Mesa LinuxCNC supported boards + other hardwares

- kewup

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

21 Jan 2020 05:54 #155295

by kewup

Mesa LinuxCNC supported boards + other hardwares was created by kewup

I am new to the LinuxCNC environment. I want to set up 3 axes high-speed Micro Milling Machine setup using LinuxCNC. I have made my Linear stage which is ball screw driven and currently using with commercial CNC controls. But now I want to shift towards the LinuxCNC platform. Please suggests to me all the list of Hardware requirements that are currently used by major of the groups???

Your Valuable suggestions help me a lot.

Your Valuable suggestions help me a lot.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7284

- Thank you received: 2125

21 Jan 2020 07:13 #155297

by cmorley

Replied by cmorley on topic Mesa LinuxCNC supported boards + other hardwares

What type of motors stepper or servo?

What kind of spindle control are you using?

How much I/O do you need for other stuff like coolant etc?

Do you wish to rigid tap eventually?

Will you want to add a 4th axis in the future?

What kind of PC interface would you like to: use printer port, PCI/PCIe or Ethernet ?

The majority of people use MESA boards but there are other options.

Chris

What kind of spindle control are you using?

How much I/O do you need for other stuff like coolant etc?

Do you wish to rigid tap eventually?

Will you want to add a 4th axis in the future?

What kind of PC interface would you like to: use printer port, PCI/PCIe or Ethernet ?

The majority of people use MESA boards but there are other options.

Chris

Please Log in or Create an account to join the conversation.

- kewup

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

21 Jan 2020 12:13 #155314

by kewup

Replied by kewup on topic Mesa LinuxCNC supported boards + other hardwares

Motors: AC Servo (200W), In future BLDC

Feedback Device: Currently using Glass scale linear encoder with 1 Micron Accuracy...But for LinuxCNC, would like to go with a rotary encoders

Spindle Control: currently using Ibag spindle (max. speed 1,20,000 RPM)

And of course, we will plan to extend to 5 axis setup in the future but no need for rigid tapping required as of now.

PC interface: Ethernet

kindly suggest better options available currently with sufficient documentation.

Feedback Device: Currently using Glass scale linear encoder with 1 Micron Accuracy...But for LinuxCNC, would like to go with a rotary encoders

Spindle Control: currently using Ibag spindle (max. speed 1,20,000 RPM)

And of course, we will plan to extend to 5 axis setup in the future but no need for rigid tapping required as of now.

PC interface: Ethernet

kindly suggest better options available currently with sufficient documentation.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

21 Jan 2020 14:55 #155325

by RotarySMP

Replied by RotarySMP on topic Mesa LinuxCNC supported boards + other hardwares

Doesn't really matter what mechanical parts you are controlling. With Mesa cards you can control just about anything.

You need to be more specific in terms of interfaces.

What inputs do the AC servo drivers support? Step/dir? +/-10V analog? CANBUS? Why would you want to downgrade AC servos to BLDC servos ( actually is there really a difference?

I take it the servos are closed loop back to the drivers. Why would you what to downgrade from linear encoders to rotary encoders for closing the position back to Linuxcnc ? Mesa cards and Linuxcnc don't care, but linear encoders remove a bunch of error sources.

What is that spindle drive interface? Step/Dir? PWM?

How many lines of I/O do you need? Count the various coolant, spindle on/off, End and home switches, drive enable, drive fault, tool height setter, probes etc.

Mark

You need to be more specific in terms of interfaces.

What inputs do the AC servo drivers support? Step/dir? +/-10V analog? CANBUS? Why would you want to downgrade AC servos to BLDC servos ( actually is there really a difference?

I take it the servos are closed loop back to the drivers. Why would you what to downgrade from linear encoders to rotary encoders for closing the position back to Linuxcnc ? Mesa cards and Linuxcnc don't care, but linear encoders remove a bunch of error sources.

What is that spindle drive interface? Step/Dir? PWM?

How many lines of I/O do you need? Count the various coolant, spindle on/off, End and home switches, drive enable, drive fault, tool height setter, probes etc.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

07 Feb 2020 18:03 - 07 Feb 2020 18:18 #156711

by drimaropoylos

Replied by drimaropoylos on topic Mesa LinuxCNC supported boards + other hardwares

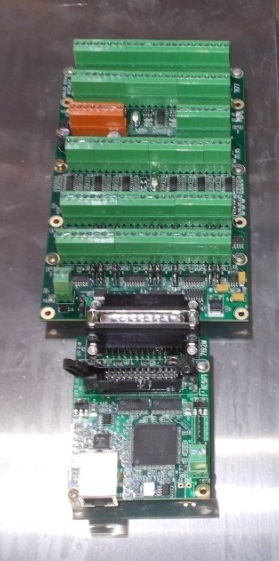

If your servos have +10,-10 volt control input then one solution is the 7I92M together with the (very popular) 7i77

store.mesanet.com/index.php?route=produc...oduct&product_id=302

store.mesanet.com/index.php?route=produc...oduct&product_id=120

store.mesanet.com/index.php?route=produc...oduct&product_id=302

store.mesanet.com/index.php?route=produc...oduct&product_id=120

Attachments:

Last edit: 07 Feb 2020 18:18 by drimaropoylos.

The following user(s) said Thank You: PKM, tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.092 seconds