- Hardware & Machines

- CNC Machines

- Milling Machines

- 1/8 to 1/4" shank tooling adaptors or dedicated cutters?

1/8 to 1/4" shank tooling adaptors or dedicated cutters?

- Oops

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 1

31 Aug 2020 00:52 #180125

by Oops

1/8 to 1/4" shank tooling adaptors or dedicated cutters? was created by Oops

Hello Everyone-

Normally I use 1/8" tooling on the CNC and 1/4" tooling in my handheld routers.

I have a boat project, 6 round hatches various sizes in 1/2" plywood that need 1/8" diameter 1/2" deep slots. It is too big for the CNC.

I tried using a bit from the home improvement store had a 1/4" shank and 1/8" cutting diameter, but it was a straight carbide, did not eject chips, took 3 passes, got hot, and broke partway in on hatch #2 of 6.

Wondering if I should just get more 1/8" upcut bits and some 1/8" to 1/4" adaptors or get dedicated 1/8" bits with built in 1/4" shanks..

For the cost of 2 router bits I could get 10 cutters and 8 adaptors. or the cutters and one Amama adaptor.

I appreciate the advice, thanks!

PS 3.175mm, 6.35mm, 13mm respectively if you're metric...

Normally I use 1/8" tooling on the CNC and 1/4" tooling in my handheld routers.

I have a boat project, 6 round hatches various sizes in 1/2" plywood that need 1/8" diameter 1/2" deep slots. It is too big for the CNC.

I tried using a bit from the home improvement store had a 1/4" shank and 1/8" cutting diameter, but it was a straight carbide, did not eject chips, took 3 passes, got hot, and broke partway in on hatch #2 of 6.

Wondering if I should just get more 1/8" upcut bits and some 1/8" to 1/4" adaptors or get dedicated 1/8" bits with built in 1/4" shanks..

For the cost of 2 router bits I could get 10 cutters and 8 adaptors. or the cutters and one Amama adaptor.

I appreciate the advice, thanks!

PS 3.175mm, 6.35mm, 13mm respectively if you're metric...

Attachments:

Please Log in or Create an account to join the conversation.

- Oops

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 1

03 Sep 2020 02:13 #180482

by Oops

Replied by Oops on topic 1/8 to 1/4" shank tooling adaptors or dedicated cutters?

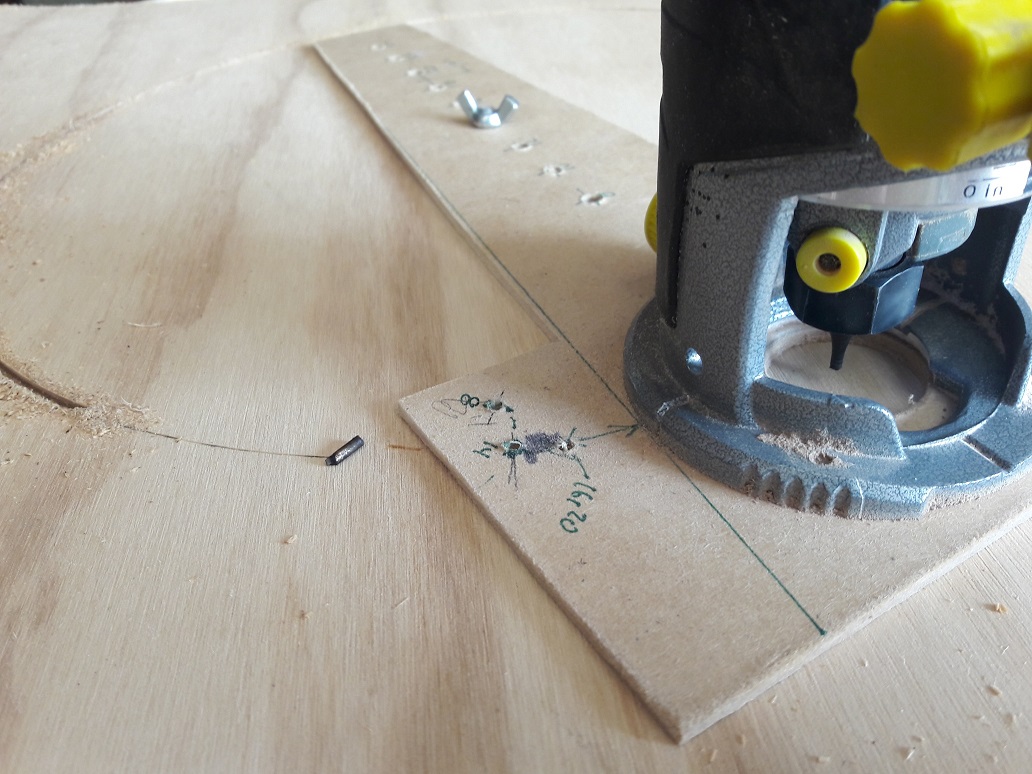

The accessories came in and worked well. The router collet had to be tightened once during the procedure (cutter ran itself out of the adapter) but the upcut bit did way better than the single straight carbide router bit. I did two passes, halfway and full through, starting in a pilot hole.

This is my whimsical approach to v-berth hatches for a small sailboat. I will probably design some 1/6 diameter pieces to act as ledges to keep the hatched from falling in the holes, with a lip to the inside to catch the cutouts and a piece in back for screws and glue to the rest of the plywood..

This is my whimsical approach to v-berth hatches for a small sailboat. I will probably design some 1/6 diameter pieces to act as ledges to keep the hatched from falling in the holes, with a lip to the inside to catch the cutouts and a piece in back for screws and glue to the rest of the plywood..

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- 1/8 to 1/4" shank tooling adaptors or dedicated cutters?

Time to create page: 0.137 seconds