Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1540

- Thank you received: 572

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1540

- Thank you received: 572

I pulled the cover and had a look.

In the schematic of my machine, that point is marked mP, which might be Messpunkt (point to take measurements). At least there are defined measuring points on the relay board called MP with a number in a circle.

.

I left it open for now, so if you need better pictures or a different angle, just let me know.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

John

Please Log in or Create an account to join the conversation.

- cgroth

- Offline

- Junior Member

-

- Posts: 28

- Thank you received: 9

Christian

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1540

- Thank you received: 572

How is your MHx00C retrofit coming along?

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1540

- Thank you received: 572

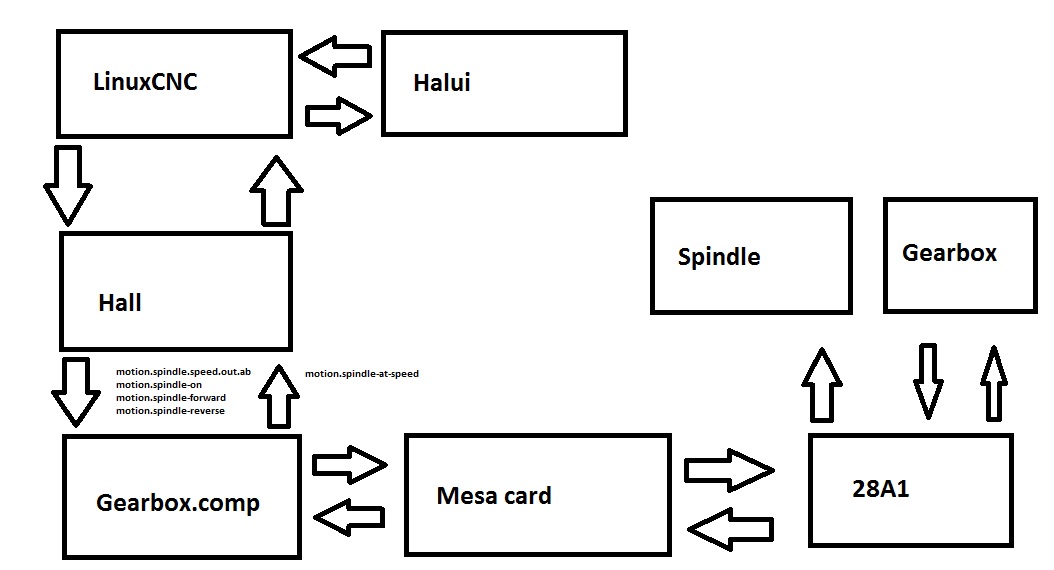

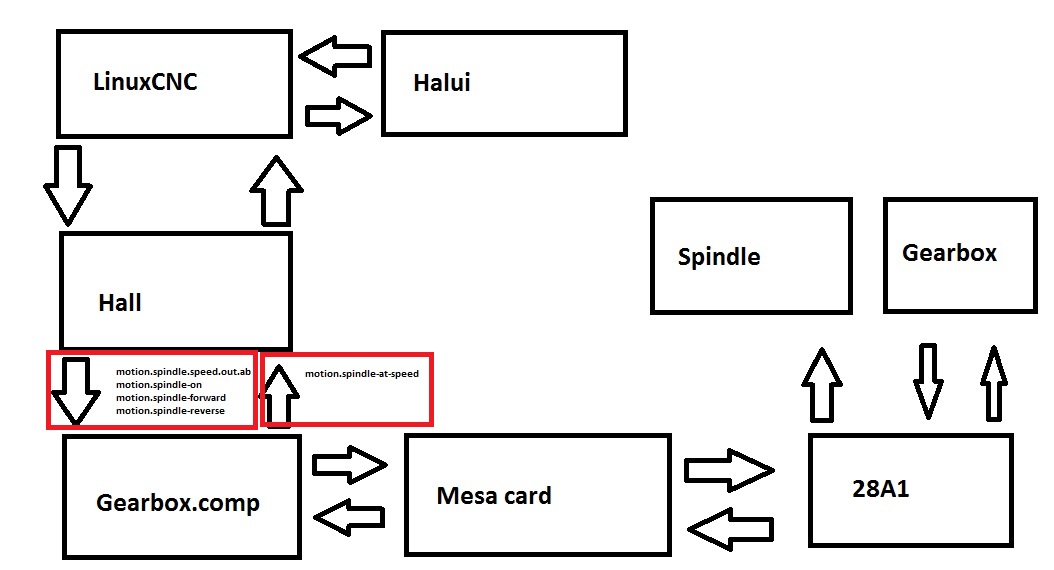

Do you have any suggestions how we can deal with Linuxcnc reacting to a spindle stop, by not only setting motion.spindle-on to false, but also setting motion.spindle.speed.out.abs to zero?

Example:

Spindle running at S500 , change to S1000 encountered in a gcode program:

- linuxcnc parses the change in S, sets motion.spindle.speed.out.abs1000

- gearbox.comp reacts to the change in S. Detects spindle running, commands a stop through halui.spindle.stop # see second issue below.

- gearbox is waiting for spindle.is.stopped to go high

- linuxcnc detects requested change in spindle state , sets motion.spindle-on false but also resets motion.spindle.speed.out.ab 0

- spindle.is.stoppped goes high

- gearbox.comp continues with gearchange, sets gearbox to match motion.spindle.speed.out.abs

- gearbox goes into neutral.

Linuxcnc is remembering last user commanded speed with an internal variable, as M3 not only restarts the spindle, but also resets motion.spindle.speed.out.abs back to that user last commanded speed. Can gearbox.comp get access to that variable? If we could have the gearbox finish the gear change to that, it would fix our problem.

2/ In the halshow's command line, we tried setp motion.spindle-on false but linuxcnc does not appear to let you set one if its internal output pins in this way. Does anyone else have a suggestion how we could give the gearbox.comp a means of stopping the spindle, without netting to halui.spindle.stop?

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

John

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1540

- Thank you received: 572

The default behavior of motion.spindle.speed.out.abs is to go to 0 when motion.spindle-on goes false (0).

John

Thanks John,

Yes. That is the problem

Your block diagram almost exactly captures what we have, except that the gearbox.comp can not set motion.spindle-on as it is an out pin from the core.comp of linuxcnc.

Agreed, we want the gearbox disconnected from the halui, but we haven't been able to identify any other way of stopping the spindle than to go through halui.spindle.stop.I thing that the logic should like this. The gearchange.comp file should directly controls spindle and gearbox and not by the Halui.

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

- Posts: 265

- Thank you received: 40

Please Log in or Create an account to join the conversation.