Hermle UWF 700 Retrofit

- Bassblaster

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 2

15 Nov 2024 20:59 - 15 Nov 2024 21:02 #314568

by Bassblaster

Hermle UWF 700 Retrofit was created by Bassblaster

Hi Guys!

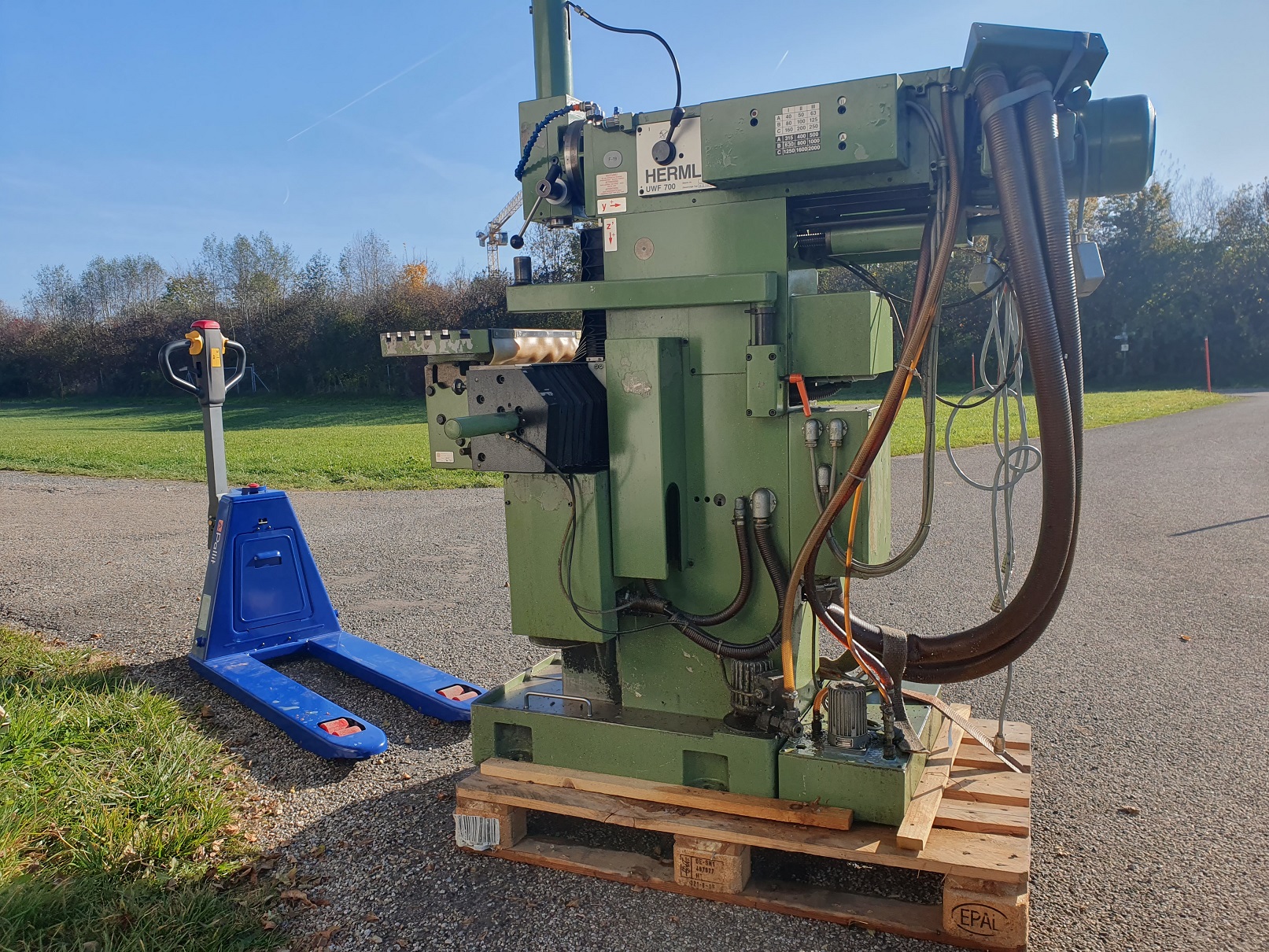

I started a new project, a retrofit of a Hermle UWF 700. It was made in 1984, 40 years ago. The mechanical condition is very good, no signs of wear anywhere, although that might also be due to the automatic lubricator. The mill has a 18-speed gearbox, maxing out at 2000rpm's. The electronics were not working anymore, so I only got the machine itself. I did get a lot of nice documentation however. Tool clamping works by a hydraulic cylinder. The gears are lubricated with an oil spray system with a seperate oil pump.This is what the Hermle looks like:

And inside my small shed:

The ways still look pretty good:

I paid 2000€ for it, which seems fine.

My Plans:

Manuel

I started a new project, a retrofit of a Hermle UWF 700. It was made in 1984, 40 years ago. The mechanical condition is very good, no signs of wear anywhere, although that might also be due to the automatic lubricator. The mill has a 18-speed gearbox, maxing out at 2000rpm's. The electronics were not working anymore, so I only got the machine itself. I did get a lot of nice documentation however. Tool clamping works by a hydraulic cylinder. The gears are lubricated with an oil spray system with a seperate oil pump.This is what the Hermle looks like:

And inside my small shed:

The ways still look pretty good:

I paid 2000€ for it, which seems fine.

My Plans:

- I want to use Servos for the three axis. I am currently thinking about 660 Watt JMC servos or some chinese ones, since I can not get my hands on anything else.

- The machine already has glass scales on all three axis. I think it should be possible to use them with a mesa board if I use three Heidenhain EXE 602 E and use them as feedback in a PID loop.

- I have a 7i96s with a 7i85, which could be able to do the trick If I use the step/dir interface of the servos, which only works in positional mode. But I read multiple times here on the forum that velocity mode is better. Otherwise I will buy something like the 7i97T.

- I might increase the low spindle speed by using a belt drive, at least 4000rpm would be nice.

- I might use an Arduino to shift the 18 gears of the gearbox. That seems simpler to me rather than using LinuxCNC to handle the shifting.

Manuel

Attachments:

Last edit: 15 Nov 2024 21:02 by Bassblaster.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

15 Nov 2024 21:45 #314572

by tommylight

Replied by tommylight on topic Hermle UWF 700 Retrofit

If you do get the step/rid servos, they will have encoder wired to their drives, so you can look at it a simple stepper system, and if you can use the scales wired to LinuxCNC, that would also close the loop in LinuxCNC, making any backlash in the system less impactful. This from LinuxCNC's point of view makes it velocity mode where LinuxCNC controls the position.

That can all be done with 7i96S and 7i85.

That can all be done with 7i96S and 7i85.

Please Log in or Create an account to join the conversation.

- Mag20011

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

13 Jun 2025 10:47 #330246

by Mag20011

Replied by Mag20011 on topic Hermle UWF 700 Retrofit

Hallo, ich habe Die gleiche Maschine wie Du gekauft. wie weit bist Du mit Deinem Umbau? Welche Servos hast Du schlussendlich verbaut? Woher kommst Du?

Viele Grüße Markus vom Bodensee 88636

Viele Grüße Markus vom Bodensee 88636

Please Log in or Create an account to join the conversation.

- Bassblaster

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 2

01 Oct 2025 18:29 - 01 Oct 2025 18:31 #335675

by Bassblaster

Sorry wegen der späten Antwort. Ich bin mitllerweile relativ weit, für zwei Sachen hatte ich noch nicht Zeit, das Einbinden der Glasmaßstäbe und die Getriebeschaltung. Momentan habe ich immer den höchsten Gang drin und nutze einen Frequenzumrichter. Ansonsten läuft die Maschine. Ich habe noch zwei Gasdruckfedern zum ausgleichen vom Gewicht des Tischs eingebaut. Die Servos sind billige China-Servos (S2 Series steht da drauf, gibts billig auf Ebay), wobei ich vielleicht nächstes mal eher bei Stepperonline kaufen würde, da die Firmware buggy ist. Ich komme aus dem Allgäu, also nicht weit weg

VG

Manuel

Replied by Bassblaster on topic Hermle UWF 700 Retrofit

Hi Markus,Hallo, ich habe Die gleiche Maschine wie Du gekauft. wie weit bist Du mit Deinem Umbau? Welche Servos hast Du schlussendlich verbaut? Woher kommst Du?

Viele Grüße Markus vom Bodensee 88636

Sorry wegen der späten Antwort. Ich bin mitllerweile relativ weit, für zwei Sachen hatte ich noch nicht Zeit, das Einbinden der Glasmaßstäbe und die Getriebeschaltung. Momentan habe ich immer den höchsten Gang drin und nutze einen Frequenzumrichter. Ansonsten läuft die Maschine. Ich habe noch zwei Gasdruckfedern zum ausgleichen vom Gewicht des Tischs eingebaut. Die Servos sind billige China-Servos (S2 Series steht da drauf, gibts billig auf Ebay), wobei ich vielleicht nächstes mal eher bei Stepperonline kaufen würde, da die Firmware buggy ist. Ich komme aus dem Allgäu, also nicht weit weg

VG

Manuel

Last edit: 01 Oct 2025 18:31 by Bassblaster.

Please Log in or Create an account to join the conversation.

- Mag20011

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

18 Oct 2025 19:42 #336667

by Mag20011

Replied by Mag20011 on topic Hermle UWF 700 Retrofit

Hallo, woher genau bist Du denn? Könnte man auch mal vorbeikommen? Oder telefonieren? 0171 4152421 Gruß Markus Scheck

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.159 seconds