Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

05 Jun 2019 10:34 #135924

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I use BT40, DIN69871 SK40, and SK40 manual tool holders in mine. The grooves for ATC gripping are different as are the flange to taper length.

I had to track down two diffent lengths of pull studs. The SK40 (both manual and ATC) tool holders used shorter ones, but once i had them, they fit and hold properly.

Mark

I had to track down two diffent lengths of pull studs. The SK40 (both manual and ATC) tool holders used shorter ones, but once i had them, they fit and hold properly.

Mark

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

05 Jun 2019 10:46 #135926

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Thanks, here's what I'm looking at:

www.olx.pl/oferta/multiplikator-omg-mo-1...7GVm.html#75ebe360bb

It's a 1:6 spindle speeder with 18000 rpm max output. I called the seller and he's basically got no idea about the item, said he was selling it for a friend. But I did get him to measure it and confirm it's a 40 taper. The price is okay and the company is legit so I'm heavily considering getting it, the ratio seems great and there'd still be plenty of torque left to take cuts in hard materials.

Or alternatively you can get it, you just have to speak Polish

www.olx.pl/oferta/multiplikator-omg-mo-1...7GVm.html#75ebe360bb

It's a 1:6 spindle speeder with 18000 rpm max output. I called the seller and he's basically got no idea about the item, said he was selling it for a friend. But I did get him to measure it and confirm it's a 40 taper. The price is okay and the company is legit so I'm heavily considering getting it, the ratio seems great and there'd still be plenty of torque left to take cuts in hard materials.

Or alternatively you can get it, you just have to speak Polish

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

05 Jun 2019 13:16 #135937

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

My thoughts about mechanical Speeders

! check the duty cycle (run time before cooling and/or Lub change) 2 check if adding a pull stud will give the correct length for those Ott pull stud grippers inside the spindle.

Me myself an I ---think the 20Krpm motors having air or water cooling are a much better way for obtaining a high speed spindle .

Thank's for keeping this thread ongoing

Bpb

9run time before cooling and or Lu

! check the duty cycle (run time before cooling and/or Lub change) 2 check if adding a pull stud will give the correct length for those Ott pull stud grippers inside the spindle.

Me myself an I ---think the 20Krpm motors having air or water cooling are a much better way for obtaining a high speed spindle .

Thank's for keeping this thread ongoing

Bpb

9run time before cooling and or Lu

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

05 Jun 2019 13:48 #135942

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Hi Bob,

Well, I do have a small 18000 rpm motor. Why I'd like a (affordable) mechanical speeder: fit both vertically and horizontally, provide much higher torque, play nice with other tools. With a cheap spindle motor it's just a manual tool change in an ER collet. I can't use my Haimer 3d taster, and I have to remove the vertical spindle head to attach the smaller motor. It's fine for work when I only use small tools (mostly I try to use just one tool and work it until it goes dull; actually, in production that's all I ever do), but what about a situation where you want to do some facing, roughing, drilling and then finishing, of which one or two operations should be done above the 4000 rpm limit of the mill.

I have some mold designs that I'd like to machine this year, budget permitting, and this kind of add on would be really handy (for more than just finishing actually). I was also thinking about some aluminum products machined from 5mm sheet stock, and there I'd certainly want to face it on both sides with the largest cutter I can afford. But my high speed motor has almost no torque and if I have to change spindles between repeatable operations then that idea is a no-starter.

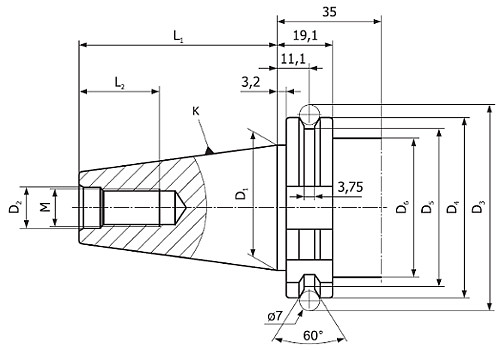

What worries me about the offer linked above is the toolholder style, it appears to be a DIN 2080 instead of the DIN 69871, and I have no idea if it's possible to make it work in the Maho. There's a section in the original manual comparing the two tool holder standards, but I don't understand French well enough to get the gist. From the drawings I'd say that 2080 is too long and wouldn't fit.

Well, I do have a small 18000 rpm motor. Why I'd like a (affordable) mechanical speeder: fit both vertically and horizontally, provide much higher torque, play nice with other tools. With a cheap spindle motor it's just a manual tool change in an ER collet. I can't use my Haimer 3d taster, and I have to remove the vertical spindle head to attach the smaller motor. It's fine for work when I only use small tools (mostly I try to use just one tool and work it until it goes dull; actually, in production that's all I ever do), but what about a situation where you want to do some facing, roughing, drilling and then finishing, of which one or two operations should be done above the 4000 rpm limit of the mill.

I have some mold designs that I'd like to machine this year, budget permitting, and this kind of add on would be really handy (for more than just finishing actually). I was also thinking about some aluminum products machined from 5mm sheet stock, and there I'd certainly want to face it on both sides with the largest cutter I can afford. But my high speed motor has almost no torque and if I have to change spindles between repeatable operations then that idea is a no-starter.

What worries me about the offer linked above is the toolholder style, it appears to be a DIN 2080 instead of the DIN 69871, and I have no idea if it's possible to make it work in the Maho. There's a section in the original manual comparing the two tool holder standards, but I don't understand French well enough to get the gist. From the drawings I'd say that 2080 is too long and wouldn't fit.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

05 Jun 2019 15:06 - 05 Jun 2019 15:11 #135948

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Looking at the photo, it "appears" that the DIN 2080 pull stud is not an integral part of the 40 Taper, but is screwed in.

Ask the seller to confirm that, as some are integral (= Useless to us).

Assuming it is removable and one of the metric 40 taper interfaces (BT40, SK40, ISO40) then it will have an M16 internal thread. In the unlikely event that it is CAT40, that would be an imperial thread.You can get the DIN69871 pull studs in different lengths, so you will be able to make the taper work. Here is a photo of the difference, before I found the shorter studs were available.

You need to also consider the anti rotation feature of the speeder. It should fit under the MAHO Vertical spindle, at least if you extended the ram a little. You might need to make a ram clamp to attach it too. Not sure whether that could fit the horizontal spindle.

Mark

Ask the seller to confirm that, as some are integral (= Useless to us).

Assuming it is removable and one of the metric 40 taper interfaces (BT40, SK40, ISO40) then it will have an M16 internal thread. In the unlikely event that it is CAT40, that would be an imperial thread.You can get the DIN69871 pull studs in different lengths, so you will be able to make the taper work. Here is a photo of the difference, before I found the shorter studs were available.

You need to also consider the anti rotation feature of the speeder. It should fit under the MAHO Vertical spindle, at least if you extended the ram a little. You might need to make a ram clamp to attach it too. Not sure whether that could fit the horizontal spindle.

Mark

Attachments:

Last edit: 05 Jun 2019 15:11 by RotarySMP.

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

05 Jun 2019 15:38 #135949

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

You're right about that feature, I didn't consider it. I'll probably skip this offer for now.

There's a company here that quoted me around 1200€ for a new mechanical speeder last year, which I thought was a pretty good offer. I'd probably be inclined to ask them about it again later this year, but they're restructuring and will reopen in October.

There's a company here that quoted me around 1200€ for a new mechanical speeder last year, which I thought was a pretty good offer. I'd probably be inclined to ask them about it again later this year, but they're restructuring and will reopen in October.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

05 Jun 2019 16:15 #135954

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

That shouldn't be a show stopper. Speeders are just planetary gearboxes, so all of them are going to require a feature like that to prevent rotation of the main body.

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

05 Jun 2019 16:28 #135958

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Think Mark is correct about end of the taper question. Can the end be removed and replaced with a pull stud ? My tired eyes thinks it may be integral an thus intended for a threaded drawbar use..

www.practicalmachinist.com/vb/dmg-mori-g...1-conversion-220395/

Hope this may help and not just add more confusion.

www.practicalmachinist.com/vb/dmg-mori-g...1-conversion-220395/

Hope this may help and not just add more confusion.

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

05 Jun 2019 17:29 #135963

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Thanks Bob, I've read a lot of old threads over on PM on the subject today. One guy said he simply cut off the cylinder at end of the taper and then screwed in a retention knob in it's place (there's a matching internal thread in the toolholder).

There's going to be a feature on all speeders, true, but I think some models don't have it protruding upwards (Henninger brand I think has it going sideways). If I have to both modify the toolholder and then it will only work with an extended quill then I don't think it's cheap enough Maybe it's worth waiting a while and ordering a new one that's made to fit my application to begin with. Dunno, just really wanted this to be a great match for my plans, but the Maho is already very much a project in my case and I need to balance it out with the business side and life in general

Maybe it's worth waiting a while and ordering a new one that's made to fit my application to begin with. Dunno, just really wanted this to be a great match for my plans, but the Maho is already very much a project in my case and I need to balance it out with the business side and life in general

There's going to be a feature on all speeders, true, but I think some models don't have it protruding upwards (Henninger brand I think has it going sideways). If I have to both modify the toolholder and then it will only work with an extended quill then I don't think it's cheap enough

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

05 Jun 2019 18:01 #135966

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Attachments:

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.245 seconds