Gecko G251x step/dir drives

- rdtsc

-

Topic Author

Topic Author

- Away

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 9

13 May 2024 21:10 #300531

by rdtsc

Gecko G251x step/dir drives was created by rdtsc

Inherited some medium-sized NEMA23 steppers and KL-4030 drivers. Got things to work on the bench at their rated 2.9A current, but the steppers will happily walk themselves right off - very noisy and vibrate terribly at low speeds. Hence why I'm attempting the Gecko G251x. www.geckodrive.com/product/g251x-digital-step-drive/ Waiting for them to arrive. Little info, only a few posts scattered about.

The manual for this drive says: under no circumstances ever switch the power to the drive while the motor is energized, or destruction will result.

Under normal circumstances the machine power would be applied, cuts made, then machine power removed (disabling all stepper drives) so that would be safe. Question is, what happens if the power goes out or circuit breaker trips during operation?

Is the damage something that wouldn't ever happen with a 36V PSU connected (added capacitance)? The G251x is likely a H-bridge design, so then does the damage stem from motor currents collapsing and manifesting as a voltage spike on the main rails? Would it be a good idea to place a 40V TVS or Zener at the G251x so that >50V isn't ever possible?

The manual for this drive says: under no circumstances ever switch the power to the drive while the motor is energized, or destruction will result.

Under normal circumstances the machine power would be applied, cuts made, then machine power removed (disabling all stepper drives) so that would be safe. Question is, what happens if the power goes out or circuit breaker trips during operation?

Is the damage something that wouldn't ever happen with a 36V PSU connected (added capacitance)? The G251x is likely a H-bridge design, so then does the damage stem from motor currents collapsing and manifesting as a voltage spike on the main rails? Would it be a good idea to place a 40V TVS or Zener at the G251x so that >50V isn't ever possible?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

13 May 2024 21:32 #300533

by tommylight

You can cut power to the AC side of things as much as you like.

-

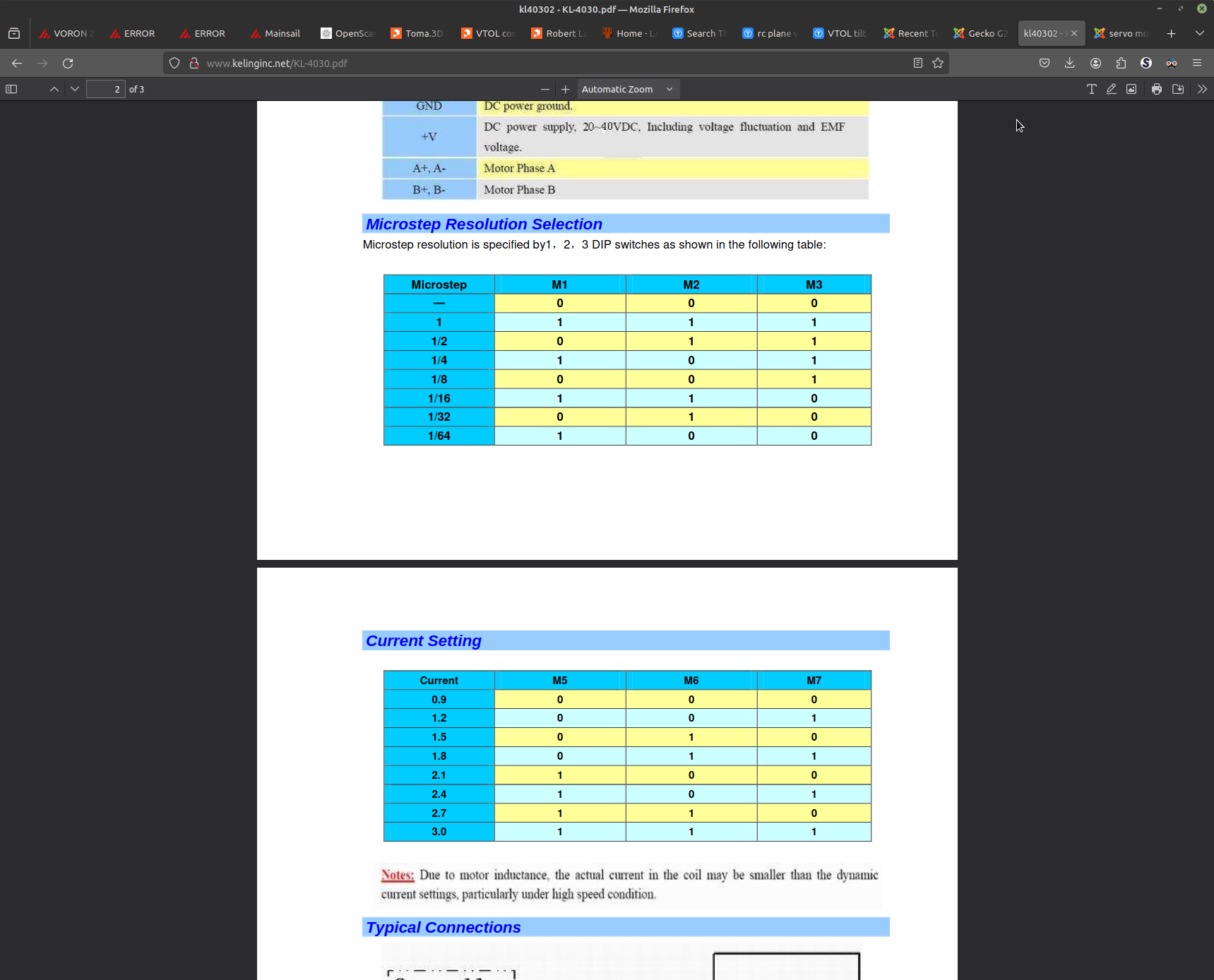

See attache picture, set the KL drives to 1/16 or 1/32 microsteps, test again, should be much smoother running. You can set to 1/64 and would be even smoother, but depending of how you are creating pulses you may need to go lower.

Also, do not push the max out of them, 2A should be enough depending on your motors

Replied by tommylight on topic Gecko G251x step/dir drives

That statement lack the main part: DC side, so should be: never cut the DC side of power to the drives, or to put it bluntly never disconnect/unplug the red+ and black- wire to the drive.The manual for this drive says: under no circumstances ever switch the power to the drive while the motor is energized, or destruction will result.

You can cut power to the AC side of things as much as you like.

-

See attache picture, set the KL drives to 1/16 or 1/32 microsteps, test again, should be much smoother running. You can set to 1/64 and would be even smoother, but depending of how you are creating pulses you may need to go lower.

Also, do not push the max out of them, 2A should be enough depending on your motors

Attachments:

Please Log in or Create an account to join the conversation.

- rdtsc

-

Topic Author

Topic Author

- Away

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 9

18 May 2024 04:58 #300888

by rdtsc

Replied by rdtsc on topic Gecko G251x step/dir drives

WOW... received the G251x's today and tried one - absolutely beautiful operation! With 2.2A to motor it happily purrs through Chips.ngc with zero motor dancing. It's so quiet, it is almost inaudible, and no more high-pitched squealing. Now that is how a stepper should run! Haven't even tweaked the tiny trimpot yet. I'll feel much better about rigidly mounting the motor to the machine now, knowing that it isn't going to quickly damage itself. The motor even seems to have more torque with less current. The longer it runs, the quieter it becomes... just fantastic.

Downside to the G251x is that it is small... I mean very small; whole thing will easily fit within a palm. Which is great for a size-constrained build or to hide the drive somewhere near the motor, but I didn't realize that 3mm terminals would be so finnicky. Had to trim off strands of the test wires to even fit. So, tip for anyone else thinking of these - plan on fine wire in the terminals. Unsure what gauge fits, maybe 18ga but certainly not 14ga. If using a cable crimper, the smallest size ferrule (white or grey in my case, 22/20ga or 0.5/0.75mm) may just barely fit.

Back to the original question - examining the drive, it does have an H-bridge for each motor winding. So when power is suddenly removed, the motor current collapses through the parasitic diodes in the H-bridges into the DC input terminals. With nothing to stop it, an opened inductor (the motor windings) could cause a voltage rise over 50V and damage the drive. If a (say, 36V) DC power supply were connected, we'd see this as a rise above 36V for some fraction of a second. But the capacitance of the supply will work to slow this rise, and that alone may be adequate (there is significant headroom to 50V.) Still, better safe than sorry, so I'll install one 36V transient voltage suppressor (TVS) right across the 36V supply. That way, if power ever does go out during operation, the bus can only get to 40-ish Volts before clamping starts. Something like a octopart.com/search?q=5KP36A-E3%2F54 would work for many (even large) steppers at 36VDC. This becomes tricky with a 48V supply though, as a 48V TVS will not start dissipating useful current until around 53V or so. In that case, some form of active clamping ("crowbar") circuitry would be needed.

Downside to the G251x is that it is small... I mean very small; whole thing will easily fit within a palm. Which is great for a size-constrained build or to hide the drive somewhere near the motor, but I didn't realize that 3mm terminals would be so finnicky. Had to trim off strands of the test wires to even fit. So, tip for anyone else thinking of these - plan on fine wire in the terminals. Unsure what gauge fits, maybe 18ga but certainly not 14ga. If using a cable crimper, the smallest size ferrule (white or grey in my case, 22/20ga or 0.5/0.75mm) may just barely fit.

Back to the original question - examining the drive, it does have an H-bridge for each motor winding. So when power is suddenly removed, the motor current collapses through the parasitic diodes in the H-bridges into the DC input terminals. With nothing to stop it, an opened inductor (the motor windings) could cause a voltage rise over 50V and damage the drive. If a (say, 36V) DC power supply were connected, we'd see this as a rise above 36V for some fraction of a second. But the capacitance of the supply will work to slow this rise, and that alone may be adequate (there is significant headroom to 50V.) Still, better safe than sorry, so I'll install one 36V transient voltage suppressor (TVS) right across the 36V supply. That way, if power ever does go out during operation, the bus can only get to 40-ish Volts before clamping starts. Something like a octopart.com/search?q=5KP36A-E3%2F54 would work for many (even large) steppers at 36VDC. This becomes tricky with a 48V supply though, as a 48V TVS will not start dissipating useful current until around 53V or so. In that case, some form of active clamping ("crowbar") circuitry would be needed.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- mboston

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

06 Dec 2024 00:33 - 06 Dec 2024 00:36 #316065

by mboston

Replied by mboston on topic Gecko G251x step/dir drives

What settings are you using for the G251X? I have been trying to tune them with no success. The motors are very loud and produce a lot of vibration, especially at low speeds. Using generic Chinese drives with the same hal (minor tweak to the stepper scale) produces significantly less noise and vibration.

Last edit: 06 Dec 2024 00:36 by mboston.

Please Log in or Create an account to join the conversation.

- rdtsc

-

Topic Author

Topic Author

- Away

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 9

05 Jul 2025 17:11 #331332

by rdtsc

Replied by rdtsc on topic Gecko G251x step/dir drives

Unsure how you could have had the complete opposite experience, mboston. There isn't much set-up possible on the G251x - it should just work out-of-the-box. There is a tiny trimpot on it that can be ever-so-slightly adjusted with a tiny screwdriver; double-check the

manual

and try giving that an adjustment at very slow speeds; it is supposed to adjust the smoothness.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.108 seconds