Remora - ethernet NVEM / EC300 / EC500 cnc board

- aaamil13

- Offline

- New Member

-

- Posts: 10

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 12

Sudo apt install python3-pip

Pip3 install tftpy

That did it for me. Sorry for the formatting but I'm on mobile but you get the idea.

Pip3 will install the python3 tftpy module. Pip will install only for the 2.7

Please Log in or Create an account to join the conversation.

- aaamil13

- Offline

- New Member

-

- Posts: 10

- Thank you received: 1

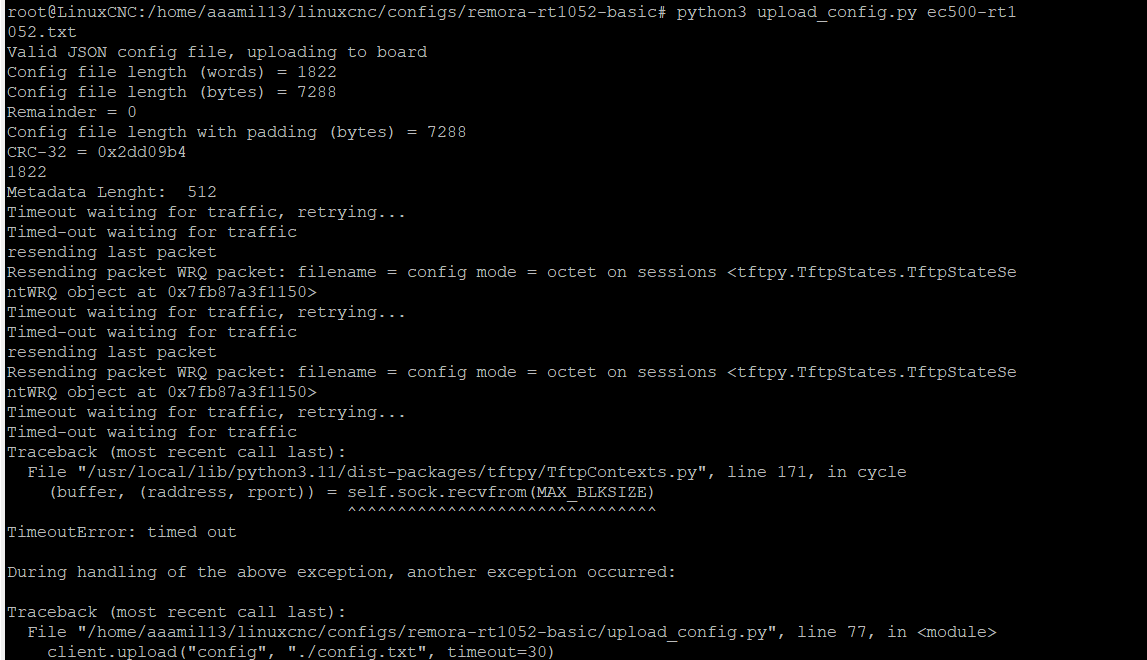

tcpdump port 69 -vv

tcpdump: listening on eno1, link-type EN10MB (Ethernet), snapshot length 262144 bytes

21:04:06.187537 IP (tos 0x0, ttl 64, id 53926, offset 0, flags [DF], proto UDP (17), length 43)

LinuxCNC.43235 > 10.10.10.10.tftp: [bad udp cksum 0x2851 -> 0x29d8!] TFTP, length 15, WRQ "config" octet

21:04:36.211690 IP (tos 0x0, ttl 64, id 61158, offset 0, flags [DF], proto UDP (17), length 43)

LinuxCNC.43235 > 10.10.10.10.tftp: [bad udp cksum 0x2851 -> 0x29d8!] TFTP, length 15, WRQ "config" octet

Unfortunately can't read debug messages on UART ( seems that TTL level shifter burned while been connected to RS232)

So i decided to compile with integrated config JSON and that is ok for me. The good news is that Version 2.0.0 with DMA is much better, the possibility to control pulse width and 500khz stepgen ( tested at 90khz and it is ok ).

Attachments:

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 954

- Thank you received: 486

The advantage of the DMA stepgen is the increased max step rate, from ~100khz to 500khz. So people with high micro stepping or reductions will be happy.May I ask what is the advantage of DMA stepgen? Is it faster or less cpu intense? Adjustable step length seems nice.

And one more question: Can it be used for generating PWM signals or is this a completly different can of worms.

At low step rates the DMA stepgen has way less CPU load. The reason for the max 500khz is the point where there is not enough time within the servo thread to do the calcs for all 6 axes. Which most people will never need all 6 axes to be that fast simultaneously.

For the last point, the downside with the DMA stepgen is that it is tied to the GPIO port used for the step and direction outputs, GPIO1. The other outputs are on GPIO2, which could be used with the sowftware PWM module if needed.

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 954

- Thank you received: 486

Please Log in or Create an account to join the conversation.

- oficinerobotica

-

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 12

Oh man .... thank you so much. I still have allot to learn.I've just added my testing LinuxCNC config and EC500 config file to the DMAstepgen branch. Hope it works for you to. I've set the joint scales high for testing.

Link for supporting your development please?

Edit:

In the remora-ec500.hal at line 9 I see "loadrt remora-nv PRU_base_freq=500000" but linuxcnc will throw an error complayning of not finding remora-nv.so. I can start linuxcnc only if I change it to "remora-eth" in the hal file.

Do I have the wrong remora components compiled for linuxcnc?

I used the remora eth branch to compile the lcnc components

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 954

- Thank you received: 486

remora-nv component is available from the following repo

github.com/scottalford75/Remora-NVEM/tre...Components/Remora-nv

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 954

- Thank you received: 486

www.gofundme.com/f/remora-firmware-development

Hoping to move onto documentation improvement now the DMA stepgen is less in my head.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11503

- Thank you received: 3857

I have given some thought to timer interrupt driven stepping, so would be interested to see how you do DMA

Please Log in or Create an account to join the conversation.