MAZAK POWER CENTER V12 retrofit (if possible)

- Osteen

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

04 Apr 2018 11:52 #108368

by Osteen

MAZAK POWER CENTER V12 retrofit (if possible) was created by Osteen

Hi guys, I'm new here, and searching for clues to retrofit the CNC we have in the company.

The machine :

A mazak Powercenter V12 which is mechnanically in quite good health, it has between 10000h and 15000h according to my boss, the mechanical maintenance is up to date.

the problem resides in the CNC which is wquite old and the axis electronic control cards (not the drivers) burn one after another, and we don't know why.

So as the cards are getting quite rare and expensive, we're looking for solutions to make a retrofit using more modern electronics.

We are at the stage of, what solutions is possible. My boss is looking for a solution based on centroid, and I'm looking for a solution based on MESA - linux CNC.

I've already asked a few question on the forum of usinages.com (french one), and Gaston48 have already been quite knowledgeable about mesa cards to use.

My objectives is to get the right configuration to drive the CNC.

the servomotors have a command using anlog 0-10V command and is using a rotary coder, it seems the same for the spindle except there's no coder.

for the rest, all is based on 24V IO and on that side is quite esay to handle.

For the axis, it was proposed to used 6i25 card with 7i85S cards but they are in STEP/DIR and not in an 0-10V, so not sure about.

Another solution is using 7i77 with 7i74 linked on the 6i25.

But for now, I don't know which is the good solution.

Do you have any suggestions about what could be done ?

thanks for all

The machine :

A mazak Powercenter V12 which is mechnanically in quite good health, it has between 10000h and 15000h according to my boss, the mechanical maintenance is up to date.

the problem resides in the CNC which is wquite old and the axis electronic control cards (not the drivers) burn one after another, and we don't know why.

So as the cards are getting quite rare and expensive, we're looking for solutions to make a retrofit using more modern electronics.

We are at the stage of, what solutions is possible. My boss is looking for a solution based on centroid, and I'm looking for a solution based on MESA - linux CNC.

I've already asked a few question on the forum of usinages.com (french one), and Gaston48 have already been quite knowledgeable about mesa cards to use.

My objectives is to get the right configuration to drive the CNC.

the servomotors have a command using anlog 0-10V command and is using a rotary coder, it seems the same for the spindle except there's no coder.

for the rest, all is based on 24V IO and on that side is quite esay to handle.

For the axis, it was proposed to used 6i25 card with 7i85S cards but they are in STEP/DIR and not in an 0-10V, so not sure about.

Another solution is using 7i77 with 7i74 linked on the 6i25.

But for now, I don't know which is the good solution.

Do you have any suggestions about what could be done ?

thanks for all

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

04 Apr 2018 14:45 #108378

by Todd Zuercher

Replied by Todd Zuercher on topic MAZAK POWER CENTER V12 retrofit (if possible)

For controlling analog drives you want a 7i77 not a 7i85. Just curious why do you think you need the 7i74? Unless you think you are going to need a bunch more digital IO than the 32 in and 16 out the 7i77 has on board, plus a similar amount from 1 additional smart serial card.

Please Log in or Create an account to join the conversation.

- Osteen

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

04 Apr 2018 15:19 #108379

by Osteen

Replied by Osteen on topic MAZAK POWER CENTER V12 retrofit (if possible)

For the 7i85, it was an advice for common installation.

For my solution i'm ok on the point that i need 7i77 for analog drives ( and the coders ?).

For the IO, I need at least more than 40 inputs for security feedback, spindle orientation control for tool change, all the commands for tool changer, the coolant and so on.. The complete chek up is not done yet to know how many input and output. For the 7i74, it was proposed by the guys on the french forum.

And for the panel control, a 7i73 to plug the jog, the buttons and switchs.

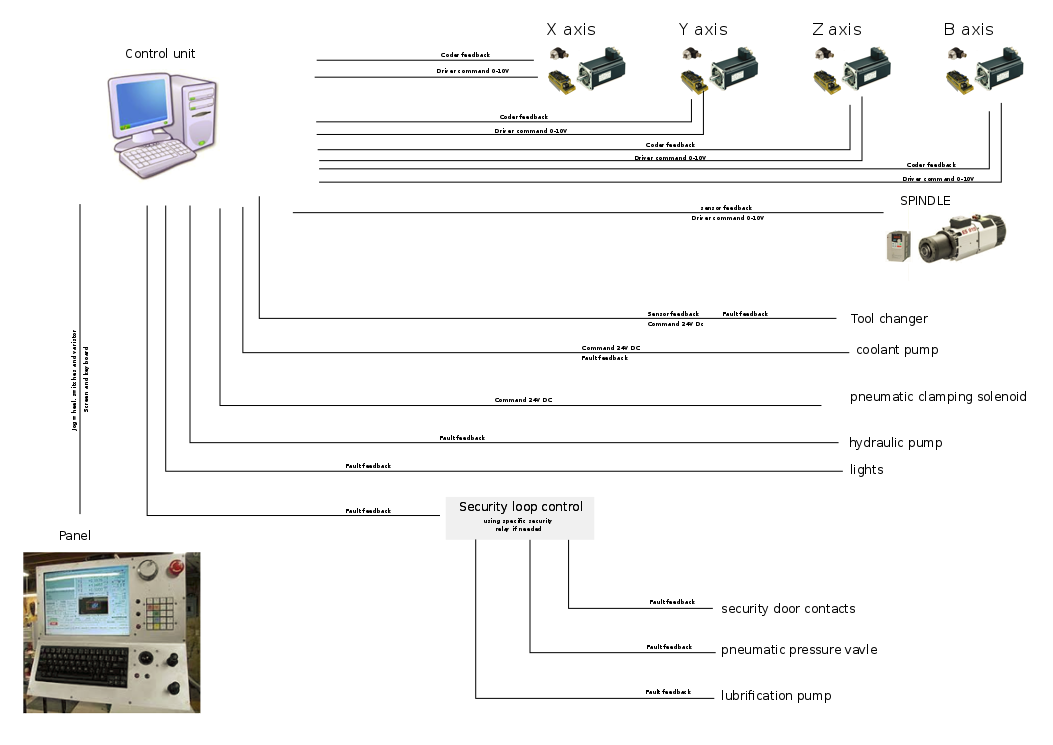

As I hear, I think it will be better to finish a diagramm of the functions of the machine before even trying to know what sorts of hardware I need.

Going to work on it fastly

thanks for your reply

For my solution i'm ok on the point that i need 7i77 for analog drives ( and the coders ?).

For the IO, I need at least more than 40 inputs for security feedback, spindle orientation control for tool change, all the commands for tool changer, the coolant and so on.. The complete chek up is not done yet to know how many input and output. For the 7i74, it was proposed by the guys on the french forum.

And for the panel control, a 7i73 to plug the jog, the buttons and switchs.

As I hear, I think it will be better to finish a diagramm of the functions of the machine before even trying to know what sorts of hardware I need.

Going to work on it fastly

thanks for your reply

Please Log in or Create an account to join the conversation.

- Osteen

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

04 Apr 2018 15:53 #108385

by Osteen

Replied by Osteen on topic MAZAK POWER CENTER V12 retrofit (if possible)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

06 Apr 2018 12:25 #108492

by andypugh

Replied by andypugh on topic MAZAK POWER CENTER V12 retrofit (if possible)

are the servo drives in good condition and reliable?

If so then a 7i77 should be all you need.

You could all the extra IO with one smart-serial card, but if you plan on also having a 7i73 (and I think that is a good idea) then you will need the 7i74 to connect a second (or more) smart-serial card.

It would be possible (just about) to do the whole retrofit with smart-serial devices, using the STMBL driver to replace the existing servo drives. This is a good solution and has been used on a few lathes already. The drawback is that the STMBL is not really commercially available, you would need to find someone ordering a batch and join-in.

If so then a 7i77 should be all you need.

You could all the extra IO with one smart-serial card, but if you plan on also having a 7i73 (and I think that is a good idea) then you will need the 7i74 to connect a second (or more) smart-serial card.

It would be possible (just about) to do the whole retrofit with smart-serial devices, using the STMBL driver to replace the existing servo drives. This is a good solution and has been used on a few lathes already. The drawback is that the STMBL is not really commercially available, you would need to find someone ordering a batch and join-in.

Please Log in or Create an account to join the conversation.

- Osteen

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

17 Apr 2018 13:38 - 17 Apr 2018 13:38 #109183

by Osteen

Replied by Osteen on topic MAZAK POWER CENTER V12 retrofit (if possible)

Yes the servo and drivers are in good shape, a test for the isolation and the coals of the DC motors will be done before modification.

The 7i73 board will be used for the control panel. the 7i77 board will be used for the drivers and coders, and so as we want to add a 4th axis which will not be plugged all the time, does this axis need to be installed on another card or can it be installed on the main board ?

For the IO, so if i understand correctly what you say, I can use the same 6i25 (or 5i25) board. But the question is, what is the best setup for IO ?

A solution is to have a 7i84 with 25pins daughter cards, but maybe a 7i46 with enough 7i64 board should be a good deal, no ?

The price is not a problem for the solution, what i'm searching for is reliability and security..

Thanks for all

The 7i73 board will be used for the control panel. the 7i77 board will be used for the drivers and coders, and so as we want to add a 4th axis which will not be plugged all the time, does this axis need to be installed on another card or can it be installed on the main board ?

For the IO, so if i understand correctly what you say, I can use the same 6i25 (or 5i25) board. But the question is, what is the best setup for IO ?

A solution is to have a 7i84 with 25pins daughter cards, but maybe a 7i46 with enough 7i64 board should be a good deal, no ?

The price is not a problem for the solution, what i'm searching for is reliability and security..

Thanks for all

Last edit: 17 Apr 2018 13:38 by Osteen.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17489

- Thank you received: 5112

17 Apr 2018 14:51 #109190

by PCW

Replied by PCW on topic MAZAK POWER CENTER V12 retrofit (if possible)

I would probably use a 6I25/7I77 and then add a 7I74 or 7I85 for more sserial channels (8 or 5)

The a 7I84 or 7I84D for additional 24V I/O

The a 7I84 or 7I84D for additional 24V I/O

Please Log in or Create an account to join the conversation.

- aventtini

-

- Visitor

-

26 Feb 2019 10:32 #127151

by aventtini

Replied by aventtini on topic MAZAK POWER CENTER V12 retrofit (if possible)

hello I have a machine olso for retrofit do you have the spindle schematic . I missing that page from manual

allex

allex

Please Log in or Create an account to join the conversation.

- Osteen

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

27 Feb 2019 19:50 #127286

by Osteen

Replied by Osteen on topic MAZAK POWER CENTER V12 retrofit (if possible)

Hi Alex..

I'm quite overwhelmed with my job right now but I'll try to look for it next week.. Don't mind reminding me if I forget your inquiry..

Mat

I'm quite overwhelmed with my job right now but I'll try to look for it next week.. Don't mind reminding me if I forget your inquiry..

Mat

Please Log in or Create an account to join the conversation.

- aventtini

-

- Visitor

-

04 Jul 2019 16:19 #138632

by aventtini

Replied by aventtini on topic MAZAK POWER CENTER V12 retrofit (if possible)

Mat a picture of the tool remove from spindle. This machine have m19 mecanical done and i cant understand how is working . Can you make a picture of the manual page on spindle please

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.095 seconds