TCP mode which is cool...

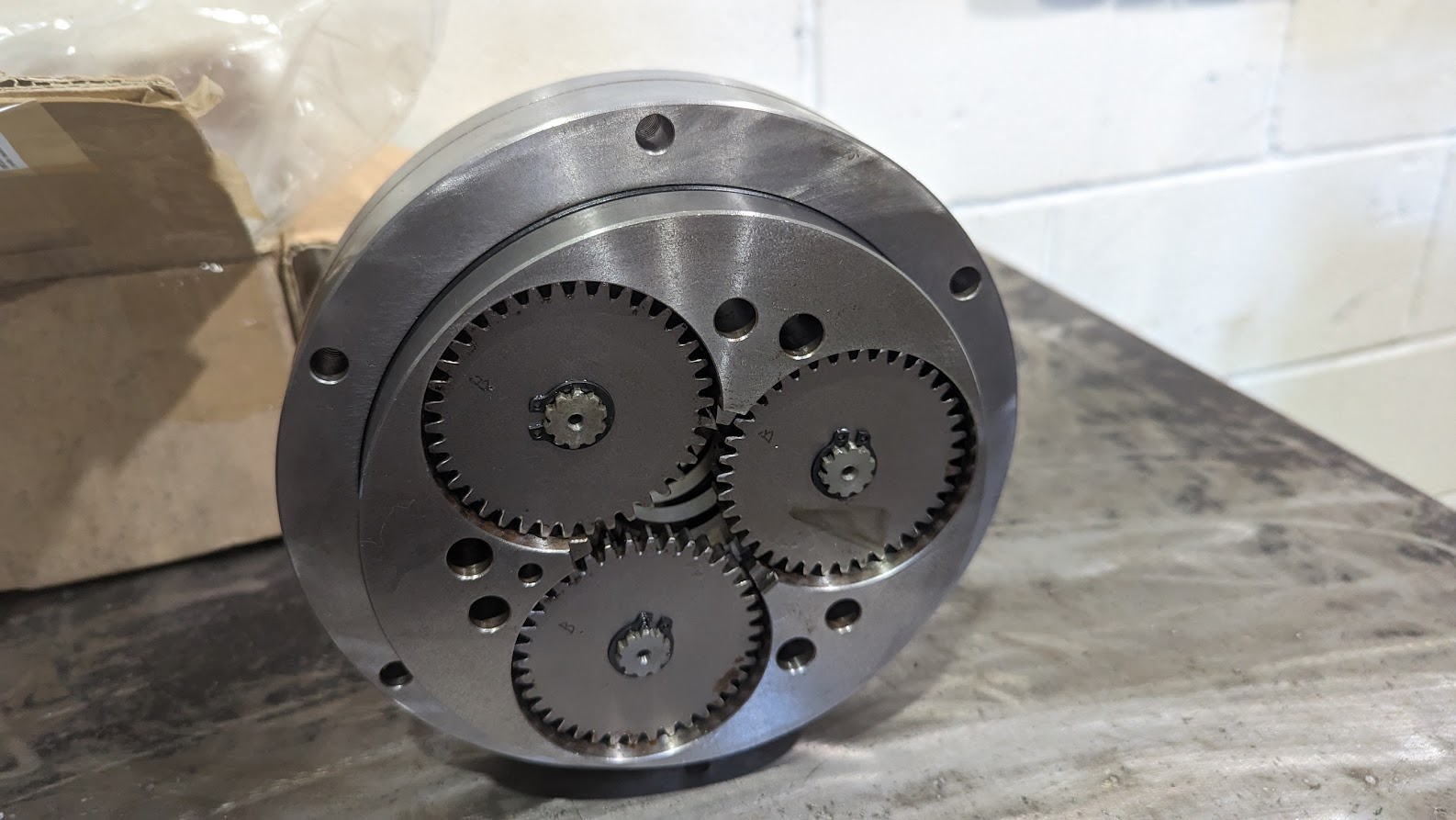

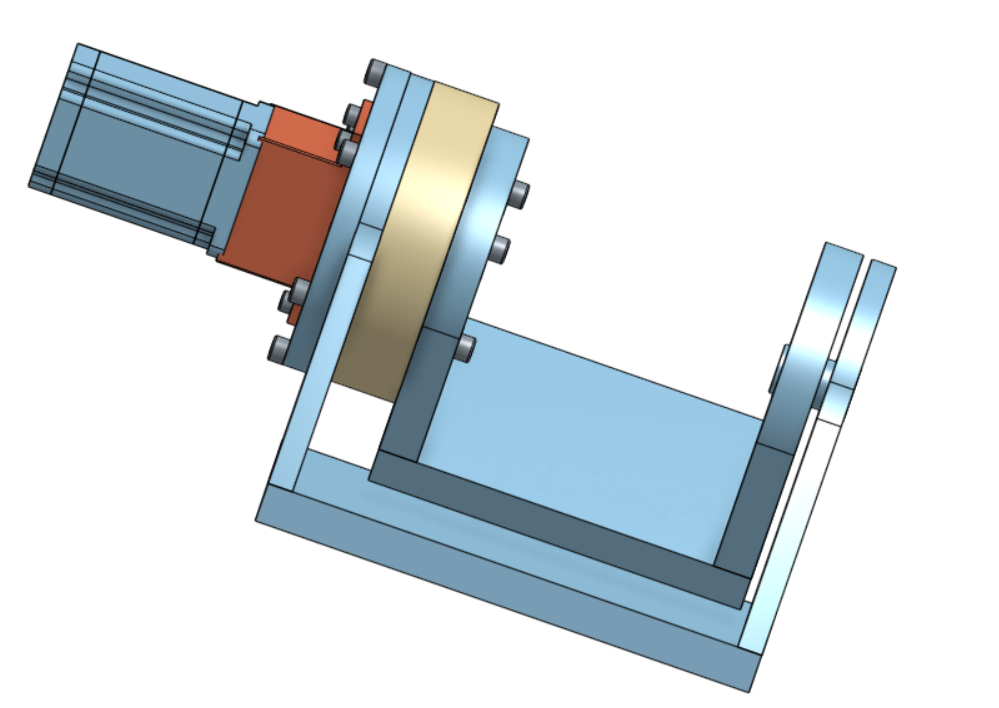

But somebody gave me a High precision rotary gearbox recently. Fortunately, I have a good gear shop who has been making parts for me for years so they are making the missing input shaft (The manufacturer had full specs.) And I have done a bit of work in Onshape. I was planning on using flat parts laser cut from 16mm or 25mm steel. Then bolt or weld together. Welding would require normalisation and machining...

Its not really a trivial project. This baby needs a 6000 rpm 1 kW servo motor to output 40 rpm. I think that is in the ballpark. What do you think/

I'm not sure where this will take me....

Attachments:

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 4

Thanks again.

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 4

Looks like you've got a very beefy cycloidal drive there! It seems a bit overkill unless you're trying to mill steel on a regular basic. I plan on starting with a somewhat inexpensive AC setup, around $600, and learn my way around 5 axis machining using very forgiving materials. I'm really curious how accurate I can get. With 3 axis machining, belt driven, I'm living in the ±0.05mm accuracy range. I'd love to be able to achieve this in 5 axis continuous land without breaking the bank, but I don't know how realistic it is.

Good luck with your project. You can't find a replacement shaft from the manufacturer of that gear box?

T-

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 31

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- 5 Axis TCP Simultaneous Kinematics Fusion 360 setup Mesa 7i76e