- Hardware & Machines

- CNC Machines

- Milling Machines

- I recived my new bt-30 spindle, please tell me if I am missing something

I recived my new bt-30 spindle, please tell me if I am missing something

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

11 Nov 2021 16:04 #226114

by PhilipME

I recived my new bt-30 spindle, please tell me if I am missing something was created by PhilipME

Hello

I recived today my bt-30 spindle. I feel there might be some missing parts.

What I am asking maybe better explained in this very short video, but it may not be proffissional not to mention anything in the body of the post

Basicly

1-The draw bar , how to center it from the pulley side?

2-the draw bar nut, against which element it will be tightened?

3-Is the tool holder in the video a match for the spindle in the video?

My best regards

Philip

I recived today my bt-30 spindle. I feel there might be some missing parts.

What I am asking maybe better explained in this very short video, but it may not be proffissional not to mention anything in the body of the post

Basicly

1-The draw bar , how to center it from the pulley side?

2-the draw bar nut, against which element it will be tightened?

3-Is the tool holder in the video a match for the spindle in the video?

My best regards

Philip

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

11 Nov 2021 17:08 #226119

by Michael

Replied by Michael on topic I recived my new bt-30 spindle, please tell me if I am missing something

To center the drawbar I would make a custom drawbar "bolt" that was the diameter of the tube and then ended in the correct thread.

If you don't have the ability to make a custom one then I would buy a bolt that is the correct length and thread. It would tighten against a thick washer and the shaft at the top of the spindle. To remove the gap between the shaft and the bolt I would find a bushing to take up the space. Don't use off the shelf all thread or cheap bolts. I would use a grade 12.9 metric fastener. Anything lower won't deal well with the repeated stress.

The taper should keep the tool aligned well enough for this product. ISO taper tools do not have a drive dog like the BT30 and I don't think this spindle would be capable of a large enough cut to require a drive dog.

That being said BT30 is usually used with a power draw bar and would have a pull stud on the tool that would be grabbed by a gripper. Not sure if there is enough room for that arraignment on this spindle.

The BT30 holder should work. As far as I know an ISO30 may work and depending on the inside bore of the spindle you purchased an NTBM30 may be best since these are designed for a drawbar similar to the one you are constructing.

The drive dog engagement is not as critical but that is a lot of play between the two. An industrial machine would normally only have 1 degree of movement.

If you don't have the ability to make a custom one then I would buy a bolt that is the correct length and thread. It would tighten against a thick washer and the shaft at the top of the spindle. To remove the gap between the shaft and the bolt I would find a bushing to take up the space. Don't use off the shelf all thread or cheap bolts. I would use a grade 12.9 metric fastener. Anything lower won't deal well with the repeated stress.

The taper should keep the tool aligned well enough for this product. ISO taper tools do not have a drive dog like the BT30 and I don't think this spindle would be capable of a large enough cut to require a drive dog.

That being said BT30 is usually used with a power draw bar and would have a pull stud on the tool that would be grabbed by a gripper. Not sure if there is enough room for that arraignment on this spindle.

The BT30 holder should work. As far as I know an ISO30 may work and depending on the inside bore of the spindle you purchased an NTBM30 may be best since these are designed for a drawbar similar to the one you are constructing.

The drive dog engagement is not as critical but that is a lot of play between the two. An industrial machine would normally only have 1 degree of movement.

The following user(s) said Thank You: PhilipME

Please Log in or Create an account to join the conversation.

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

11 Nov 2021 17:38 - 11 Nov 2021 22:17 #226122

by PhilipME

Replied by PhilipME on topic I recived my new bt-30 spindle, please tell me if I am missing something

Excellent

Very clear I can get a bolt made as you mentioned.. it is the best idea. But to get some thing machined here is very expensive.

I am also thinking of the second option you mentioned

making some kind of a bushing made to center the draw bar.

I do not know if a 3d printed bushing (100% infill) can take the abuse.

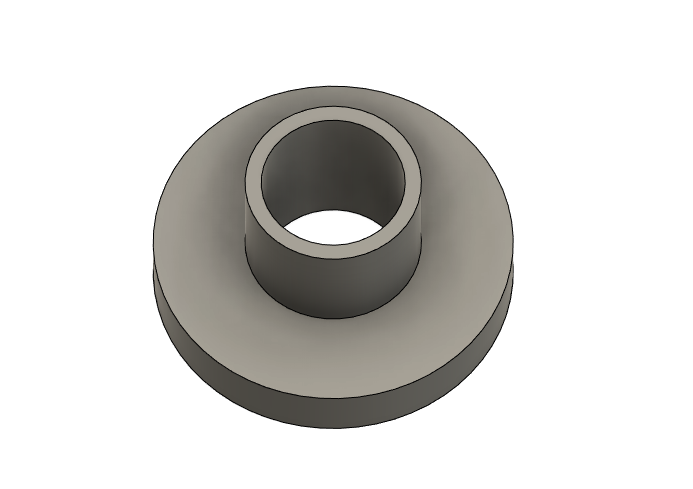

the inner diameter of the bushing (spacer) will be 12mm (the rod diameter), and the outer diameter is the id of the shaft. this is only for centering, I do not see any torsional loads will be exerted on such piece (both elements rotating) unless the nut wants to get loose with vibration. which may present other safety consequencies more than damaging the spacer.

with such 3d printed piece, I use vey thick washer to be able to torque the draw bar nut to the shaft. I have to use some locktite.

If the 3d printed part fails, I think I can machine one out of aluminum using the same machine that I want the bt30 spindle for. I will use a high speed spindle with precautions.

Thanks very much for giving me ideas.

Philip

edit:

this is what I mean

Very clear I can get a bolt made as you mentioned.. it is the best idea. But to get some thing machined here is very expensive.

I am also thinking of the second option you mentioned

making some kind of a bushing made to center the draw bar.

I do not know if a 3d printed bushing (100% infill) can take the abuse.

the inner diameter of the bushing (spacer) will be 12mm (the rod diameter), and the outer diameter is the id of the shaft. this is only for centering, I do not see any torsional loads will be exerted on such piece (both elements rotating) unless the nut wants to get loose with vibration. which may present other safety consequencies more than damaging the spacer.

with such 3d printed piece, I use vey thick washer to be able to torque the draw bar nut to the shaft. I have to use some locktite.

If the 3d printed part fails, I think I can machine one out of aluminum using the same machine that I want the bt30 spindle for. I will use a high speed spindle with precautions.

Thanks very much for giving me ideas.

Philip

edit:

this is what I mean

Attachments:

Last edit: 11 Nov 2021 22:17 by PhilipME.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

12 Nov 2021 03:10 #226177

by spumco

Replied by spumco on topic I recived my new bt-30 spindle, please tell me if I am missing something

McMaster-Carr sells grade 12.9 metric all-thread. Add a flanged heavy hex nut to the top and a bearing washer between the nut and your 'top hat' centering bushing.

Coat everything (nut, washer, top hat, drawbar) lightly with never-seize. It also helps to machine or grind the nut and washer very flat, but you can sand & polish them flat on a surface plate to reduce friction while torquing the drawbar.

Pin the nut to the all-thread and you've got a no-machining drawbar.

For your bushing a 3d printed item will be fine to locate the drawbar radially, but if the drawbar compresses the bushing flange when tightening it'll fail.

Coat everything (nut, washer, top hat, drawbar) lightly with never-seize. It also helps to machine or grind the nut and washer very flat, but you can sand & polish them flat on a surface plate to reduce friction while torquing the drawbar.

Pin the nut to the all-thread and you've got a no-machining drawbar.

For your bushing a 3d printed item will be fine to locate the drawbar radially, but if the drawbar compresses the bushing flange when tightening it'll fail.

The following user(s) said Thank You: PhilipME

Please Log in or Create an account to join the conversation.

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

12 Nov 2021 12:37 #226219

by PhilipME

Replied by PhilipME on topic I recived my new bt-30 spindle, please tell me if I am missing something

Thank you very much spumco

I placed order for never seez

For the 3d printed part, I will have to agree that it will not stand a chance when tightening the nut against it.

My best regards

Philip

I placed order for never seez

For the 3d printed part, I will have to agree that it will not stand a chance when tightening the nut against it.

My best regards

Philip

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- I recived my new bt-30 spindle, please tell me if I am missing something

Time to create page: 0.085 seconds