PCB milling with laser - power off when Z is up

- yello

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

15 Oct 2013 15:58 #39862

by yello

PCB milling with laser - power off when Z is up was created by yello

I did some PCB milling were I converted the Gerber data to PCB milling insulation data to remove the copper and leave the tracks. That works well (if the laminate is flat).

Now I like to try photosensitive laminate and expose the same insulation data with laser. The advantage is that I am not so Z-axis sensitive (PCB laminate is often not totally flat).

But when I go from one track to the next track the CNC tool will move up, and move the next track. When I do that with the laser the laser power will stay ON and the travel track will be exposed.

Is there a way to switch the laser power OFF when the Z-Axis moves up?

Or is there any way to incorporate that into software/hardware?

Now I like to try photosensitive laminate and expose the same insulation data with laser. The advantage is that I am not so Z-axis sensitive (PCB laminate is often not totally flat).

But when I go from one track to the next track the CNC tool will move up, and move the next track. When I do that with the laser the laser power will stay ON and the travel track will be exposed.

Is there a way to switch the laser power OFF when the Z-Axis moves up?

Or is there any way to incorporate that into software/hardware?

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

15 Oct 2013 16:07 #39863

by cncbasher

Replied by cncbasher on topic PCB milling with laser - power off when Z is up

how are you switching the laser on and off ?

use the same as if it was a spindle i.e M3 and M5 to turn off

so you may need to adjust your gcode or postprocessor to add the approprate codes

it might be helpful to add a delay to allow the laser to turn off and on , i have had to do that on some lasers that had mechanical shutters , so it may work in your case

also diode lasers are extremley broad in beam size and extrainious light patterens , so you may need to sheild the laser and just have for argument a 0.5mm hole for the beam

use the same as if it was a spindle i.e M3 and M5 to turn off

so you may need to adjust your gcode or postprocessor to add the approprate codes

it might be helpful to add a delay to allow the laser to turn off and on , i have had to do that on some lasers that had mechanical shutters , so it may work in your case

also diode lasers are extremley broad in beam size and extrainious light patterens , so you may need to sheild the laser and just have for argument a 0.5mm hole for the beam

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

15 Oct 2013 18:21 #39868

by andypugh

Of course! There is always a way with LinuxCNC.

The ddt function can be used to detect if the spindle is going up or down: www.linuxcnc.org/docs/html/man/man9/ddt.9.html

Then the abs function can be used to create pins for "is-positive" (going up) or "is-negative" (going down) www.linuxcnc.org/docs/html/man/man9/abs.9.html

Then you can use a flip-flop connected to the is-positive and is-negative to latch the state www.linuxcnc.org/docs/html/man/man9/flipflop.9.html

Replied by andypugh on topic PCB milling with laser - power off when Z is up

Is there a way to switch the laser power OFF when the Z-Axis moves up?

Of course! There is always a way with LinuxCNC.

The ddt function can be used to detect if the spindle is going up or down: www.linuxcnc.org/docs/html/man/man9/ddt.9.html

Then the abs function can be used to create pins for "is-positive" (going up) or "is-negative" (going down) www.linuxcnc.org/docs/html/man/man9/abs.9.html

Then you can use a flip-flop connected to the is-positive and is-negative to latch the state www.linuxcnc.org/docs/html/man/man9/flipflop.9.html

Please Log in or Create an account to join the conversation.

- yello

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

16 Oct 2013 11:53 - 16 Oct 2013 12:39 #39936

by yello

I use only XYZ data, the spindle on/off and speed I do manually.

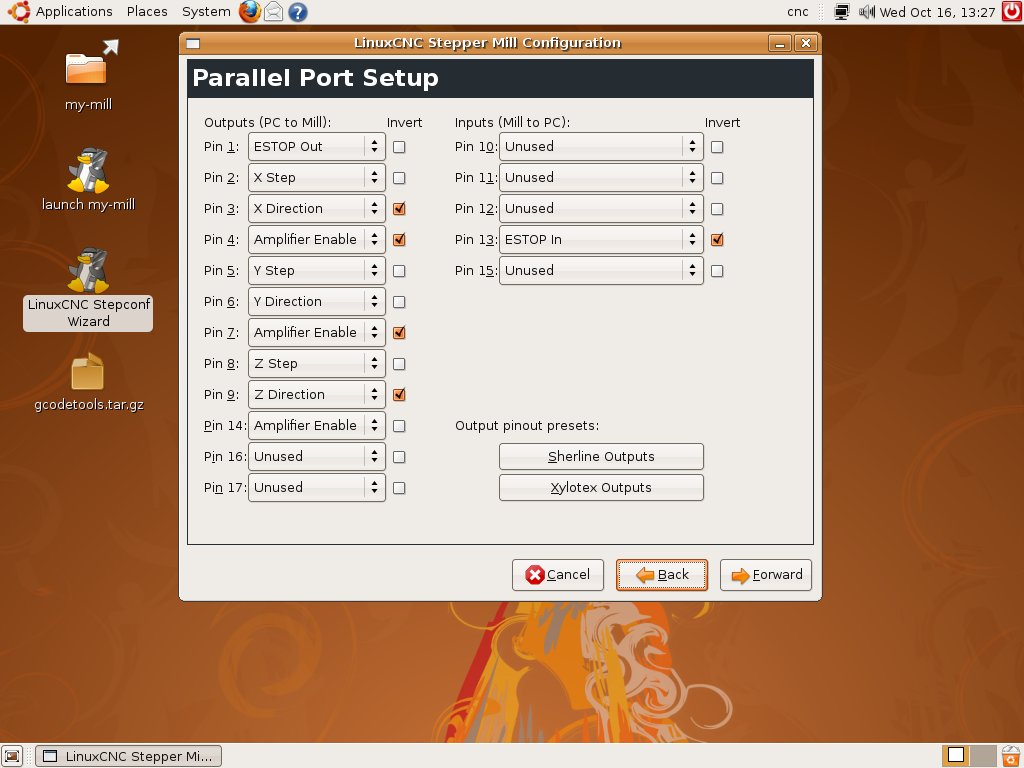

I have of course extra pins in the parallel cable. How do I get there? Get the wires out, or?

And what function I should use exactly? I saw there are some digital pins, what do they do? Go high (5V) when ON? Is so then I could simply put a relays or FET there. (Relays is maybe not so good because of the buzz)

My BluRay 100mW LD has a very simple 1 lens optic. I get a small focus point, maybe 0.5mm or less (hard to see). I could work with tube and a hole at the end. So far I didn't do any exposure tests. A better, or more suitable optic would be another option. So in case you have any link or advice.......

Replied by yello on topic PCB milling with laser - power off when Z is up

how are you switching the laser on and off ?

use the same as if it was a spindle i.e M3 and M5 to turn off

I use only XYZ data, the spindle on/off and speed I do manually.

I have of course extra pins in the parallel cable. How do I get there? Get the wires out, or?

And what function I should use exactly? I saw there are some digital pins, what do they do? Go high (5V) when ON? Is so then I could simply put a relays or FET there. (Relays is maybe not so good because of the buzz)

also diode lasers are extremley broad in beam size and extrainious light patterens , so you may need to sheild the laser and just have for argument a 0.5mm hole for the beam

My BluRay 100mW LD has a very simple 1 lens optic. I get a small focus point, maybe 0.5mm or less (hard to see). I could work with tube and a hole at the end. So far I didn't do any exposure tests. A better, or more suitable optic would be another option. So in case you have any link or advice.......

Last edit: 16 Oct 2013 12:39 by yello.

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

16 Oct 2013 15:15 - 16 Oct 2013 15:18 #39941

by cncbasher

Replied by cncbasher on topic PCB milling with laser - power off when Z is up

add in stepconf a spindle output , so select a spare pin as Spindle CW , this will give you an output that you can drive a relay and will give you on/off with M3 / M5

also if you add spindle pwm to a pin that would give you an output to vary the power level of the diode , using the spindle value as a level , if you can interface the pwm output to your laser driver

also if you add spindle pwm to a pin that would give you an output to vary the power level of the diode , using the spindle value as a level , if you can interface the pwm output to your laser driver

Last edit: 16 Oct 2013 15:18 by cncbasher.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

16 Oct 2013 16:04 #39943

by andypugh

There is a certain advantage to the approach of using HAL to detect "virtual" Z-axis motion, the existing milling G-code can be used.

(though possibly not, as it is likely to create a "negative")

Replied by andypugh on topic PCB milling with laser - power off when Z is up

how are you switching the laser on and off ?

use the same as if it was a spindle i.e M3 and M5 to turn off

There is a certain advantage to the approach of using HAL to detect "virtual" Z-axis motion, the existing milling G-code can be used.

(though possibly not, as it is likely to create a "negative")

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

16 Oct 2013 16:21 #39944

by cncbasher

Replied by cncbasher on topic PCB milling with laser - power off when Z is up

I'd be interested to look at that approach Andy ,

ok using M3/M5 is not ideal, however it does work , and i have used it running a 2Kw laser ,

i had more problems with the THC than anything else .. , in the end i prefixed the head height to run 1mm above the plate , as a temp measure , it's still running that way 5 years later

ok using M3/M5 is not ideal, however it does work , and i have used it running a 2Kw laser ,

i had more problems with the THC than anything else .. , in the end i prefixed the head height to run 1mm above the plate , as a temp measure , it's still running that way 5 years later

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

16 Oct 2013 16:36 #39945

by andypugh

Well, as I suggested above, I think it would be:

axis.2.motor-pos-cmd => ddt = > abs

abs.is-positive => flipflop.reset

abs.is-negative => flipflop.set

flipflop.out => laser-death-ray

Replied by andypugh on topic PCB milling with laser - power off when Z is up

I'd be interested to look at that approach

Well, as I suggested above, I think it would be:

axis.2.motor-pos-cmd => ddt = > abs

abs.is-positive => flipflop.reset

abs.is-negative => flipflop.set

flipflop.out => laser-death-ray

Please Log in or Create an account to join the conversation.

Time to create page: 0.155 seconds