Retrofitting a 1986 Maho MH400E

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19782

- Thank you received: 4604

25 Nov 2018 23:48 #121356

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

I don't think you need the or2, the GUI turns the spindle on outside of HAL.

You can just connect the button direct to halui.spindle.start to add a manual spindle start button.

You can just connect the button direct to halui.spindle.start to add a manual spindle start button.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

28 Nov 2018 07:48 #121515

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks Andy, I didn't look at that yet, but probably will need OR2, as I have already netted the HALUI pins to the gearbox COMP, so it can turn the spindle on and off.

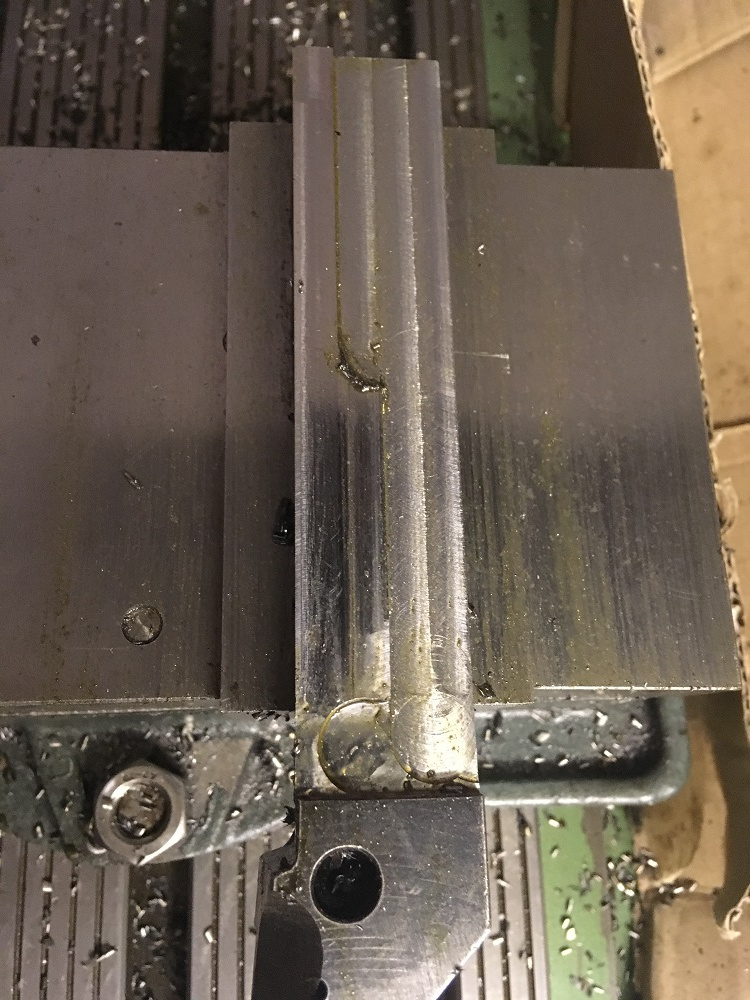

Yesterday, I made a new, much more conservative program to mill down the sandvik lathetool holder, using a brand new 10mm chinese HSS four flute. Use 2mm depth of cut, 50% engagement, 480rpm and 75mm/min feed. The first ~250mm went fine with nice chips, but then it died.

Although I did use cutting oil, itprobably need flood coolant to keep HSS cool enough to work in that steel. Oh well, another end mill for the hall of shame. Lucky I bought the Clarkson T&C grinder last year.

Mark

Yesterday, I made a new, much more conservative program to mill down the sandvik lathetool holder, using a brand new 10mm chinese HSS four flute. Use 2mm depth of cut, 50% engagement, 480rpm and 75mm/min feed. The first ~250mm went fine with nice chips, but then it died.

Although I did use cutting oil, itprobably need flood coolant to keep HSS cool enough to work in that steel. Oh well, another end mill for the hall of shame. Lucky I bought the Clarkson T&C grinder last year.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

28 Nov 2018 20:36 #121549

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Hi, I think that you should connect hal and not halui pins to gearbox COMP for machine control. I thing halui pins intended use is for the user interface, hardware and software.

John

John

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

28 Nov 2018 20:46 #121551

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Controlling the spindle from an independent bouton and from the rest of the software with or statement needs more thought.

John

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

29 Nov 2018 09:28 - 29 Nov 2018 09:29 #121582

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Last edit: 29 Nov 2018 09:29 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

29 Nov 2018 09:40 #121583

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

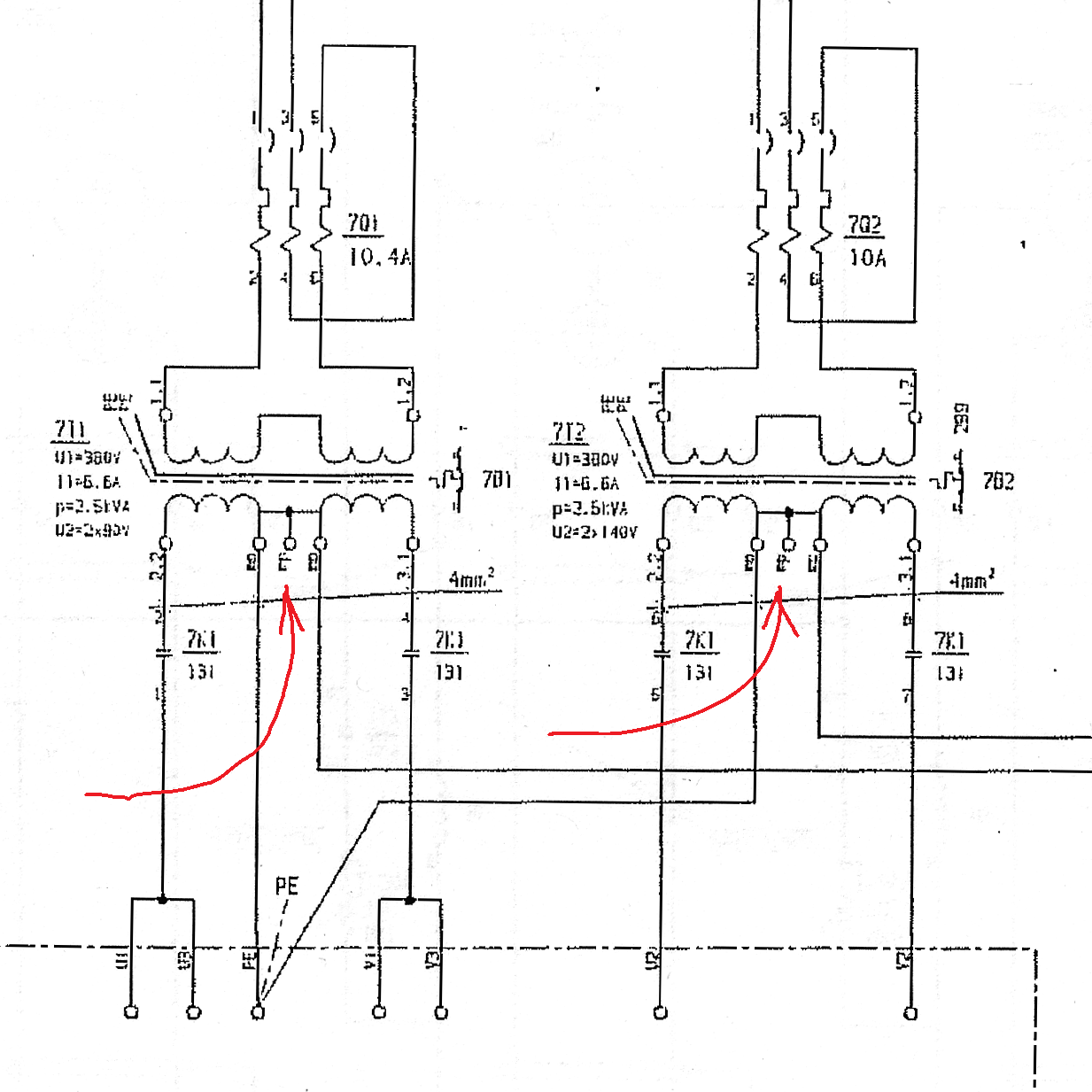

Can you take a close photo to transformers connections?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

29 Nov 2018 09:50 #121584

by RotarySMP

Hi John, thanks for your input, you are right about that. The relevant spindle control nets which I currently have are these:

And here are the functions which I have had to comment out due to conflicts.

I used the halui.spindle.stop to give the gearbox control of stopping the spindle. Since there is no motion.spindle-stop pin, should I have the gearbox net to the motion.spindle-on pin and setp false to stop it? Or just have the gearbox comp setp motion.spindle-on false, from within it's code without going through a net?

Mark

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi, I think that you should connect hal and not halui pins to gearbox COMP for machine control. I thing halui pins intended use is for the user interface, hardware and software.

Controlling the spindle from an independent bouton and from the rest of the software with or statement needs more thought.

John

Hi John, thanks for your input, you are right about that. The relevant spindle control nets which I currently have are these:

net sig_get_commanded_speed mh400e-gearbox.spindle-speed-in-abs <= motion.spindle-speed-out-abs

net sig_return_actual_speed mh400e-gearbox.spindle-speed-out => motion.spindle-speed-in

net sig_return_spindle-at-speed mh400e-gearbox.spindle-at-speed => motion.spindle-at-speed

net sig_stop_spindle mh400e-gearbox.stop-spindle => halui.spindle.stop

net spindle-on motion.spindle-on => hm2_5i25.0.7i84.0.2.output-13

net spindle-cw motion.spindle-forward => hm2_5i25.0.7i84.0.2.output-12

net spindle-ccw motion.spindle-reverse => hm2_5i25.0.7i84.0.2.output-11And here are the functions which I have had to comment out due to conflicts.

#net maho_panel.r0c3_sig-out maho_panel.key.r0c3 => halui.spindle.stop

#net maho_panel.r2c4_sig-out maho_panel.key.r2c4 => halui.spindle.reverse

#net maho_panel.r4c1_sig-out maho_panel.key.r4c1 => halui.spindle.forwardI used the halui.spindle.stop to give the gearbox control of stopping the spindle. Since there is no motion.spindle-stop pin, should I have the gearbox net to the motion.spindle-on pin and setp false to stop it? Or just have the gearbox comp setp motion.spindle-on false, from within it's code without going through a net?

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

29 Nov 2018 09:56 #121586

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi John,

Lucky my new bellows have not yet arrived, so I still have the guards off and can easily remove the cover and photograph the transformers. Will probably have to wait for the weekend though.

Mark

Lucky my new bellows have not yet arrived, so I still have the guards off and can easily remove the cover and photograph the transformers. Will probably have to wait for the weekend though.

Mark

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

29 Nov 2018 15:09 #121591

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

I think the ''setp motion.spindle-on false'' approach is beter.

John

John

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

03 Dec 2018 14:19 #121750

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Can a comp even set a parameter directly? I thought the way the HAL works is that the comp connects to the rest of the hal through pins, so a comp can not change a setting it is not connected to though a pin.

When the gearbox comp wants to stop the spindle, it sets

to 1

I netted that to, but if I changed that net toand invert it , it should do the same thing, but free up my halui.spindle.stop pin for my external button shouldn't it?

Mark

When the gearbox comp wants to stop the spindle, it sets

pin out bit stop_spindle = 0 "Start or stop spindle";to 1

I netted that to

halui.spindle.stopmotion.spindle-onMark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.252 seconds