Backlash on double nut ballscrew

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

10 May 2016 13:14 #74444

by emcPT

Backlash on double nut ballscrew was created by emcPT

I am trying to repair a machine that is in good mechanical condition except the backlash that it presents on the X and Y axis.

The backlash is constant for all the travel so I am hopeful that I can eliminate the backlash on the nut.

Nut is double type that I think is made for this propose - to eliminate backlash.

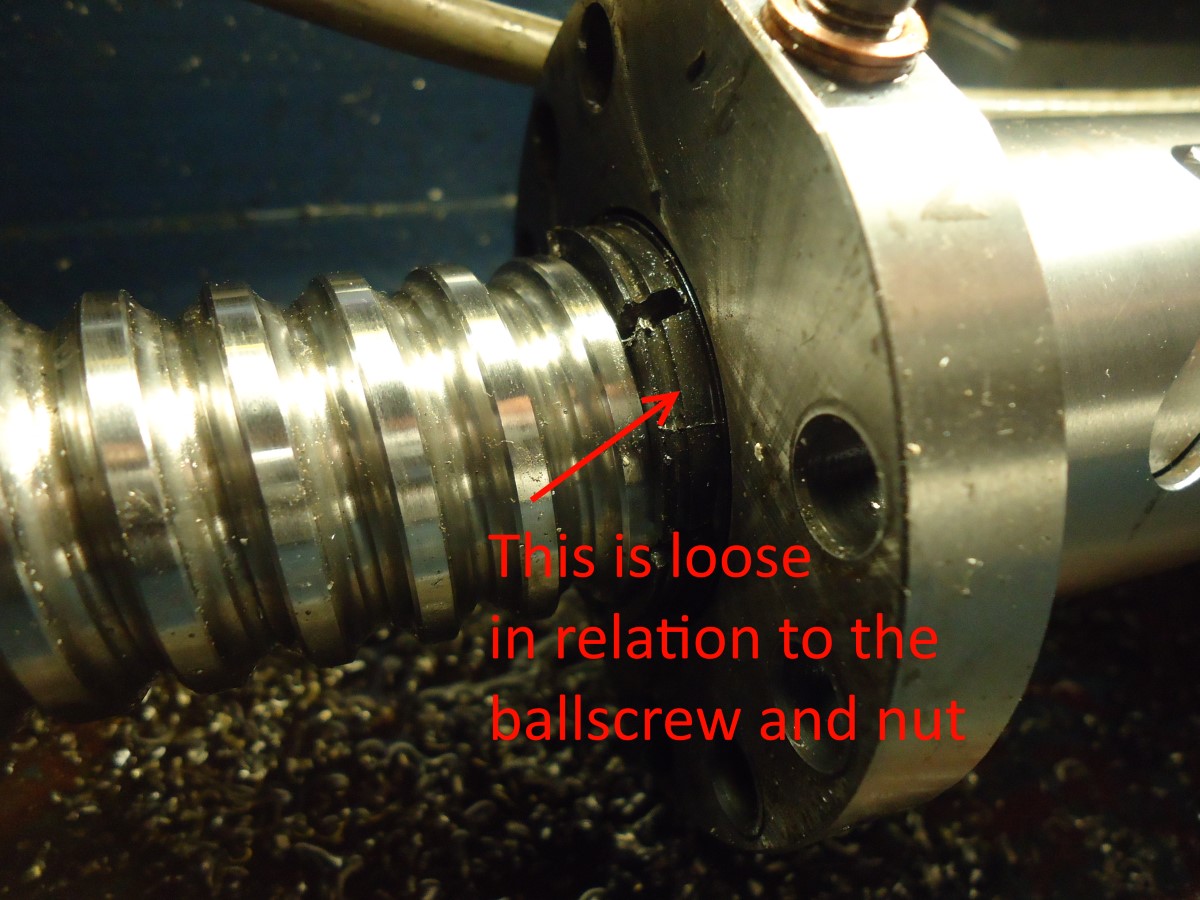

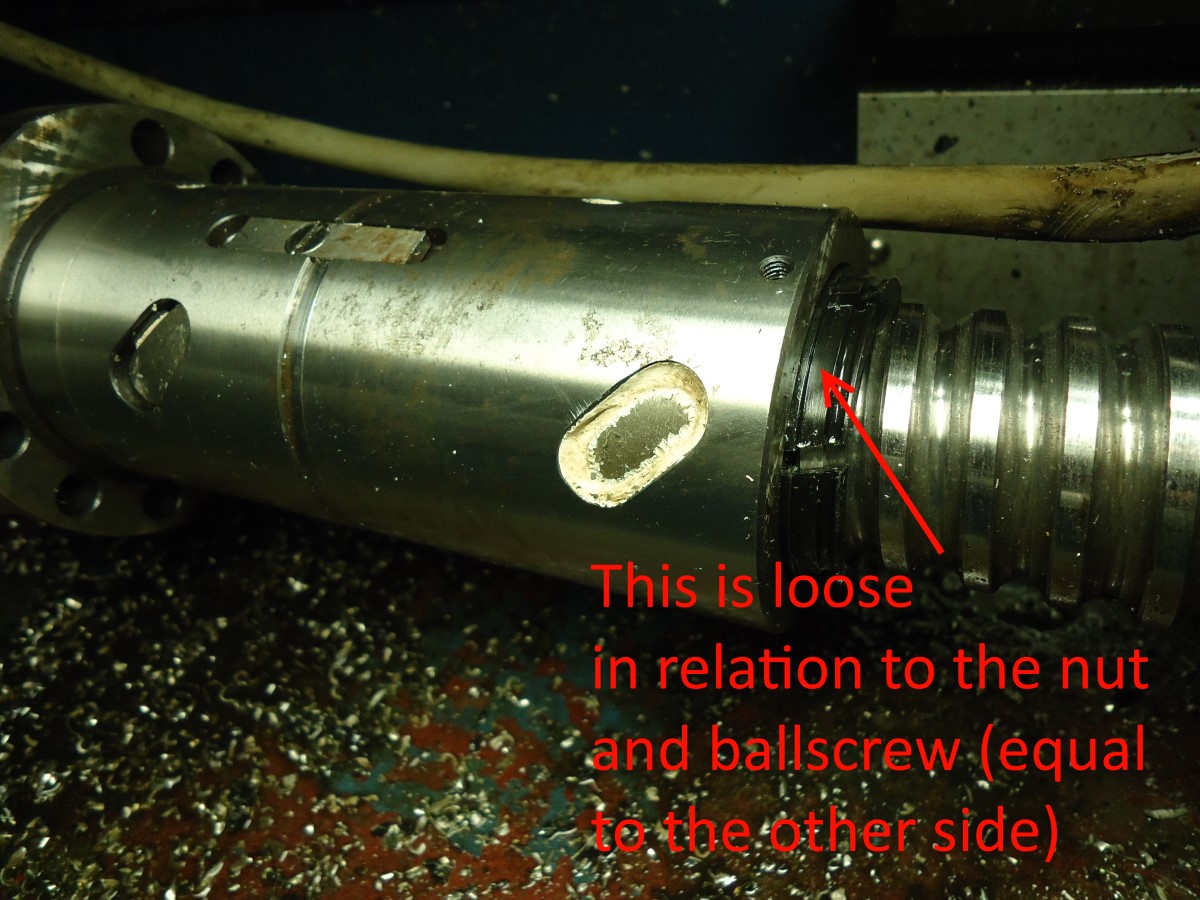

I have attached 3 photos. I do not know if the nut can be safely opened from the center, and I also do not know if the black covers at the end (that have angular slots) are meant to be loose.

Any information is welcome as I do not want to damage the nuts and I never did this kind of work.

Thank you

The backlash is constant for all the travel so I am hopeful that I can eliminate the backlash on the nut.

Nut is double type that I think is made for this propose - to eliminate backlash.

I have attached 3 photos. I do not know if the nut can be safely opened from the center, and I also do not know if the black covers at the end (that have angular slots) are meant to be loose.

Any information is welcome as I do not want to damage the nuts and I never did this kind of work.

Thank you

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

10 May 2016 13:34 - 10 May 2016 13:43 #74446

by Todd Zuercher

Replied by Todd Zuercher on topic Backlash on double nut ballscrew

The black things on the ends are just seals or wipers that are supposed to help keep crud out and lubrication in. The tab with the ? mark locks the 2 halves together with the shim in between the 2 halves.

I would look more closely at the support bearings for the screw, checking them for end play.

I'm not necessarily recommending this, but if the backlash is indeed in the nuts, if you remove the locking tab you would be able to turn the nuts closer together (misaligning the tab slots), You then might be able to find a shim that would let you take out the slop and put it back together. But if it is already tight, you might have some difficulty getting the slot realigned good enough to replace the tab, so don't blame me if you can't get it back together.

I would look more closely at the support bearings for the screw, checking them for end play.

I'm not necessarily recommending this, but if the backlash is indeed in the nuts, if you remove the locking tab you would be able to turn the nuts closer together (misaligning the tab slots), You then might be able to find a shim that would let you take out the slop and put it back together. But if it is already tight, you might have some difficulty getting the slot realigned good enough to replace the tab, so don't blame me if you can't get it back together.

Last edit: 10 May 2016 13:43 by Todd Zuercher.

The following user(s) said Thank You: emcPT

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

10 May 2016 15:55 - 10 May 2016 16:23 #74451

by emcPT

Replied by emcPT on topic Backlash on double nut ballscrew

The supports bearings are ok. I can feel the backlash by one hand in the ballscrew and the other in the nut, so it is really on the nut.

When you say that I can turn the nuts, do you mean that one have internal thread and the other external, so that when I turn one against the other the distance between both will be lower and therefore the backlash will be lower?

If I cannot re align the slots I can place them back on the original position or there might be a risk of loosing balls or something dangerous?

Work is done inside the machine in a poor position for me, so I must be prepared for what will might come.

When you say that I can turn the nuts, do you mean that one have internal thread and the other external, so that when I turn one against the other the distance between both will be lower and therefore the backlash will be lower?

If I cannot re align the slots I can place them back on the original position or there might be a risk of loosing balls or something dangerous?

Work is done inside the machine in a poor position for me, so I must be prepared for what will might come.

Last edit: 10 May 2016 16:23 by emcPT.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

10 May 2016 16:47 #74459

by Todd Zuercher

Replied by Todd Zuercher on topic Backlash on double nut ballscrew

I don't think there is risk of loosing balls unless you open the ball returns, or remove the nut from the screw.

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

10 May 2016 18:08 #74467

by emcPT

Replied by emcPT on topic Backlash on double nut ballscrew

I was the last hour inside the machine but it payed off.

I removed the screw and like you said the two nuts disengaged without any ball lost. Thigh them up against each other until the preload is ok. Now is time to make another locking, this time with a offset and I think that the job is done!

Thanks again.

I removed the screw and like you said the two nuts disengaged without any ball lost. Thigh them up against each other until the preload is ok. Now is time to make another locking, this time with a offset and I think that the job is done!

Thanks again.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

10 May 2016 18:59 #74471

by Todd Zuercher

Replied by Todd Zuercher on topic Backlash on double nut ballscrew

Add a spacer shim between the nuts and keep the key the same.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

11 May 2016 04:51 #74485

by jmelson

Well, apparently, there is NO preload in this unit any longer, for some reason.

As Todd says, adding a bit of spacer between the two nuts should fix the problem, and ought to be easy to adjust to get the desired preload. I'd use brass shim stock, and cut it into two half-rings that can be slipped between the nuts. When it is all right, then you could wrap electrical tape around the extra spacer so it won't work out over time.

Jon

Replied by jmelson on topic Backlash on double nut ballscrew

No, there are two completely separate ballnuts on the screw. If you remove the little screw and the key it holds, the second nut will screw back away from the one with the mounting flange (I think!) There is a spacer between the two nuts. This spacer sets the preload that is SUPPOSED to be present. So, the way this is supposed to work is that the nuts are screwed together squeezing the spacer until they put the short section of ballscrew in tension between the two nuts.When you say that I can turn the nuts, do you mean that one have internal thread and the other external, so that when I turn one against the other the distance between both will be lower and therefore the backlash will be lower?

Well, apparently, there is NO preload in this unit any longer, for some reason.

As Todd says, adding a bit of spacer between the two nuts should fix the problem, and ought to be easy to adjust to get the desired preload. I'd use brass shim stock, and cut it into two half-rings that can be slipped between the nuts. When it is all right, then you could wrap electrical tape around the extra spacer so it won't work out over time.

Jon

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

11 May 2016 12:20 #74499

by Todd Zuercher

Replied by Todd Zuercher on topic Backlash on double nut ballscrew

No, cut a full circle then slit only one side, then with the 2 halve seperated by several inches, twist the slit circle to slip it around the screw. this way it will be self retaining and you won't have to worry about it falling out.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

11 May 2016 16:21 #74518

by jmelson

It could also slip off-center and start scraping against the screw. But, your method will probably work fine.

Jon

Replied by jmelson on topic Backlash on double nut ballscrew

No, cut a full circle then slit only one side, then with the 2 halve seperated by several inches, twist the slit circle to slip it around the screw. this way it will be self retaining and you won't have to worry about it falling out.

It could also slip off-center and start scraping against the screw. But, your method will probably work fine.

Jon

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

11 May 2016 16:35 #74519

by Todd Zuercher

Replied by Todd Zuercher on topic Backlash on double nut ballscrew

If you feel you need something around the outside to retain the shims, how about an ordinary worm drive clamp. (I'd trust that a lot more than tape.)

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.121 seconds