Remora - ethernet NVEM / EC300 / EC500 cnc board

- GeramyL

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 6

08 Sep 2023 04:54 #280243

by GeramyL

Replied by GeramyL on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Well I’m excited, maybe too excited? I wish there was a way we could buffer like 10ms of data at one time rather than from what I’m seeing send a make steps command and then a stop make steps command to stop. It would prevent over travel, or if we could build some sort of system that tells the rt1052 where position end is going to be until the next call so it knows not to overshoot or in the case there is some sort of glitch in communication. Scott would any of this be possible and if so what would be the easiest way to implement it?

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

08 Sep 2023 05:01 #280244

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

DMA stepgen version It's now running in a hacked together way.... now trying to get a config that will run at higher joint scales without throwing following errors.

LinuxCNC sends velocity (frequency) commands to the controller and then uses the returned position (step count) in the control loop. So LinuxCNC is doing the work to keep the joint within the following error band.

Over / undershoot is controlled by the proportional (pgain) setting for each joint.

Remora monitors the communication with LinuxCNC and if it stops, then all motion and outputs are halted.

LinuxCNC sends velocity (frequency) commands to the controller and then uses the returned position (step count) in the control loop. So LinuxCNC is doing the work to keep the joint within the following error band.

Over / undershoot is controlled by the proportional (pgain) setting for each joint.

Remora monitors the communication with LinuxCNC and if it stops, then all motion and outputs are halted.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- GeramyL

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 6

08 Sep 2023 18:29 - 09 Sep 2023 14:04 #280284

by GeramyL

Replied by GeramyL on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

I’m editing this comment, now with DMA running the step generation my settings of base frequency 65,000 and DMA frequency of 120,000 I get lower pings thanks Scott and there seems to be no more inaccuracy in the steps, tested with an indicator and the steps that should happen, happen always. It does seem there is a minor bug somewhere when sending a bunch of commands via a hand controller in the LinuxCNC side when going back and forth a bunch at 2% the motor flips direction but you have to try very hard to make this happen, I’ll help track down the bug later I think it’s nearly impossible for this to happen in a real life CNC scenario.

Last edit: 09 Sep 2023 14:04 by GeramyL.

Please Log in or Create an account to join the conversation.

- cnc-phil

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

08 Sep 2023 20:29 - 08 Sep 2023 21:15 #280290

by cnc-phil

Replied by cnc-phil on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

@scotta

I just spent 15 minutes searching how to send you a coffee. Without success. Could not find a link here searching the coffee term, I know I read it somewhere, sometime. Searched on github. Please update your profiles on howto spend you something, here and on github and in the readme-markdown files! Thanks

I just spent 15 minutes searching how to send you a coffee. Without success. Could not find a link here searching the coffee term, I know I read it somewhere, sometime. Searched on github. Please update your profiles on howto spend you something, here and on github and in the readme-markdown files! Thanks

Last edit: 08 Sep 2023 21:15 by cnc-phil.

The following user(s) said Thank You: tommylight, scotta

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

08 Sep 2023 21:35 #280294

by scotta

www.gofundme.com/f/remora-firmware-development

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Hi, thanks and a great comment. I'll need to add a comment and the following link.@scotta

I just spent 15 minutes searching how to send you a coffee. Without success. Could not find a link here searching the coffee term, I know I read it somewhere, sometime. Searched on github. Please update your profiles on howto spend you something, here and on github and in the readme-markdown files! Thanks

www.gofundme.com/f/remora-firmware-development

The following user(s) said Thank You: cnc-phil

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

08 Sep 2023 22:05 #280295

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

For those interested in the DMA stepgen development, it's looking awesome. Got it running yesterday and GeramyL is busy helping out with bug fixes. 500kHz, so minimum step width for stepper drivers will now be the limiting factor.

The following user(s) said Thank You: Murphy

Please Log in or Create an account to join the conversation.

- slawekgonet

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 4

09 Sep 2023 09:14 #280323

by slawekgonet

Replied by slawekgonet on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

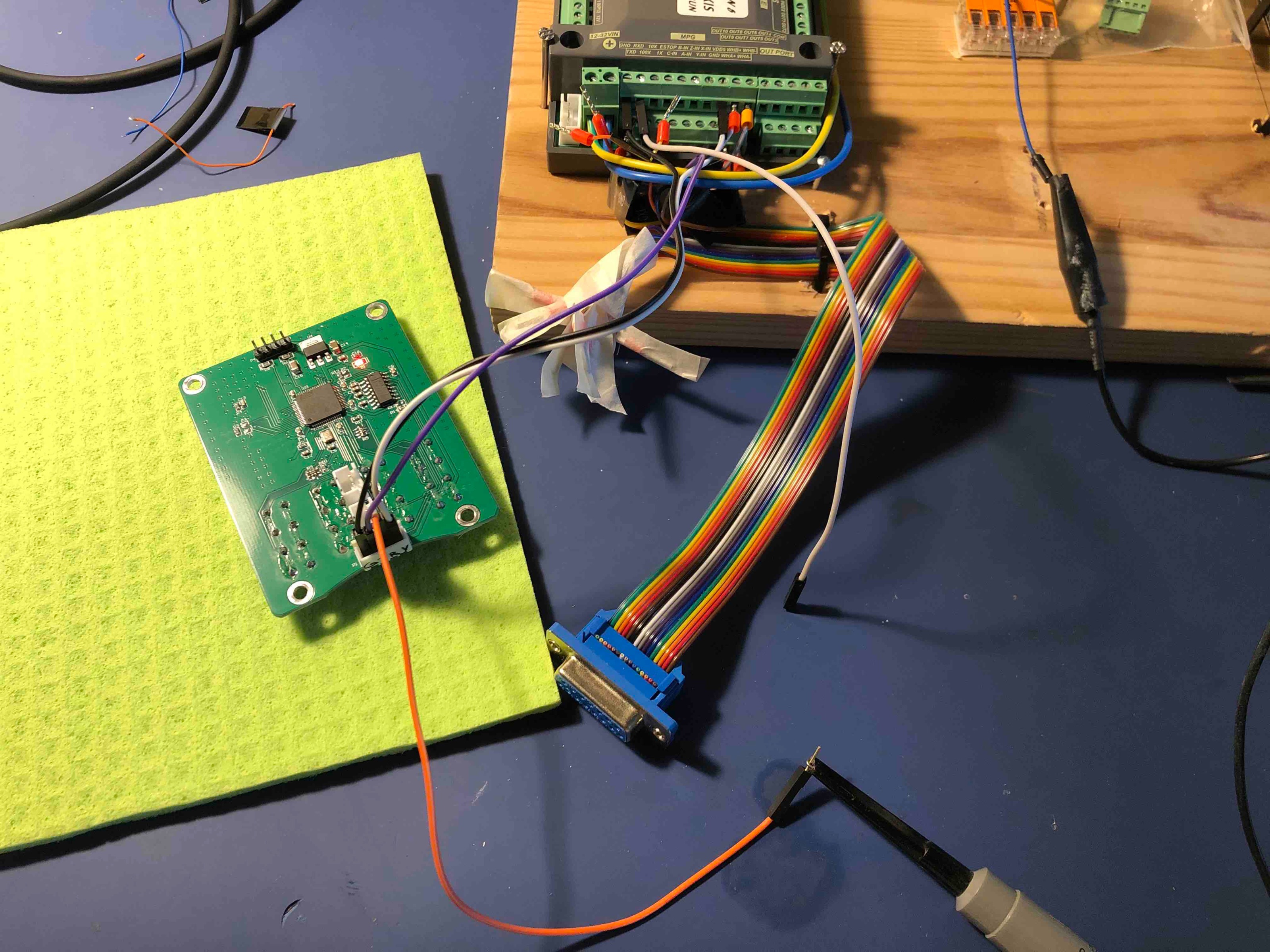

About the lack of transmission from my NVMPG:

I tried disassembling the MPG and taking some measurements.

To begin with: TX from Remora on NVME v5 to MPG is working fine, display is updated accordingly to LinuxCNC status. Only RX part, transmission from MPG to NVME is not there.

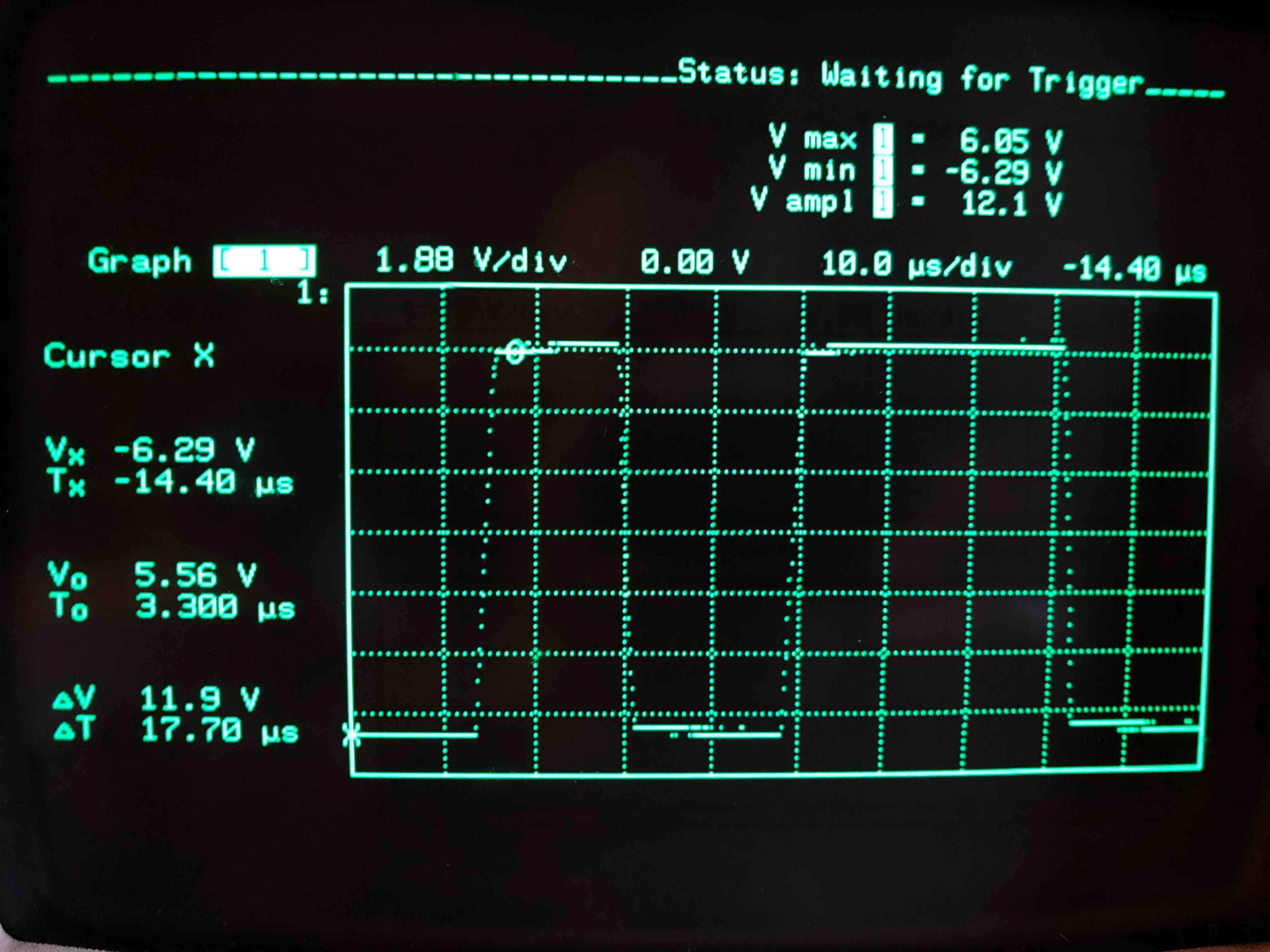

1. I tried plugging my scope directly to RX port on NVMPG internal board while without it being connected to NVME (TX, Vdd and GND are still attached to NVME and the display is updating) - see the `rx_floating.jpeg` image. I was getting correct (I guess) RS232 -5V/ 5V, similar to what was received on TX port (`rx_osci.jpeg`).

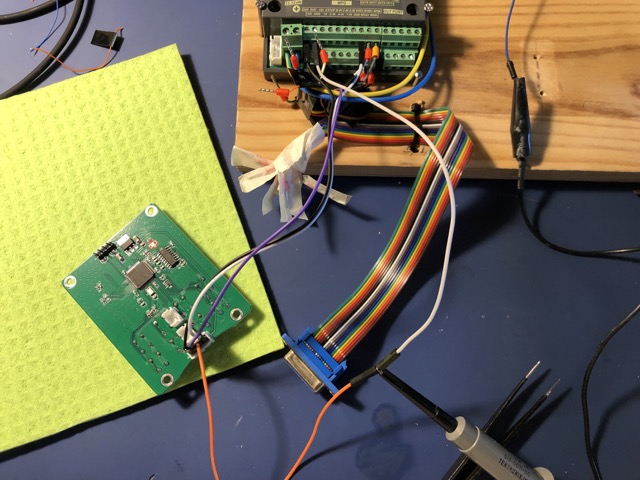

2. Second test was to try connecting RX port to NVME with probe in line. Unfortunately, I was not able to observer any signal at all. See the connection:

Any ideas why it might be the case? It at least looks like pull-down resistor between RX and GND in my NVME is bad/short-circuited (if it is even present in this design?).

- Resistance between MPG's GND and RX on NVME is around 25 ohm (with board disconnected from power)

- For comparison, between COM and INP3 (that works as expected) I'm seeing around 45kOhm.

I tried disassembling the MPG and taking some measurements.

To begin with: TX from Remora on NVME v5 to MPG is working fine, display is updated accordingly to LinuxCNC status. Only RX part, transmission from MPG to NVME is not there.

1. I tried plugging my scope directly to RX port on NVMPG internal board while without it being connected to NVME (TX, Vdd and GND are still attached to NVME and the display is updating) - see the `rx_floating.jpeg` image. I was getting correct (I guess) RS232 -5V/ 5V, similar to what was received on TX port (`rx_osci.jpeg`).

2. Second test was to try connecting RX port to NVME with probe in line. Unfortunately, I was not able to observer any signal at all. See the connection:

Any ideas why it might be the case? It at least looks like pull-down resistor between RX and GND in my NVME is bad/short-circuited (if it is even present in this design?).

- Resistance between MPG's GND and RX on NVME is around 25 ohm (with board disconnected from power)

- For comparison, between COM and INP3 (that works as expected) I'm seeing around 45kOhm.

Attachments:

Please Log in or Create an account to join the conversation.

- GeramyL

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 6

09 Sep 2023 18:30 #280342

by GeramyL

Replied by GeramyL on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Have you checked to see if the RX/TX works at all like trying to output or print data through it and connect it to another device like arduino, pc, pi?

Please Log in or Create an account to join the conversation.

- slawekgonet

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 4

09 Sep 2023 20:09 #280346

by slawekgonet

Replied by slawekgonet on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Will try to check that.

One more question that came to my mind: in Remora, does the pendant state is transmitted via RX/TX or the A+/A- and B+/B- pairs?

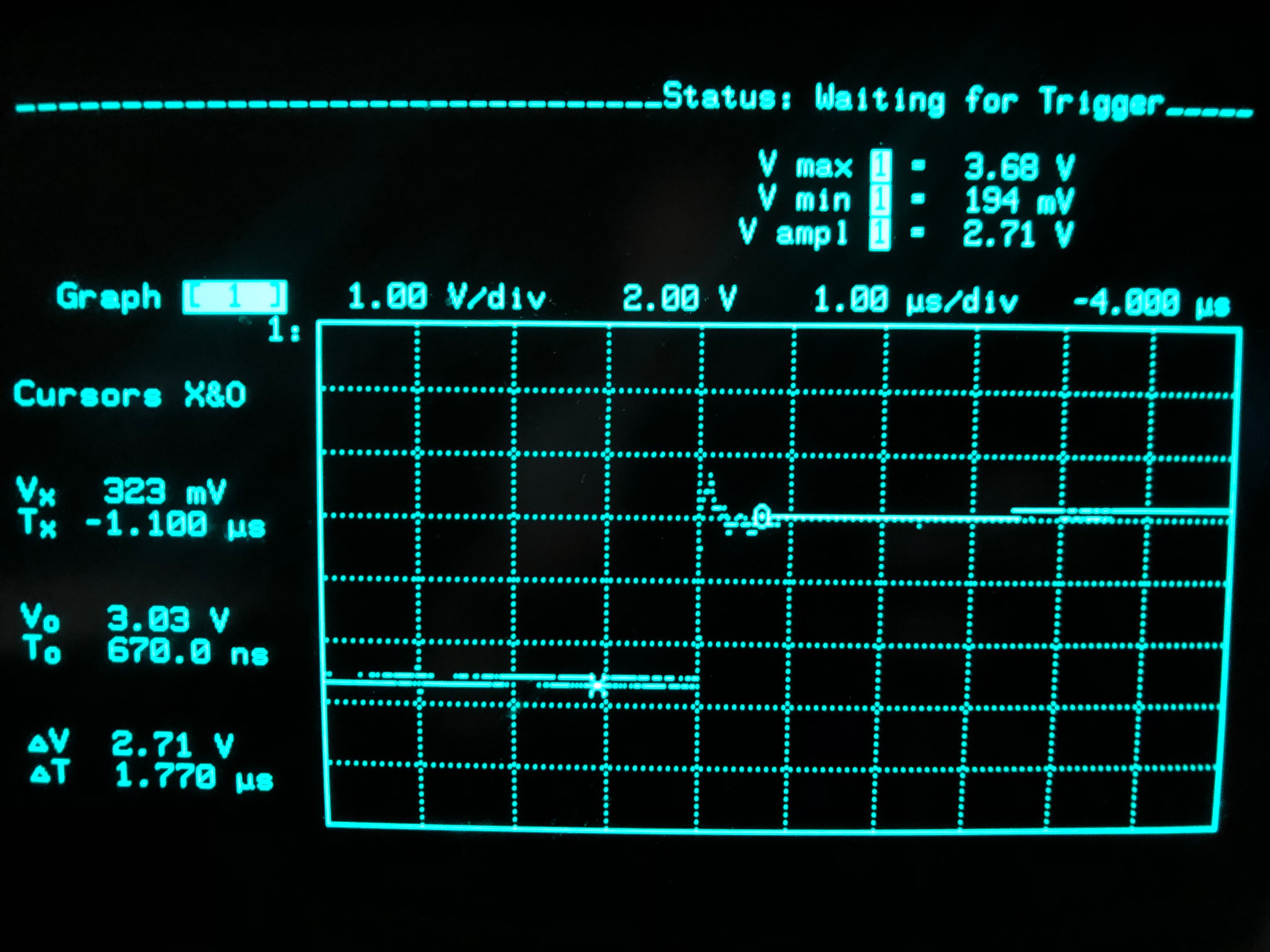

I'm asking because even though it seems that I might possibly have some issues with RX line, the AB pairs seem to correctly send spikes when pendant wheel is turned. This is for example B+ pin when turning pendant clockwise:

So, for pendant on MPG to work, you only connect RX/TX or also AB pairs?

One more question that came to my mind: in Remora, does the pendant state is transmitted via RX/TX or the A+/A- and B+/B- pairs?

I'm asking because even though it seems that I might possibly have some issues with RX line, the AB pairs seem to correctly send spikes when pendant wheel is turned. This is for example B+ pin when turning pendant clockwise:

So, for pendant on MPG to work, you only connect RX/TX or also AB pairs?

Attachments:

Please Log in or Create an account to join the conversation.

- GeramyL

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 6

09 Sep 2023 22:04 - 09 Sep 2023 22:35 #280353

by GeramyL

Replied by GeramyL on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

I couldn't answer that for you I got no idea, but it should be in the config file, the code for the mpg module shows only TX/RX Pin 9 and Pin 10, but it looks like it only requires uart which means TX/RX for the mpg module, but I also believe the uart can be changed to other pins I have to double check that so don't quote me. Maybe we can make a custom bin with changed pins for UART.

Last edit: 09 Sep 2023 22:35 by GeramyL.

Please Log in or Create an account to join the conversation.

Time to create page: 0.417 seconds