Retrofitting a 1986 Maho MH400E

- R2AIV

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

23 Mar 2019 10:09 #129347

by R2AIV

Replied by R2AIV on topic Retrofitting a 1986 Maho MH400E

I have same machine like other's on this thread. PID settings can be closer.

2RotarySMP: thank you! I wall try it!

2RotarySMP: thank you! I wall try it!

Please Log in or Create an account to join the conversation.

- R2AIV

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

05 Apr 2019 15:53 #130344

by R2AIV

Replied by R2AIV on topic Retrofitting a 1986 Maho MH400E

Hi All! How you solve a problem with lube? I don't understand how lube subsystem works. Whether there is a component for lubing?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

05 Apr 2019 15:57 #130345

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

On mine, the lube unit is self controlled, with an internal timer relay which gives about 15 sec of oil on start up and then ever 20min.

Mark

Mark

Please Log in or Create an account to join the conversation.

- R2AIV

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

05 Apr 2019 15:58 #130346

by R2AIV

Replied by R2AIV on topic Retrofitting a 1986 Maho MH400E

What i must do with the "lube" input signal on machine?

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

05 Apr 2019 16:42 #130352

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi,

do you have the schematics for your Machine ?

There are (little) differences through the years.

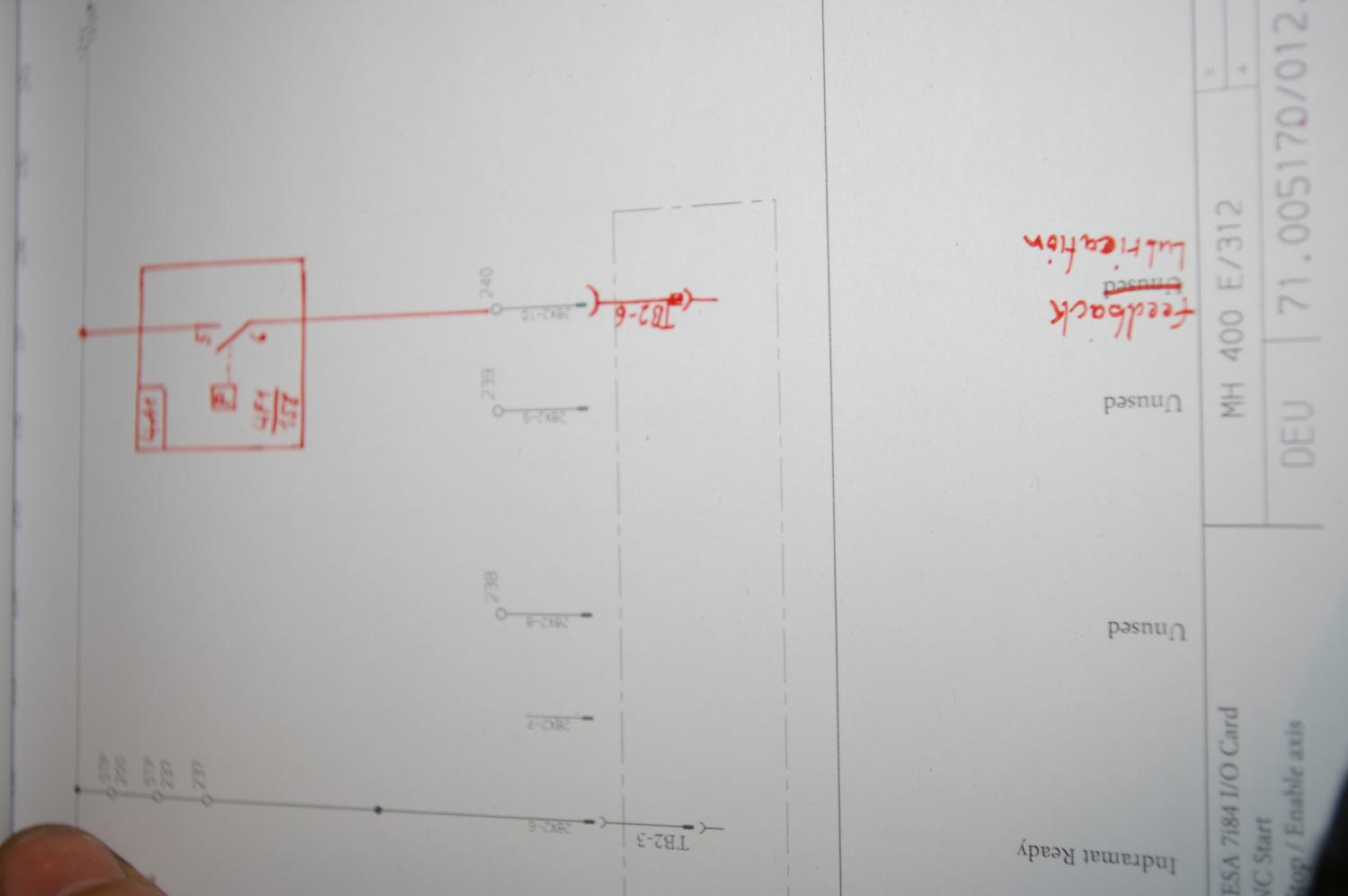

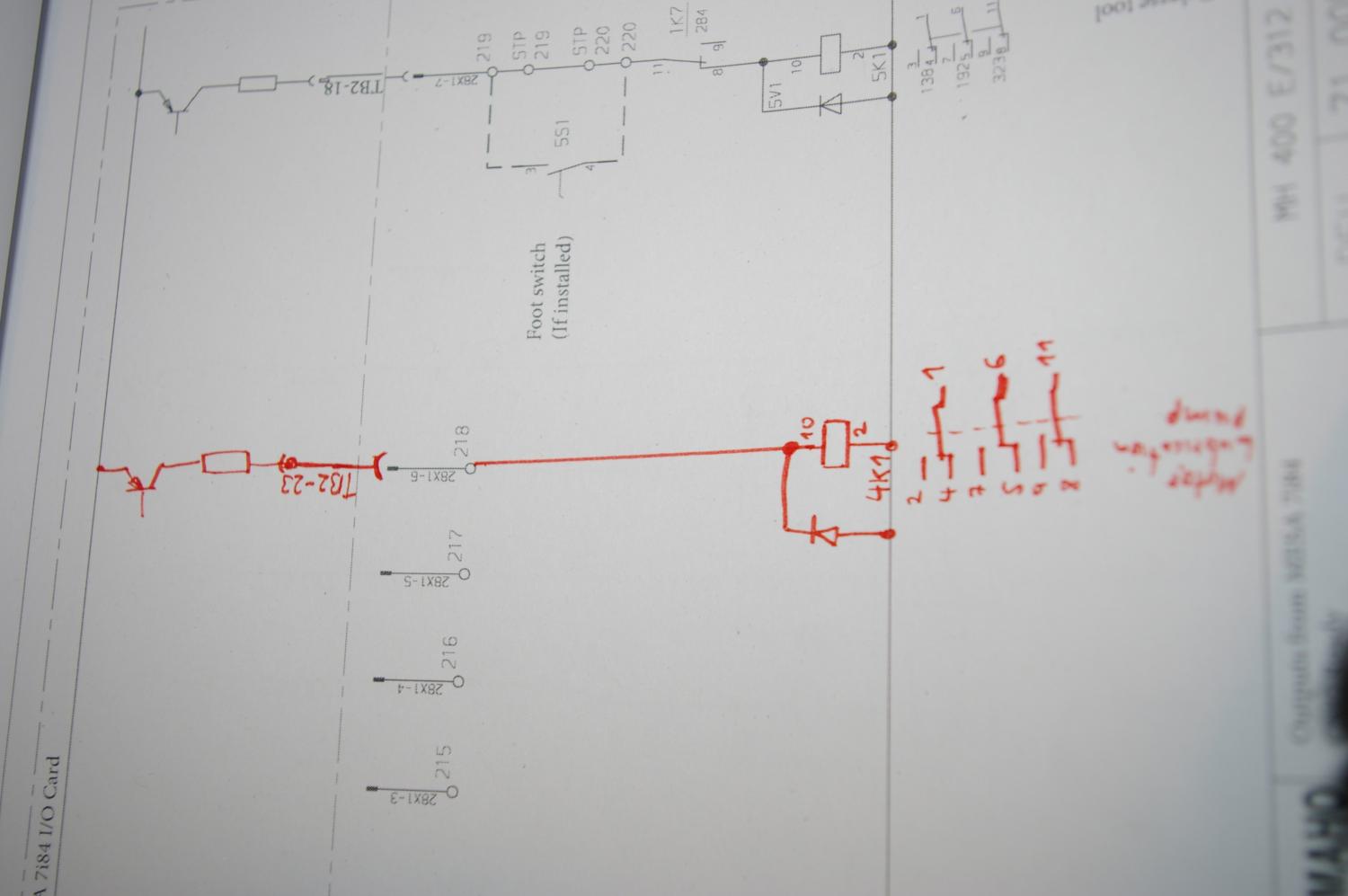

The timing of the lube on my machine is controlled via lube.py which I already sent you. It has an output to switch on the motor and a feedback signal.

See the attached schematics of the connections I made.

You might have Mark's older version which has an internal timer and probably no feedback.

do you have the schematics for your Machine ?

There are (little) differences through the years.

The timing of the lube on my machine is controlled via lube.py which I already sent you. It has an output to switch on the motor and a feedback signal.

See the attached schematics of the connections I made.

You might have Mark's older version which has an internal timer and probably no feedback.

Please Log in or Create an account to join the conversation.

- R2AIV

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

05 Apr 2019 16:51 #130353

by R2AIV

Replied by R2AIV on topic Retrofitting a 1986 Maho MH400E

Yes, i have feedback signal. What can i do for attach python module to my linuxcnc?

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

05 Apr 2019 17:09 - 05 Apr 2019 17:10 #130356

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi

it can be seen in my config file "MAHO_MH400E_postgui.hal":

#central lubrication

loadusr -W /etc/linuxcnc/MAHO_MH400E/lube

net lube-run lube.run => hm2_5i25.0.7i84.1.3.output-14

net machine-is-enabled lube.machine_status <= motion.motion-enabled

net spindle-on lube.spindle_status <= motion.spindle-on

net lube-ps-float-sw lube.pressuresw_floatsw <= hm2_5i25.0.7i84.1.3.input-21

All you have to do is change the path "/etc/linuxcnc/MAHO_MH400E/lube" according to where you put "lube" and, of course,

wire up the lubrication pump. If you connect it to different input and/or output pins, you have to adapt that, too.

Hanno

it can be seen in my config file "MAHO_MH400E_postgui.hal":

#central lubrication

loadusr -W /etc/linuxcnc/MAHO_MH400E/lube

net lube-run lube.run => hm2_5i25.0.7i84.1.3.output-14

net machine-is-enabled lube.machine_status <= motion.motion-enabled

net spindle-on lube.spindle_status <= motion.spindle-on

net lube-ps-float-sw lube.pressuresw_floatsw <= hm2_5i25.0.7i84.1.3.input-21

All you have to do is change the path "/etc/linuxcnc/MAHO_MH400E/lube" according to where you put "lube" and, of course,

wire up the lubrication pump. If you connect it to different input and/or output pins, you have to adapt that, too.

Hanno

Last edit: 05 Apr 2019 17:10 by hanmon.

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

08 Apr 2019 18:17 #130523

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Hey guys,

Small update from me - got LinuxCNC installed on a dedicated ITX motherboard with an Intel i3 CPU. Just combed through this thread and Mark's instructions to make a detailed list of all the necessary components I'll have to get from the nearby electronics store tomorrow. Then I'll connect all the Mesa parts to the PC and see if they communicate with each other before moving on to tampering with the mill.

Ashamed to admit this, but I'd been working under the assumption that the PCIe port is backwards compatible with a regular PCI port

I bought parts for an AMD Ryzen machine at first, realized my mistake and went out and bought the used i3 parts at a service point. Mobos with new chipsets don't really have PCI slots it turns out. Had I known that, I'd have gotten a Mesa PCIe FPGA card (6i25) or an Ethernet one (7i92). Does the Ethernet option have any particular downsides?

One thing that came to my mind, which someone else might use in the future, is that you could easily mount the PC behind a flatscreen monitor in place of the original CRT display. There's plenty of room to fit in an ITX board and a PSU (provided some kind of custom mounting plates, which is what you have to make anyway if the PC is in the back) in that chassis.

With the 7i92, you'd only need to run one Ethernet cable through the original conduit, say, replacing the video cable, from the pulpit to the electric cabinet. IMO, that would make for an elegant solution where you have all the PC parts in the control panel and all the Mesa cards in the electric cabinet. You wouldn't have to worry about USB or Ethernet ports b/c the MoBo would be easily accessible. That could also save a lot of room for additional servo drives (4th/5th axis) and a VFD in the cabinet if you're smart with crafting mounting plates for the Mesa chips.

You could use the pulpit to fit your own control panel. This solution obviously also comes with the downside of the panel having certain dimensions which you might find suboptimal for controlling LinuxCNC.

One question, probably a stupid one: how is the PC powered on? If the main switch is still used, do you connect anything to the PWR pins on the motherboard to make it start when you turn the switch? Do you turn on the PC separately? I'm rather an electronics noob I'm afraid, it just seems to me that a PC won't power on just because the PSU is energized and I have to jumper the PWR pins to start the machine now.

Small update from me - got LinuxCNC installed on a dedicated ITX motherboard with an Intel i3 CPU. Just combed through this thread and Mark's instructions to make a detailed list of all the necessary components I'll have to get from the nearby electronics store tomorrow. Then I'll connect all the Mesa parts to the PC and see if they communicate with each other before moving on to tampering with the mill.

Ashamed to admit this, but I'd been working under the assumption that the PCIe port is backwards compatible with a regular PCI port

I bought parts for an AMD Ryzen machine at first, realized my mistake and went out and bought the used i3 parts at a service point. Mobos with new chipsets don't really have PCI slots it turns out. Had I known that, I'd have gotten a Mesa PCIe FPGA card (6i25) or an Ethernet one (7i92). Does the Ethernet option have any particular downsides?

One thing that came to my mind, which someone else might use in the future, is that you could easily mount the PC behind a flatscreen monitor in place of the original CRT display. There's plenty of room to fit in an ITX board and a PSU (provided some kind of custom mounting plates, which is what you have to make anyway if the PC is in the back) in that chassis.

With the 7i92, you'd only need to run one Ethernet cable through the original conduit, say, replacing the video cable, from the pulpit to the electric cabinet. IMO, that would make for an elegant solution where you have all the PC parts in the control panel and all the Mesa cards in the electric cabinet. You wouldn't have to worry about USB or Ethernet ports b/c the MoBo would be easily accessible. That could also save a lot of room for additional servo drives (4th/5th axis) and a VFD in the cabinet if you're smart with crafting mounting plates for the Mesa chips.

You could use the pulpit to fit your own control panel. This solution obviously also comes with the downside of the panel having certain dimensions which you might find suboptimal for controlling LinuxCNC.

One question, probably a stupid one: how is the PC powered on? If the main switch is still used, do you connect anything to the PWR pins on the motherboard to make it start when you turn the switch? Do you turn on the PC separately? I'm rather an electronics noob I'm afraid, it just seems to me that a PC won't power on just because the PSU is energized and I have to jumper the PWR pins to start the machine now.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21231

- Thank you received: 7249

09 Apr 2019 01:19 #130533

by tommylight

That can be set in BIOS so it turns on automatically when power is present . Takes about 20 seconds to do, just press DEL or F2 or F10 immediately after pressing the power button, then look for power options and there should be something like power on after power failure and set it to ON.

Replied by tommylight on topic Retrofitting a 1986 Maho MH400E

One question, probably a stupid one: how is the PC powered on? If the main switch is still used, do you connect anything to the PWR pins on the motherboard to make it start when you turn the switch? Do you turn on the PC separately? I'm rather an electronics noob I'm afraid, it just seems to me that a PC won't power on just because the PSU is energized and I have to jumper the PWR pins to start the machine now.

That can be set in BIOS so it turns on automatically when power is present . Takes about 20 seconds to do, just press DEL or F2 or F10 immediately after pressing the power button, then look for power options and there should be something like power on after power failure and set it to ON.

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

09 Apr 2019 04:03 #130544

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Glemigobles

Sorry, but I forgot which Maho you have. Think it may be a MH500e. Anyway , to muddy the water so to say

" Ethernet one (7i92). Does the Ethernet option have any particular downsides? " .

From Linuxcnc Logs 4-2-19 about 8:24 AM , noticed a comment from pcw / Mesa .

" pcw_home: Ethernet is a bit harder to setup and requires the uspace version of LinuxCNC

pcw_home: if you have something exotic to control that needs a fast servo thread (faster than 1 KHz) PCI/PCIE is better

pcw_home: but at the default 1 KHz, Ethernet is fine and has the added benefit of electrical isolation and the ability to work with mini-pcs that have no slots " He also makes a comment referring to the current Trajectory Planner component of LinuxCNC which I thought was referring to Mother Board speed if a "Jerk" component is added in the future.

What I have never seen discussed is

what ( servo thread -1KHz or more ) is needed for a Maho MH?00?? such that the conversion will result in equal or greater performance of the final MH?00?? version. I think the final MH?00?? version used a 5?? series processor --but it only had to run the machine and no Wi-Fi ,hard drive,really nice graphic display,probe,tool setter, thread milling,You-Tube,etc. I am referring to using the existing servo motors (DC or later permanent magnet type) and their Indrament motor drive - the later variable speed spindle motor and it's Indramet motor drive - plus 2 more axis. So it would be a 6 axis control-- XYZ = 3 and spindle =1 and B an C axis = 2 . Plus a 20 tool tool changer for me!

Not too clear to me is your question of powering up the PC via the Main switch. " tommylight " has described changing the Bios . Or are you wanting to power the PC but not power the rest of the machine? Powering just the PC and/or the Mesa boards could be useful for maintenance.

Like your thought about reusing the existing operator consul / pulpit .Hope that is what you end up doing! Now if someone would write a "component" so the existing keyboard and hand controller could be used -It would be just peachy . Do you know how to program in "C or C+ or C++"?

Hope to read an see more of your conversion--

Bob

PS Thank you Mark for all you have done/doing

PPS R2AIV what is the latest ?

Sorry, but I forgot which Maho you have. Think it may be a MH500e. Anyway , to muddy the water so to say

" Ethernet one (7i92). Does the Ethernet option have any particular downsides? " .

From Linuxcnc Logs 4-2-19 about 8:24 AM , noticed a comment from pcw / Mesa .

" pcw_home: Ethernet is a bit harder to setup and requires the uspace version of LinuxCNC

pcw_home: if you have something exotic to control that needs a fast servo thread (faster than 1 KHz) PCI/PCIE is better

pcw_home: but at the default 1 KHz, Ethernet is fine and has the added benefit of electrical isolation and the ability to work with mini-pcs that have no slots " He also makes a comment referring to the current Trajectory Planner component of LinuxCNC which I thought was referring to Mother Board speed if a "Jerk" component is added in the future.

What I have never seen discussed is

what ( servo thread -1KHz or more ) is needed for a Maho MH?00?? such that the conversion will result in equal or greater performance of the final MH?00?? version. I think the final MH?00?? version used a 5?? series processor --but it only had to run the machine and no Wi-Fi ,hard drive,really nice graphic display,probe,tool setter, thread milling,You-Tube,etc. I am referring to using the existing servo motors (DC or later permanent magnet type) and their Indrament motor drive - the later variable speed spindle motor and it's Indramet motor drive - plus 2 more axis. So it would be a 6 axis control-- XYZ = 3 and spindle =1 and B an C axis = 2 . Plus a 20 tool tool changer for me!

Not too clear to me is your question of powering up the PC via the Main switch. " tommylight " has described changing the Bios . Or are you wanting to power the PC but not power the rest of the machine? Powering just the PC and/or the Mesa boards could be useful for maintenance.

Like your thought about reusing the existing operator consul / pulpit .Hope that is what you end up doing! Now if someone would write a "component" so the existing keyboard and hand controller could be used -It would be just peachy . Do you know how to program in "C or C+ or C++"?

Hope to read an see more of your conversion--

Bob

PS Thank you Mark for all you have done/doing

PPS R2AIV what is the latest ?

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.429 seconds