Retrofitting a MAHO MH600T

- schuetzbuilds

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 6

20 Aug 2024 14:32 #308216

by schuetzbuilds

Retrofitting a MAHO MH600T was created by schuetzbuilds

Hi All,My brother and I recently purchased an old MAHO MH600T with the intention of retrofitting it using LinuxCNC, a 7i77, a 7i84, and the GmoccaPy interface. We began our project by following Mark's thread, which provided invaluable information—without it, we would have been lost. The machine originally came with an old Heidenhain 332 CNC controller, but unfortunately, the video output seems to be broken. Since this compact module also contained the EXE interfaces, we had to replace them with three EXE602 modules to read the linear scales.This is working fine (we are currently ignoring the c-axis...) and the cable cabinet still had a convenient place for its three new members.

At this stage, we have successfully set up the endstop chain and the linear motion system (encoders and the Indramat drives for X, Y, and Z axes), using conservative values for the PID controller and homing. Our next step is to get the "accessories" working, such as flood coolant, the tool holder, and basic spindle control (including potentially allowing for manual gear changes). While the machine behaves as expected when we press the test buttons on the relay board, we are facing difficulties controlling these functions via LinuxCNC. I have a few questions about this (apologies if they seem basic, but I am new to LinuxCNC and HAL).

1. I wired the 2K2 relay for the coolant pump to output-15 of my 7i84, with field power supplied by the 24V line. The pump operates correctly when I test the relay using its test button, but attempting to activate the relay from the Mesa card causes the machine to go into an emergency stop. Even connecting the relay to my field power alone triggers a shutdown. I've double-checked the wiring (I have a connection from output 15 to the test lead MP12 and to the relay), swapped the relay with a known working one (19K1, machine on), and tested the output without anything connected (it pulls up and down correctly). I initially thought it might be an issue with using a different 24V line, but the "machine on" relay is functioning. I'm currently suspecting a short circuit, but there is no error message displayed by the controller—just the fact that the machine goes into E-Stop. Is there a hidden log or extended error message that might provide more information?

2. The spindle: For a first test, I wanted to have the spindle on/off working, which just should be the three relays 1K8, 1K9, 1K10, connected to output 12, 13, and 14 on the 7i84. but with the following hal code, nothing happens, when pressing spindle start, and the pins of the 7i84 are floating at roughly 13V. So it seems the pins are not connected in the hal. Is there something I am overlooking, do I need to use the halui pins?:3. The gearbox. The good news is that our machine is equipped with an 18-speed gearbox, similar to Mark's, but the sensing configuration is slightly different. While the outputs are the same, we only have nine inputs, which means we're missing the "Links-Mitte" switch that indicates whether the gear motor should turn left or right. Has anyone modified the gearbox component for the MH400E to accommodate this configuration, or has a working original MAHO with this arrangment and could share, how the gearshift is done there? I somehow hope, that it is just an easy modification, but my C is a bit rusty, so we will se how this goes.

Kind regards

Sebastian

At this stage, we have successfully set up the endstop chain and the linear motion system (encoders and the Indramat drives for X, Y, and Z axes), using conservative values for the PID controller and homing. Our next step is to get the "accessories" working, such as flood coolant, the tool holder, and basic spindle control (including potentially allowing for manual gear changes). While the machine behaves as expected when we press the test buttons on the relay board, we are facing difficulties controlling these functions via LinuxCNC. I have a few questions about this (apologies if they seem basic, but I am new to LinuxCNC and HAL).

1. I wired the 2K2 relay for the coolant pump to output-15 of my 7i84, with field power supplied by the 24V line. The pump operates correctly when I test the relay using its test button, but attempting to activate the relay from the Mesa card causes the machine to go into an emergency stop. Even connecting the relay to my field power alone triggers a shutdown. I've double-checked the wiring (I have a connection from output 15 to the test lead MP12 and to the relay), swapped the relay with a known working one (19K1, machine on), and tested the output without anything connected (it pulls up and down correctly). I initially thought it might be an issue with using a different 24V line, but the "machine on" relay is functioning. I'm currently suspecting a short circuit, but there is no error message displayed by the controller—just the fact that the machine goes into E-Stop. Is there a hidden log or extended error message that might provide more information?

2. The spindle: For a first test, I wanted to have the spindle on/off working, which just should be the three relays 1K8, 1K9, 1K10, connected to output 12, 13, and 14 on the 7i84. but with the following hal code, nothing happens, when pressing spindle start, and the pins of the 7i84 are floating at roughly 13V. So it seems the pins are not connected in the hal. Is there something I am overlooking, do I need to use the halui pins?:

net spindle-enable hm2_5i25.0.7i84.0.2.output-12

net spindle-cw hm2_5i25.0.7i84.0.2.output-13

net spindle-ccw hm2_5i25.0.7i84.0.2.output-14Kind regards

Sebastian

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

20 Aug 2024 20:51 #308245

by PCW

Replied by PCW on topic Retrofitting a MAHO MH600T

Are you sure that:

1. 7I84 has +24V field power

2, The relay board 0V common connects to the 24V common

1. 7I84 has +24V field power

2, The relay board 0V common connects to the 24V common

Please Log in or Create an account to join the conversation.

- schuetzbuilds

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 6

21 Aug 2024 15:37 - 22 Aug 2024 12:33 #308306

by schuetzbuilds

Replied by schuetzbuilds on topic Retrofitting a MAHO MH600T

Uhhhh, I think you’ve hit the nail on the head… How embarrassing…The 7i84 is powered by a 24V field power, but it's connected to a completely separate 24V rail (24V Logic, marked in red), while the relay board is connected to a different 24V source (marked in blue) with no common ground between them. I’ll fix that tomorrow. Thank you!

EDIT: Yes, that was the issue. Now the coolant pump is working. And after fixing a small mistake in my hal the spindle is now also starting. Now only the gear train remains (and the fourth axis...)

EDIT: Yes, that was the issue. Now the coolant pump is working. And after fixing a small mistake in my hal the spindle is now also starting. Now only the gear train remains (and the fourth axis...)

Last edit: 22 Aug 2024 12:33 by schuetzbuilds.

Please Log in or Create an account to join the conversation.

- schuetzbuilds

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 6

22 Aug 2024 15:04 - 22 Aug 2024 15:06 #308403

by schuetzbuilds

Replied by schuetzbuilds on topic Retrofitting a MAHO MH600T

So after the crucial tip from pcw I got the outputs working and configured the lube system. As for the hydraulic draw bar I repurposed the former cycle start button from our very simple hand held. After looking at the code for the central lubrication, I modified it a bit to fit the drawbar application and loaded it as drawbar component, which will only release the drawbar, if the spindle is not running.

It connects via Hal similar to the central lubrication component (wiki.linuxcnc.org/cgi-bin/wiki.pl?CentralizedLubricator).

It connects via Hal similar to the central lubrication component (wiki.linuxcnc.org/cgi-bin/wiki.pl?CentralizedLubricator).

# drawbar

loadusr -W /home/maho/linuxcnc/configs/maho_mh600t/drawbar.py

net drawbar-open drawbar.open => hm2_5i25.0.7i84.0.2.output-03

net machine-is-enabled drawbar.machine_status <= motion.motion-enabled

net spindle-enable drawbar.spindle_status

net drawbar-sw drawbar.open_sw <= hm2_5i25.0.7i77.0.0.input-00

Last edit: 22 Aug 2024 15:06 by schuetzbuilds.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

22 Aug 2024 16:47 #308412

by RotarySMP

Replied by RotarySMP on topic Retrofitting a MAHO MH600T

Good on you. Nice work getting another Maho going.

Cheers,

Mark

Cheers,

Mark

Please Log in or Create an account to join the conversation.

- schuetzbuilds

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 6

22 Aug 2024 18:43 #308425

by schuetzbuilds

Replied by schuetzbuilds on topic Retrofitting a MAHO MH600T

It's still a work in progress, but the computer is now mounted on the tray where the original controller used to be. It's quite convenient since the tray folds out of the cable cabinet, making the computer easily accessible.

Good on you. Nice work getting another Maho going.

Cheers,

Thank you, Mark. Your MAHO videos are actually the reason we decided to get a MAHO and go ahead with the retrofit.Mark

Attachments:

The following user(s) said Thank You: RotarySMP, besriworld

Please Log in or Create an account to join the conversation.

- schuetzbuilds

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 6

06 Sep 2024 14:30 #309501

by schuetzbuilds

Replied by schuetzbuilds on topic Retrofitting a MAHO MH600T

The last few days have been busy, but we added the fourth axis and build a new enclosure for the monitor. We repurposed the original base and just added an aluminium plate. The monitor enclosure is also from aluminium we had laying around.

Now the maho feels much more modern and with the physical buttons around the display we don´t have to manually switch the 19K1 relay (thanks to the hal or2).

We just started implementing the gear change as a python HAL component (that seemed faster, than trying to modify the C-Code from the MH400 gearbox) and got it to read the gears/speeds from the machine. But the machine is currently in a state of emergeny (stop) as our hydraulic pump is striking. Not quite sure if it is the pump or the hydraulic relais/pressure switch, but for now this is stopping us from further testing until it is solved. Has anyone else also experienced problems with their hydraulic pump (a HAWE FP12M-H1)?

Now the maho feels much more modern and with the physical buttons around the display we don´t have to manually switch the 19K1 relay (thanks to the hal or2).

We just started implementing the gear change as a python HAL component (that seemed faster, than trying to modify the C-Code from the MH400 gearbox) and got it to read the gears/speeds from the machine. But the machine is currently in a state of emergeny (stop) as our hydraulic pump is striking. Not quite sure if it is the pump or the hydraulic relais/pressure switch, but for now this is stopping us from further testing until it is solved. Has anyone else also experienced problems with their hydraulic pump (a HAWE FP12M-H1)?

Attachments:

The following user(s) said Thank You: tommylight, besriworld, COFHAL

Please Log in or Create an account to join the conversation.

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 43

19 Sep 2024 07:54 #310429

by Finngineering

Replied by Finngineering on topic Retrofitting a MAHO MH600T

Nice to see another Maho, and a MH600T at that. I am also in the process of converting mine to LinuxCNC:

forum.linuxcnc.org/30-cnc-machines/49758...mizing-a-maho-mh600t

Do you have the schematics for the MH600T? I have been working off of MH600E schematics I found online. I don't think they should differ too much, though. But if you have MH600T schematics, I sure wouldn't mind a copy.

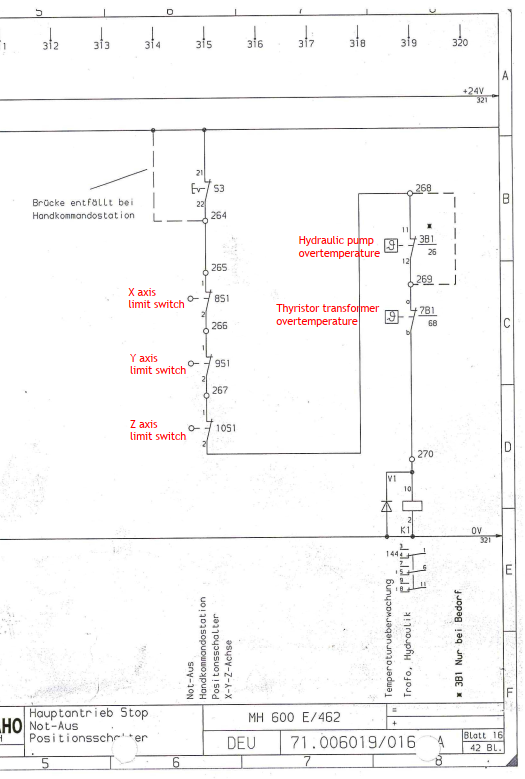

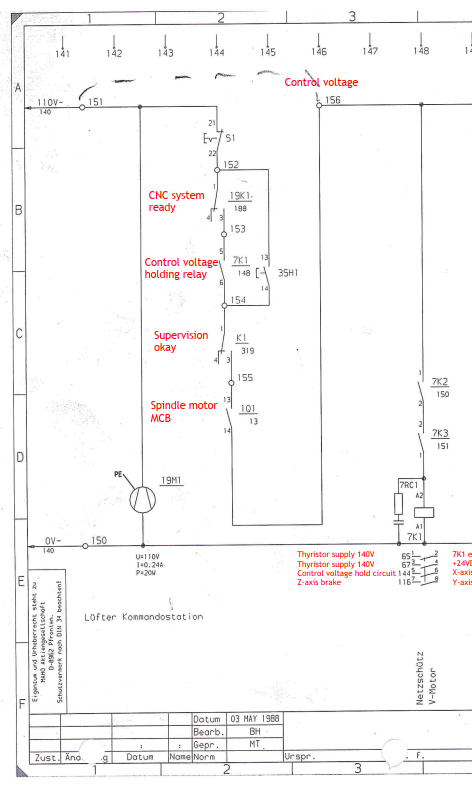

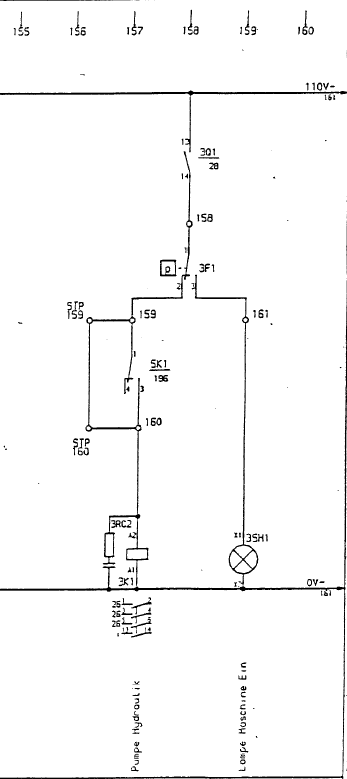

Did you manage to fix the issue with the hydraulic pump? From what I see in the schematics I use, only the hydraulic pump overtemperature switch should be involved in the machine power/e-stop The temperature switch is 3B1 is needed to pull relay K1, which in turn is needed to "turn on" the machine by latching 7K1.

forum.linuxcnc.org/30-cnc-machines/49758...mizing-a-maho-mh600t

Do you have the schematics for the MH600T? I have been working off of MH600E schematics I found online. I don't think they should differ too much, though. But if you have MH600T schematics, I sure wouldn't mind a copy.

Did you manage to fix the issue with the hydraulic pump? From what I see in the schematics I use, only the hydraulic pump overtemperature switch should be involved in the machine power/e-stop The temperature switch is 3B1 is needed to pull relay K1, which in turn is needed to "turn on" the machine by latching 7K1.

Attachments:

Please Log in or Create an account to join the conversation.

- schuetzbuilds

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 6

19 Sep 2024 19:41 #310474

by schuetzbuilds

Replied by schuetzbuilds on topic Retrofitting a MAHO MH600T

Wow, your conversion looks like a lot of work. Very impressive (and a very clean control cabinet!).

Yes, the schematics came with our machine, I am more than willing to share the pdf of the schematics with you.

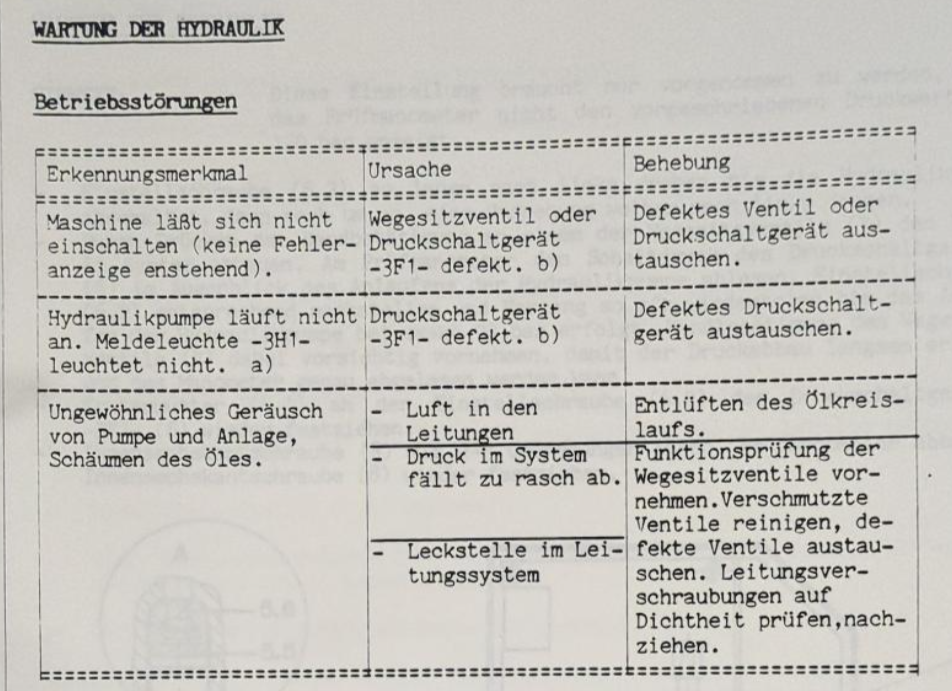

No, currently I was not able to fix the issue, as I am currently out of country. We have the same e-stop chain and I also thought, maybe it was just the overtemperatur switch, but the manual for the original control also listed the possibility of a malfunction of 3F1 (Druckschaltgeraet), but i am currently not quite sure, how that would keep the machine off...

Yes, the schematics came with our machine, I am more than willing to share the pdf of the schematics with you.

No, currently I was not able to fix the issue, as I am currently out of country. We have the same e-stop chain and I also thought, maybe it was just the overtemperatur switch, but the manual for the original control also listed the possibility of a malfunction of 3F1 (Druckschaltgeraet), but i am currently not quite sure, how that would keep the machine off...

Attachments:

Please Log in or Create an account to join the conversation.

- Finngineering

- Away

- Premium Member

-

Less

More

- Posts: 91

- Thank you received: 43

20 Sep 2024 05:51 #310493

by Finngineering

Replied by Finngineering on topic Retrofitting a MAHO MH600T

Thank you for the kind words, and you are doing a nice job yourself.

Currently out of the country... sounds all too familiar. For me it's the largest reason why it seems to take me so long to finish my Maho - I'm so often away from home.

Maybe I jumped to conclusions / misinterpreted the information regarding the hydraulic pump. It depends on how you reached the conclusion that the machine is in emergency stop. In my opinion, the machine is in emergency stop if you don't have the 110 VAC "control voltage" at terminal 156 (with reference to terminal 150), shown in my second screenshot in the previous post. If you don't have 110 VAC at terminal 156 and the reason is related to the hydraulic pump, then I don't see much other reasons than the temperature switch. But in that case, the issue could also be caused by a few other things than the hydraulic pump.

On the other hand, if you determine that the machine is in emergency stop because light 3SH1 doesn't light up or the hydraulic pump doesn't run (for a short while) when switching on the power to the machine and pressing the 3SH1 "on" button, then there may be many other reasons, including 3F1. If this is the case, I would first measure the AC voltage across terminals 156-150 (after you have pressed the 3SH1 "on" button). If you don't get 110 VAC there, the issue can be one of many things, and to determine which would require some more measurements. Easy things that come to mind in that case could anyway be axis overtravel / limit switch.

Let us know in case you need some help troubleshooting once you get back to it.

Currently out of the country... sounds all too familiar. For me it's the largest reason why it seems to take me so long to finish my Maho - I'm so often away from home.

Maybe I jumped to conclusions / misinterpreted the information regarding the hydraulic pump. It depends on how you reached the conclusion that the machine is in emergency stop. In my opinion, the machine is in emergency stop if you don't have the 110 VAC "control voltage" at terminal 156 (with reference to terminal 150), shown in my second screenshot in the previous post. If you don't have 110 VAC at terminal 156 and the reason is related to the hydraulic pump, then I don't see much other reasons than the temperature switch. But in that case, the issue could also be caused by a few other things than the hydraulic pump.

On the other hand, if you determine that the machine is in emergency stop because light 3SH1 doesn't light up or the hydraulic pump doesn't run (for a short while) when switching on the power to the machine and pressing the 3SH1 "on" button, then there may be many other reasons, including 3F1. If this is the case, I would first measure the AC voltage across terminals 156-150 (after you have pressed the 3SH1 "on" button). If you don't get 110 VAC there, the issue can be one of many things, and to determine which would require some more measurements. Easy things that come to mind in that case could anyway be axis overtravel / limit switch.

Let us know in case you need some help troubleshooting once you get back to it.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.451 seconds