Retrofitting a 1986 Maho MH400E

- Mccartymachine1

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 2

23 Jan 2020 02:22 #155488

by Mccartymachine1

Replied by Mccartymachine1 on topic Retrofitting a 1986 Maho MH400E

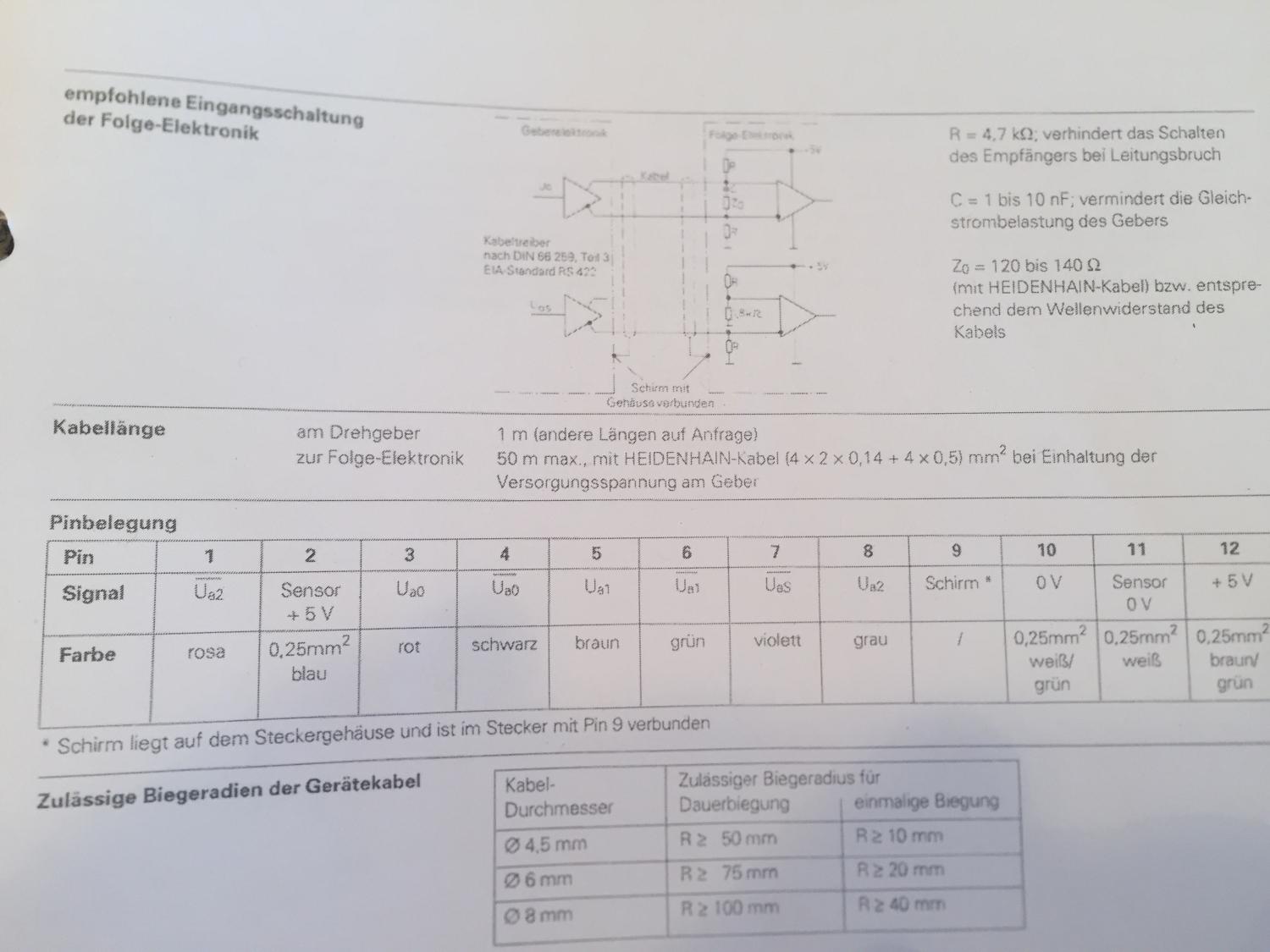

I still have not figured out a way to get a digital read out on the screen showing the position of the rotary table. Mine also has the rod271 encoder. My machine is a mh600c and I am running a 7i77, 5i25, and the original servo drives. I got some documentation on the rod271 but the wire colors do not match what maho used. Don't want to connect wrong and fry encoder. Need help with wiring and ini please.

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

23 Jan 2020 05:37 #155506

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi Mccartymachine1

Am sorry I can't answer your question.

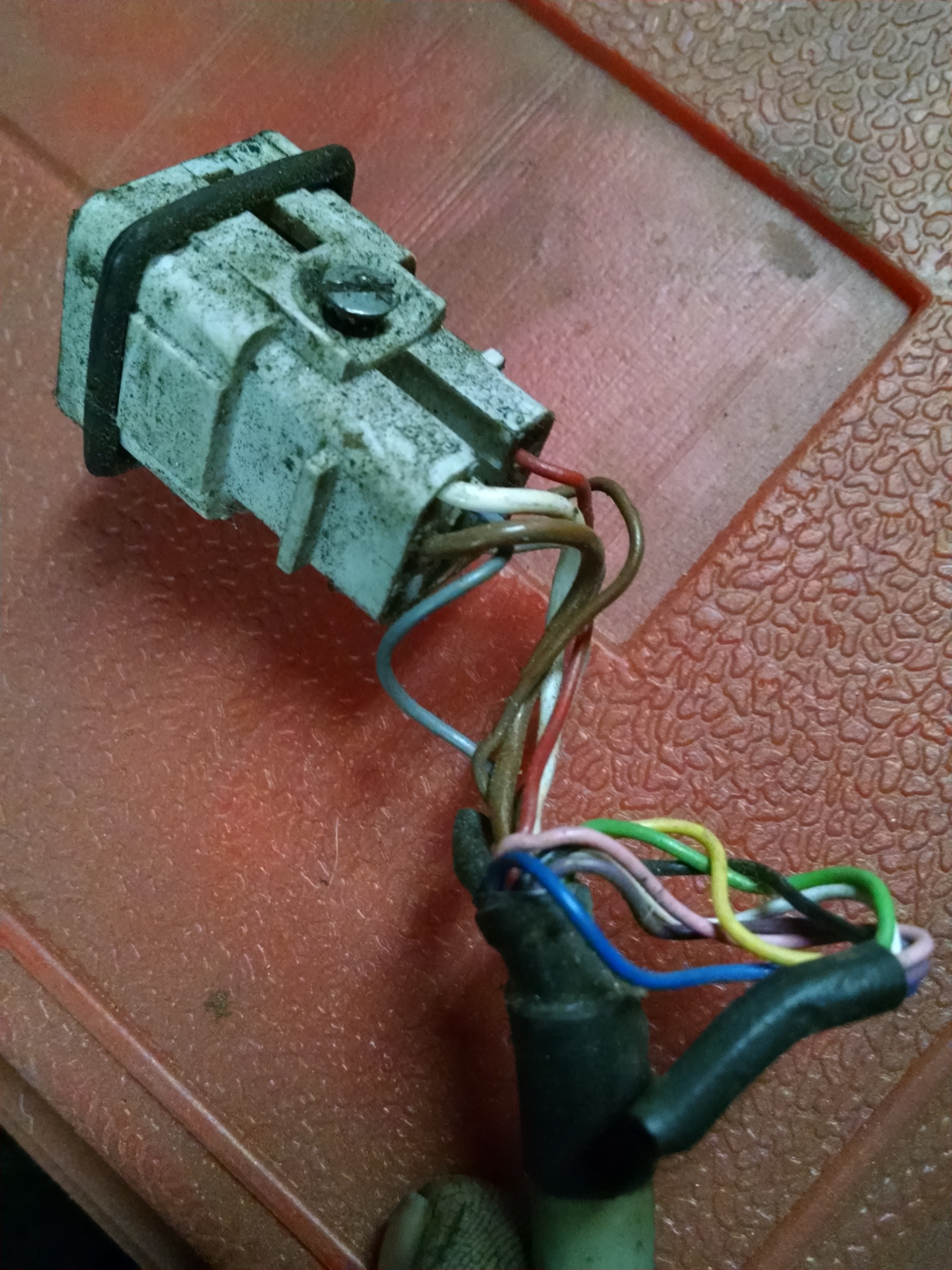

My thoughts are it would help others , who may have a answer, if you could post your ini. file an the ROD 271 doc. I think the ROD 271 has TTL output so should be able to wire directly to your 7i77. Meaning that it doesen't require a Exe-Bd as your Heindehain scales do. Your documentation will note what the TTL voltage level is. Might be useful to get a Photo of the dissembled connector showing the pins an pin wiring. Darn pastel colours an OEM parts can be a bother.

Also I guess you may want use of the index - reference mark and how to off set it for homing. Especially if the rotary table is servo controlled.

What are you doing to cause the table hydraulic brakes to release? If the rotary table is servo controlled then might be worthwhile to also include your HAL file . What user interface are you using ?

What the heck throw in a photo of the rotary table too ! Please

Stay warm

Bob

P.S. Forgot to mention -include a MAHO schematic section showing the Rod wiring. Don't think they used the differential TTL signal , that to me is just asking for trouble. Could have been due to how Philips control boards were designed.

Am sorry I can't answer your question.

My thoughts are it would help others , who may have a answer, if you could post your ini. file an the ROD 271 doc. I think the ROD 271 has TTL output so should be able to wire directly to your 7i77. Meaning that it doesen't require a Exe-Bd as your Heindehain scales do. Your documentation will note what the TTL voltage level is. Might be useful to get a Photo of the dissembled connector showing the pins an pin wiring. Darn pastel colours an OEM parts can be a bother.

Also I guess you may want use of the index - reference mark and how to off set it for homing. Especially if the rotary table is servo controlled.

What are you doing to cause the table hydraulic brakes to release? If the rotary table is servo controlled then might be worthwhile to also include your HAL file . What user interface are you using ?

What the heck throw in a photo of the rotary table too ! Please

Stay warm

Bob

P.S. Forgot to mention -include a MAHO schematic section showing the Rod wiring. Don't think they used the differential TTL signal , that to me is just asking for trouble. Could have been due to how Philips control boards were designed.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

23 Jan 2020 07:35 #155513

by RotarySMP

That is useful to know. Thanks.

Mark

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

It is a MH600E, the new ball screw is from a MH400E x axis. Exactly the same dimensions for y axis of MH600E

John

That is useful to know. Thanks.

Mark

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Jan 2020 08:58 #155517

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Attachments:

The following user(s) said Thank You: drimaropoylos, Azzrael

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Jan 2020 10:19 #155522

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

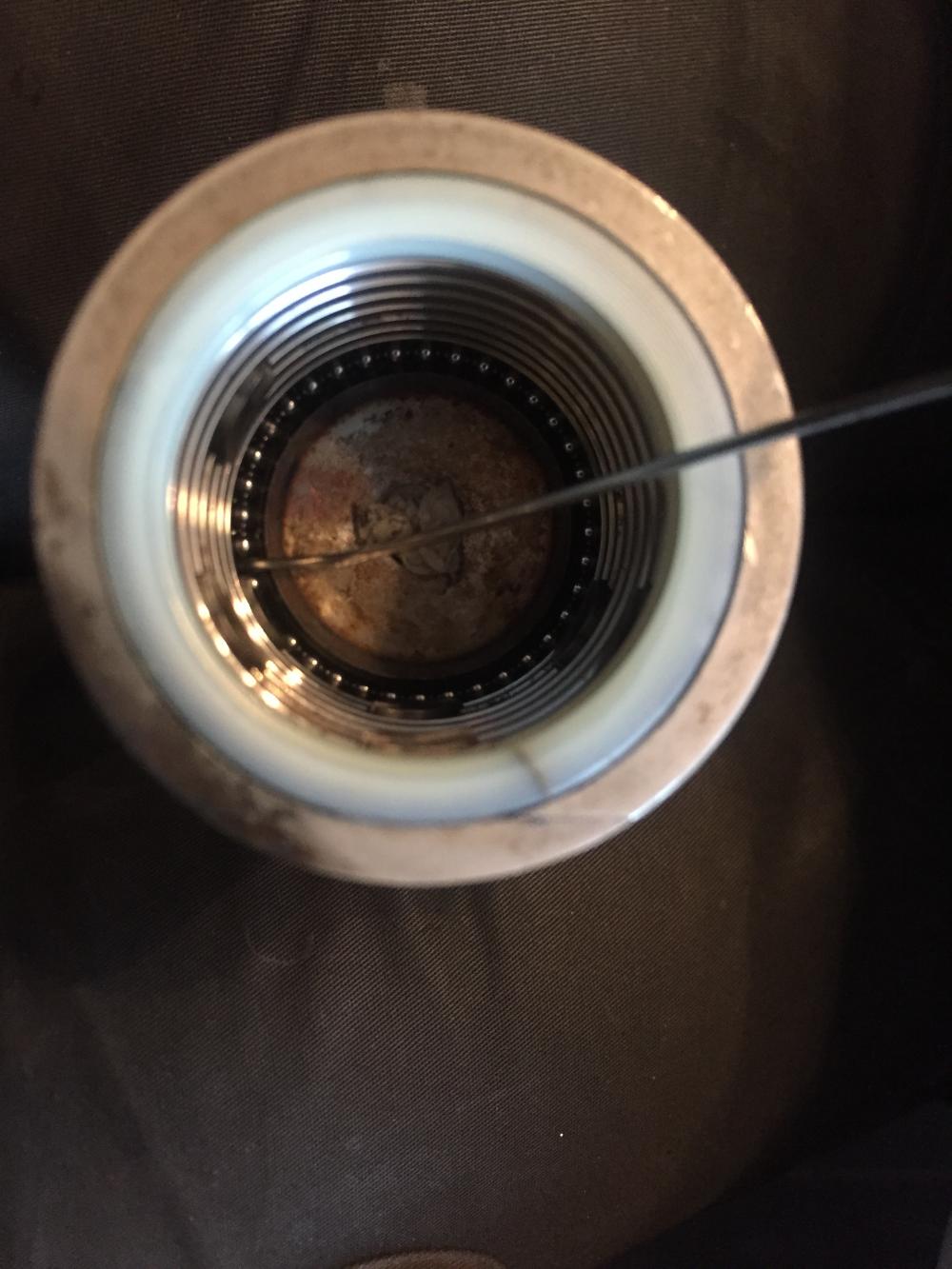

First of all no more jokes about my balls

37 per line is the correct number which gives a gap of 1.5mm.

The whole operation takes approximately 10-15 minutes and does not need any lubrication or auxiliaries.

- Count 37 balls in a jar and pour them into the nut having turned to a point where they can fall into the correct turn.

- Find the sweet spot where they just fit into the deflector.

- Use a non-magnetic needle, wire or screw-driver and push them all in.

- Turn the nut to the next pitch and continue

In my opinion it is perfect now with the P10 balls with diameter 3.51mm.

I can now still turn it with two fingers and sense a little pre-load, a little.

I think that someone has fiddled around before and filled in too few balls which lead to a jam that cracked one or more balls at the hardened deflectors.

The 240 balls before weren't enough, I'm sure. Now I have 259 in total.

(You can never have enough balls, lol)

37 per line is the correct number which gives a gap of 1.5mm.

The whole operation takes approximately 10-15 minutes and does not need any lubrication or auxiliaries.

- Count 37 balls in a jar and pour them into the nut having turned to a point where they can fall into the correct turn.

- Find the sweet spot where they just fit into the deflector.

- Use a non-magnetic needle, wire or screw-driver and push them all in.

- Turn the nut to the next pitch and continue

In my opinion it is perfect now with the P10 balls with diameter 3.51mm.

I can now still turn it with two fingers and sense a little pre-load, a little.

I think that someone has fiddled around before and filled in too few balls which lead to a jam that cracked one or more balls at the hardened deflectors.

The 240 balls before weren't enough, I'm sure. Now I have 259 in total.

(You can never have enough balls, lol)

Attachments:

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

23 Jan 2020 10:57 #155529

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

If we are no longer allowed to discuss your balls, it looks like you're screwed!

Mark

Mark

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Mccartymachine1

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 2

23 Jan 2020 12:33 #155538

by Mccartymachine1

Replied by Mccartymachine1 on topic Retrofitting a 1986 Maho MH400E

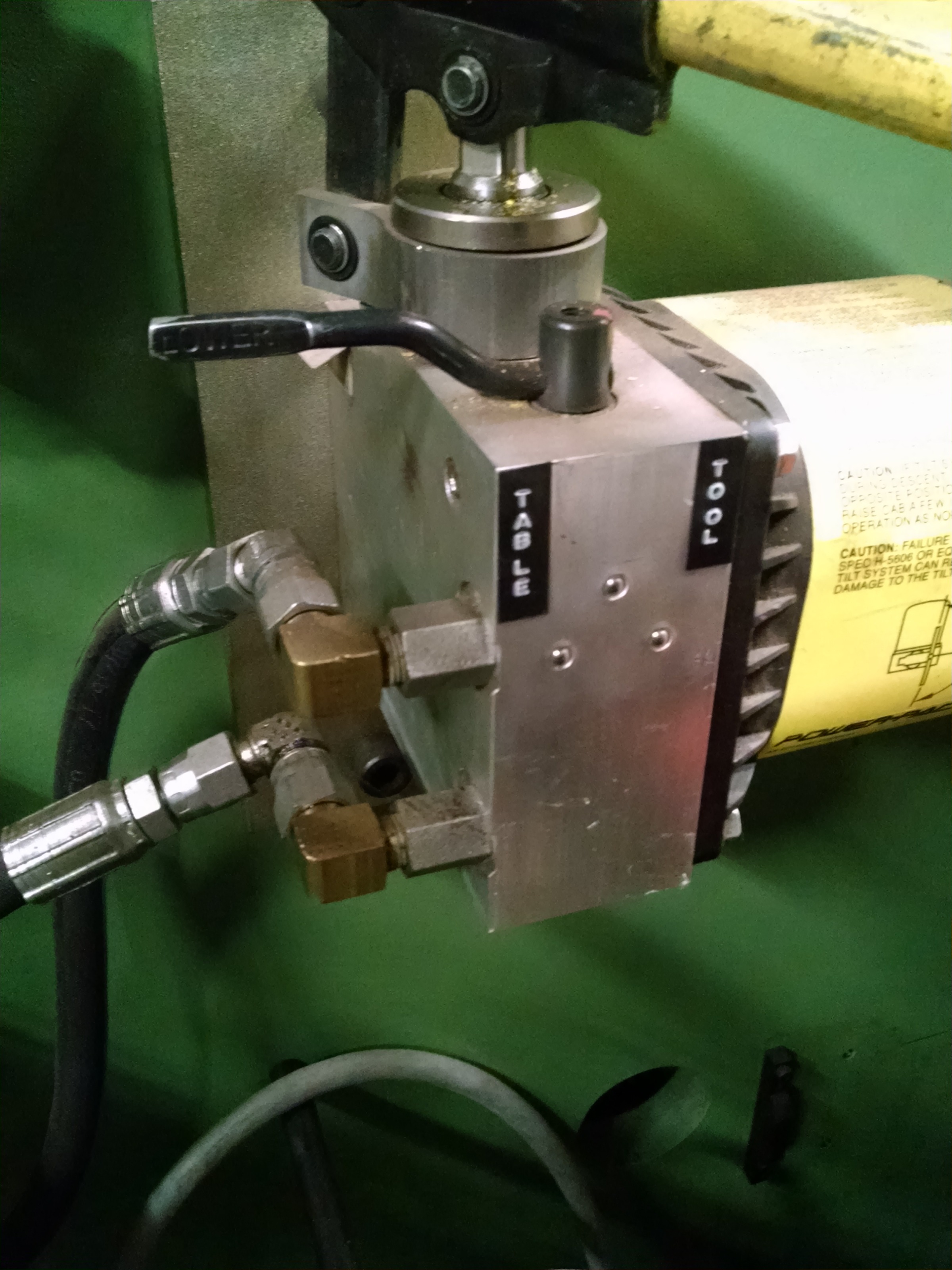

It is a manual table. The hydraulic release for table and tool have been changed to manual pump (originally designed for duel acting cylinder to lift a truck cab). Scales where Philips and I changed for Chinese 1um Sino brand scales. Working great. Have not even started ini or Hal for table encoder. I am not good with that stuff. Most of my Hal and ini where cut and paste from examples.

Please Log in or Create an account to join the conversation.

- Mccartymachine1

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 2

23 Jan 2020 12:54 #155541

by Mccartymachine1

Replied by Mccartymachine1 on topic Retrofitting a 1986 Maho MH400E

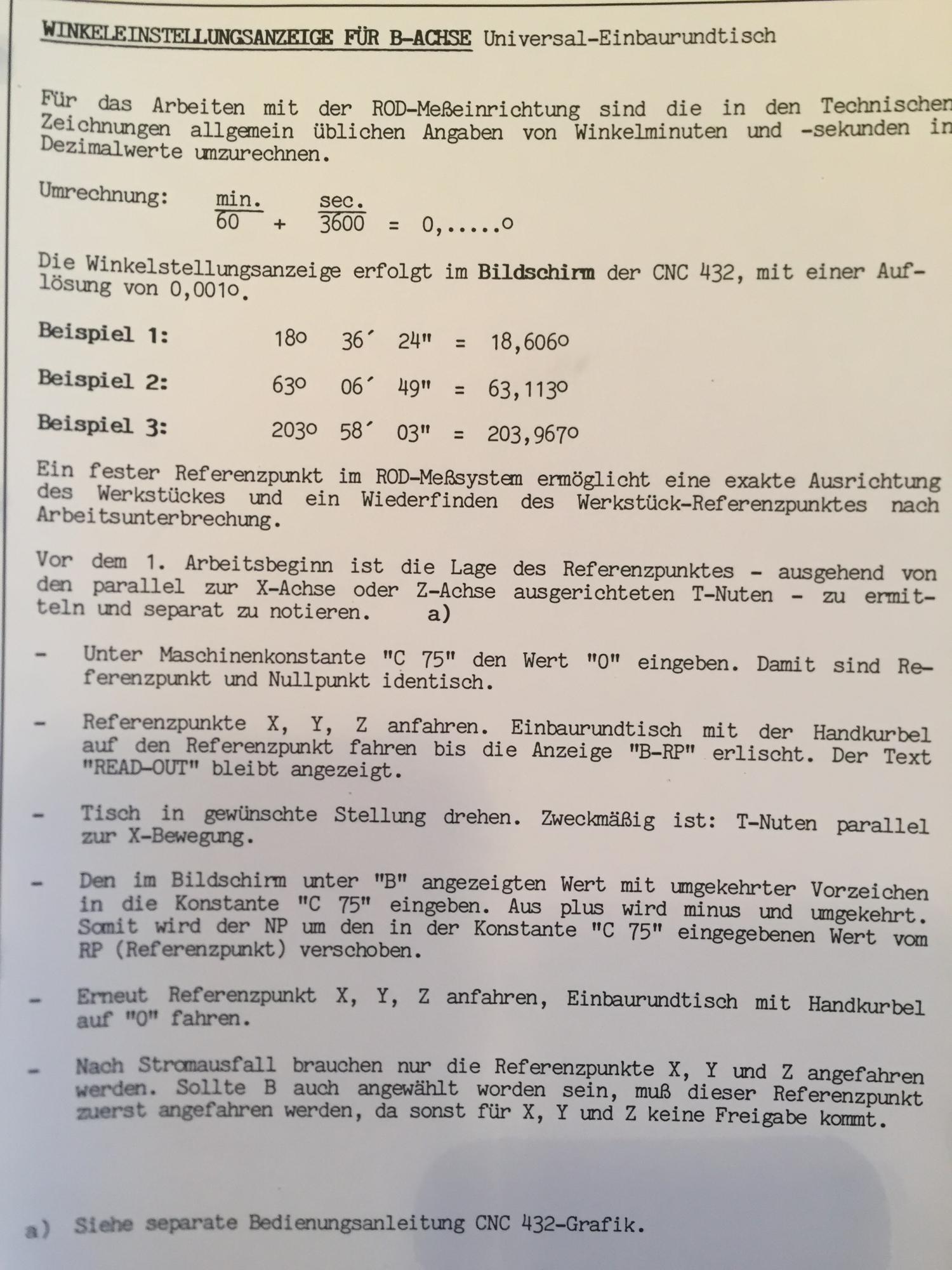

Looks like brown is +5v, white is 0v. What are Ua0, Ua1, and Ua2? I'm assuming ref, A, and B.

I don't mind not using a reference. Want to be able to manually home table to 0 degrees and have DRO function separate from cnc functions.

Machine is running on 240v single phase. 100A breaker.

I'm in Pennsylvania, so yes it's cold but garage is heated : )

I don't mind not using a reference. Want to be able to manually home table to 0 degrees and have DRO function separate from cnc functions.

Machine is running on 240v single phase. 100A breaker.

I'm in Pennsylvania, so yes it's cold but garage is heated : )

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

23 Jan 2020 13:23 #155543

by RotarySMP

On Heidenhain linear scales, Ua 0 is the reference, so that is probably consistant across evrything they do.If you have the ref signal you may as well input it to LinuxCNC. If you input that to LinuxCNC, you could probably quite easily have a workflow to manually zero that axis with a lot less hassle than setting up a DTI, and probably more accurate and repeatably.

What is the benefit of having a C axis on a CNC? I can see the benefit of a B axis, and even more so stacked A and B, A and C or B and C, but a C axis alone doesn't seem to bring much to the party that you can't do with interpolation. I guess the MAHO's do have the head rotation as a manual B axis, so if the job needs it, and you have the patience, with a C axis you can do pretty much any 5 axis indexing job.

Mark

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Looks like brown is +5v, white is 0v. What are Ua0, Ua1, and Ua2? I'm assuming ref, A, and B.

I don't mind not using a reference. Want to be able to manually home table to 0 degrees and have DRO function separate from cnc functions.

On Heidenhain linear scales, Ua 0 is the reference, so that is probably consistant across evrything they do.If you have the ref signal you may as well input it to LinuxCNC. If you input that to LinuxCNC, you could probably quite easily have a workflow to manually zero that axis with a lot less hassle than setting up a DTI, and probably more accurate and repeatably.

What is the benefit of having a C axis on a CNC? I can see the benefit of a B axis, and even more so stacked A and B, A and C or B and C, but a C axis alone doesn't seem to bring much to the party that you can't do with interpolation. I guess the MAHO's do have the head rotation as a manual B axis, so if the job needs it, and you have the patience, with a C axis you can do pretty much any 5 axis indexing job.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

23 Jan 2020 14:26 - 23 Jan 2020 14:35 #155545

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

When you start the machine you must home all the axis, including the table c axis. Using the index you can align the table t-slots compared with the rest of the machine very accurately, and not have to use the indicator on every startup.

On e VMC the c axis (alone) is not that useful, but on a machine with tilting head and horizontal spindle a rotary table is very useful.

John

On e VMC the c axis (alone) is not that useful, but on a machine with tilting head and horizontal spindle a rotary table is very useful.

John

Last edit: 23 Jan 2020 14:35 by drimaropoylos.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.667 seconds